Evaporation pretreatment process method for alkaline peroxide mechanical pulp

A process method and pretreatment technology, applied in the direction of concentrated waste liquid, etc., can solve the problems of low alkali recovery efficiency, large consumption, waste, etc., and achieve the effects of high recovery efficiency, improved utilization efficiency, and high alkali recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

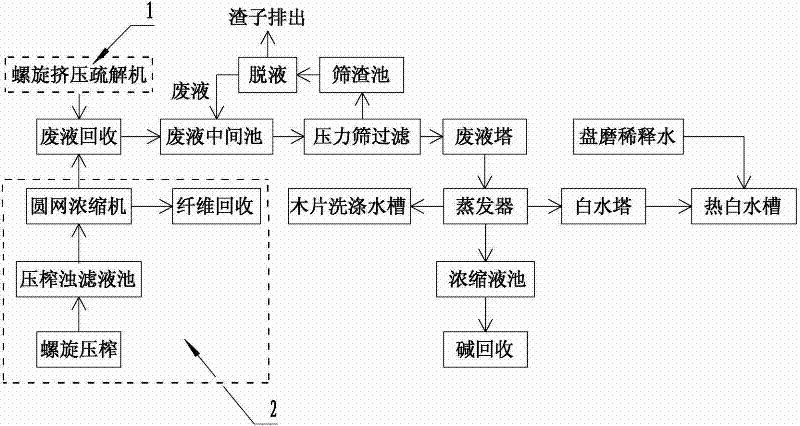

[0017] For ease of description, the following describes the invention of the chemical machine pulp alkali recovery evaporation pretreatment process method in detail with reference to the accompanying drawings:

[0018] As shown in the figure, a chemical pulp alkali recovery evaporation pretreatment process method includes a waste liquid recovery process and an alkali recovery process. The waste liquid recovery process collects filtered water from the chemical pulp production process to the waste liquid intermediate tank In the alkali recovery process, the collected waste liquid in the waste liquid intermediate pool is subjected to alkali recovery treatment, and the alkali recovery treatment also includes the following evaporation pretreatment steps:

[0019] (A) Pressure filtration of the waste liquid, the waste liquid in the waste liquid intermediate tank is filtered through a pressure screen, the slag produced by the filtering is discharged into the sieving residue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com