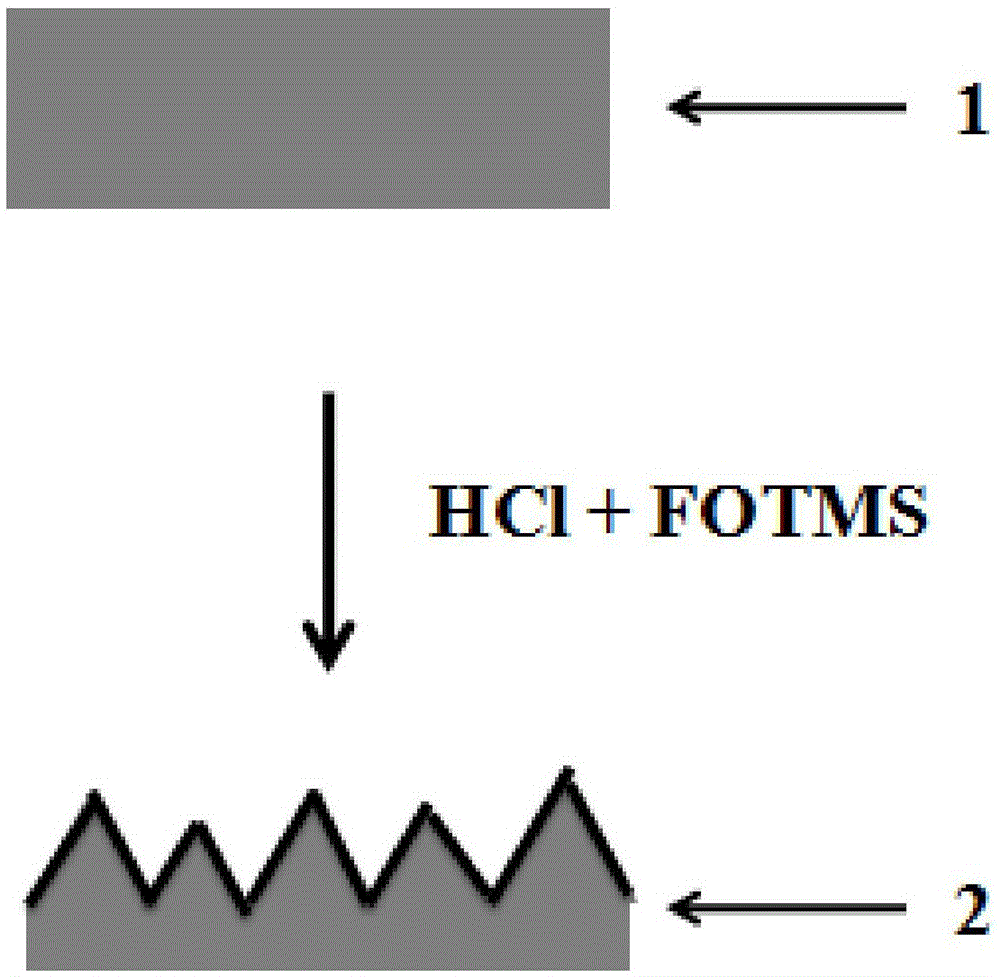

Preparing method of three-dimensional network super-hydrophobic surface

A superhydrophobic surface, three-dimensional network technology, applied in surface etching compositions, chemical instruments and methods, metal material coating processes, etc. and other problems, to achieve the effects of excellent superhydrophobicity, good long-term stability, and short experimental period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Ⅰ. Cut out a 304 stainless steel sheet with a size of 30×20×0.2mm, put it in an ultrasonic cleaning machine and clean it with chloroform, acetone, absolute ethanol, and deionized water for 10 minutes. After cleaning, take it out and blow it dry with nitrogen ,stand-by.

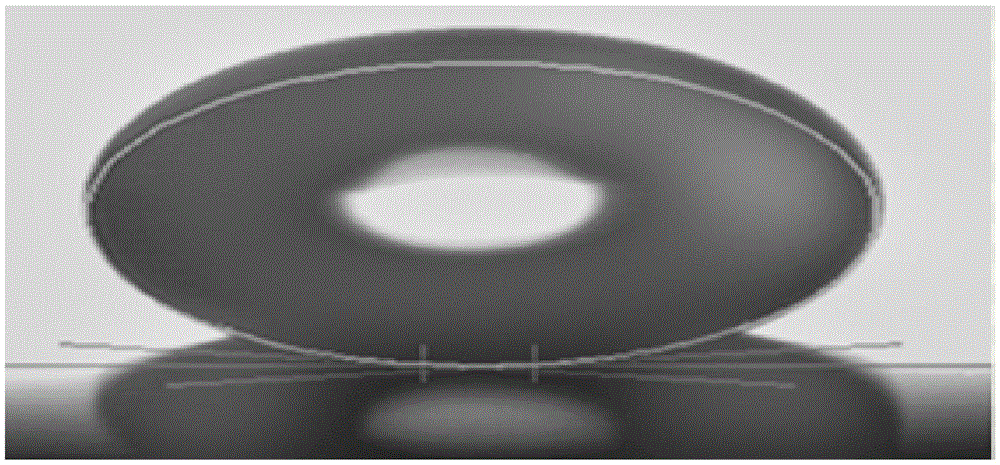

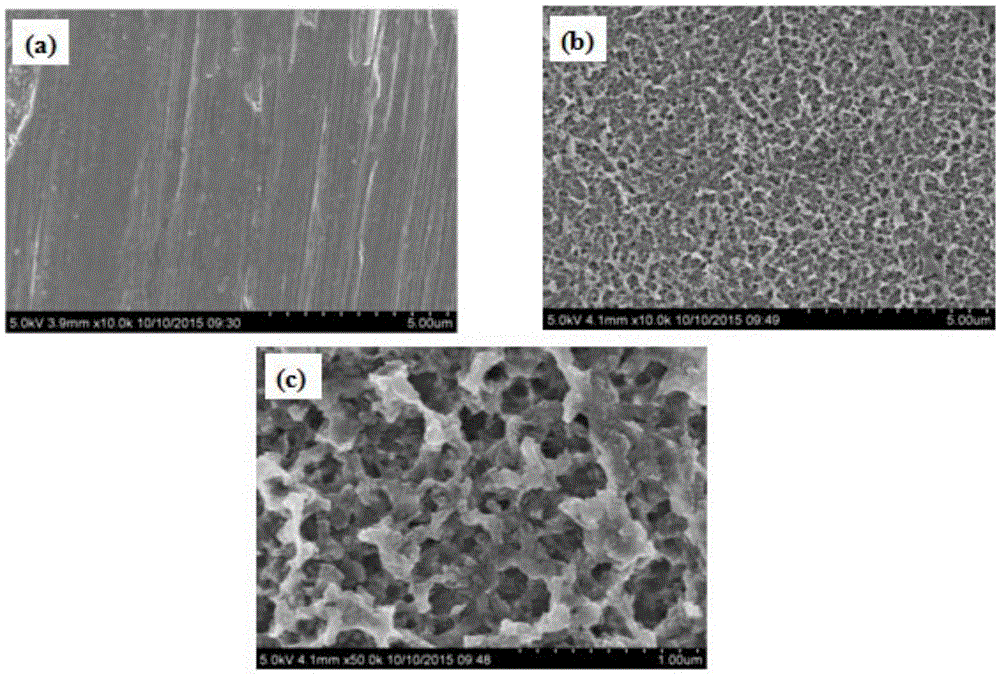

[0034] Ⅱ. Use a capillary to measure about 0.15 μL of alkylchlorosilane (1H,1H,2H,2H-perfluorooctyltrichlorosilane, FOTMS) and add it to a hydrochloric acid solution with a concentration of 1mol / L to form a mixed solution, and place it side by side Stir well on a magnetic stirrer. At room temperature, the cleaned stainless steel sheet was etched in a mixed solution for 50 min. After etching, the steel sheet was taken out, rinsed with deionized water, and dried with nitrogen to obtain a stainless steel surface with superhydrophobic properties. At the same time, the The surface also has a certain oleophobicity (rapeseed oil, crude oil).

[0035] The reaction formula of the chemical reaction in the etchi...

Embodiment 2

[0039] Ⅰ. Cut out an aluminum sheet with a size of 30×20×0.2mm, put it in an ultrasonic cleaning machine, and use chloroform, acetone, absolute ethanol, and deionized water to ultrasonically clean it for 10 minutes. After cleaning, take it out and blow it dry with nitrogen. stand-by.

[0040]Ⅱ. Use a capillary to take about 0.5 μL of alkylalkoxysilane (1H,1H,2H,2H-perfluorodecyltriethoxysilane) and add it to a sodium hydroxide solution with a concentration of 2mol / L to form a mixed solution , and placed on a magnetic stirrer to stir evenly. At room temperature, place the cleaned aluminum sheet in a mixed solution to etch for 30 minutes. After etching, take out the aluminum sheet, rinse it with deionized water, and dry it with nitrogen to obtain an aluminum surface with superhydrophobic properties. At the same time, the surface It also has certain oil repellency. The reaction formula of the chemical reaction in the etching process is:

[0041] 2Al+2NaOH+2H 2 O=2NaAlO 2 +3H...

Embodiment 3

[0043] Ⅰ. Cut out a silicon wafer with a size of 30×20×0.2mm, place it in an ultrasonic cleaning machine, and use chloroform, acetone, absolute ethanol, and deionized water to ultrasonically clean it for 10 minutes. After cleaning, take it out and blow it dry with nitrogen. stand-by.

[0044] II. Take 0.75 μL of fatty acid (perfluorodecanoic acid) and add it to potassium hydroxide solution with a concentration of 0.5 mol / L to make a mixed solution, and place it on a magnetic stirrer to stir evenly. At room temperature, place the cleaned silicon wafer in a mixed solution to etch for 60 minutes. After the etching is completed, take out the silicon wafer, rinse it with deionized water, and dry it with nitrogen to obtain a silicon surface with superhydrophobic properties. The surface also has a certain degree of oleophobicity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com