A decontamination and sand removal machine

A sand remover and decontamination technology, applied in the field of mechanical equipment, can solve the problems of high energy consumption for sand lifting by air flow, large depth of grit chamber, etc., and achieve the effects of saving operation and maintenance costs, large filtration area, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

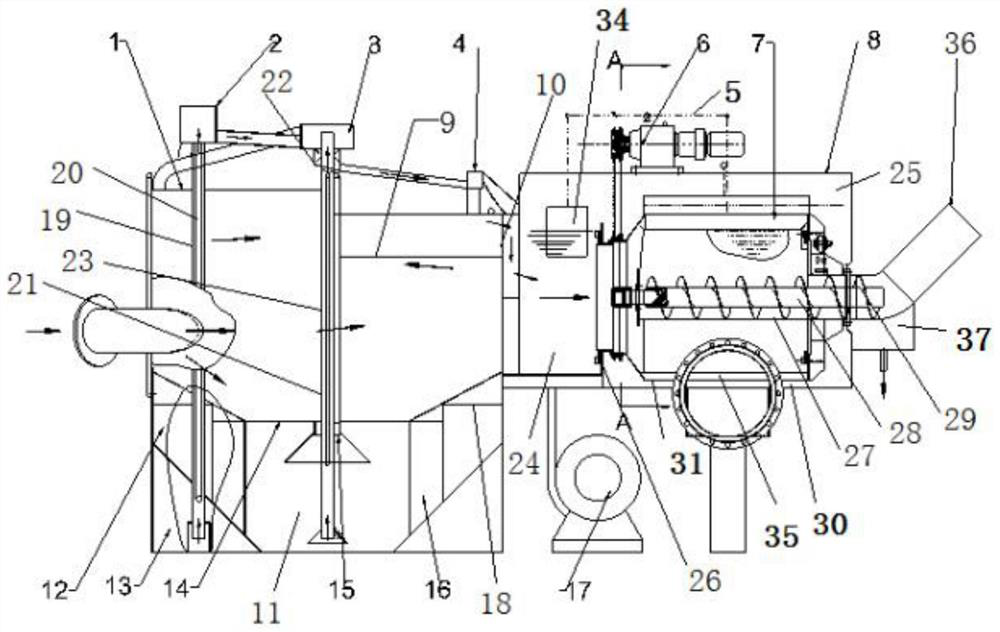

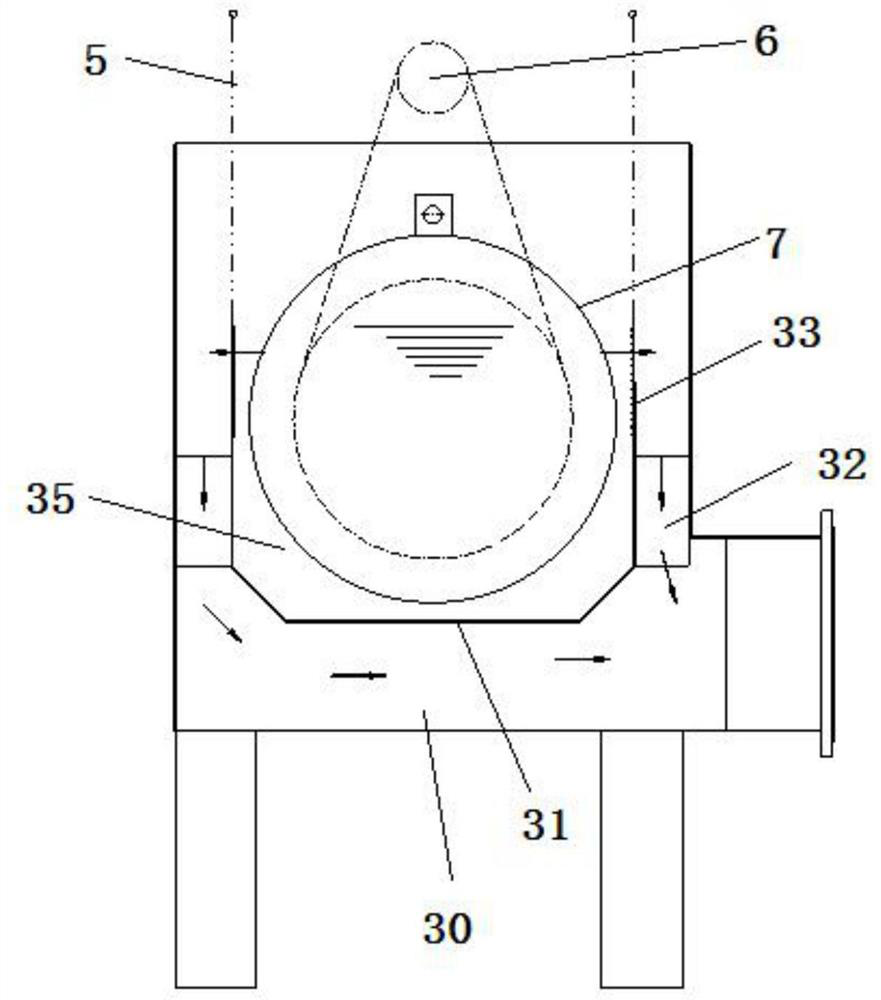

[0038] example, as figure 1 , 2 A kind of cleaning and de-sanding machine shown, including a cyclone grit chamber 1, a grid pool 8 installed on the end of the cyclone grit chamber 1; Pool 1 end. The middle of the water inlet end of the cyclone grit chamber 1 is tangentially provided with a water inlet pipe, wherein the upper part is provided with a guide baffle 9, and the end of the cyclone grit chamber 1 is located above the guide baffle 9 and the water inlet of the grid pool 8 is arranged. The connected overflow port 10; the bottom of the cyclone grit chamber 1 is provided with a central sand hopper 11, and the outer ring of the central sand hopper 11 is provided with an expanded sand groove 16 that communicates with it; Bucket 11. The upper end of the central sand hopper 11 is provided with a slag separating orifice 14, and below the slag separating orifice 14, an aeration sand washing device 15 is installed; The tank 12, the filtered water tank 13, the extended sand ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com