Removable, easy-to-replace Spindle Seal Water Filter Circlip Filter

A spindle seal and filter technology, which is applied in the field of hydraulic machinery, can solve the problems of easy damage, difficult cleaning and high cost of the filter, and achieve the effects of low production cost, reduced production cost and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

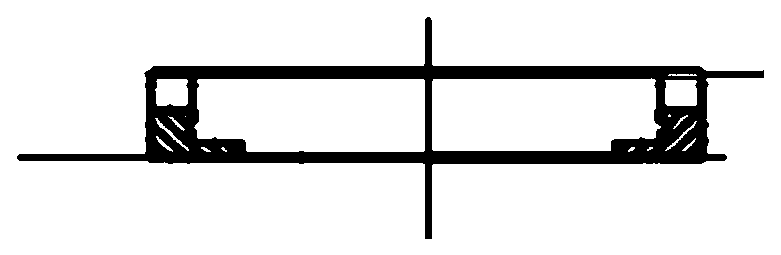

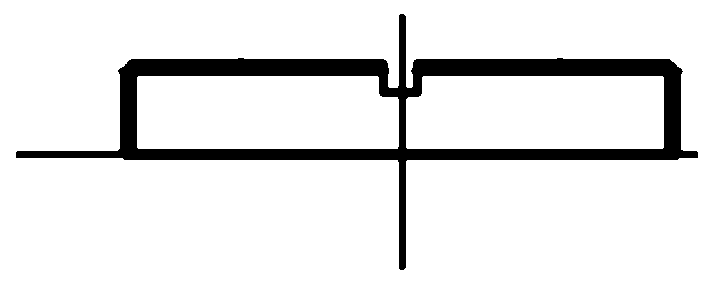

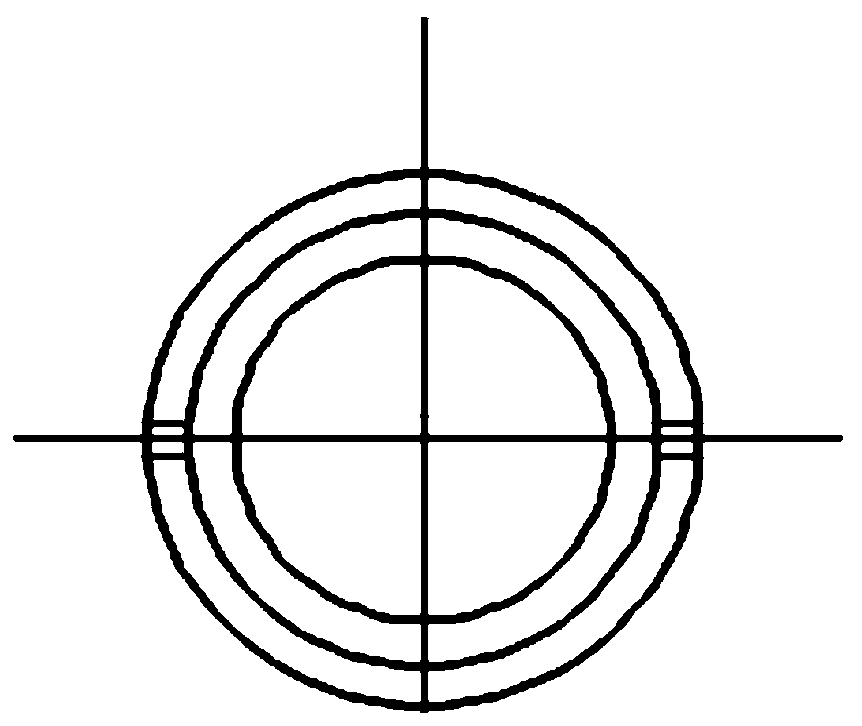

[0025] The present invention is a circlip type filter screen of a main shaft sealing water filter which can be decomposed and cleaned and is easy to replace. The clamp sleeve of the clamp spring type filter screen of the present invention is made of stainless steel, and specifically includes: clamp sleeve 1, filter screen 2, Pressure ring 3 and circlip 4. The ferrule 1 and the filter screen 2 are connected by a circlip 4, and the filter screen 2 is also provided with a pressure ring 3 to fix the filter screen 2 in the ferrule 1. The specific structure is as follows Figure 1-Figure 3 as well as Figure 10-Figure 11 Shown.

[0026] The following is a detailed introduction to each component:

[0027] Filter 2: According to the required size, the whole stainless steel filter is crimped, and then the joint is welded and sealed to make the filter cylindrical. The opening of the filter is provided with an outer edge, such as Figure 4-Figure 5 Shown.

[0028] Pressure ring 3: According to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com