Barning type power tool with preventer for avoiding mechanical parts overheat in tools

A technology of power tools and combustion chambers, which is applied in the field of combustion-type fastener driving tools, and can solve the problems of not being able to provide small tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

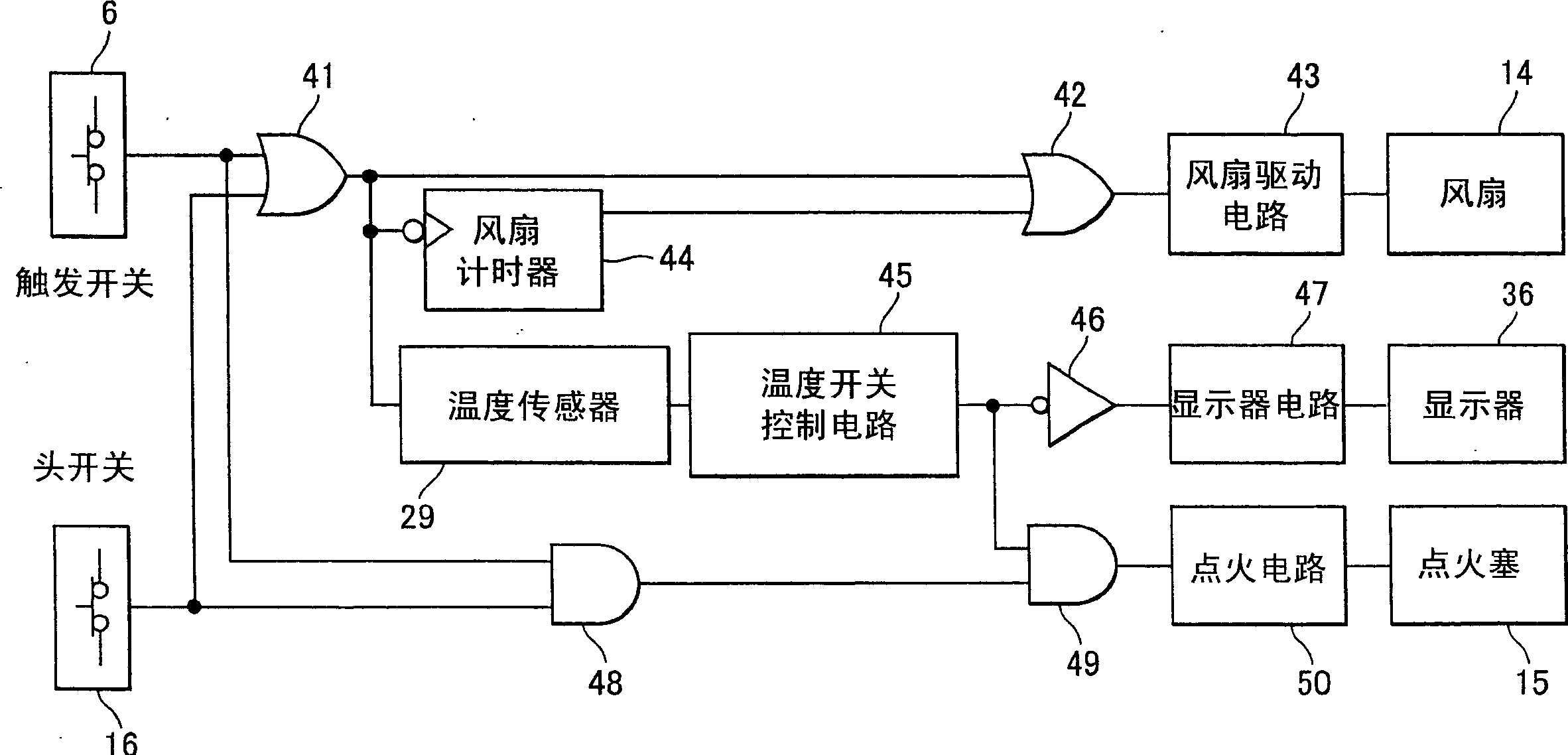

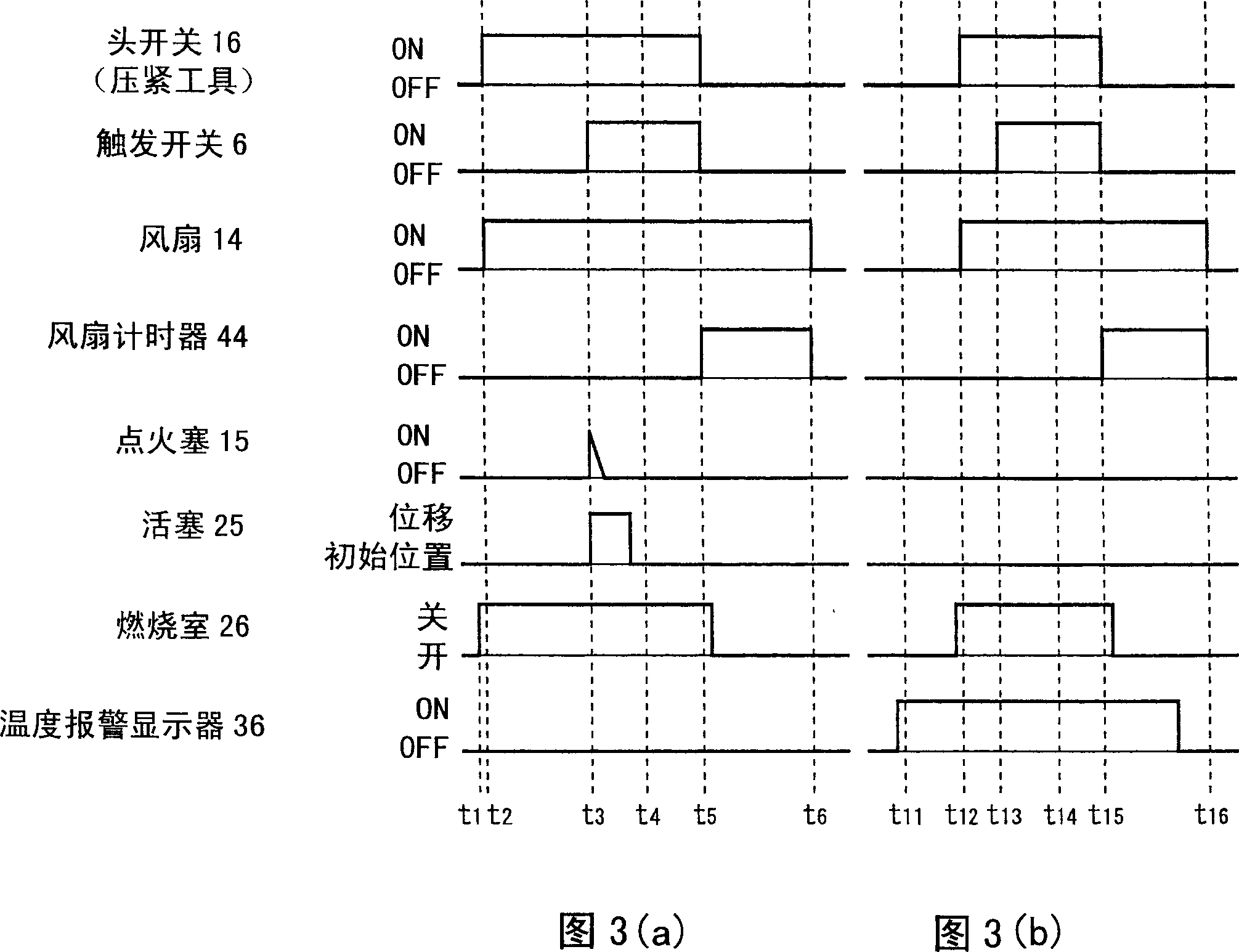

[0035] The following will refer to figure 1 to 3(b) specifically describe the combustion type power tool according to the first embodiment of the present invention. This embodiment is suitable for combustion type nail drivers. The combustion type nail driver 1 has a housing 2 constituting an outer frame, and includes a main housing 2A and a canister housing 2B juxtaposed with the main housing 2A. The main housing 2A has a top end portion provided with a top end cover 4 in which an air intake port is formed, and has a bottom end portion in which an air discharge port (not shown) is formed.

[0036] A gas tank 5 including combustible gas therein is detachably provided in the tank case 2B. A handle 7 with a trigger switch 6 extends from the tank housing 2B. A battery for driving the motor 3 and a glow plug 15 which will be described later are accommodated in the handle 7 . A storage case 8 and a tail cap 9 are provided at the bottom of the main case 2A and the tank case 2B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com