Method and device for producing sodium cyanide through mixed pyrolysis of ammonia, light oil and natural gas

A technology of natural gas and sodium cyanide, applied in the directions of metal cyanide, simple alkali metal cyanide, hydrogen separation, etc., can solve the problems of unstable product quality, insufficient supply, affecting output, etc., to solve the difficulty of purchasing raw materials and prolong the use. deadline, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

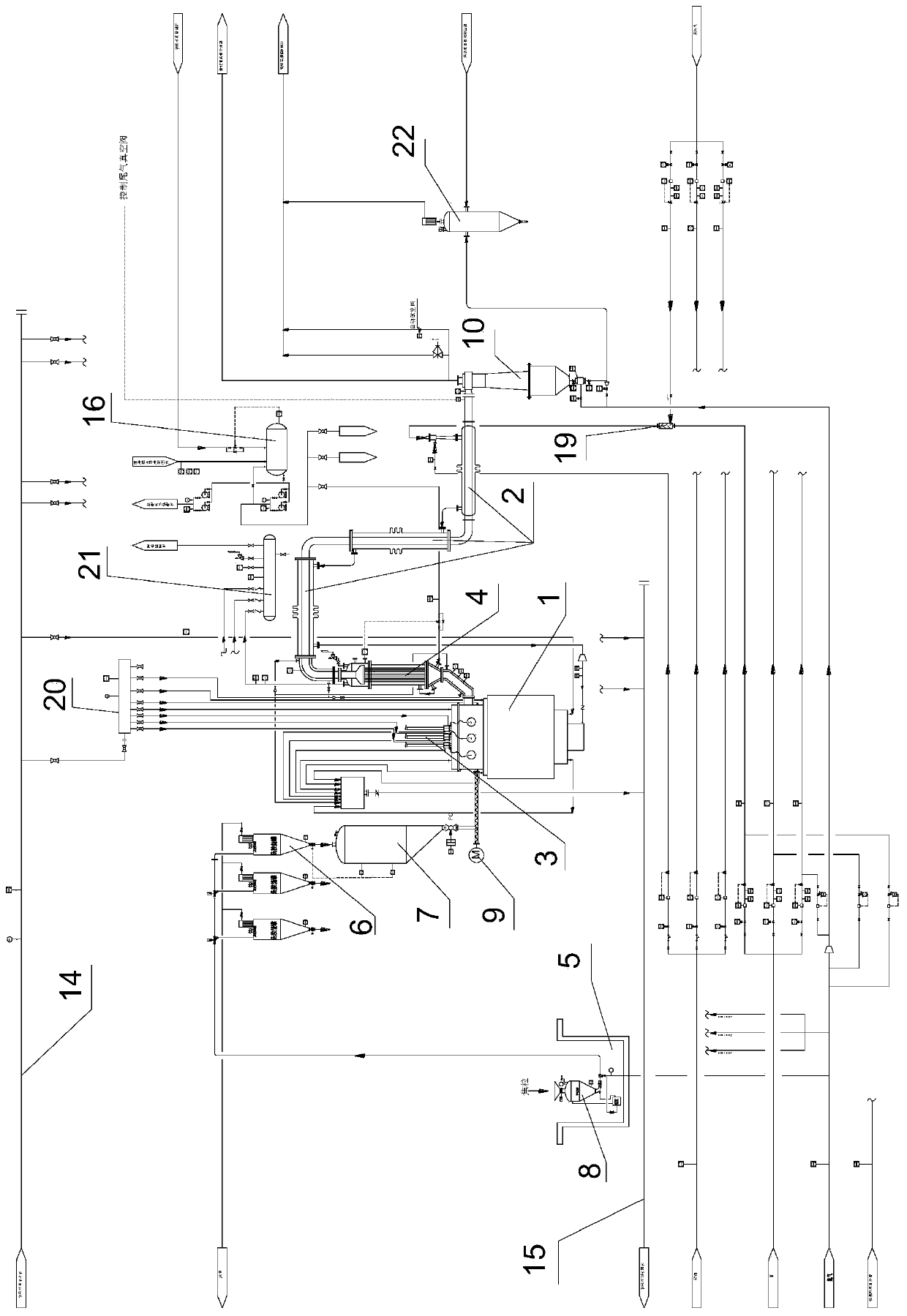

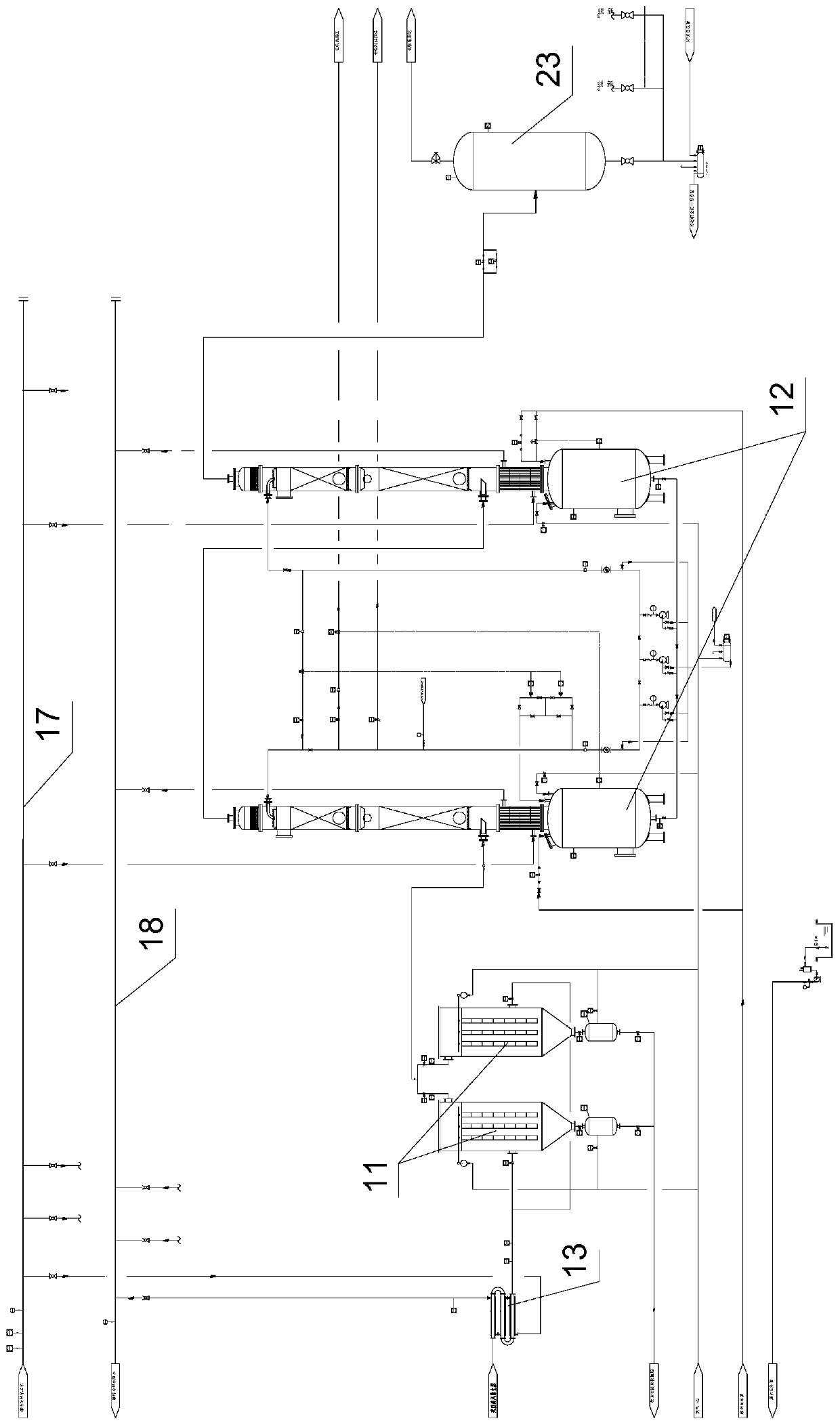

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0027] In order to make the selection of raw materials more flexible and prolong the service life of the device as much as possible, the present invention provides a method for producing sodium cyanide by mixed cracking of ammonia, light oil and natural gas. After heating, the coke particles are used as the conductive carrier, and under the action of the discharge of the cracking electricity, the cracking reaction is carried out to generate hydrogen cyanide gas, which is absorbed by lye to generate sodium cyanide, and the hydrogen-containing tail gas is dehydrogenated and deaminated After recovery,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com