Preparation method for super-hydrophobic silica particle and super-hydrophobic coating

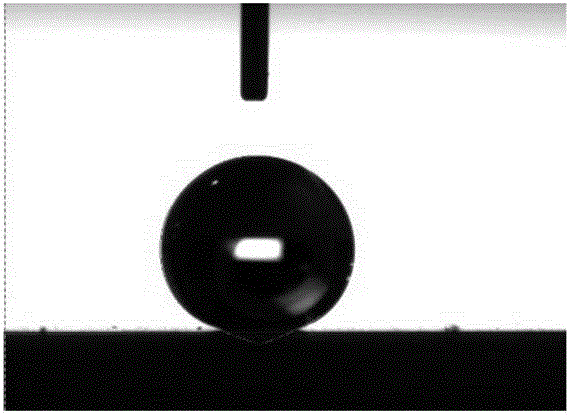

A super-hydrophobic coating, silica technology, applied in silica, silica, coating and other directions, can solve the problems of time-consuming pretreatment steps, strict process conditions, expensive chemical modifiers and special equipment, etc. Good effect, simple and practical effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Modification of nano-silica particles

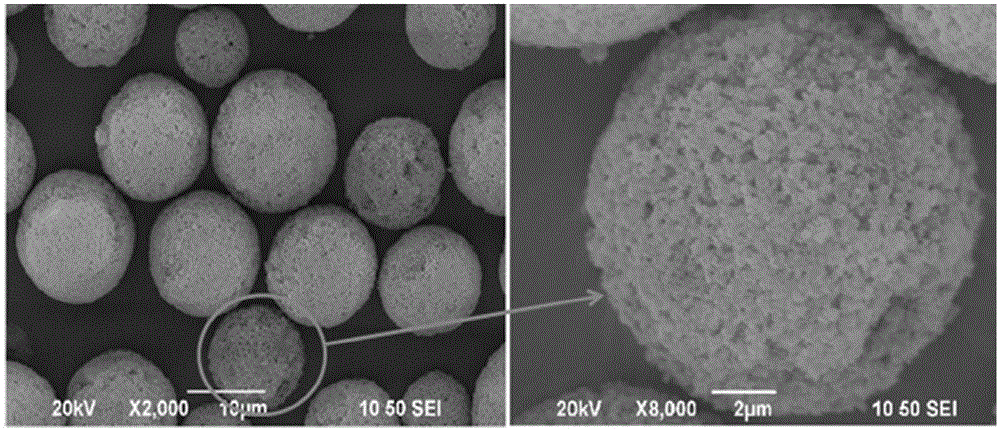

[0039]Add 3.0 g of nano-silica particles with an average particle size of 50 nm and 3.6 g of distilled water into 100 mL of ethanol, and ultrasonically disperse for 30 min; Wherein the material molar ratio is SiO 2 :H 2 O:TEOS=1:4:1:0.2-0.5), and stir evenly, then use 1mol / L hydrochloric acid to adjust the pH value to 2.0-3.0, then electromagnetically stir at room temperature for 24h, and then use ammonia water with a mass fraction of 1.2% to adjust The pH value was 6.0-7.5, and the stirring was continued for 0.5h to obtain a milky white suspension.

[0040] (2) Ultrasonic spray drying

[0041] Pass the milky white suspension obtained in step (1) of this embodiment into an ultrasonic spray dryer through a peristaltic pump for drying, and during the drying process, ultrasonic dispersion is used; in this process, the inlet temperature of the spray dryer is 90°C , the flow rate of the milky white suspension is 300mL / h, and th...

Embodiment 2

[0045] (1) Modification of nano-silica particles

[0046] Add 3.0g of nano-silica particles with an average particle size of 50nm and 3.6g of distilled water into 100mL of ethanol, and ultrasonically disperse for 30min; (wherein the material molar ratio is SiO 2 :H 2 O:TEOS=1:4:1:0.2-0.5), and stir evenly, then use 1mol / L hydrochloric acid to adjust the pH value to 2.0-. Adjust the pH value to 6.0-7.5, and continue to stir for 0.5h to obtain a milky white suspension.

[0047] (2) Ultrasonic spray drying

[0048] Pass the milky white suspension obtained in step (1) of this embodiment into an ultrasonic spray dryer through a peristaltic pump for drying, and during the drying process, ultrasonic dispersion is used; in this process, the inlet temperature of the spray dryer is 90°C , the flow rate of the milky white suspension is 300mL / h, and the fan frequency is 50Hz; through this step, white particles can be collected.

[0049] (3) Preparation of superhydrophobic coating

...

Embodiment 3

[0053] (1) Modification of nano-silica particles

[0054] Add 3.0g of nano-silica particles with an average particle size of 50nm and 3.6g of distilled water into 100mL of ethanol, and ultrasonically disperse for 30min; then add 2.215g of amino-containing silane (ATEOS) and fluorine-containing silane (FTEOS) The material molar ratio is SiO 2 :H 2 O:ATEOS=5:20:1:0.2-0.5), and stir evenly, then use 1mol / L hydrochloric acid to adjust the pH value to 2.0-3.0, then electromagnetically stir at room temperature for 24h, and then adjust with 1.2% ammonia water The pH value was 6.0-7.5, and the stirring was continued for 30 minutes to obtain a milky white suspension.

[0055] (2) Ultrasonic spray drying

[0056] Pass the milky white suspension obtained in step (1) of this embodiment into an ultrasonic spray dryer through a peristaltic pump for drying, and during the drying process, ultrasonic dispersion is used; in this process, the inlet temperature of the spray dryer is 90°C , th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com