Transparent super-hydrophobic nano-array and preparation method thereof

A nano-array, super-hydrophobic technology, applied in the field of transparent super-hydrophobic nano-array preparation, can solve the problems of increasing difficulty and high cost, and achieve the effects of excellent super-hydrophobic performance, mild reaction, and avoiding sedimentation and agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A method for preparing a transparent superhydrophobic nano-array, the steps are:

[0050] (1) Preparation of the seed layer: first, the reaction precursor zinc acetate dihydrate, the stabilizer ethanolamine, the surfactant polyethylene glycol, and deionized water were respectively added to the solvent ethylene glycol methyl ether, and the Magnetic stirring and mixing for 20 minutes, then in a constant temperature water bath at 60°C, magnetic stirring at 1500r / m for 2 hours, after standing and aging for 24 hours, to obtain a seed sol with a concentration of 0.1-0.25M, and then use a homogenizer to drop the seed sol onto the substrate On the surface, first mix the glue at a speed of 900r / m for 15s, then at a speed of 3000r / m for 20s, then put the substrate into a vacuum tube furnace and treat it for 10min under the condition of nitrogen protection at 350°C, and then nanometer particles can be obtained on the surface of the substrate. Zinc oxide seed layer;

[0051] (2) N...

Embodiment 1

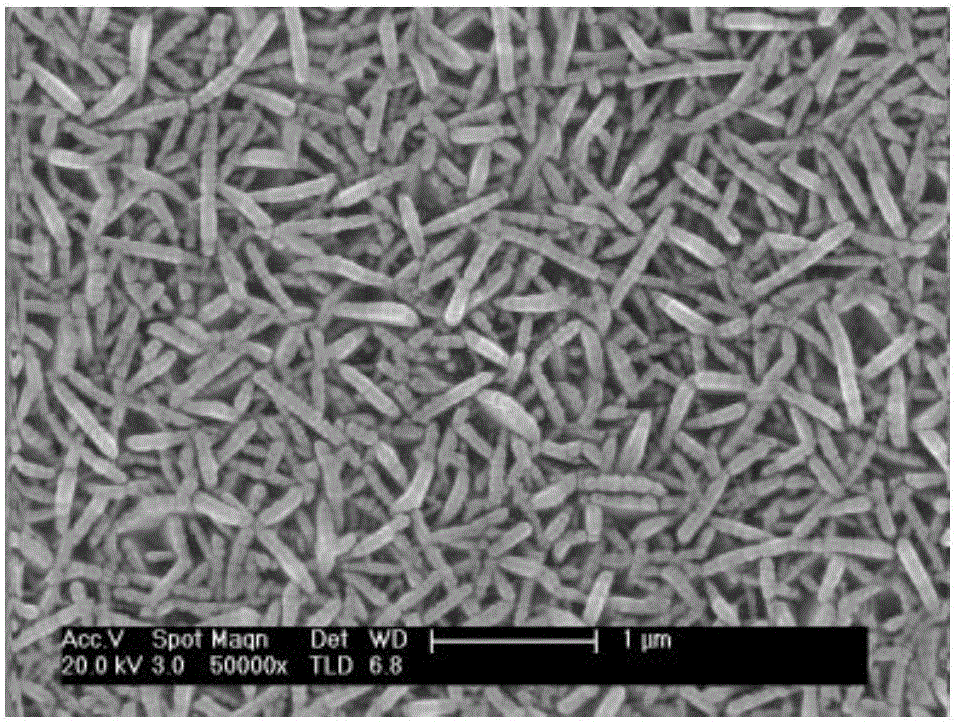

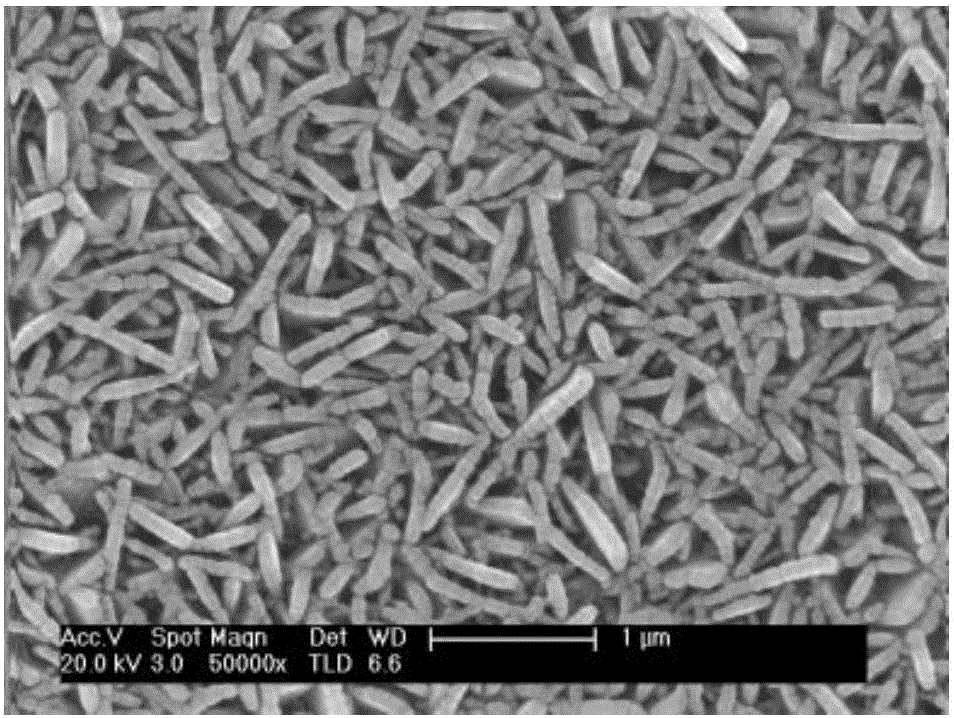

[0055] Growth of ZnO Nanoarrays on Cu Substrate at 35℃

[0056] Prepare a layer of ZnO colloidal film on the clean Cu substrate by using the prepared seed crystal colloid with a concentration of 0.25M and spin-coating with a desktop coating machine; after annealing at 350°C for 10 minutes in a nitrogen atmosphere, a layer of ZnO colloid is formed on the surface of the substrate. Uniform and dense nano-scale ZnO seed layer; in the KOH and Zn(NO 3 ) 2 Prepared 0.5M Zn(OH) at pH=12 4 2- In the reaction system, the ZnO array thin film was grown on the Cu sheet with the seed layer as the substrate and grown in a water bath at 35°C for 6 hours. The double-sided morphologies are as follows figure 1 , figure 2 shown.

Embodiment 2

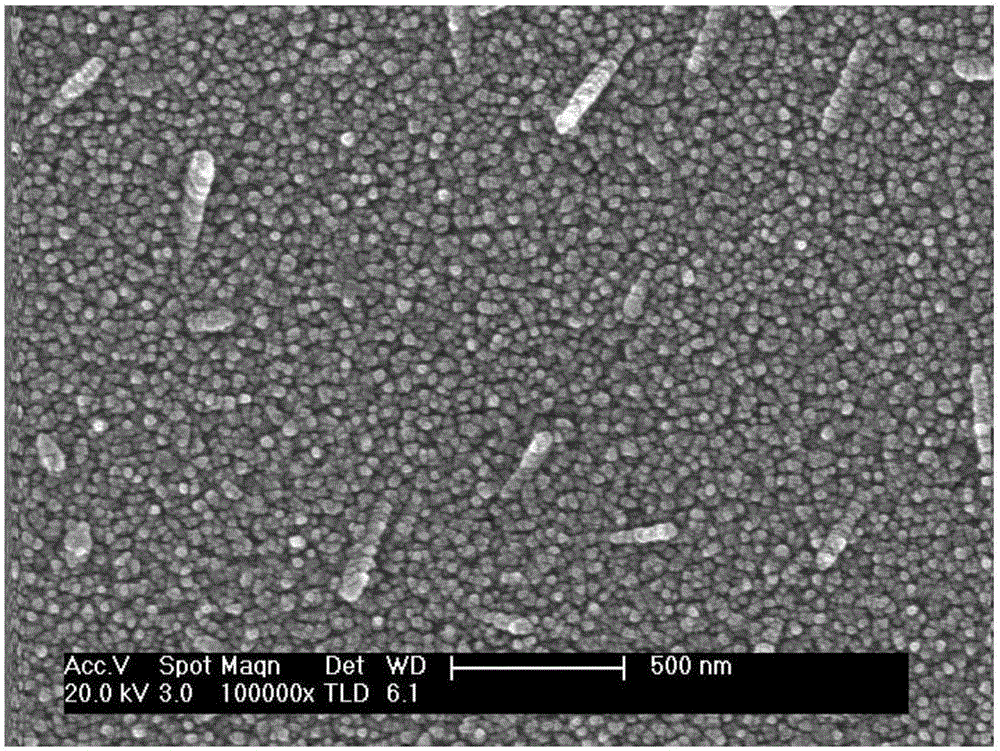

[0058] Growth of ZnO nanoarrays on glass substrates at 35°C

[0059] Prepare a layer of ZnO colloid film on a clean glass substrate by spraying the colloid with a concentration of 0.1M; after annealing at 350°C for 10 minutes in a nitrogen atmosphere, a layer of uniform and dense nano-scale is formed on the surface of the substrate. ZnO seed layer; in the KOH and Zn(NO 3 ) 2 Prepared 0.09M Zn(OH) at pH=12 4 2- In the reaction system, the ZnO array was prepared after the glass sheet with the seed layer was prepared as the substrate and grown in a water bath at 35°C for 0.5-4 hours. The double-sided morphologies were as follows: image 3 , Figure 4 As shown, the light transmittance as Figure 5 As shown, the contact angle shape is as Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com