Pneumatic tyre

A technology of pneumatic tires and tires, which is applied in the direction of special tires, tire parts, tire tread/tread pattern, etc., and can solve the problems of uneven ground pressure on the ground surface, easy wear, reduced handling stability and partial wear performance, etc. , to achieve the effect of high drainage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

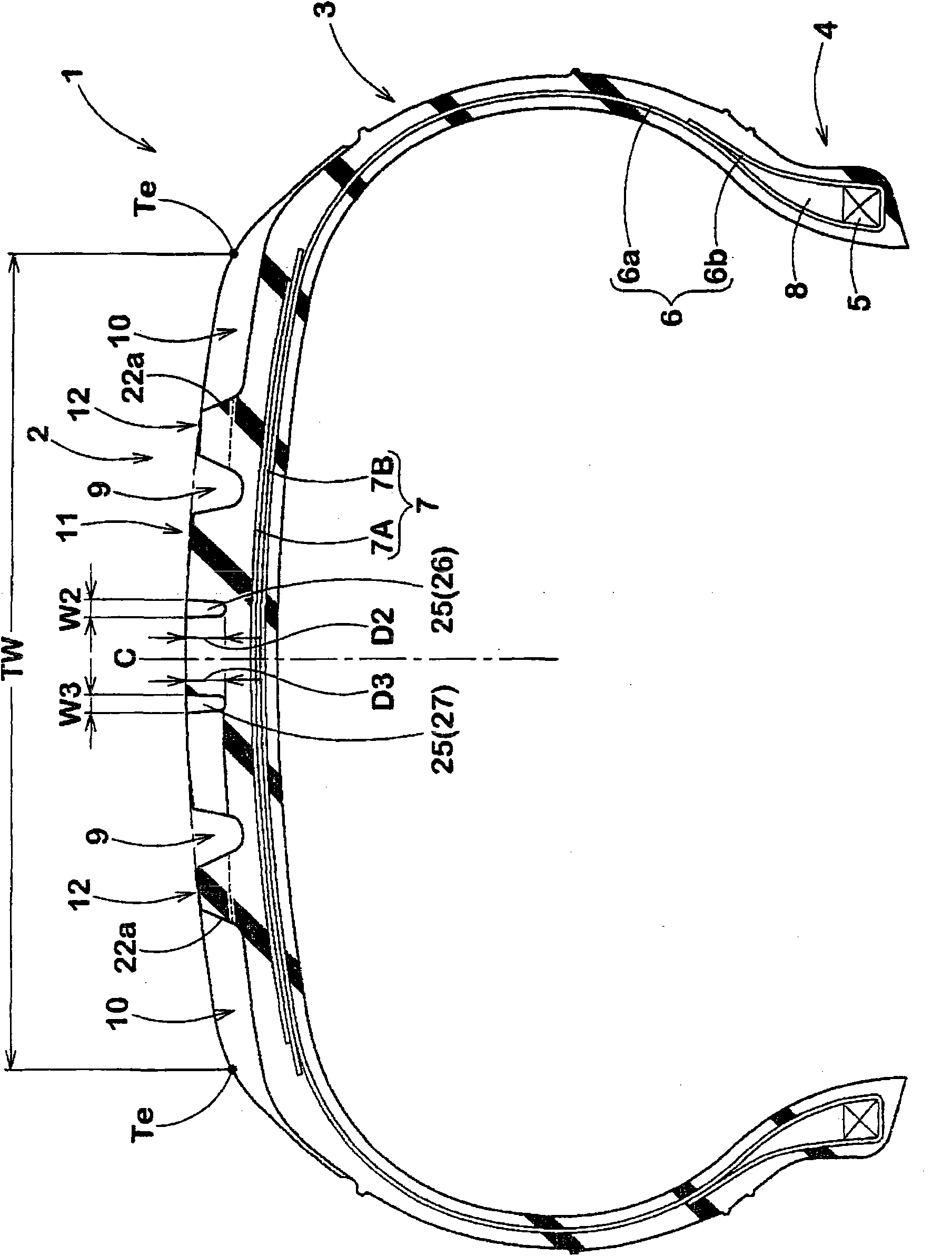

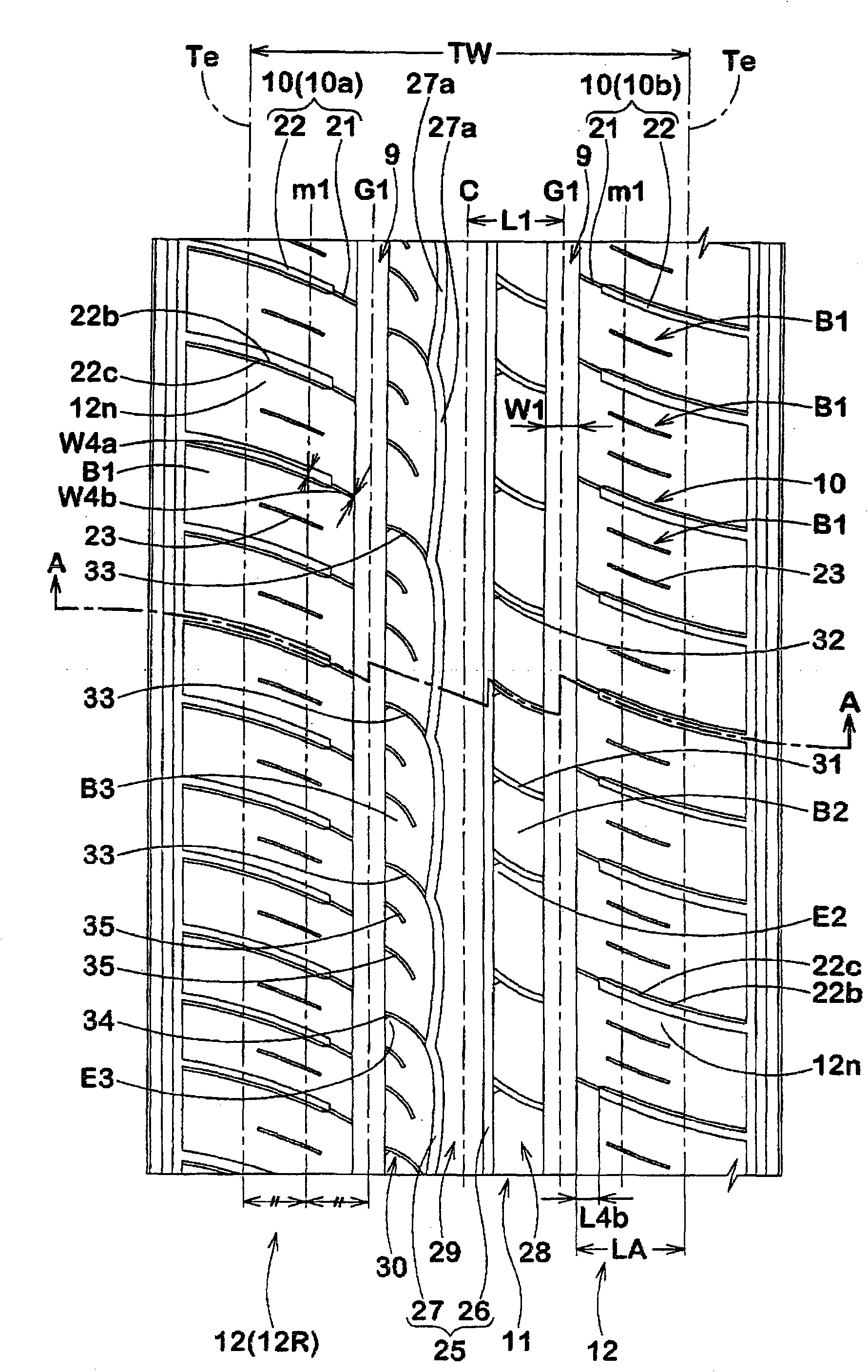

[0081] Based on the specifications in Table 1, a trial production with figure 1 internal structure and figure 2 The size of the tread pattern is 175 / 65R15 pneumatic tires for passenger cars, and the handling stability is tested. The internals of the tires are the same. Each specification is as follows.

[0082] Tread width TW: 130mm

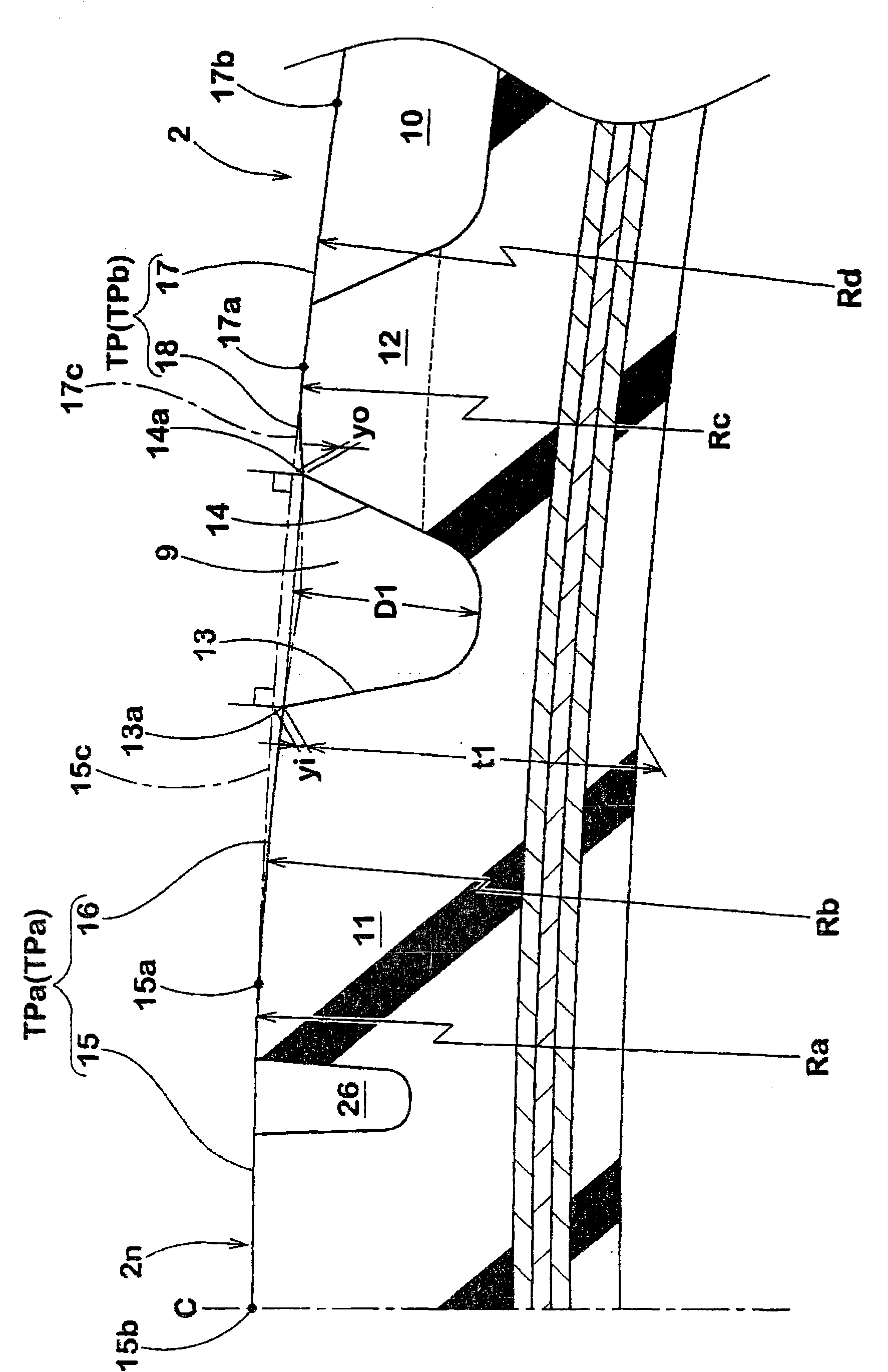

[0083] Groove width W1 of shoulder longitudinal groove: 10.0mm

[0084] Groove depth D1 of shoulder longitudinal groove: 8.2mm

[0085] Arrangement position L1 / TW of shoulder longitudinal groove: 23%

[0086] Angle θ1 of the groove wall on the tire equator side of the shoulder longitudinal groove: 15 degrees

[0087] Length ratio L4b / LA of the narrow portion of the shoulder lateral groove: 21%

[0088] Groove width W2 of straight longitudinal groove: 2.9mm

[0089] Groove width W3 of wavy longitudinal groove: 3.0mm

[0090] Groove depth D2 of straight longitudinal groove: 6.4mm

[0091] Groove depth D3 of wavy longitudinal groove: 6.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com