A method for preparing grouting material behind the wall of an earth pressure shield using waste diorite slag

A technology of post-wall grouting and grouting materials, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems of high transportation costs of muck, a large amount of muck piled up, and expensive purchase prices, and achieve good environmental benefits , saving costs, and solving procurement difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

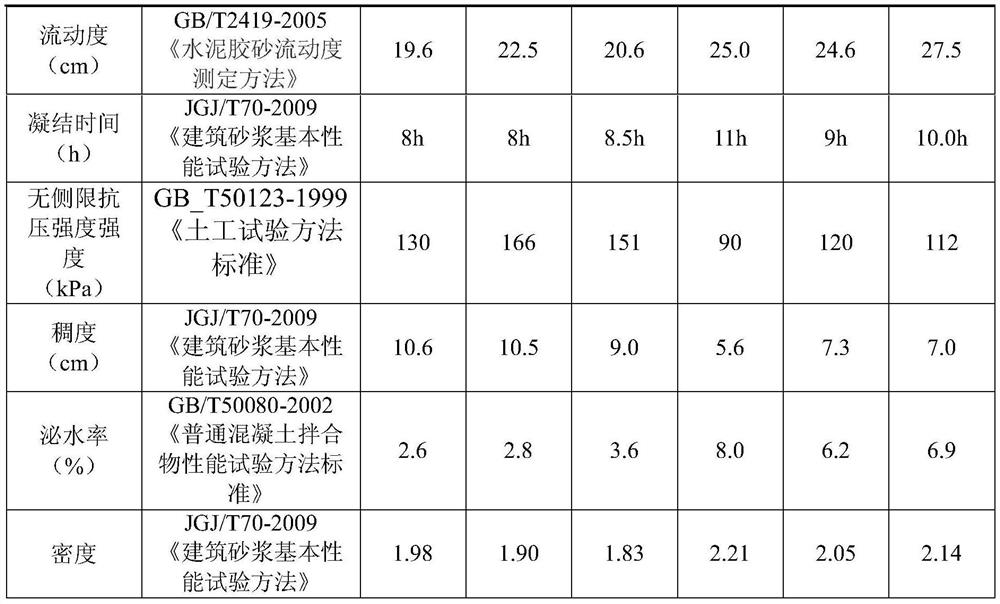

Embodiment 1

[0024] The earth pressure shield provided in this embodiment uses waste diorite slag to prepare grouting material behind the wall, specifically including the following steps:

[0025] (1) Repeatedly washing and soaking the dregs discharged during the excavation of the diorite stratum shield until the dregs are not muddy, and then sent to the oven for drying;

[0026] (2) The slag treated in step (1) is sent to a sieving machine for screening, and the particles greater than 0.5mm are removed by a primary sieve with an aperture of 2mm and a secondary sieve with an aperture of 0.5mm;

[0027] (3) Mix the sieved muck with the middle sand of the raw material at a ratio of 2:1 to make mixed sand. The sieved dregs replace 2 / 3 of the quality of the sand in the raw material. The raw material formula of the slurry is as follows: Obtained: 270kg of primary fly ash, 54kg of P42.5 Portland cement, 108kg of bentonite, 900kg of mixed sand (600kg of sieved dregs and 300kg of medium sand) and ...

Embodiment 2

[0030] The earth pressure shield provided in this example uses waste diorite slag to prepare grouting material behind the wall, and the difference from Example 1 is that in step (2), the raw material formula of the slurry is: 270kg primary powder Fly ash, 54kg P42.5 Portland cement, 108kg bentonite, 900kg mixed sand (540kg screened muck and 360kg medium sand) and 450kg water.

[0031] Others are the same as embodiment 1.

Embodiment 3

[0033] The earth pressure shield provided in this example uses waste diorite slag to prepare grouting material behind the wall, and the difference from Example 1 is that in step (2), the raw material formula of the slurry is: 270kg primary powder Fly ash, 54kg P42.5 Portland cement, 108kg bentonite, 900kg mixed sand (450kg screened muck and 450kg medium sand) and 450kg water.

[0034] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com