Major diameter rotary type heat exchanger rotor structure and its radial separator

A rotary heat exchanger technology, applied in heat exchanger types, indirect heat exchangers, moving tube heat exchangers, etc., can solve problems such as insufficient welding operation space, optimize rotor structure design, reduce size , The effect of solving procurement difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

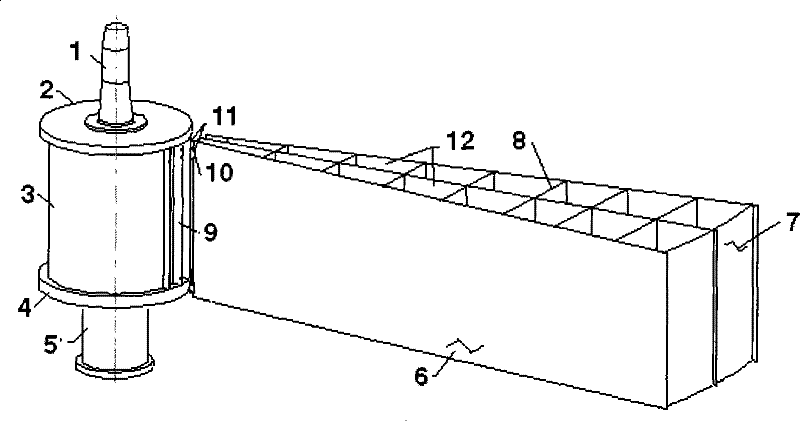

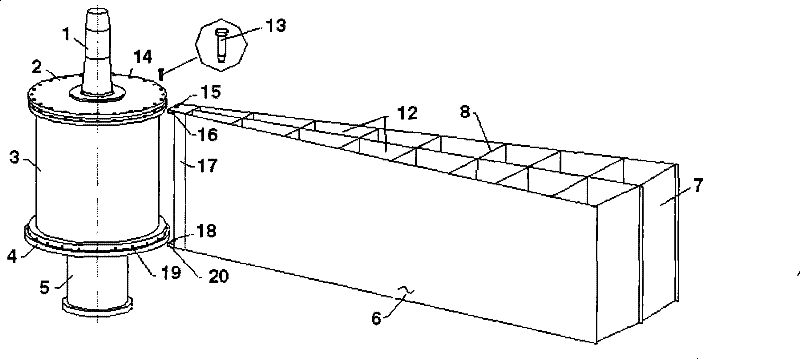

[0043] Such as Figure 4 As shown, it is a schematic structural diagram of a large-diameter rotary heat exchanger rotor. The large-diameter rotary heat exchanger rotor includes a central cylinder, and the central cylinder is composed of a guide end shaft 1, an upper end cover 2, The central cylinder 3, the lower end cover 4 and the supporting end shaft 5 are composed. The periphery of the rotor is divided into a heat transfer element compartment grid 14 by a radial partition 6, a rotor arc shell plate 7, and a transverse partition 8. The connection between the radial partition 6 The connecting plate 10, the connecting pin hole 11 and the connecting ear plate 9 of the central cylinder are connected to form a cantilever beam structure, and the outer peripheral part is provided with a middle radial partition (24).

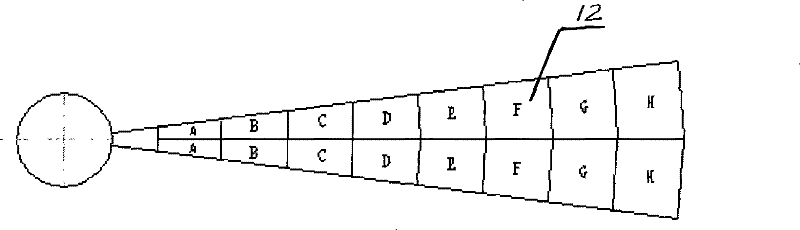

[0044] The inner radial compartments A1, B1, C1, and D1 of the heat transfer element compartment grid 14 are one compartment, and the outer radial compartments E, F, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com