Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Low fracture toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

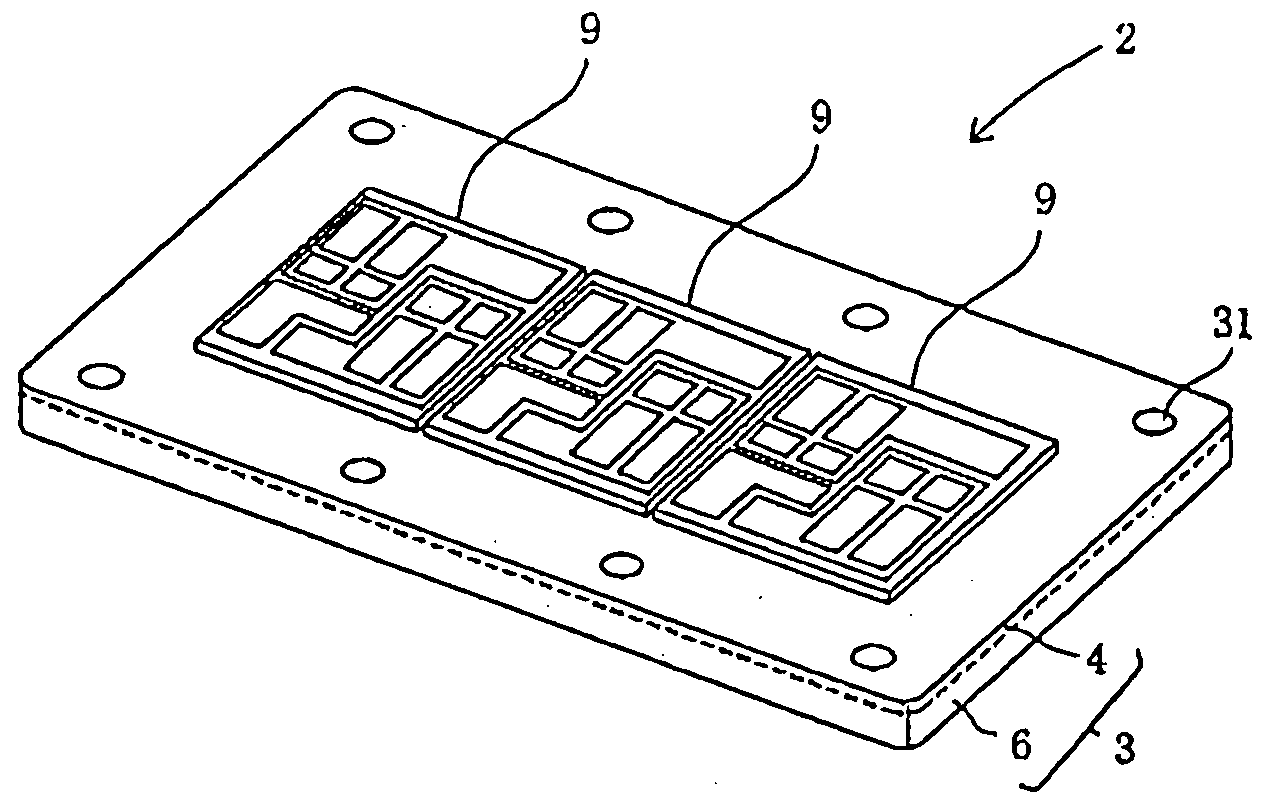

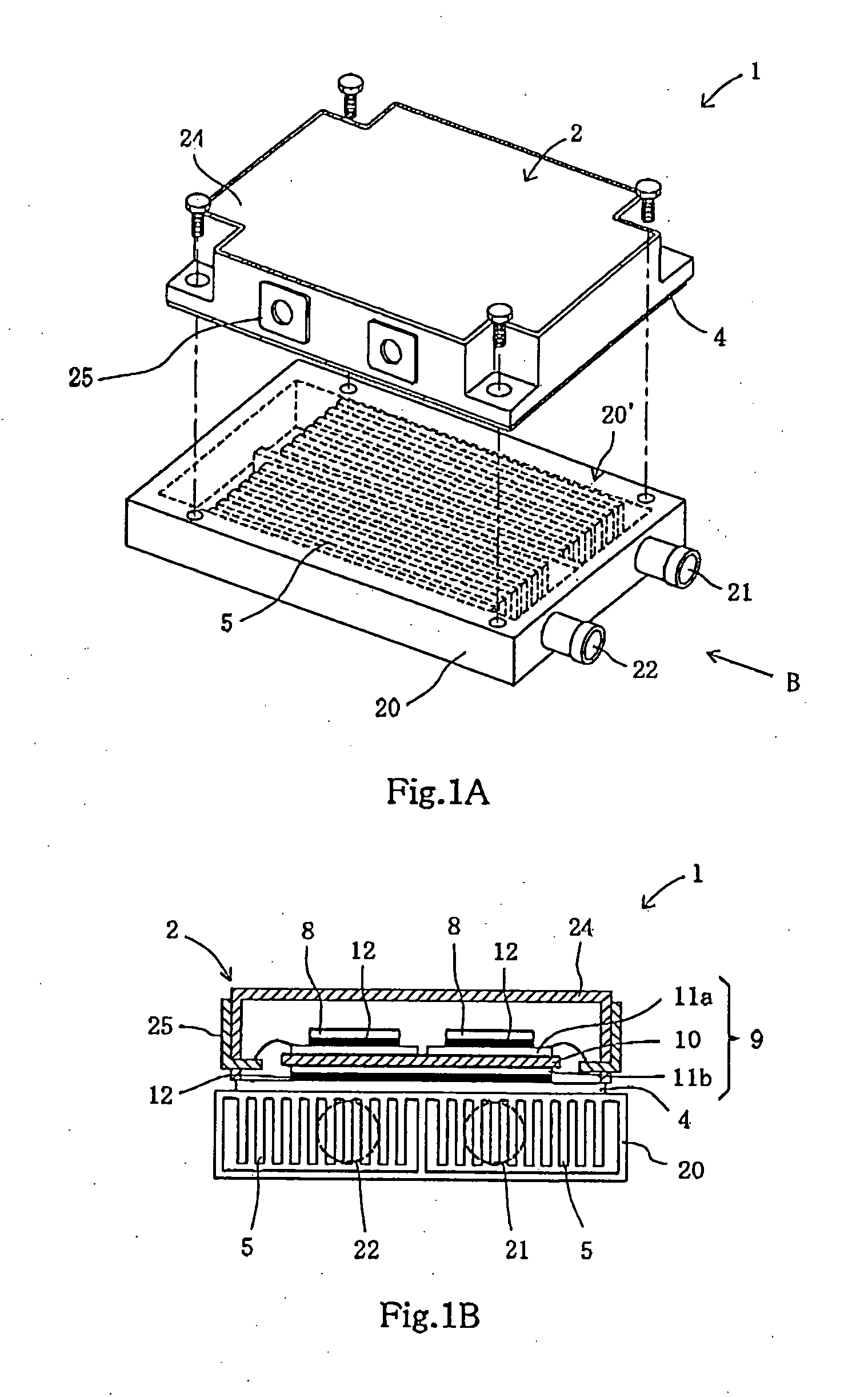

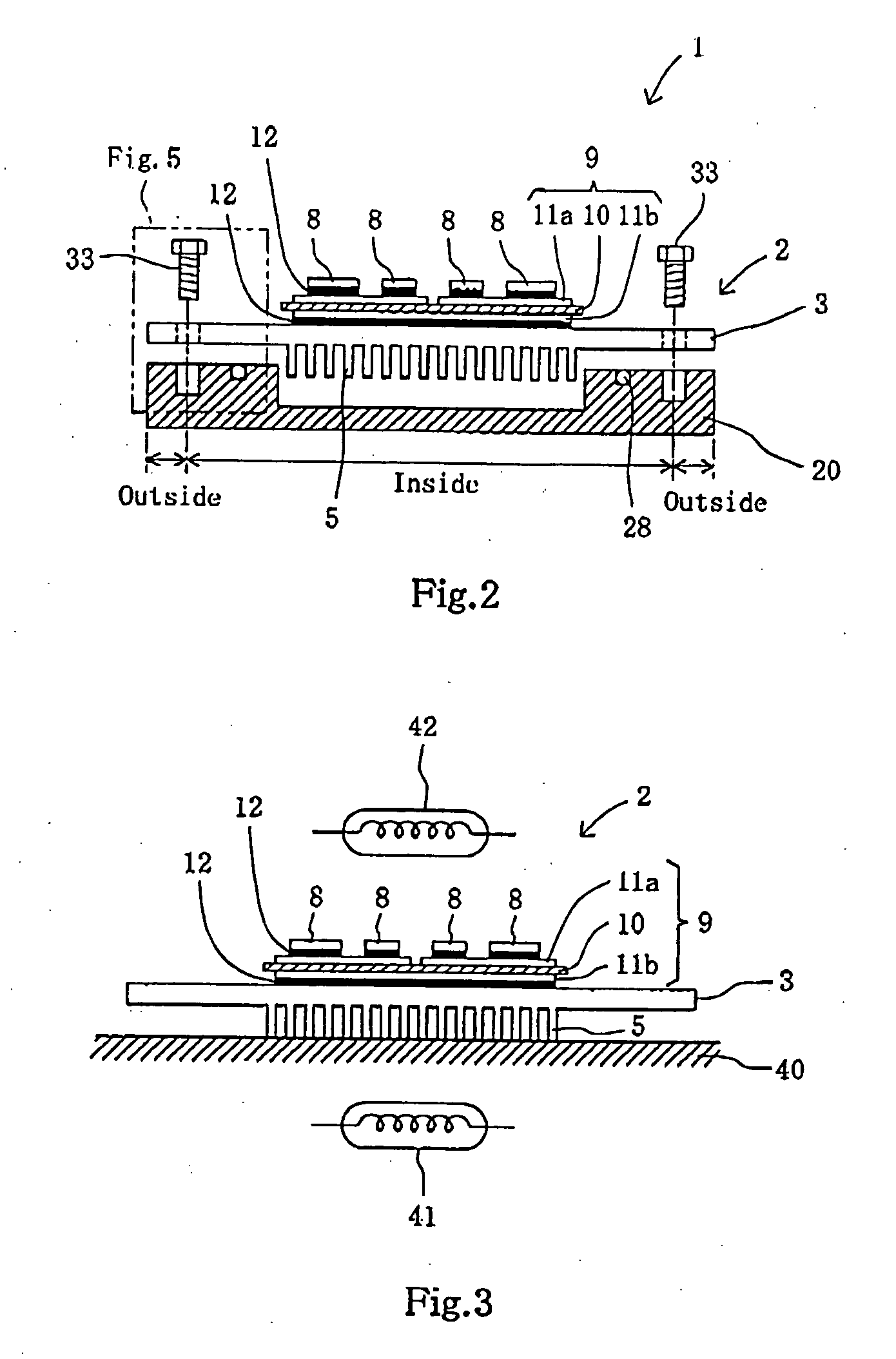

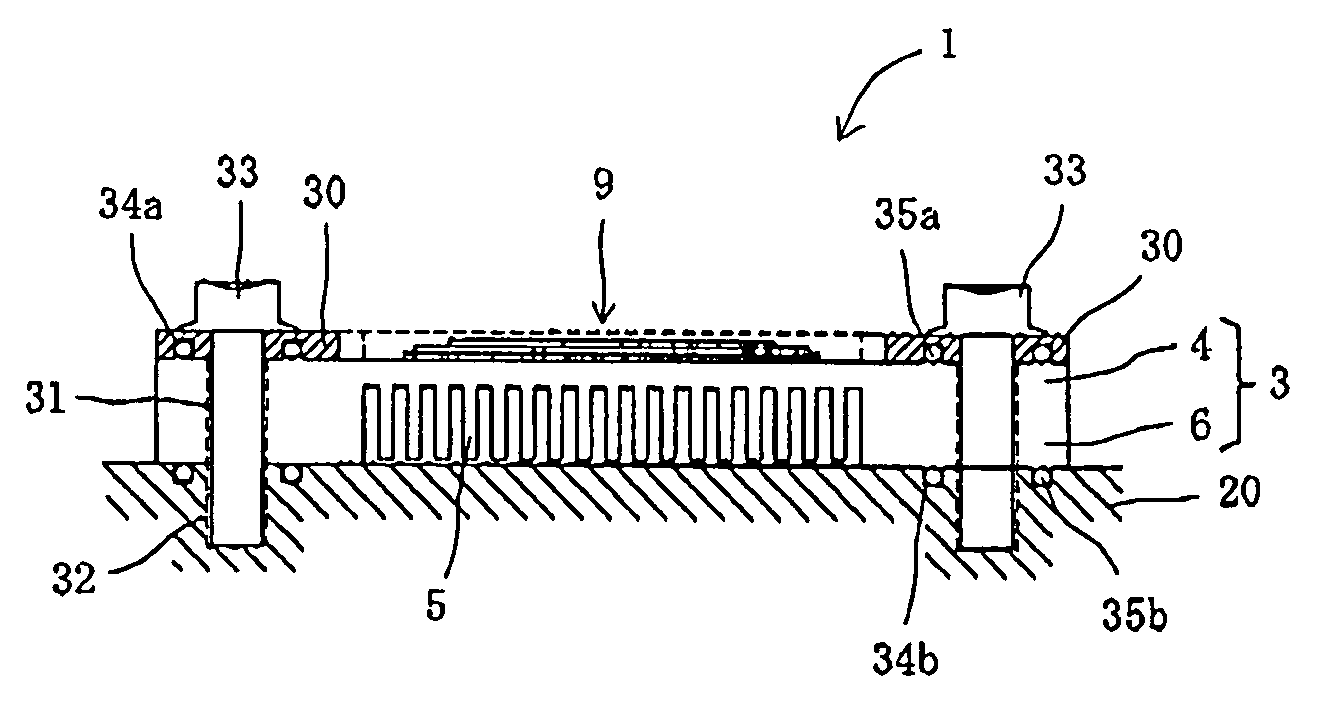

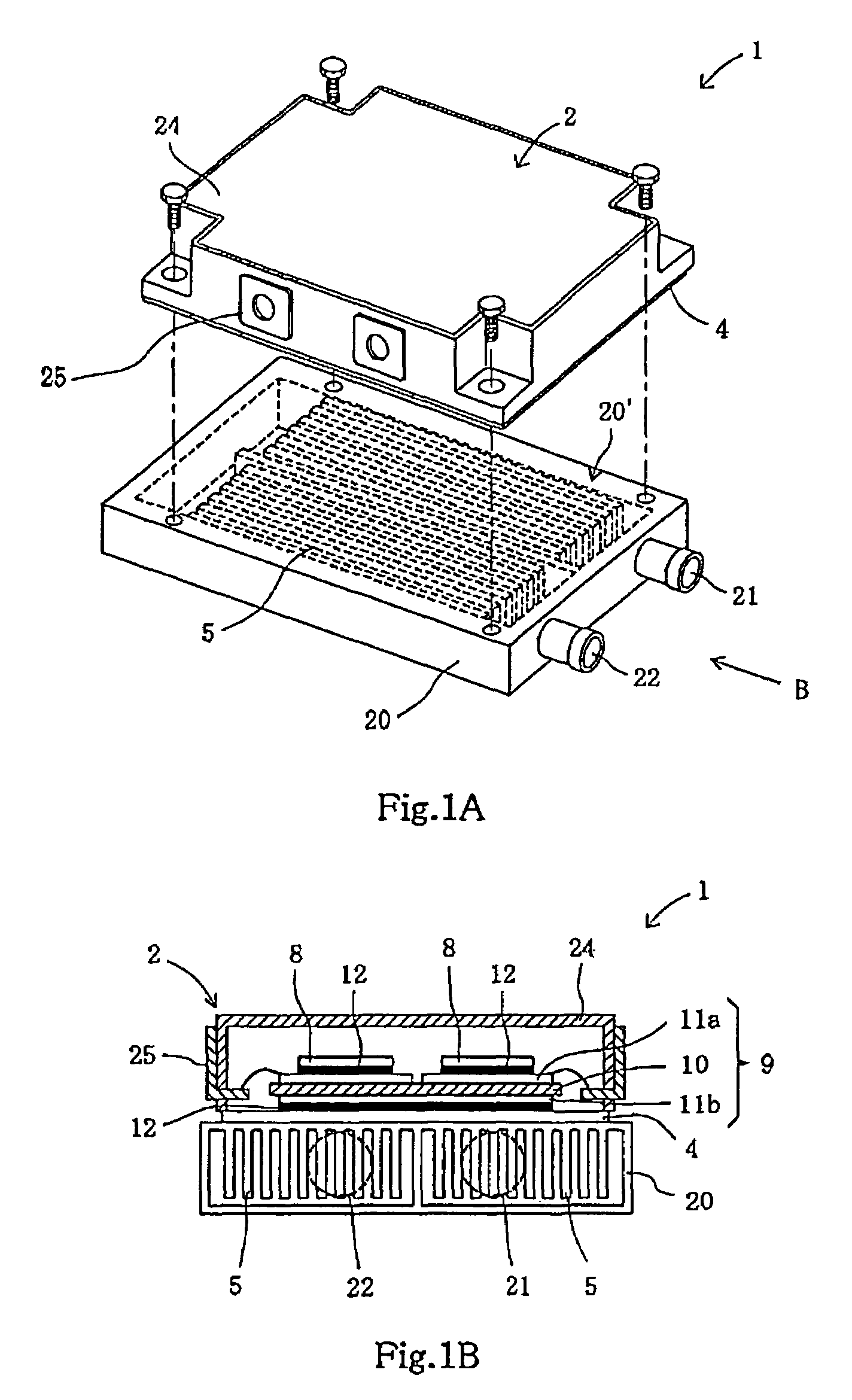

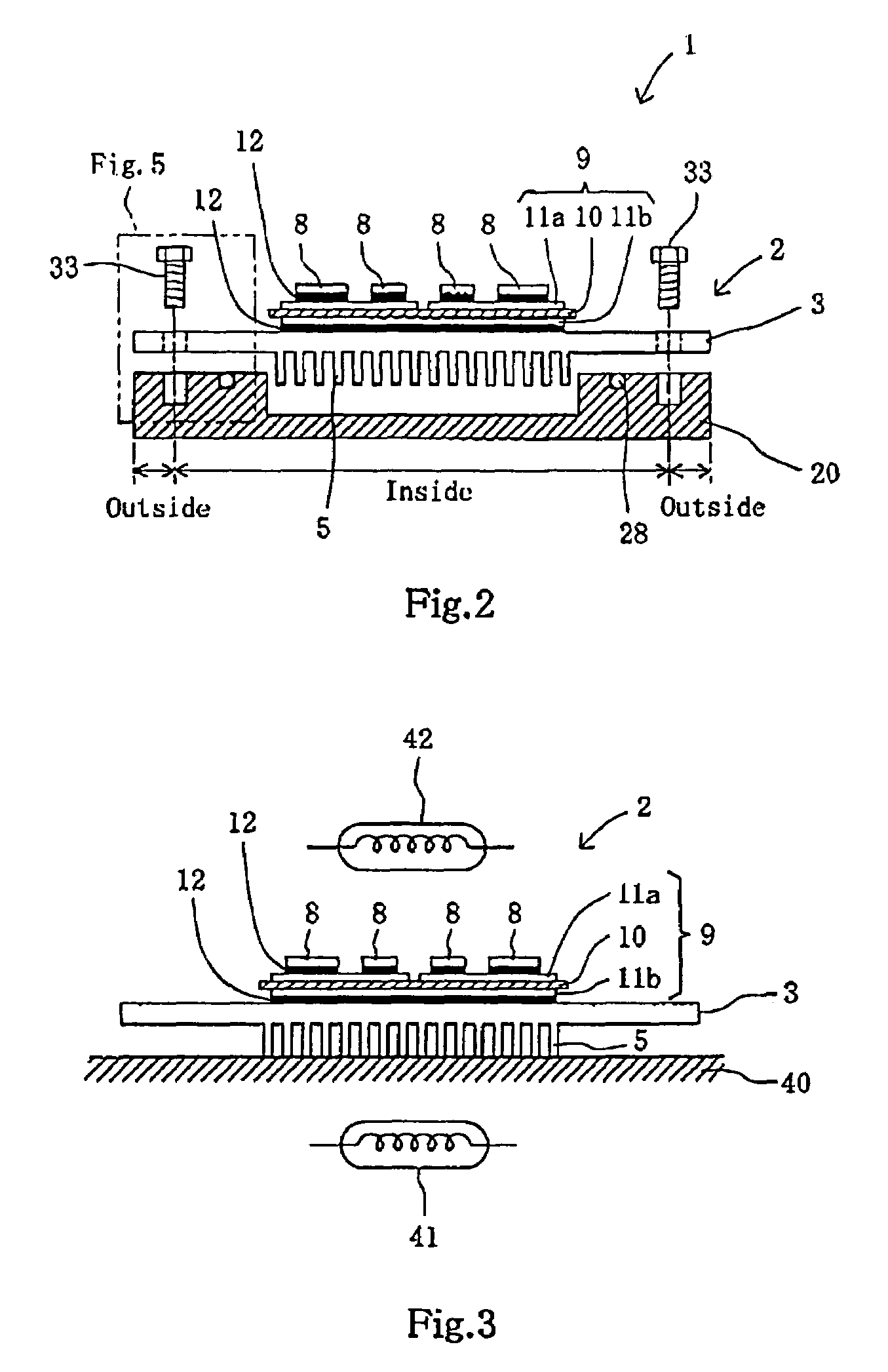

Power semiconductor module, and power semiconductor device having the module mounted therein

InactiveUS20080237847A1Avoid it happening againDegree of reductionSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceHeat sink

A power semiconductor module according to the present invention includes: a planar base plate having a plurality of insulated substrates soldered on the top surface, the insulated substrates each having power semiconductor elements to be cooled mounted thereon; a plurality of radiation fins projecting from the bottom surface side of the base plate; and a peripheral wall projecting from the bottom surface side of the base plate so as to surround the radiation fins, the projecting length of the radiation fins is less than or equal to that of the peripheral wall, and the peripheral wall has end surfaces present in the same plane. In addition, a power semiconductor device having the power semiconductor module mounted therein includes: at least one reinforcing plate disposed on the top surface side of the base plate via a first buffering member; and a cooling jacket fixed to the bottom surface side of the base plate via a second buffering member with a plurality of tightening fixtures passing through the reinforcing plate and the base plate, the cooling jacket having a flow passage for a cooling medium formed to intervene in a position with respect to the base plate, and the first buffering member and the second buffering member are respectively disposed at least inside and outside with respect to the tightening fixtures.

Owner:NICHICON CORP

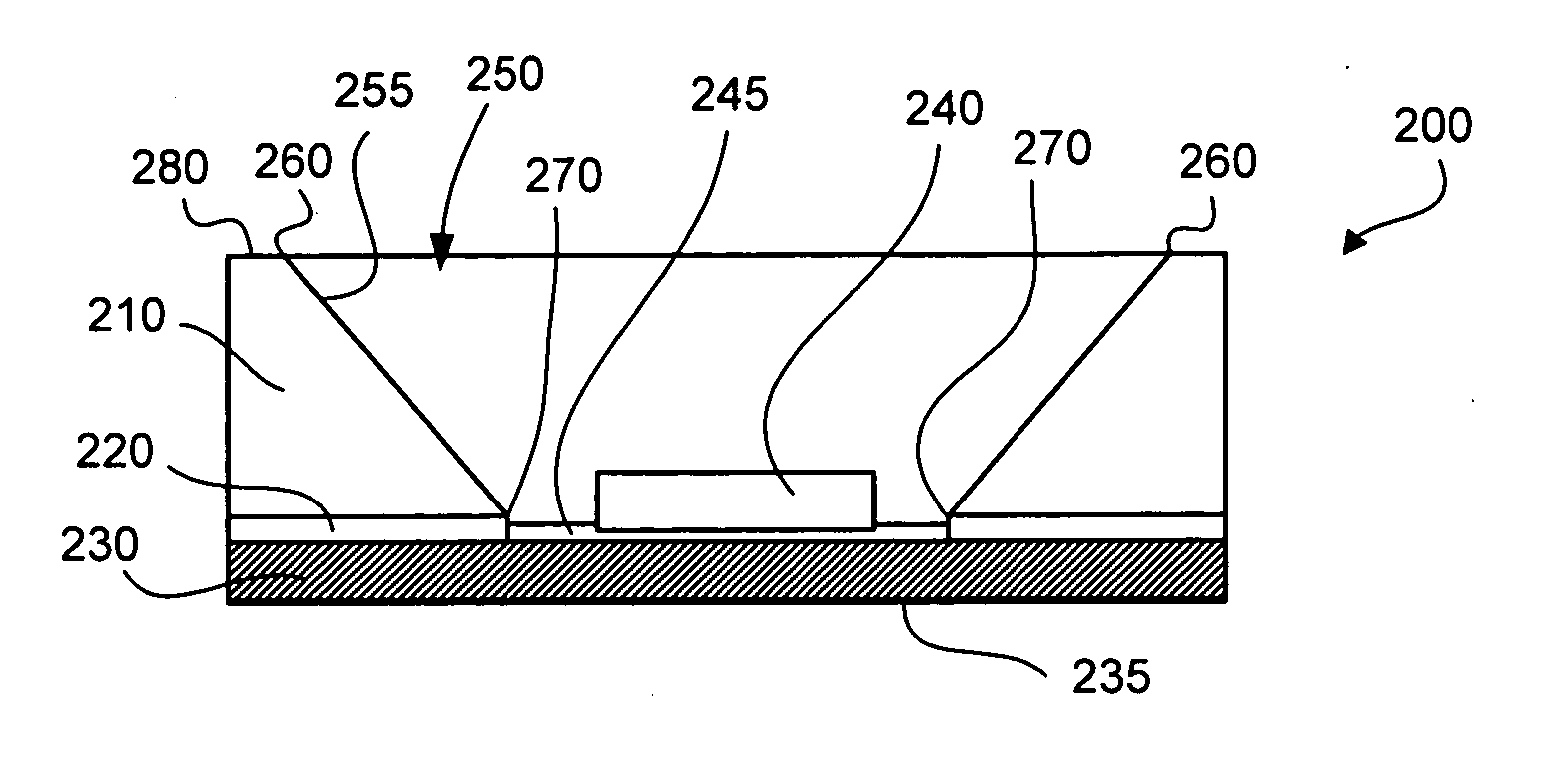

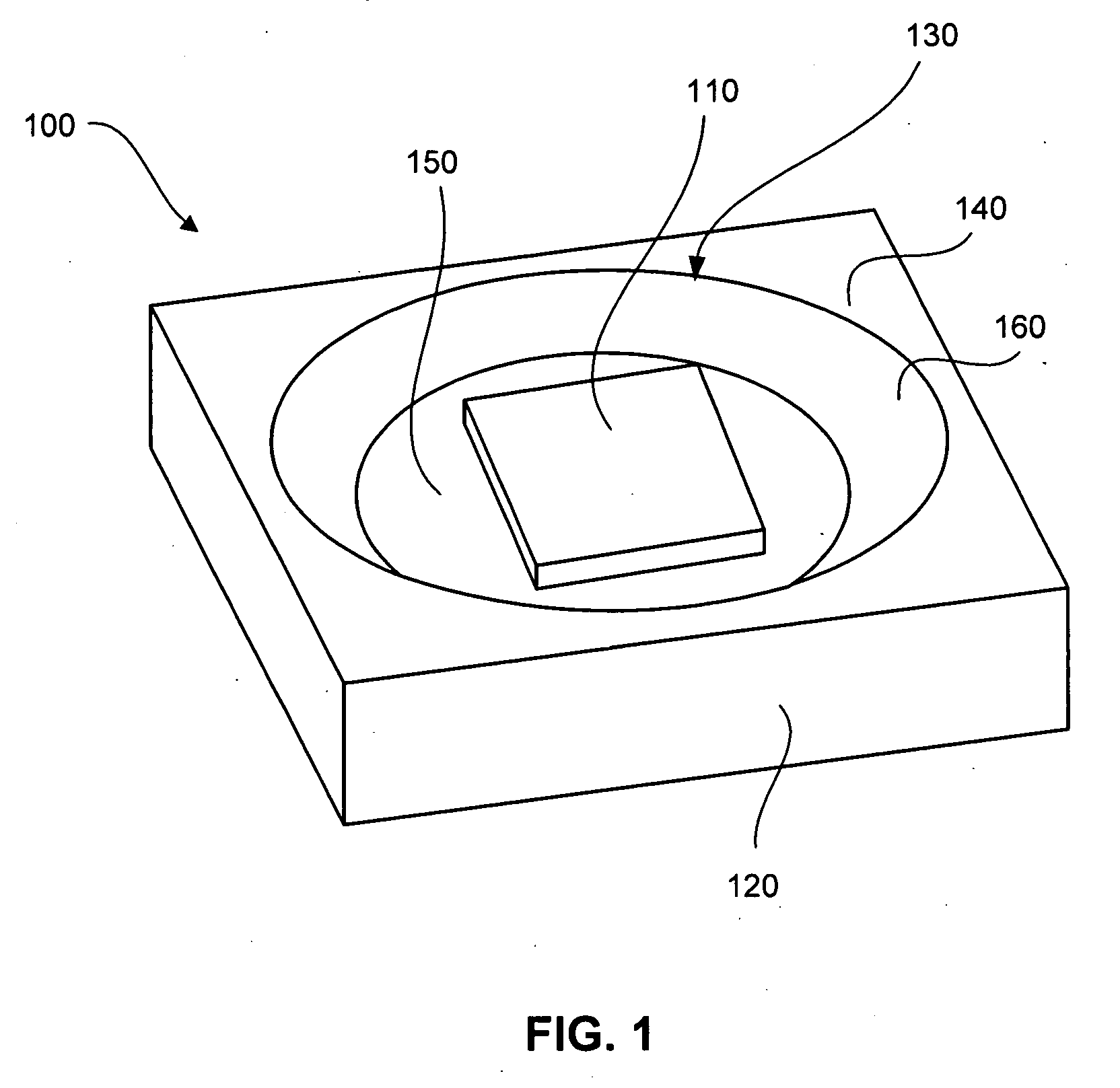

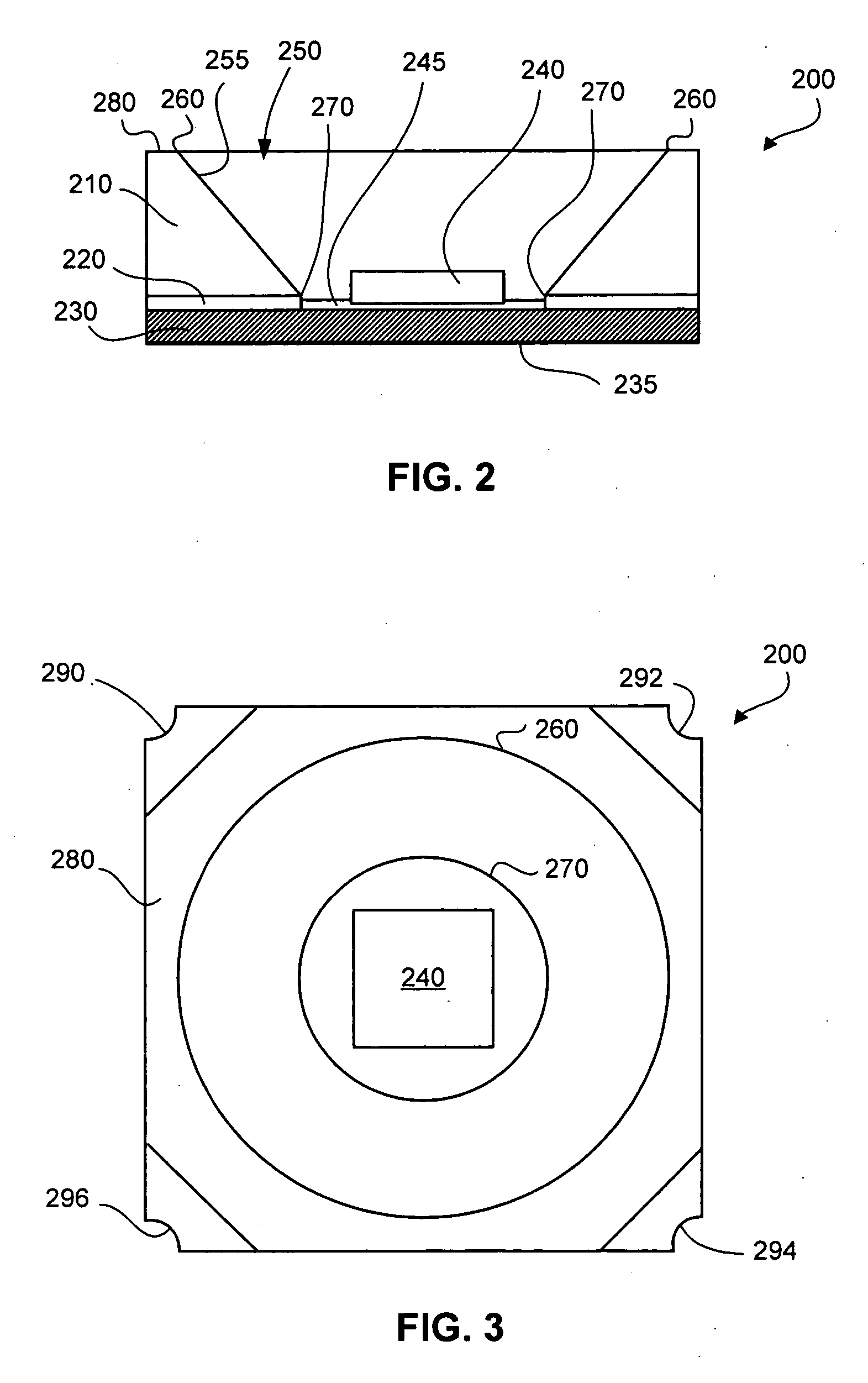

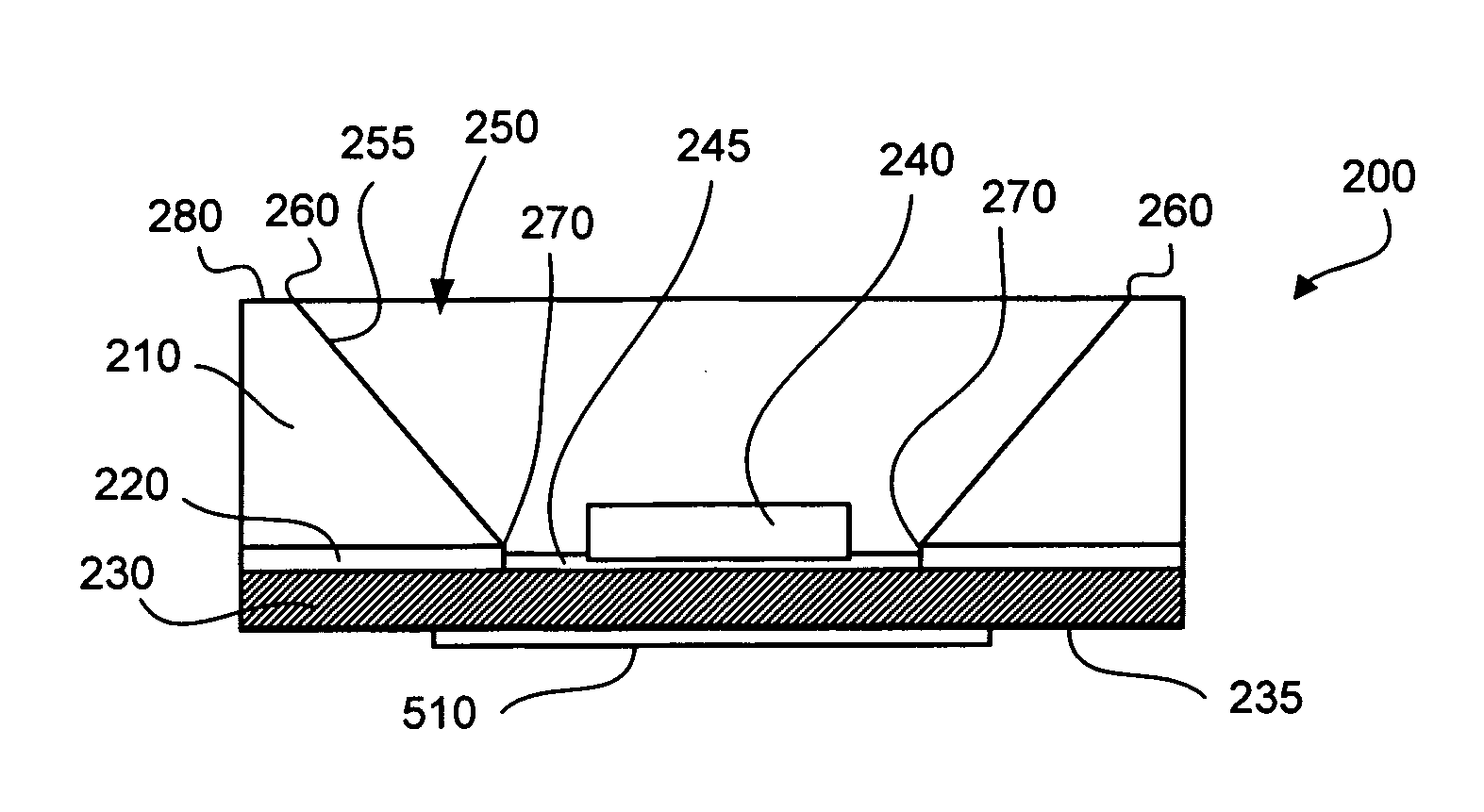

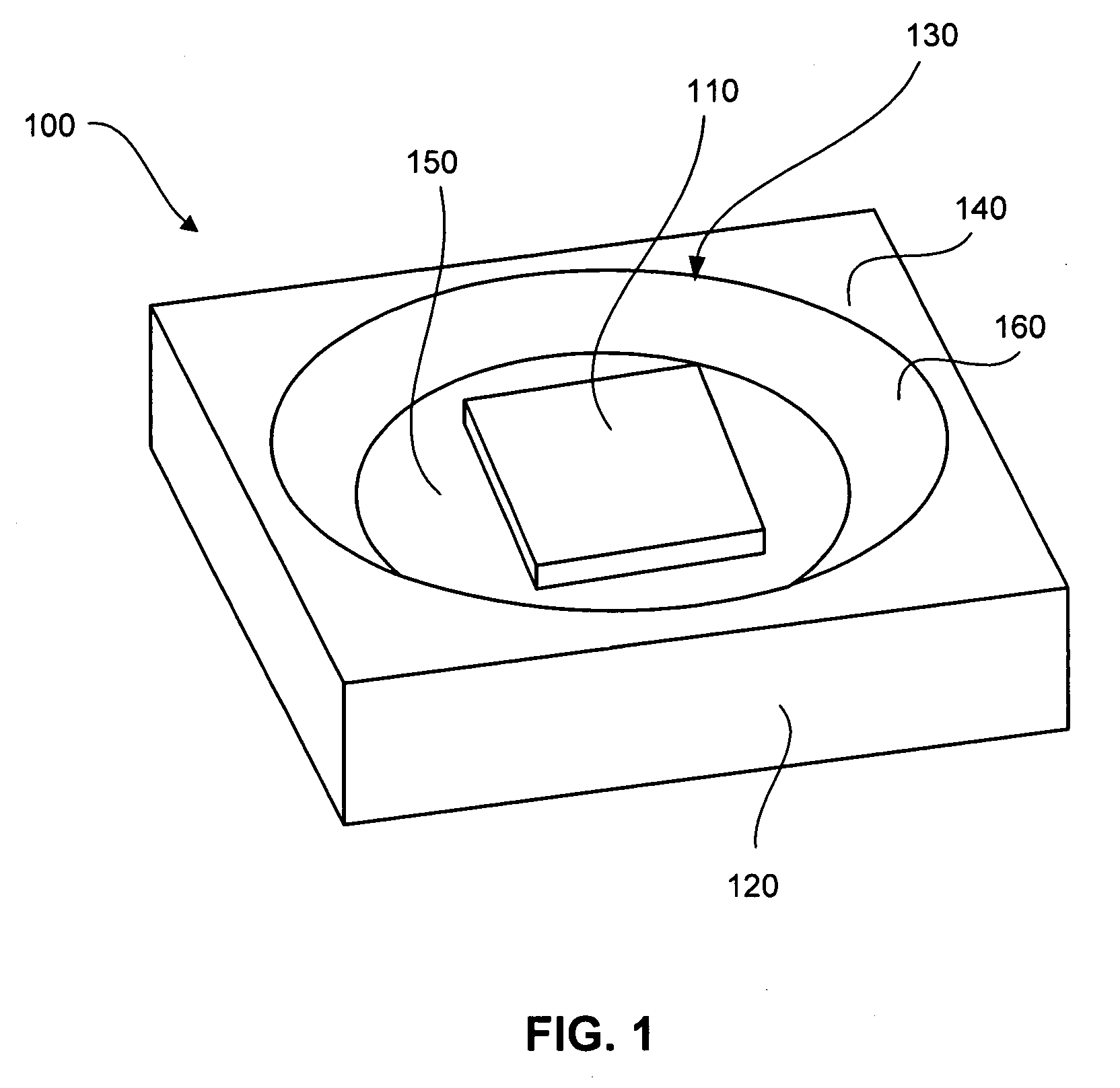

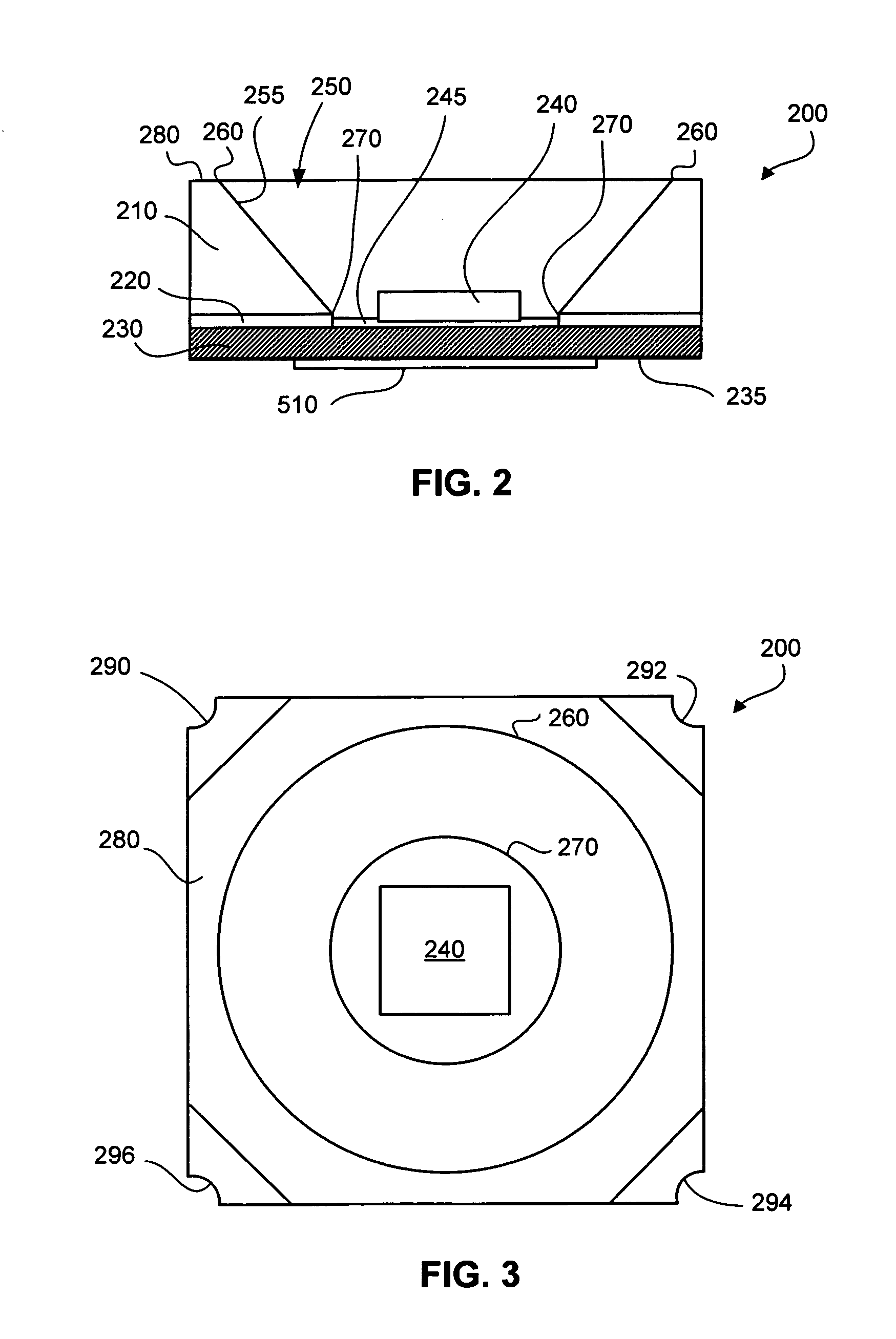

LED package with structure and materials for high heat dissipation

ActiveUS20060091415A1Improve cooling effectLow fracture toughnessSemiconductor/solid-state device detailsSolid-state devicesConductive materialsThermal expansion

LED packages are provided that include a material that is both thermally conductive and has a coefficient of thermal expansion that is matched to that of an LED. The material can be a ceramic such as aluminum nitride. The package has a body that includes a bottom surface and a cavity disposed into the body. The cavity has a floor for bonding to the LED so that the LED sits within the cavity. The thermally conductive material is disposed between the floor of the cavity and the bottom surface of the package. The body can be fabricated from a number of layers where the thermally conductive material is in a layer disposed between the floor and the bottom surface. The other layers of the body can also be fabricated from the thermally conductive material. A light emitting device is made by attaching the LED to the LED package.

Owner:LED ENGIN

LED package with structure and materials for high heat dissipation

ActiveUS7772609B2Facilitate conductionIncrease heatSemiconductor/solid-state device detailsSolid-state devicesConductive materialsThermal expansion

LED packages are provided that include a material that is both thermally conductive and has a coefficient of thermal expansion that is matched to that of an LED. The material can be a ceramic such as aluminum nitride. The package has a body that includes a bottom surface and a cavity disposed into the body. The cavity has a floor for bonding to the LED so that the LED sits within the cavity. The thermally conductive material is disposed between the floor of the cavity and the bottom surface of the package. The body can be fabricated from a number of layers where the thermally conductive material is in a layer disposed between the floor and the bottom surface. The other layers of the body can also be fabricated from the thermally conductive material. A light emitting device is made by attaching the LED to the LED package.

Owner:LED ENGIN

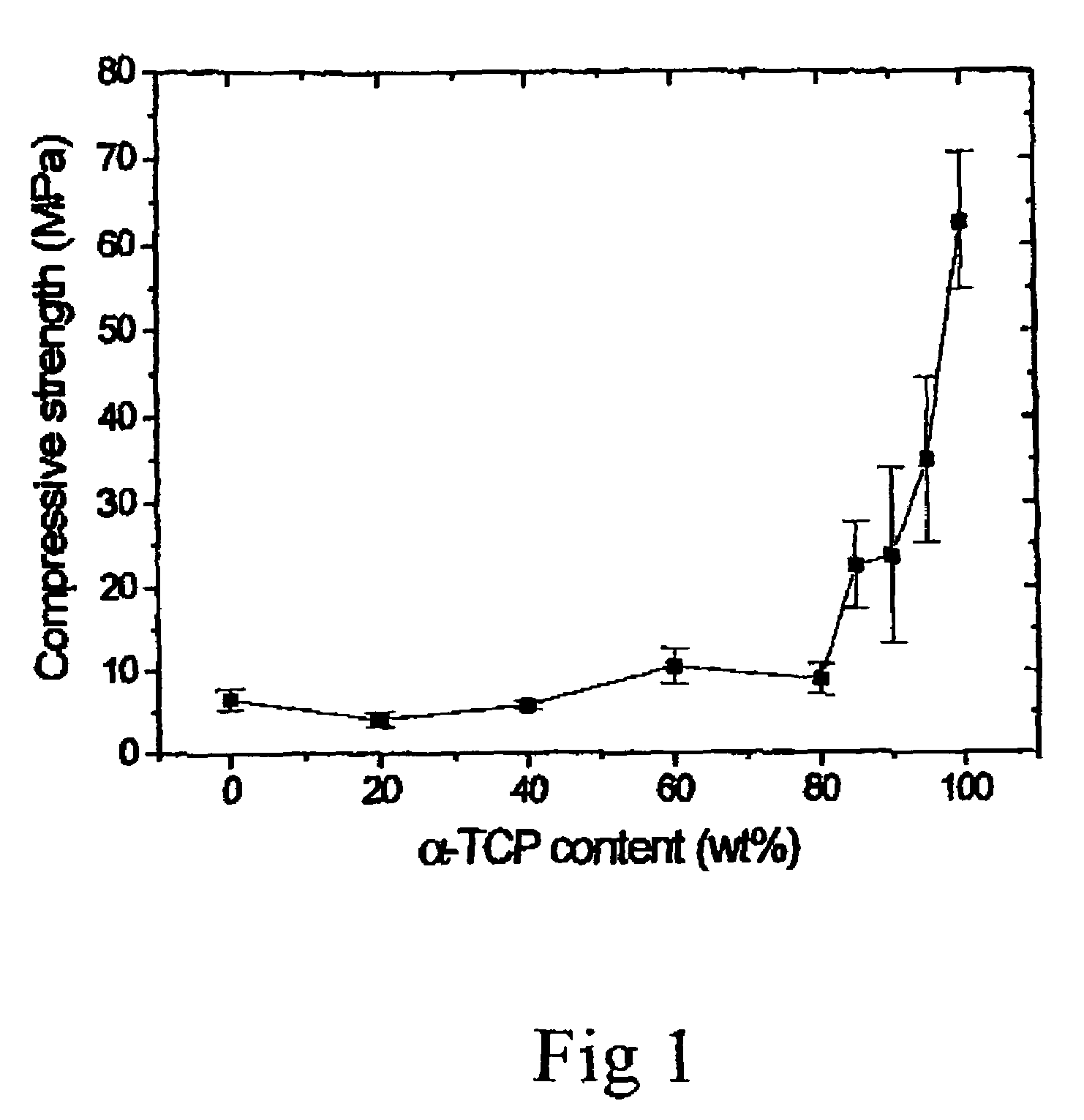

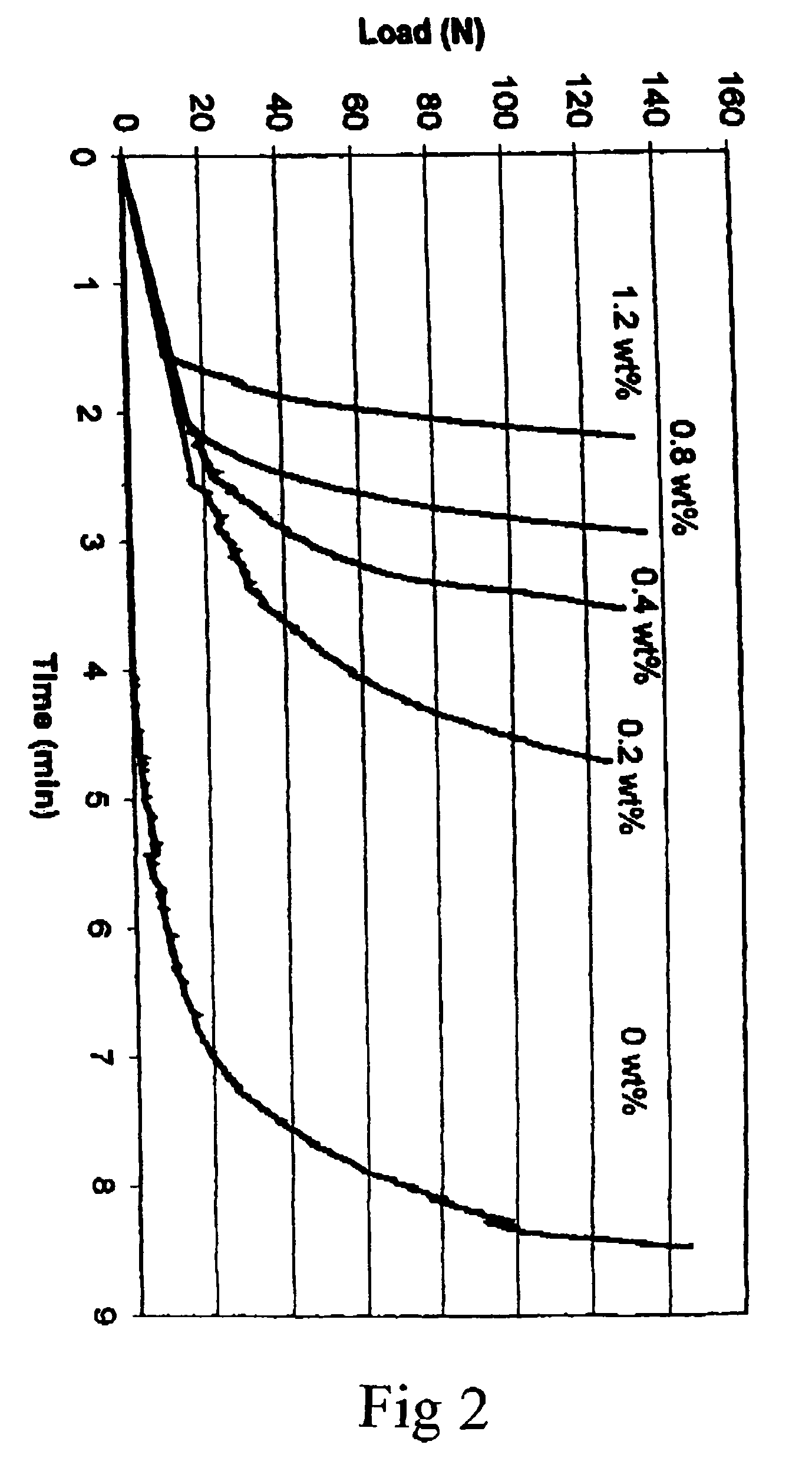

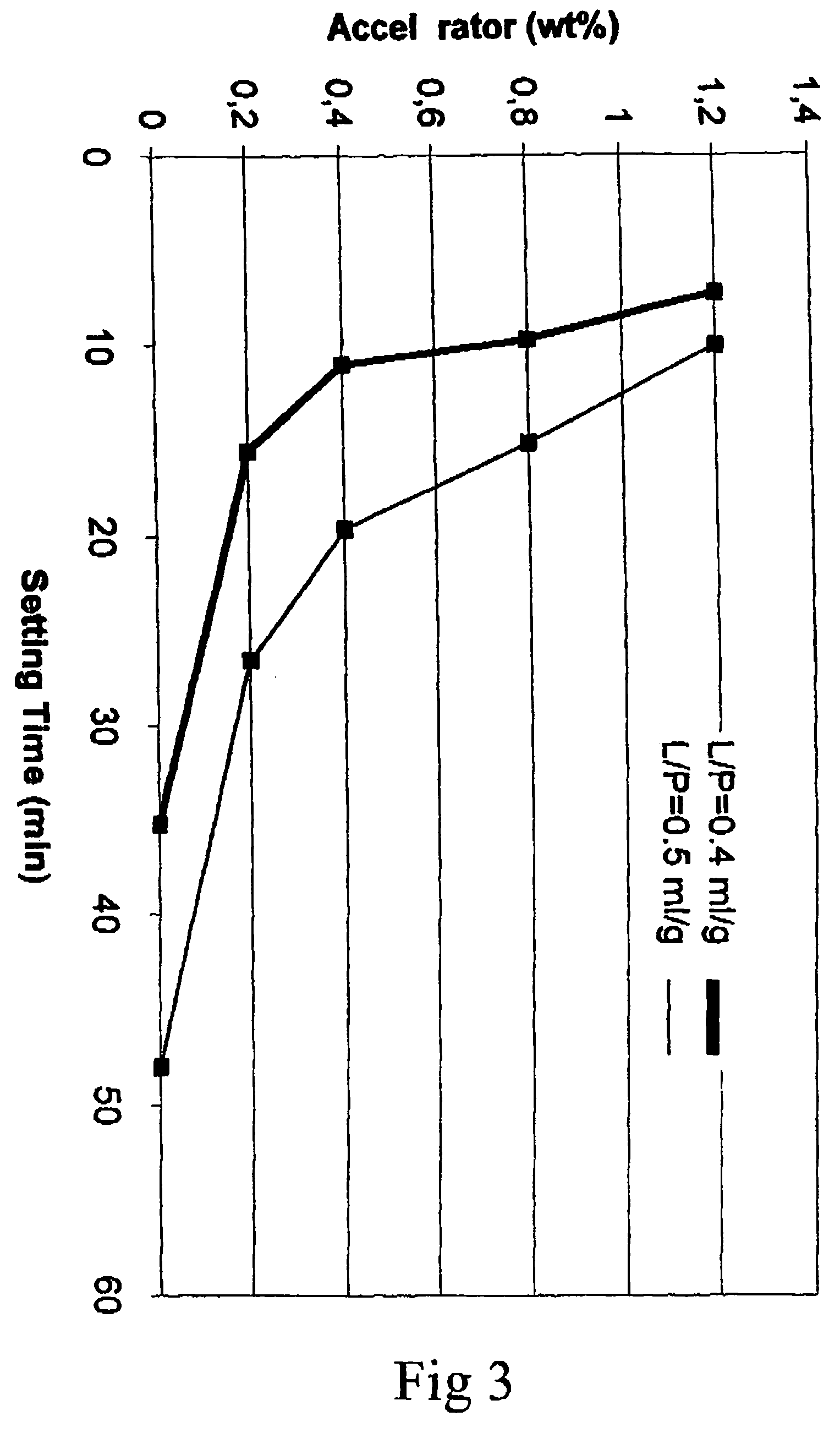

Composition for an injectable bone mineral substitute material

InactiveUS7417077B2High mechanical strengthHigh viscosityBiocidePowder deliveryCalcium biphosphateInjectable bone

The invention refers to an injectable composition for a bone mineral substitute material, which comprises a dry powder mixed with an aqueous liquid. The powder comprises a first reaction component comprising a calcium sulphate hemihydrate with the capability of being hardened to calcium sulphate dihydrate when reacting with said aqueous liquid; a second reaction component, which comprise a calcium phosphate with the capability of being hardened to a calcium phosphate cement when reacting with said aqueous liquid; and at least one accelerator for the reaction of said first and / or second reaction component with said aqueous liquid. A method of producing an injectable bone mineral substitute material is also provided, wherein the composition is mixed in a closed mixing and delivery system for delivery.

Owner:BONE SUPPORT

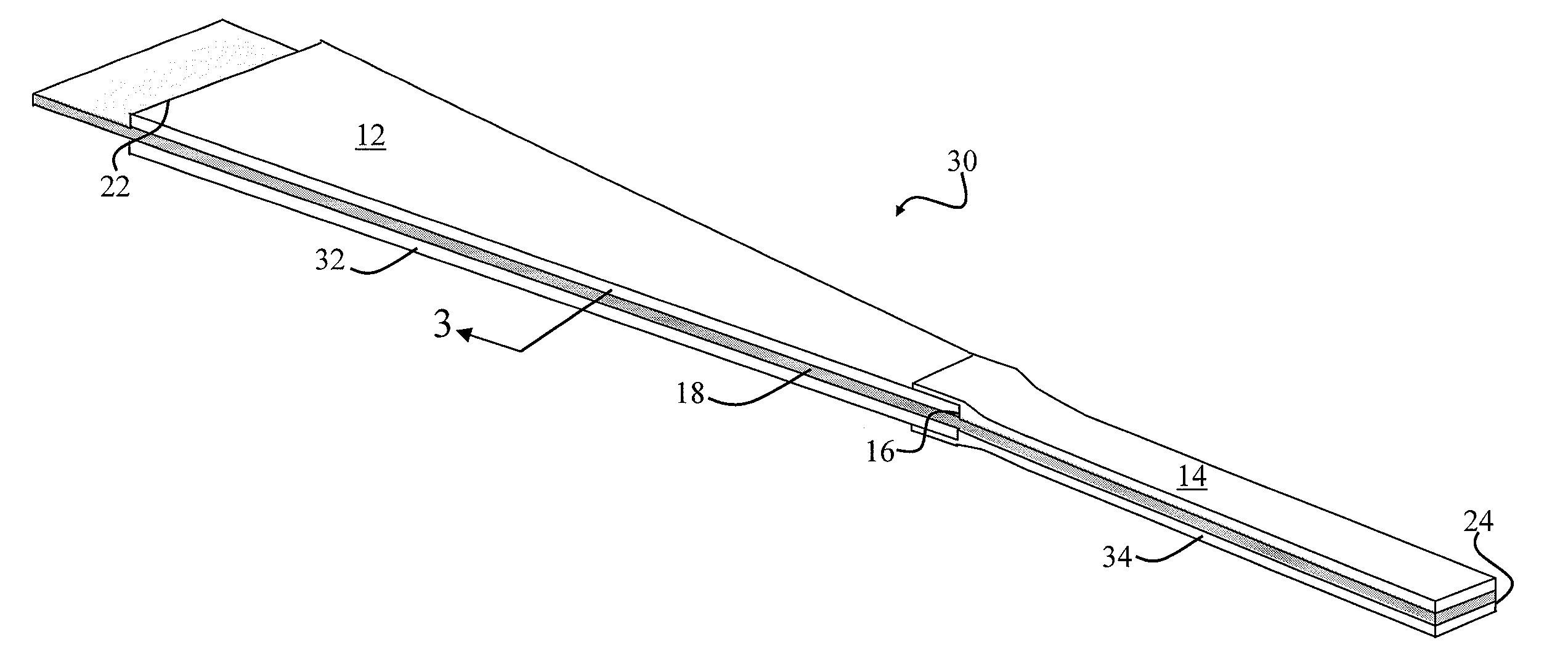

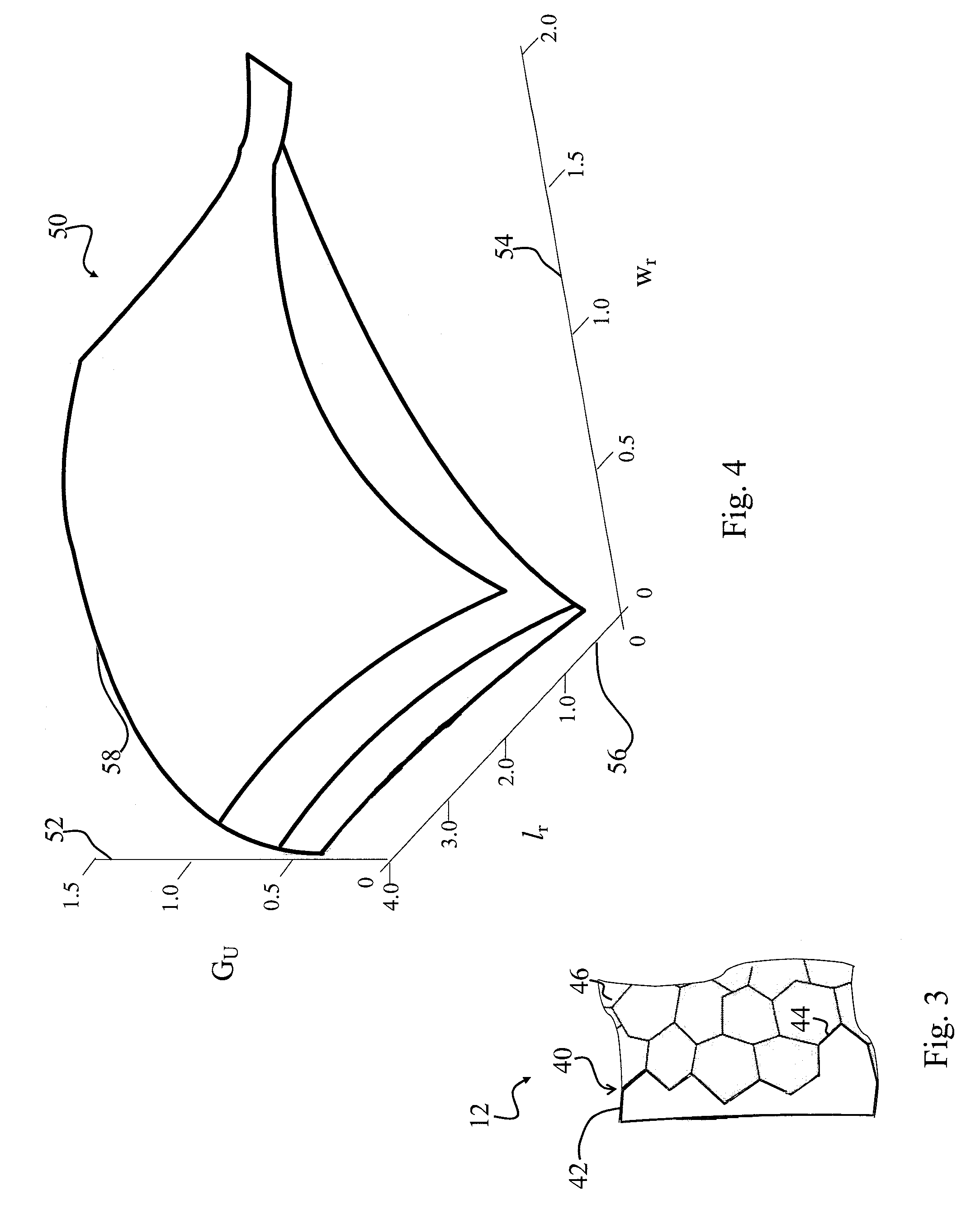

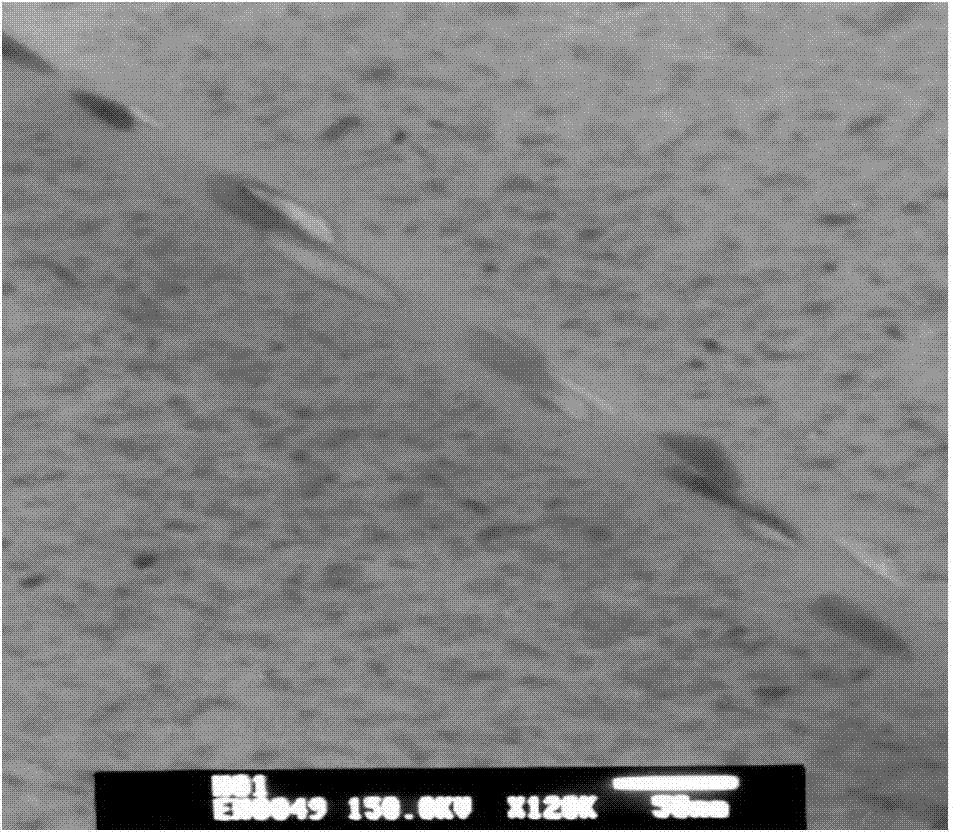

High performance piezoelectric actuator

InactiveUS7368860B2Improvement factorLow fracture toughnessPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsPiezoelectric actuatorsEngineering

A high performance piezoelectric actuator. The actuator includes a piezoelectric material exhibiting a selectively tapered width sufficient to enhance actuator fracture load capabilities. A passive material is disposed on or integrated with the piezoelectric material. A drive system is connected to the piezoelectric material. The drive system is capable of selectively applying an electric field to the piezoelectric material. In specific embodiment, the piezoelectric material includes a curved piezoelectric layer exhibits a default state of compression along a surface of the piezoelectric layer.

Owner:RGT UNIV OF CALIFORNIA

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

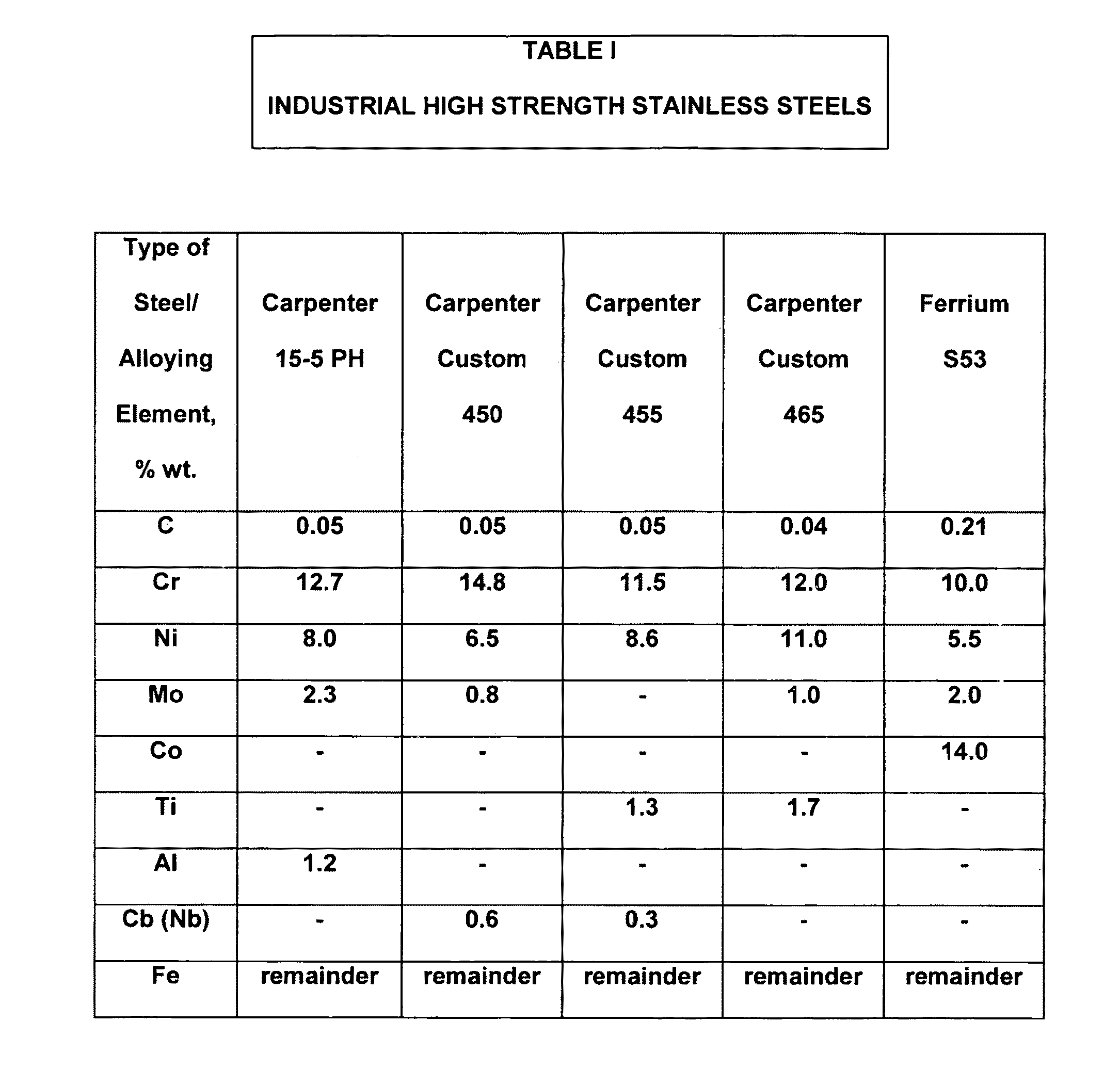

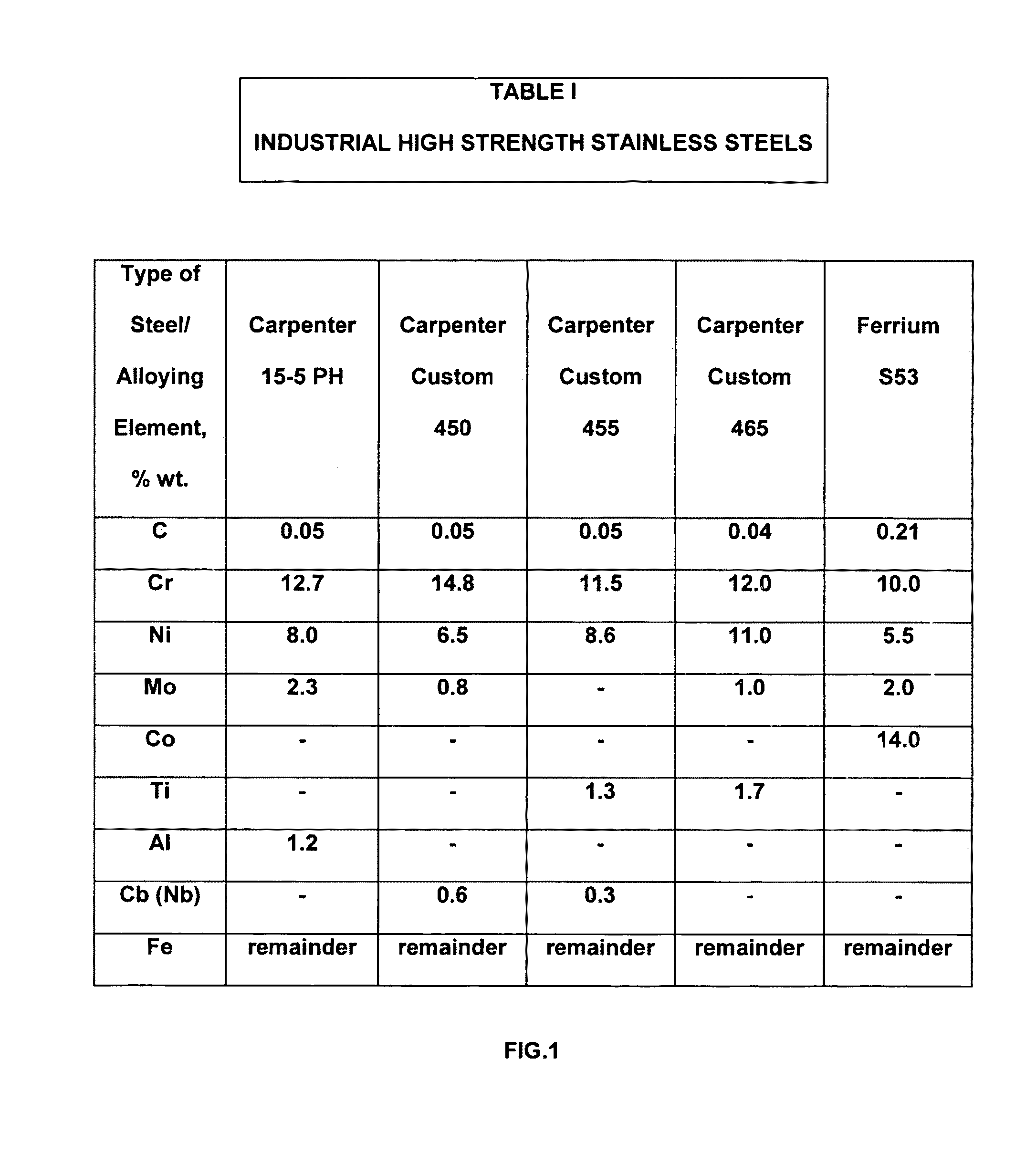

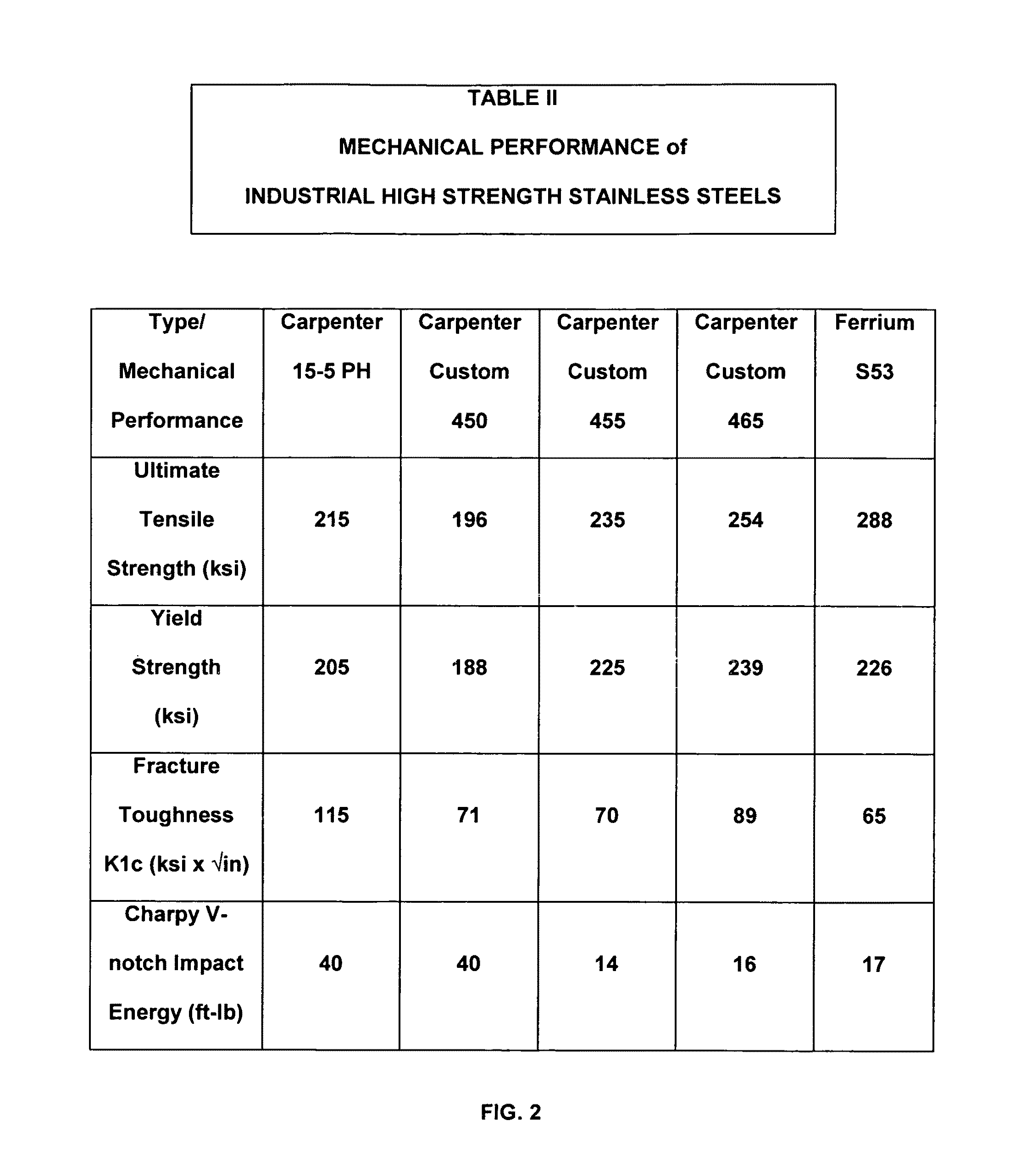

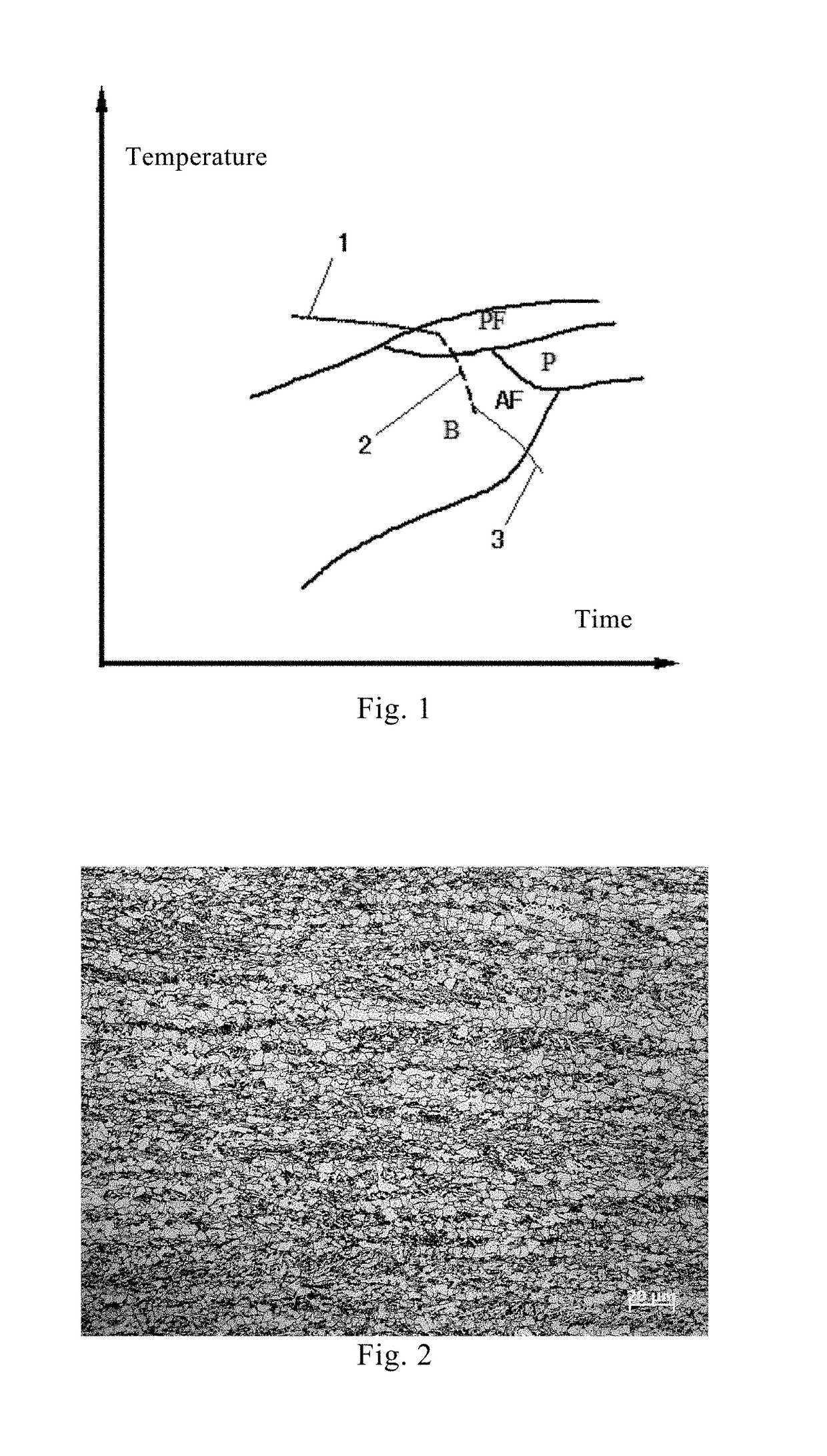

Low cost high strength martensitic stainless steel

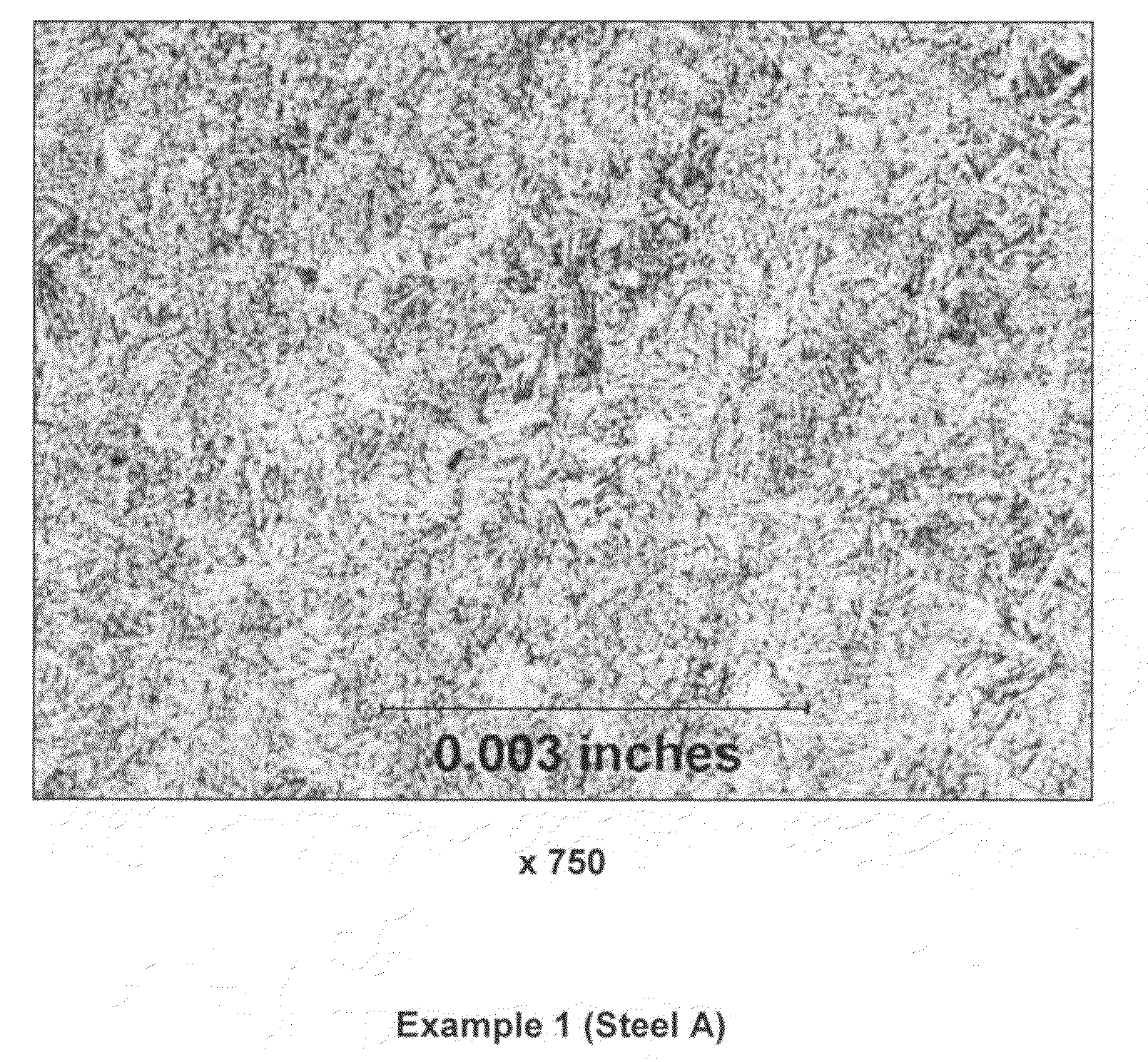

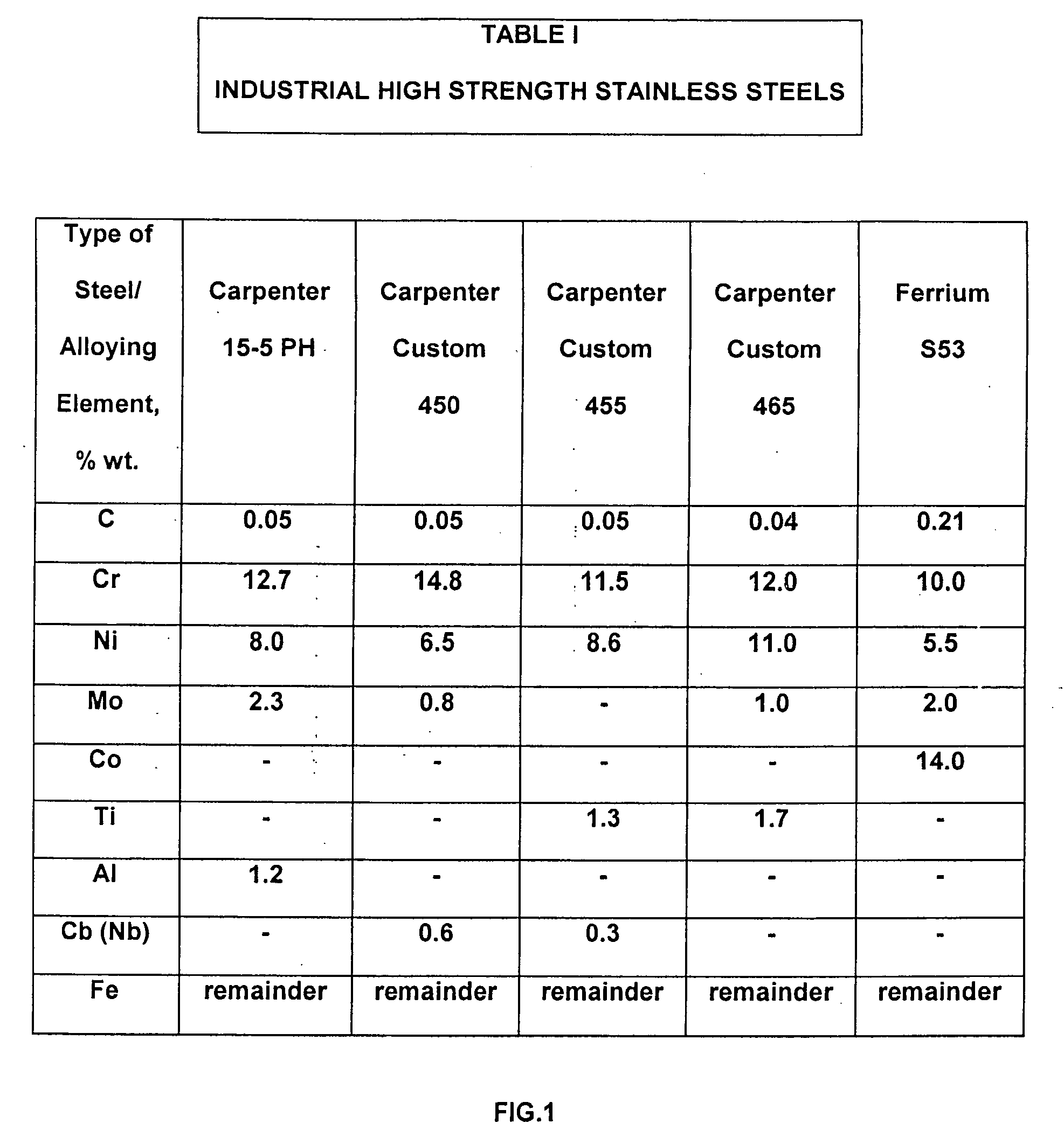

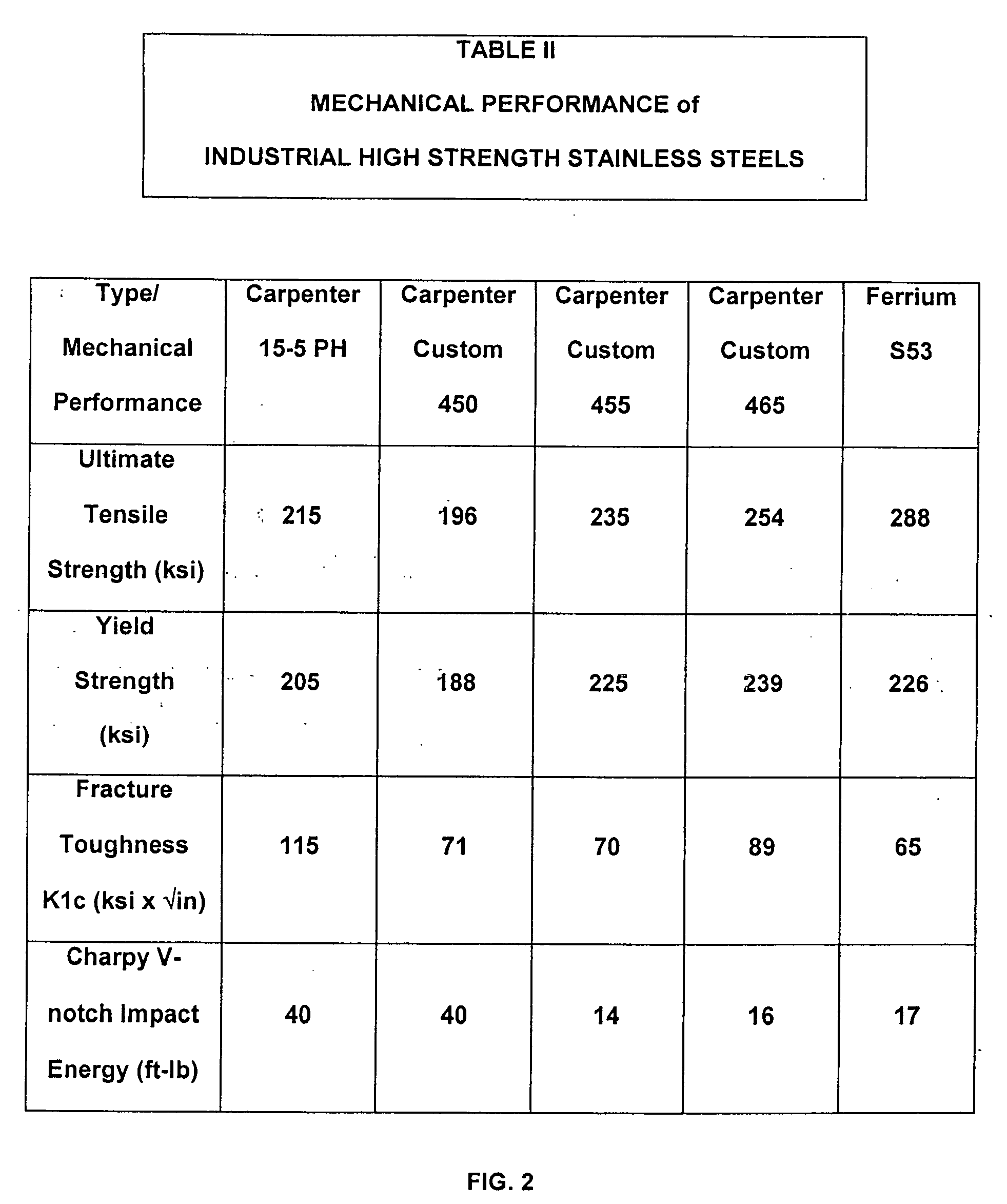

A cobalt-free low cost high strength martensitic stainless steel, with concentration of Ni up to 3.0% and Mo up to 1.0% of weight, has HRC of 53, UTS of 297 ksi, YS of 220 ksi, Charpy V-notch impact energy of 17.8 ft-lb, corrosion resistance in salt spray test ASTM 117. The steel was melted in an open induction furnace and vacuum arc remelting (VAR) and / or electroslag remelting (ESR) were not used to refine the steel. Further processing included homogenized annealing, hot rolling, and recrystallization annealing. The steel was heat treated by oil quenching, refrigeration, and low tempering. The steel has a microstructure consisting essentially of small packets of fine martensite laths, retained austenite, and carbides as centers of growth of the martensite laths. The cost and energy in making the steel are substantially reduced.

Owner:FEDCHUN VLADIMIR A +1

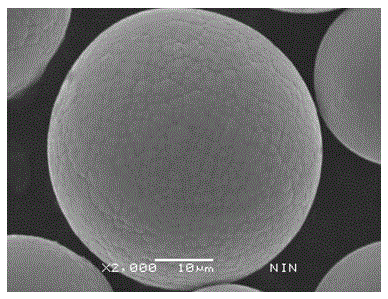

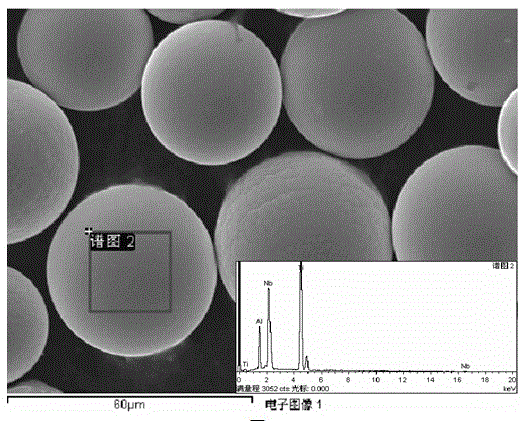

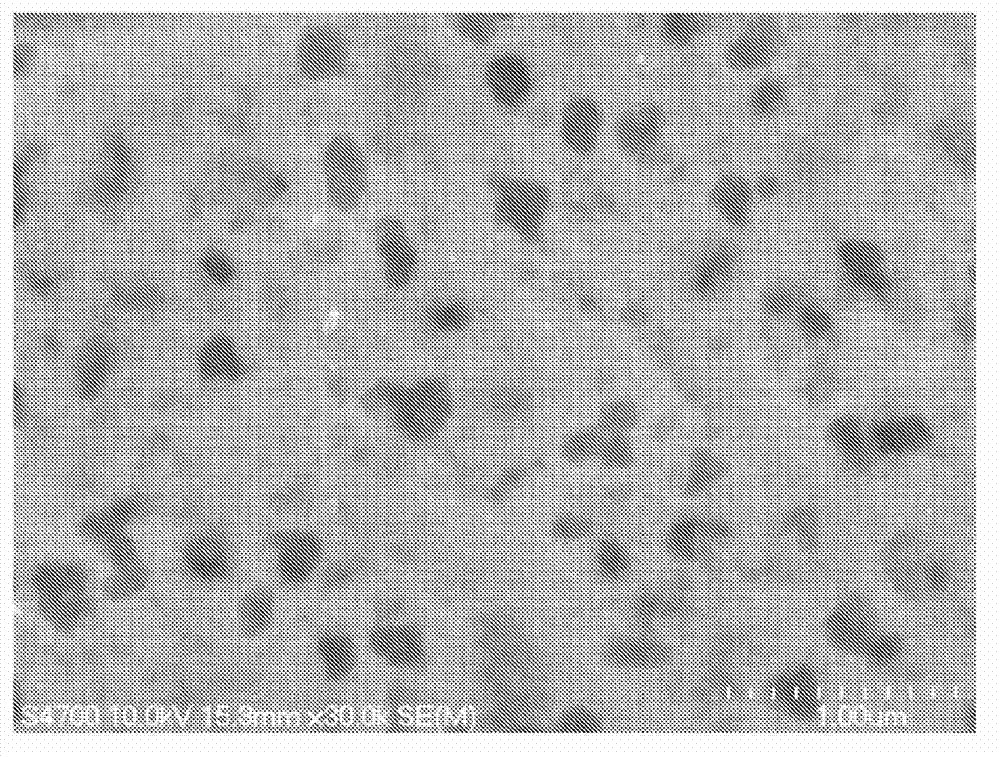

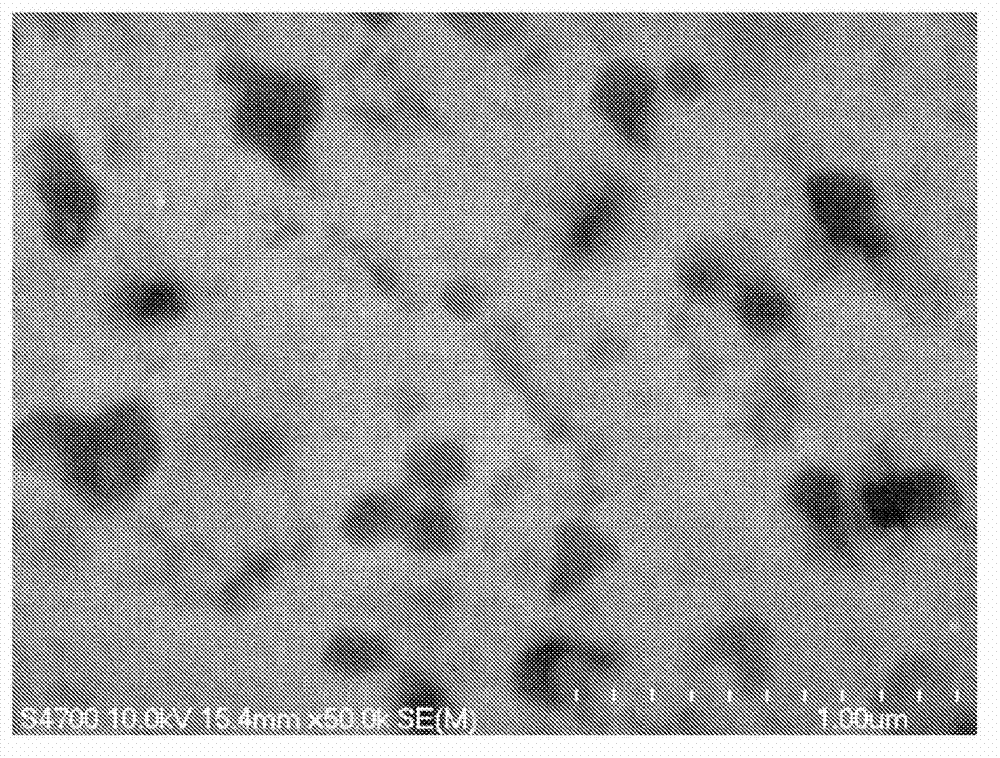

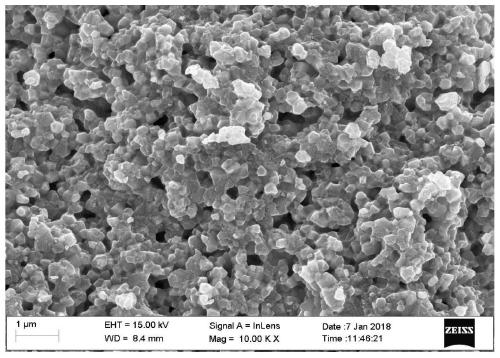

Preparing method for ultra-fine high-purity Ti2AlNb alloy powder

ActiveCN105537603AHigh purityHigh sphericityTransportation and packagingMetal-working apparatusAlloyUltra fine

The invention provides a preparing method for ultra-fine high-purity Ti2AlNb alloy powder. The preparing method comprises the following steps that 1, components of a Ti2AlNb base alloy are used as ingredients and smelted into a Ti2AlNb alloy bar; 2, finish turning is carried out on the smelted Ti2AlNb alloy bar, the diameter of a processed electrode bar ranges from 10 mm to 100 mm, and the length ranges from 100 mm to 1000 mm; 3, the electrode bar is loaded into a reaction chamber, the reaction chamber is vacuumized, and helium or argon or helium and argon mixed gas is introduced into the reaction chamber; 4, plasma gun powder of PREP powder manufacturing equipment ranges from 100 kW to 300 kW, a plasma torch comprises a tungsten cathode and a copper anode, the electrode bar is not used as an electrode, the end of the electrode bar is heated to be melted uniformly, atomized drops are tossed out from the end of the electrode bar, the drops are cooled fast in an inert gas environment to form spherical particles, and the spherical particles drop into a bottom collector of the reaction chamber; 5, prepared Ti2AlNb alloy powder is screened and packaged in the inert gas protection environment; 6, the Ti2AlNb alloy powder prepared through the method has the advantages of being ultra-fine, high in purity, high in spherical degree and low in oxygen content.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Sintered zirconia, and sintering composition and calcined object therefor

ActiveCN103080045ACheap manufacturingInhibition of low temperature deteriorationZirconium oxidesX-rayMaterials science

Provided is sintered zirconia which can be inhibited from deteriorating at low temperatures. Also provided are a sintering composition and a calcined object which are precursors for the sintered zirconia. The burned surface of the sintered zirconia gives an X-ray diffraction pattern in which the ratio of the height of the peak present around the location where a [200] peak assigned to the cubic system is to appear to the height of the peak present around the location where a [200] peak assigned to the tetragonal system is to appear is 0.4 or more, and a region located at a depth of 100 [mu]m or more from the burned surface gives an X-ray diffraction pattern in which the ratio of the height of the peak present around the location where a [200] peak assigned to the cubic system is to appear to the height of the peak present around the location where a [200] peak assigned to the tetragonal system is to appear is 0.3 or less.

Owner:NORITAKE CO LTD

Carbon-silicon carbide base composite material toughened by carbon fiber and its preparation method

InactiveCN1868971AWell matched thermal expansionLow temperature crack defect reductionCeramic layered productsFiberCarbon fibers

A carbon fiber toughened carbon-silicon carbide based composition with high thermal expansion match performance, low-temp antioxidizing performance, toughness and purity features that its reinforcing phase is carbon fiber, its basic body phase is the alternatively laminated 2-5 carbon-silicon carbide layers, and its external layer is silicon carbide for high antioxidizing performance. Its preparing process is sequential impregnation and thermodecomposing of boronphenolic aldehyde and polycarbonsilane.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Power semiconductor module, and power semiconductor device having the module mounted therein

InactiveUS7564129B2Low fracture toughnessInhibit the generation of cracksSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceHeat sink

Owner:NICHICON CORP

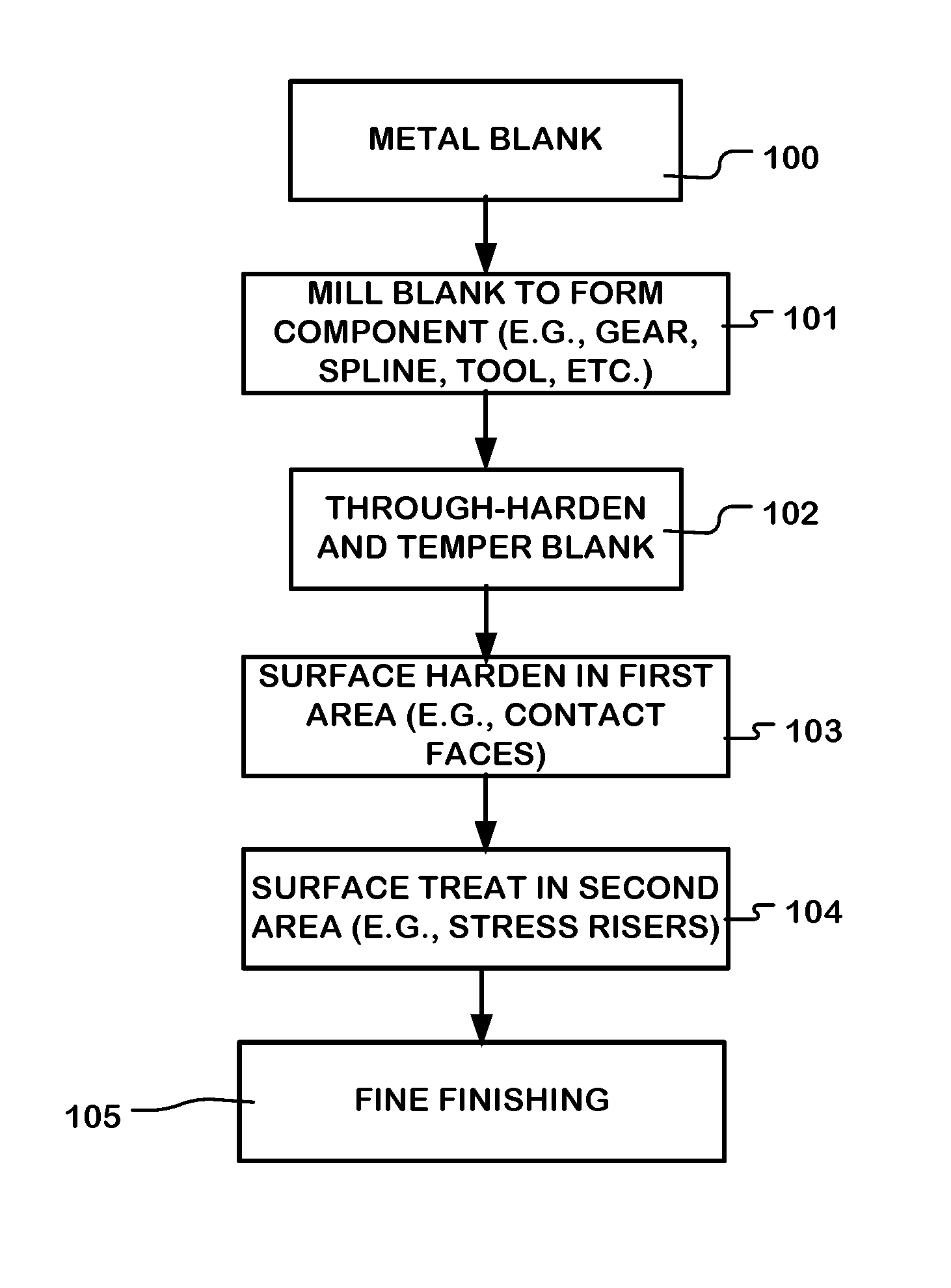

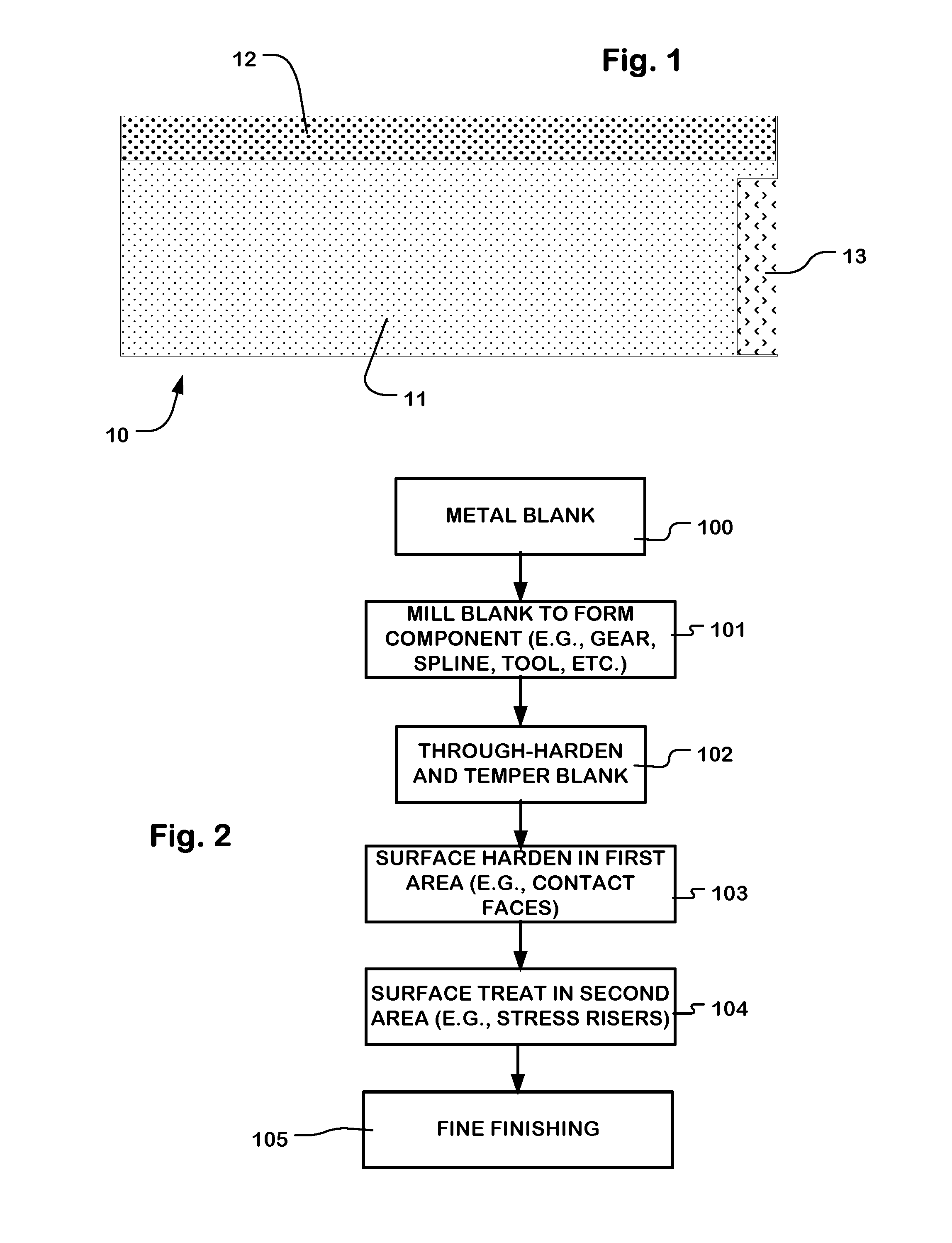

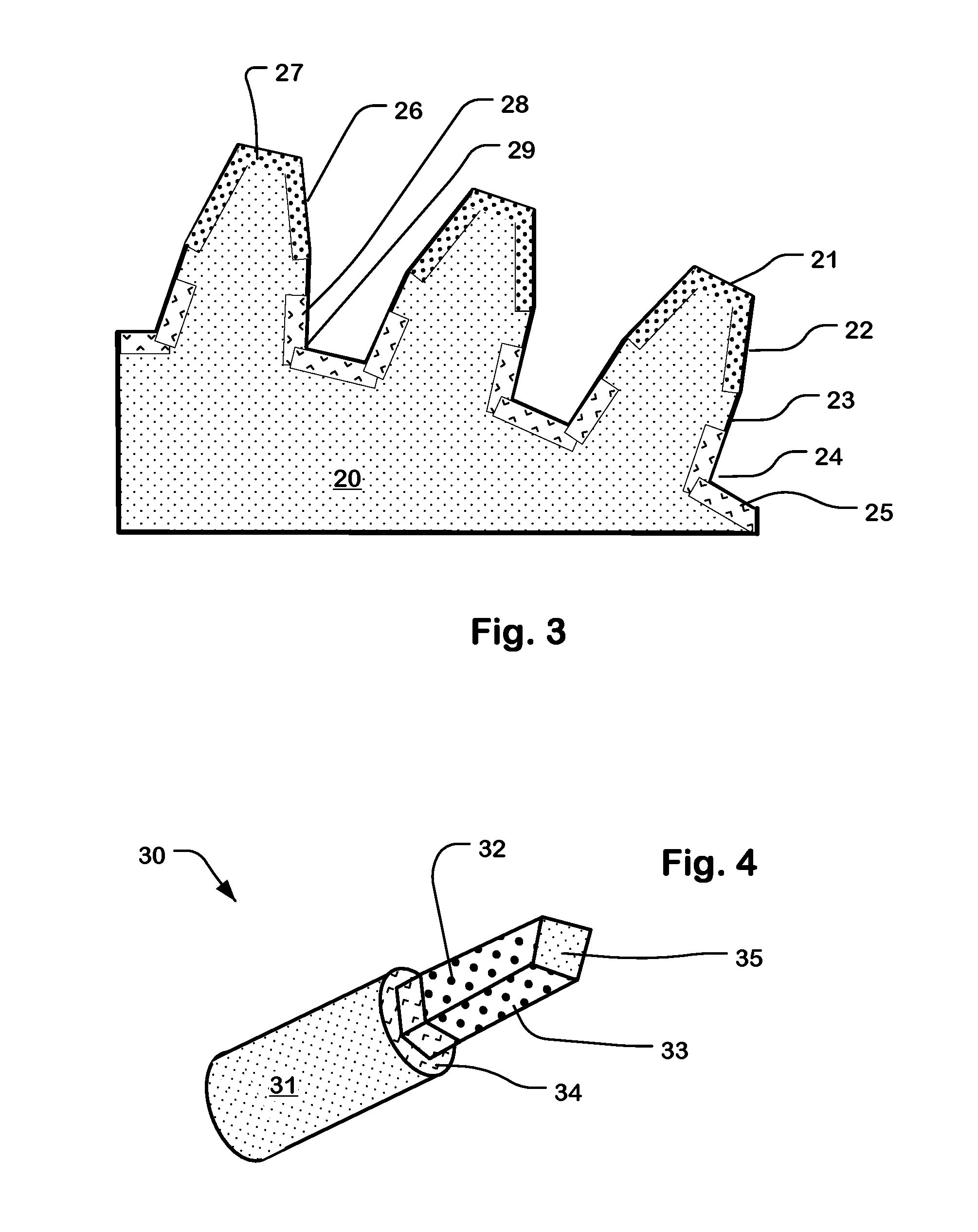

High fatigue strength components requiring areas of high hardness

ActiveUS20160298203A1Easy to wearImprove fatigue strengthAdditive manufacturing apparatusSolid state diffusion coatingSurface layerCoupling

Metal components subject to wear or contact fatigue in a first area, and subject to bending, axial and / or torsional stress loading in a second area comprise a surface hardened, first surface layer in the first area; and a surface compressive-stress treated, second surface layer in the second area. The second surface layer has a material hardness different from, and typically lower than the first surface layer, and induced residual compressive stress to improve fatigue strength. Example components described include a gear, a cog, a pinion, a rack, a splined shaft, a splined coupling, a torqueing tool and a nut driving tool. A hybrid manufacturing process is described, including area-selective surface hardening combined with a process to add compressive stress to fatigue failure prone areas.

Owner:METAL IMPROVEMENT

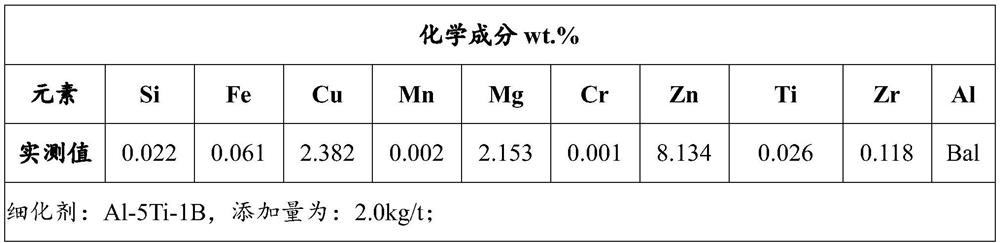

Aluminum alloy for anti-chloridion-corrosion type aluminum alloy oil pipe and pipe manufacturing method of aluminum alloy

The invention discloses aluminum alloy for an anti-chloridion-corrosion type aluminum alloy oil pipe and a pipe manufacturing method of the aluminum alloy. The aluminum alloy comprises, by weight, 6.90%-7.49% of Zn, 2.10%-2.30% of Mg, 0.05%-0.10% of Cu, 0.10%-0.30% of Mn, 0.10%-0.30% of Cr, 0.01%-0.02% of Ti, 0.15%-0.2% of Zr, 0.05%-0.1% of Sc, and the balance Al and inevitable impurities. The strength performance of the aluminum alloy is improved significantly through matching of the high-content Zn and the low-content Mg. The strength and the repeated loading resistance of the aluminum alloy are improved through the appropriate-content Mn and the appropriate-content Cr, and the good plasticity and toughness of the aluminum alloy are ensured. The micro-content Ti, the micro-content Zr and the micro-content Sc serve as supplement and improvement. The structure stability and the performance reliability of the aluminum alloy are ensured through grain refinement and precipitation strengthening. The aluminum alloy for the anti-chloridion-corrosion type aluminum alloy oil pipe is high in overall specific strength, good in corrosion resistance, low in cost, good in processability and high in qualified product ratio.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Low cost high strength martensitic stainless steel

A cobalt-free low cost high strength martensitic stainless steel, with concentration of Ni up to 3.0% and Mo up to 1.0% of weight, has HRC of 53, UTS of 297 ksi, YS of 220 ksi, Charpy V-notch impact energy of 17.8 ft-lb, corrosion resistance in salt spray test ASTM 117. The steel was melted in an open induction furnace and vacuum arc remelting (VAR) and / or electroslag remelting (ESR) were not used to refine the steel. Further processing included homogenized annealing, hot rolling, and recrystallization annealing. The steel was heat treated by oil quenching, refrigeration, and low tempering. The steel has a microstructure consisting essentially of small packets of fine martensite laths, retained austenite, and carbides as centers of growth of the martensite laths. The cost and energy in making the steel are substantially reduced.

Owner:FEDCHUN VLADIMIR A +1

Boride-silicon carbide-boron carbide ternary ceramic-base composite material and preparation method thereof

InactiveCN101265108AGrowth inhibitionGood for fine grain strengthening mechanismBorideUltra-high-temperature ceramics

The invention relates to a boride-silicon carbide-boron carbide ternary ceramic matrix composite material and a production method thereof. The invention relates to a ternary ceramic matrix composite material and a production method thereof, and solves the problem of poor toughness of the existing ultrahigh temperature ceramic materials. The inventive boride-silicon carbide-boron carbide ternary ceramic matrix composite material is made from, by volume percentages, 50%-80% of borides, 10%-30% of silicon carbide and 5%-30% of boron carbide. The production method comprises the following steps: (1) wet mixing and sieving; and (2) hot-press sintering. The maximal bending strength of the boride-silicon carbide-boron carbide ternary ceramic matrix composite material reaches 890 MPa, and the maximal fracture toughness thereof reaches 7.1 MPa / m<2>.

Owner:HARBIN INST OF TECH

X80 pipeline steel with good strain-aging performance, pipeline tube and method for producing same

ActiveUS20180073094A1High strengthImprove toughnessFurnace typesWork cooling devicesMetallurgyImpurity

Owner:BAOSHAN IRON & STEEL CO LTD

Method for strengthening lamellar wood ceramic by using carbon fiber

The invention discloses a method for strengthening lamellar wood ceramic by using carbon fiber. The method is characterized by comprising the following steps: by taking thermosetting resin and biomass material as base materials, crushing and pulverizing the biomass material into biomass carbon powder, mixing the biomass carbon powder with thermosetting resin to prepare a sheet-shaped thermosetting resin-biomass carbon powder composite material; then, preparing the sheet-shaped thermosetting resin-biomass carbon powder composite material into the carbon fiber-strengthened lamellar composite material with different thicknesses under a certain temperature and pressure; and finally, placing the carbon fiber-strengthened lamellar composite material into a high-temperature sintering furnace for hot-pressing and sintering to obtain the wood material with the carbon fiber-strengthened lamellar structure.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Toughened ceramic for insulator and preparation method of toughened ceramic

The invention discloses toughened ceramic for an insulator and a preparation method of the toughened ceramic. The toughened ceramic is prepared from, by weight, 2-3 parts of aluminum borate whiskers, 70-80 parts of silicon carbide micro powder with the proper size, 20-30 parts of aluminum nitride micro powder with the proper size, 1-1.5 parts of calcium fluoride powder, 10-15 parts of carbon powder, 10-15 parts of molybdenum silicide, 6-8 parts of ethyl orthosilicate, 3-5 parts of absolute ethyl alcohol, 3-5 parts of purified water and 1.5-2.5 parts of thermoplastic phenolic resin. By means of the steps of raw material preparation, insulator pre-preparation, insulator sintering and completing, the high-tenacity insulation ceramic with the volume resistivity larger than or equal to 2*1,013 omega-cm, the dielectric strength larger than or equal to 750 kV / cm, the thermal conductivity larger than or equal to 25 W / m.K, the bending strength larger than or equal to 400 Mpa, the Young modulus larger than or equal to 320 Gpa and the breaking tenacity larger than or equal to 25 Mpa is formed. The toughened ceramic is good in economical efficiency, resistant to high temperature oxidation and high in breaking tenacity, and the functions of main materials complement one another.

Owner:宁波高智科技咨询服务有限公司

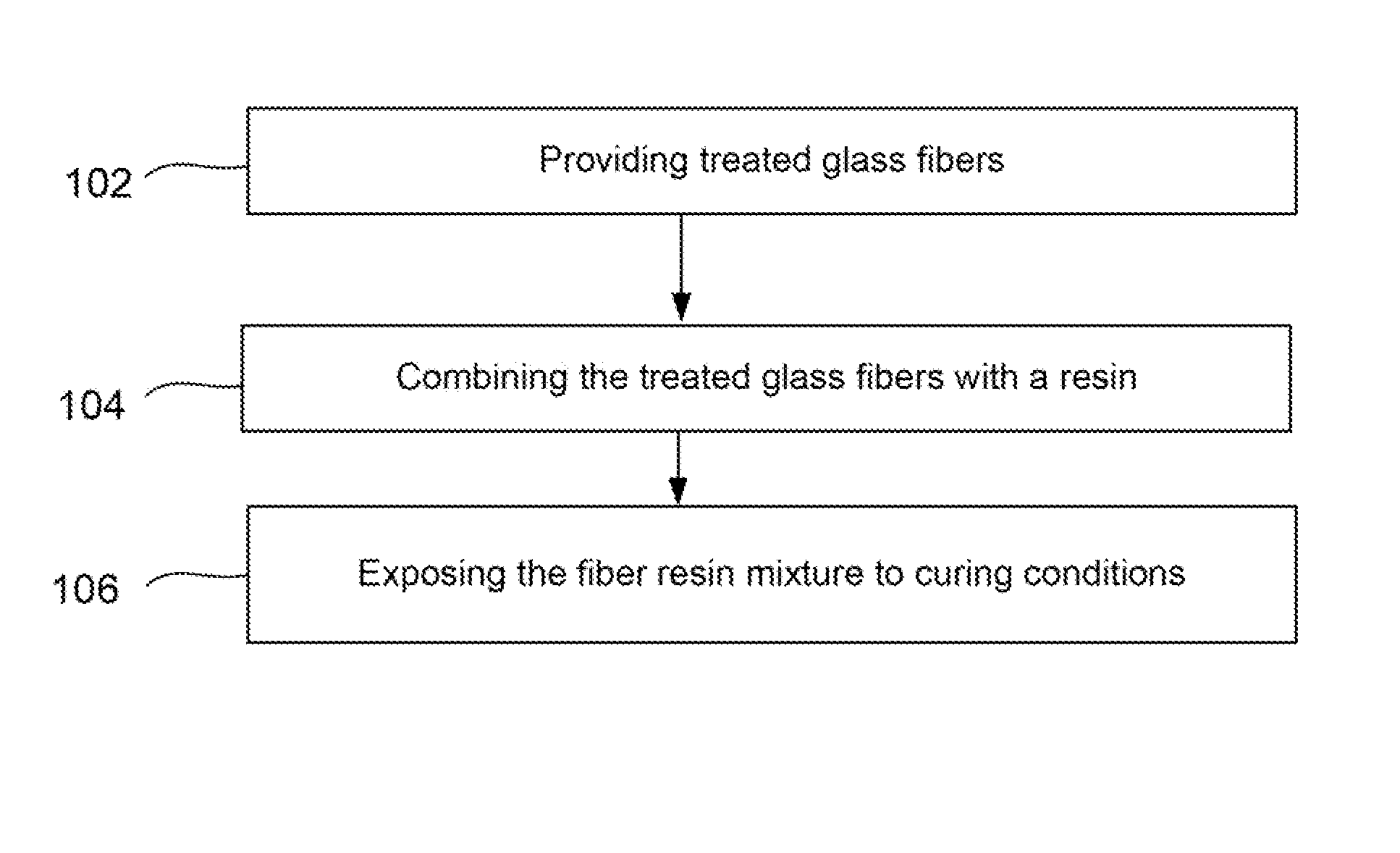

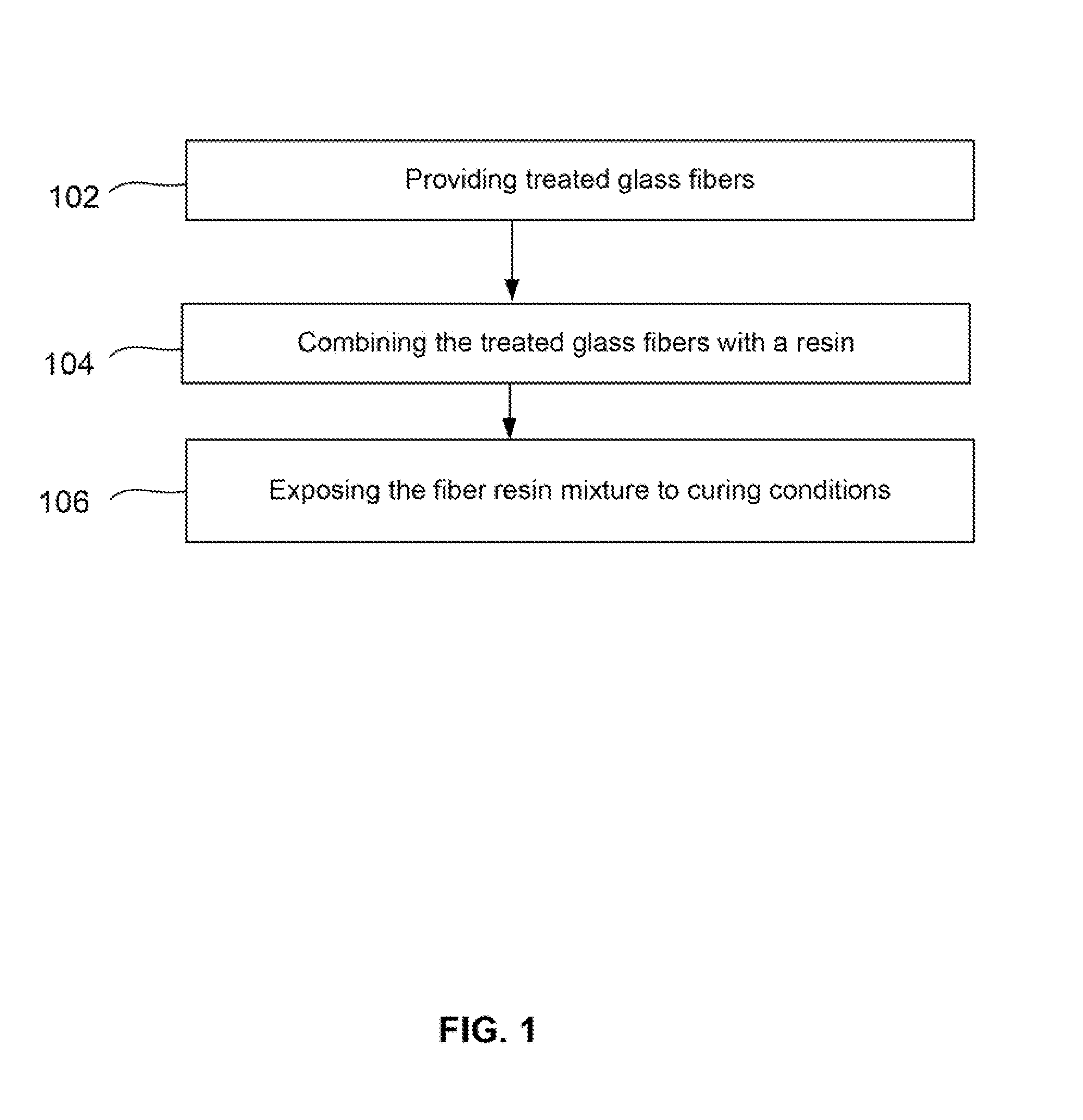

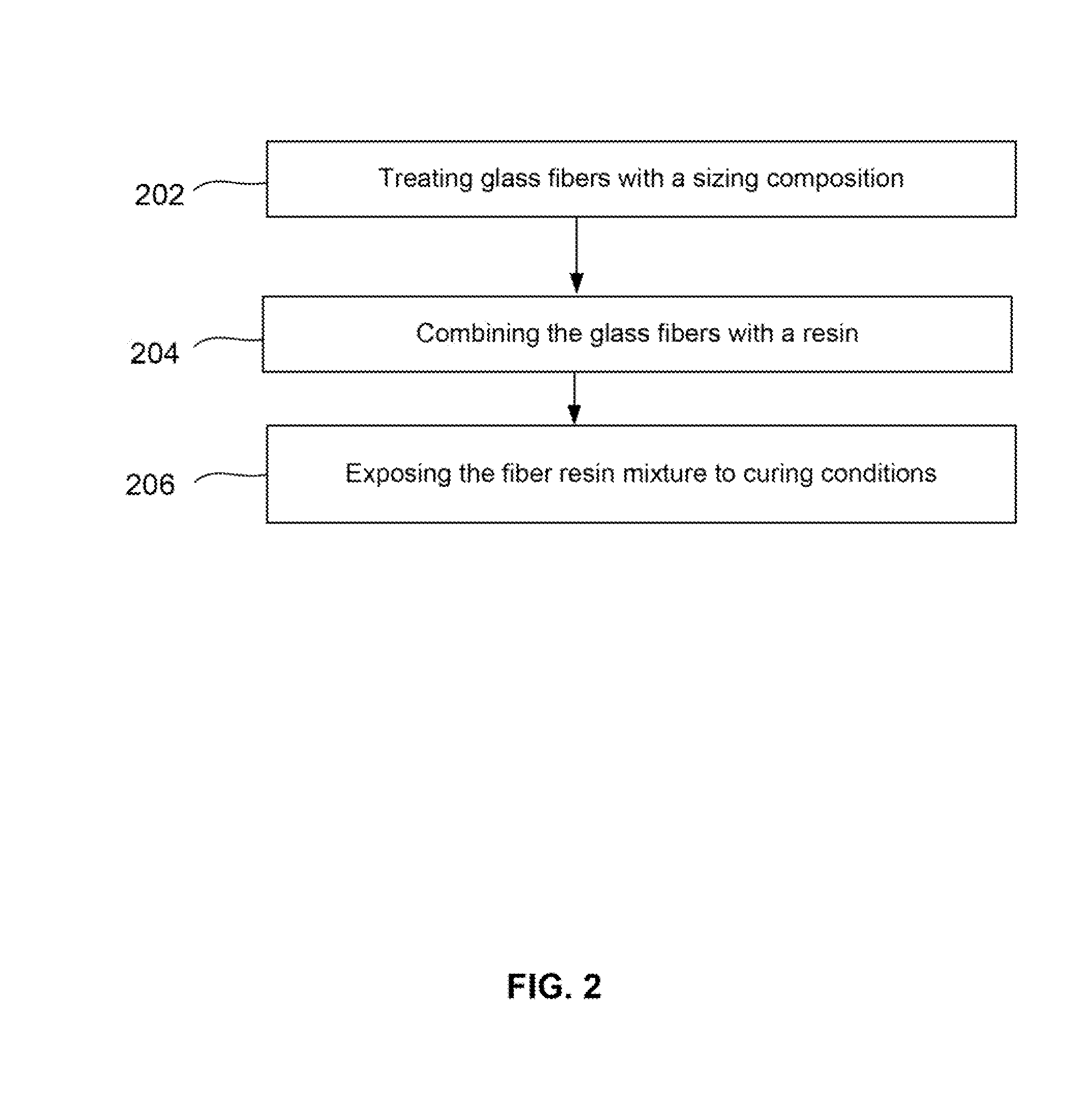

Fiber reinforced composites made with coupling-activator treated fibers and activator containing reactive resin

ActiveUS20140256201A1High in fiberImproves composite mechanical propertyCeramic shaping apparatusAnimal housingGlass fiberIn situ polymerization

This invention relates to a process of making a fiber-reinforced composite. Glass fibers may be provided. These glass fibers may be treated with a sizing composition that has a coupling-activator compound with the formula: S—X-(A)n, where S represents a silicon-containing coupling moiety capable of bonding to the surface of glass fibers, X represents a linking moiety, and (A)n represents one or more polymerization activator moieties. The treated glass fibers may be combined with a resin to make a fiber-resin mixture. The resin may have a monomer, a catalyst, and an activator compound capable of initiating a polymerization of the monomer. The monomer may be a lactam or lactone having 3-12 carbon atoms in the main ring. The fiber-resin mixture may then be cured so that the monomer polymerizes to form a thermoplastic polymer matrix of the fiber-reinforced composite. The thermoplastic polymer matrix may be formed by in situ polymerization initiated from both the surface of the glass fibers and the resin. The fiber-reinforced composite formed may be at least 70 wt. % glass fiber.

Owner:JOHNS MANVILLE CORP

Glass Composition

InactiveUS20100273635A1Easy can be thermally toughenedHigh in strain point and softening pointChemistry

Owner:CENT GLASS CO LTD

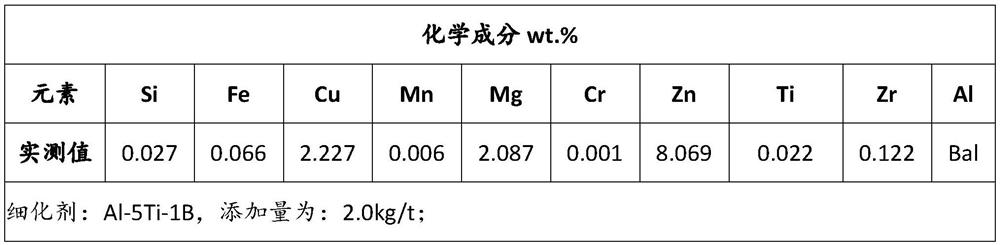

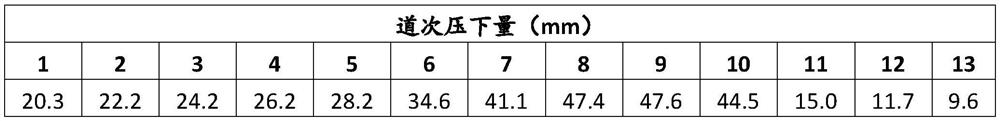

Preparation method of high-strength, high-toughness and corrosion-resistant 7055 aluminum alloy medium-thickness plate

The invention relates to a preparation method of a high-strength, high-toughness and corrosion-resistant 7055 aluminum alloy medium-thickness plate, and belongs to the field of aluminum alloy machining. The preparation method comprises the steps of material proportioning, smelting, casting, homogenizing, sawing and milling, preheating, hot rolling, solid solution quenching, pre-stretching and aging. According to the preparation method of the high-strength, high-toughness and corrosion-resistant 7055 aluminum alloy medium-thickness plate, parameters of various process steps are optimized, the Zn / Mg ratio and the Cu / Mg ratio are reasonably controlled, and a foundation is laid for obtaining a finished product with good performance; a two-stage homogenization system of 465 DEG C / (10-15) h + 475 DEG C / (20-25) h is adopted, an eutectic structure is eliminated on the premise of avoiding overburning of an aluminum alloy cast ingot, and a primary phase generated in the casting process is regulated and controlled; crystalline grains are completely crushed and refined by adopting a rolling mode with a large machining rate and a large rolling reduction in a middle pass; the initial rolling temperature and the final rolling temperature are accurately controlled, so that the recrystallization degree and the grain size of the plate are controlled, and then the strength, the fracture toughness and the exfoliation corrosion resistance of the plate are improved; and a three-stage aging system (100-110) DEG C / 24h + (175-185) DEG C / (30-120) min + 121 DEG C / 24h is adopted, so that the comprehensive performance of a finished product is improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

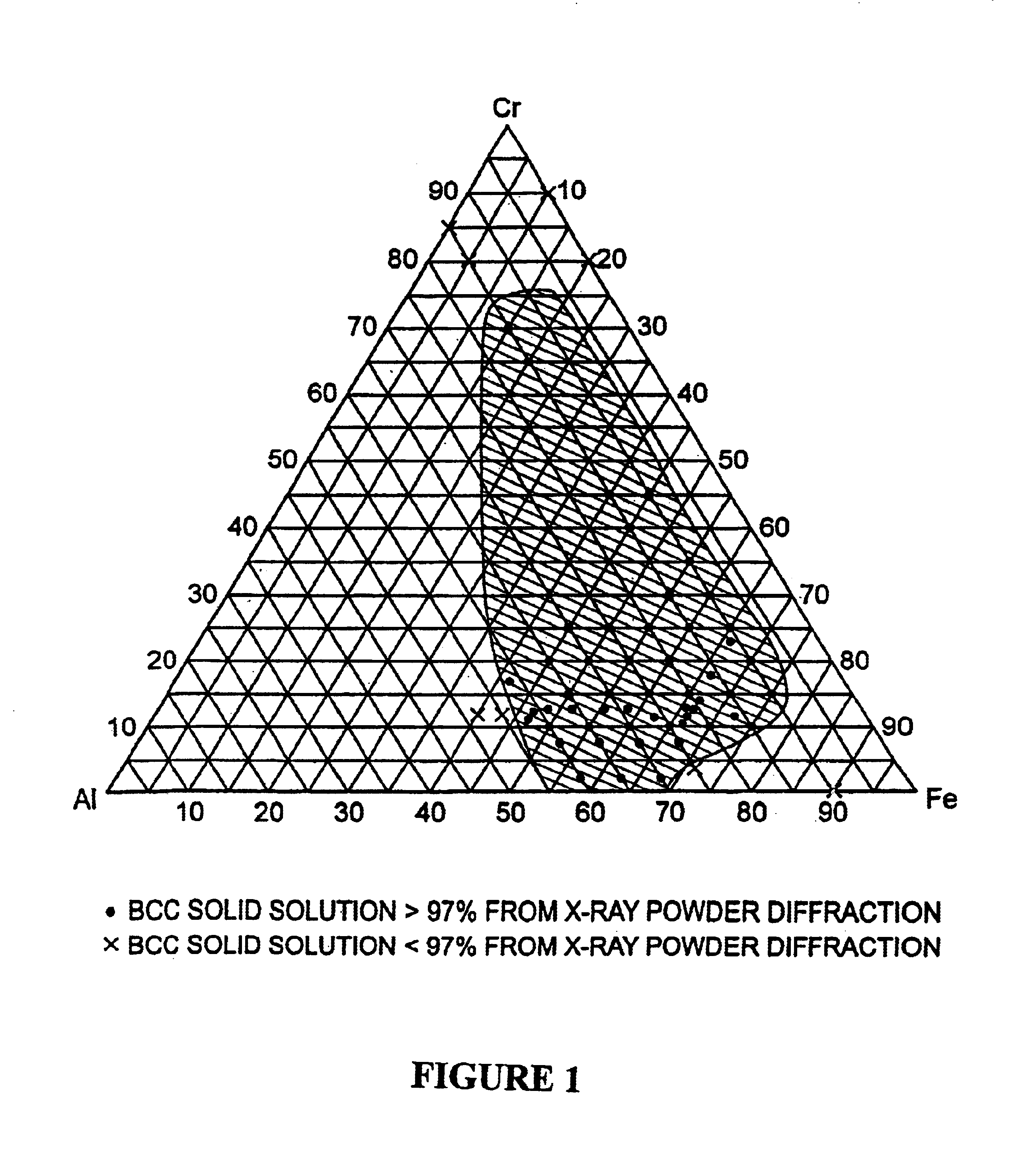

Iron base high temperature alloy and method of making

InactiveUS6841011B2Low densityImprove tensile propertiesPump componentsBlade accessoriesRoom temperatureSolid solution

The present invention is directed to an iron, aluminum, chromium, carbon alloy and a method of producing the same, wherein the alloy has g good room temperature ductility, excellent high temperature oxidation resistance and ductility. The alloy includes about 10 to 70 at. % iron, about 10 to 45 at. % aluminum, about 1 to 70 at. % chromium and about 0.9 to 15 at. % carbon. The invention is also directed to a material comprising a body-centered-cubic solid solution of this alloy, and a method for strengthening this material by the precipitation of body-centered-cubic particles within the solid solution, wherein the particles have substantially the same lattice parameters as the underlying solid solution. The ease of processing and excellent mechanical properties exhibited by the alloy, especially at high temperatures, allows it to be used in high temperature structural applications, such as a turbocharger component.

Owner:LIN HUI

High-strength aluminum alloy and preparation method thereof

The invention relates to aluminum alloy and provides high-strength aluminum alloy with the tensile strength of more than 700MPa and a preparation method thereof. The high-strength aluminum alloy comprises the following raw materials in percentage by weight: 0.10%-0.14% of Fe, 0.03%-0.04% of Mn, 0.02%-0.04% of Si, 0.01%-0.06% of Ti, 0.03%-0.09% of B, 2.2%-2.9% of Zn, 0.9%-1.0% of Mg, 1.1%-1.3% of Cu, 0.5%-1.0% of Ce, 0.1%-0.4% of Sc and the balance of Al.

Owner:FUJIAN MINFA ALUMINUM

Preparation method of low-zirconium mullite cast steel brick

The invention relates to a preparation method of a low-zirconium mullite cast steel brick, and belongs to the field of preparation of refractory materials. The raw material formula of the low-zirconium mullite cast steel brick provided by the invention comprises electrically smelted mullite, zirconium oxide, Guangxi white clay, andalusite, kyanite and lignin. According to the method provided by the invention, type and grain size of the raw materials are selected to be matched with the sintering temperature and time provided by the invention, so that the prepared low-zirconium mullite cast steel brick has the characteristics of excellent scouring resistance, high temperature resistance, small creep deformation, high compression strength, good thermal stability and the like, and is suitable for being used in large steel ingot casting in nuclear power products.

Owner:四川锦圆耐材有限公司

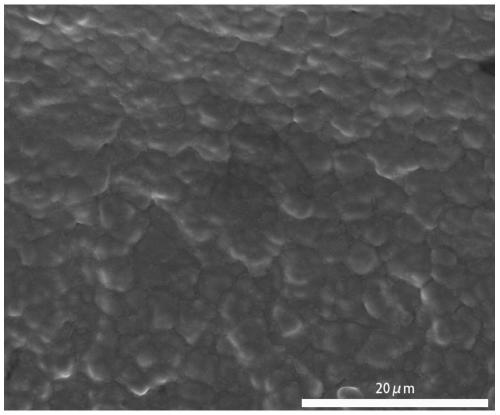

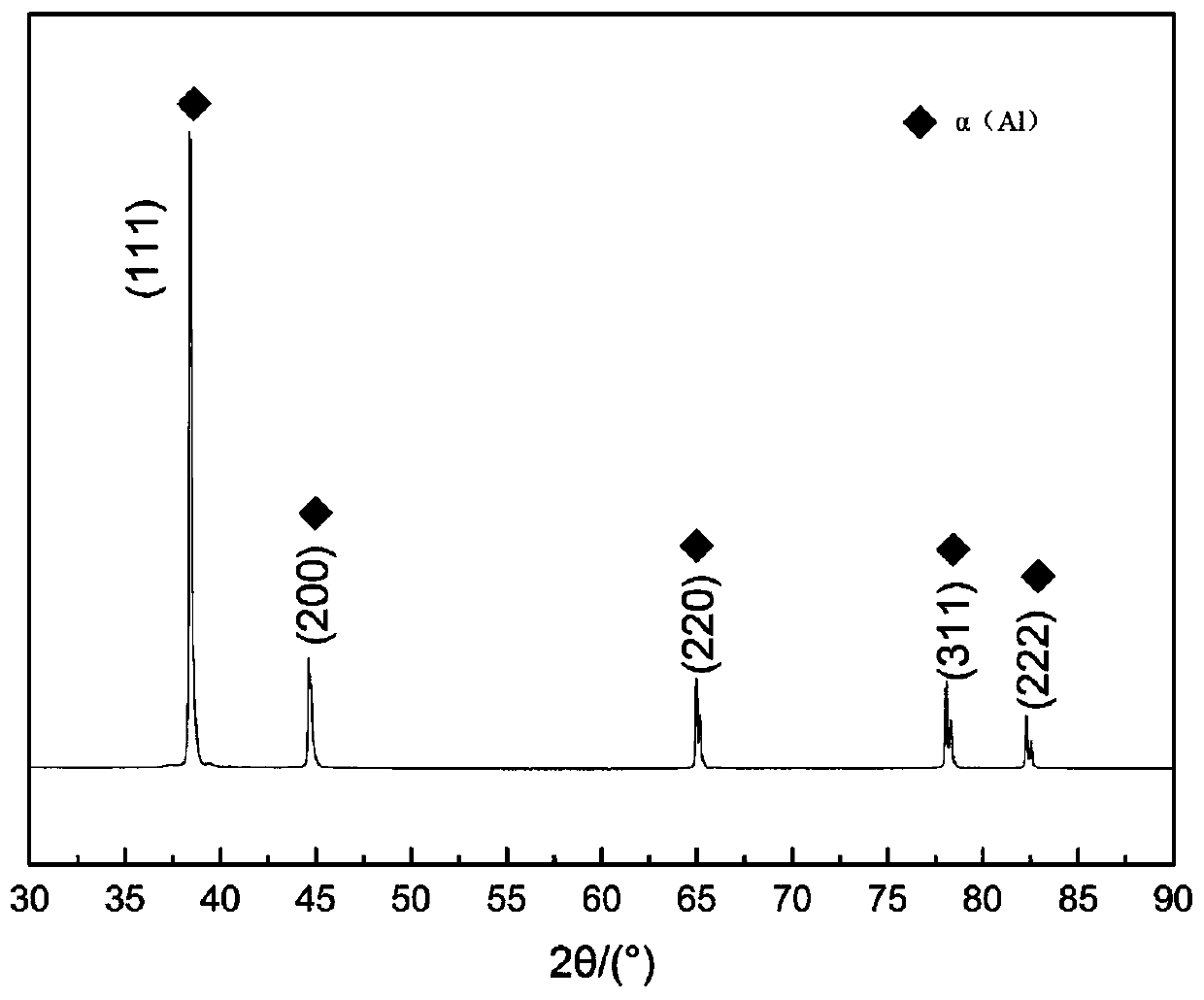

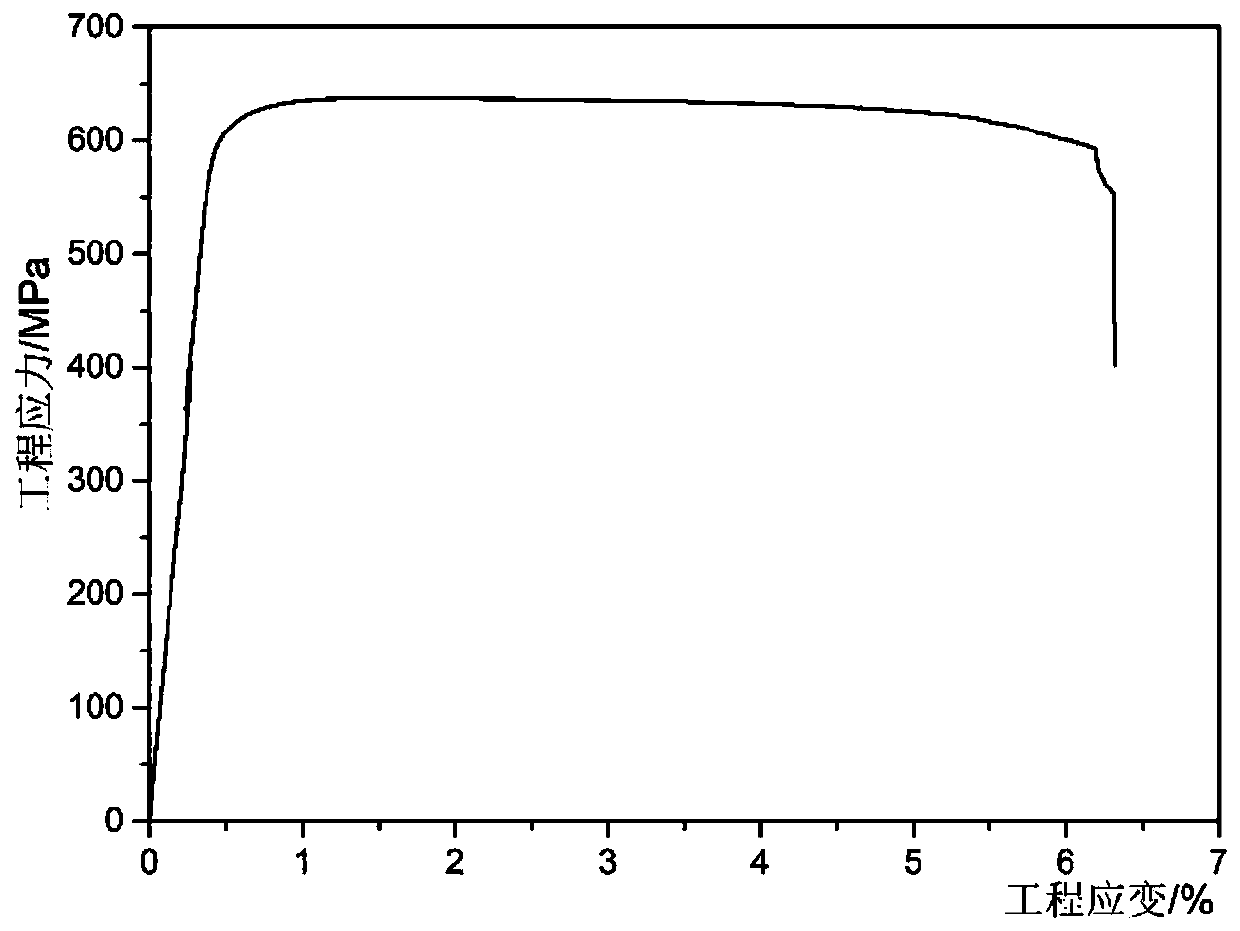

Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy and preparation method thereof

The invention relates to an Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy which is prepared from the following components in percentage by mass: 10-12 percent of Zn, 2-3 percent of Mg, 0.5-1.5 percent of Cu, smaller than 0.2 percent of a total amount of Fe and Si, smaller than 0.2 percent of impurity and the balance of Al. A preparation method for the Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy comprises the following steps of step 1, adding industrial pure aluminum in a crucible resistance furnace for heating and complete melting according to the mass percentage, and then sequentially adding a Cu source, a Zn source and an Mg source until all the materials are thoroughly molten; step 2, performing stirring, refining with degassing and slag skimming; step 3, spraying a prepared metal liquid to a copper roller to prepare a strip; step 4, performing cold isostatic pressing on the strip obtained through rapid solidification to obtain a cold-pressed blank; step 5, performing hot extrusion on the cold-pressed blank to obtain an extruded rod; and step 6, finally, performing heat treatment on the extruded rod. By adopting the technical method provided by the invention, the process flow is simplified, the material utilization rate is high, and the Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy has high strength and shaping and has a good application prospect in the fields of aerospace, automobiles and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

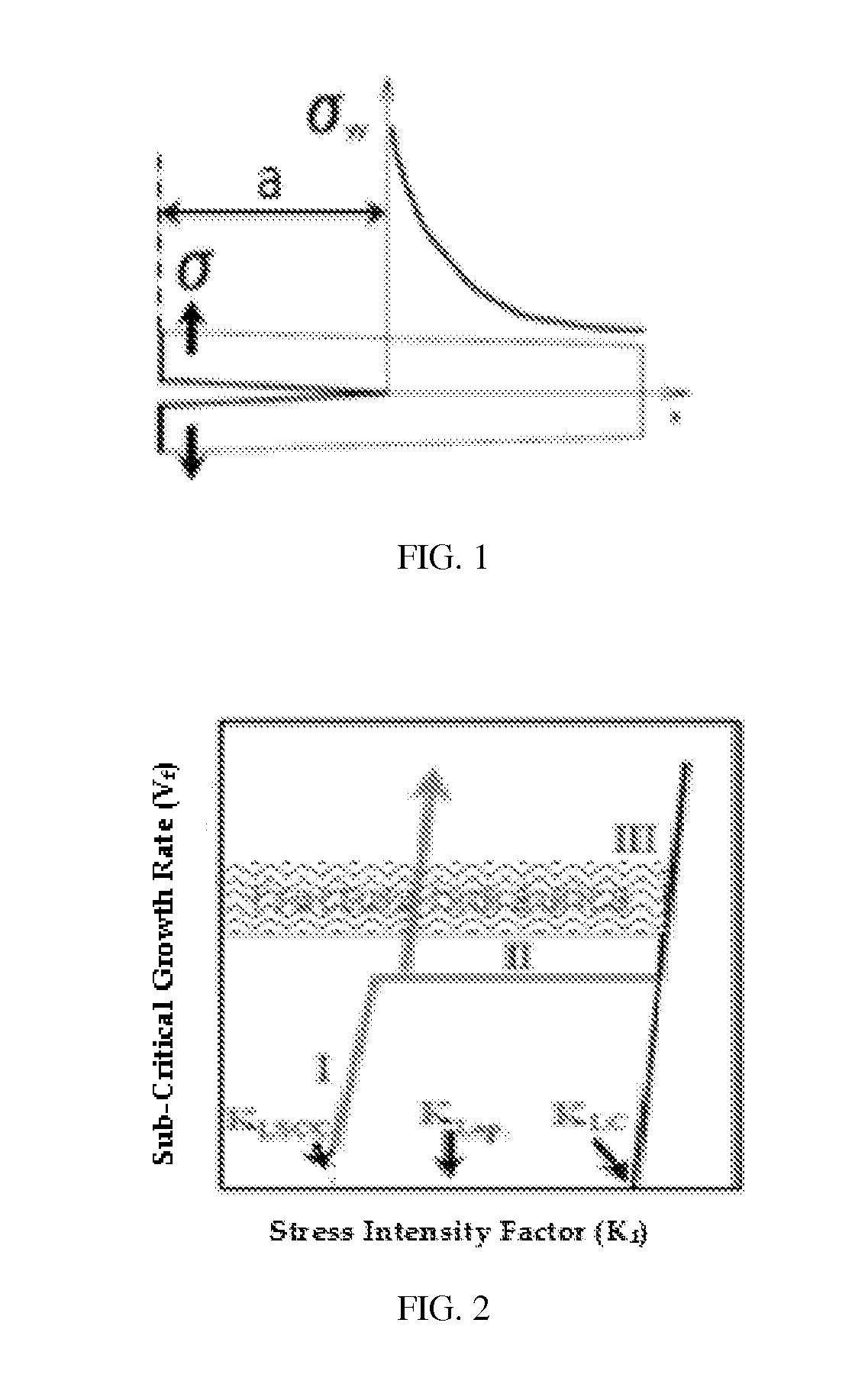

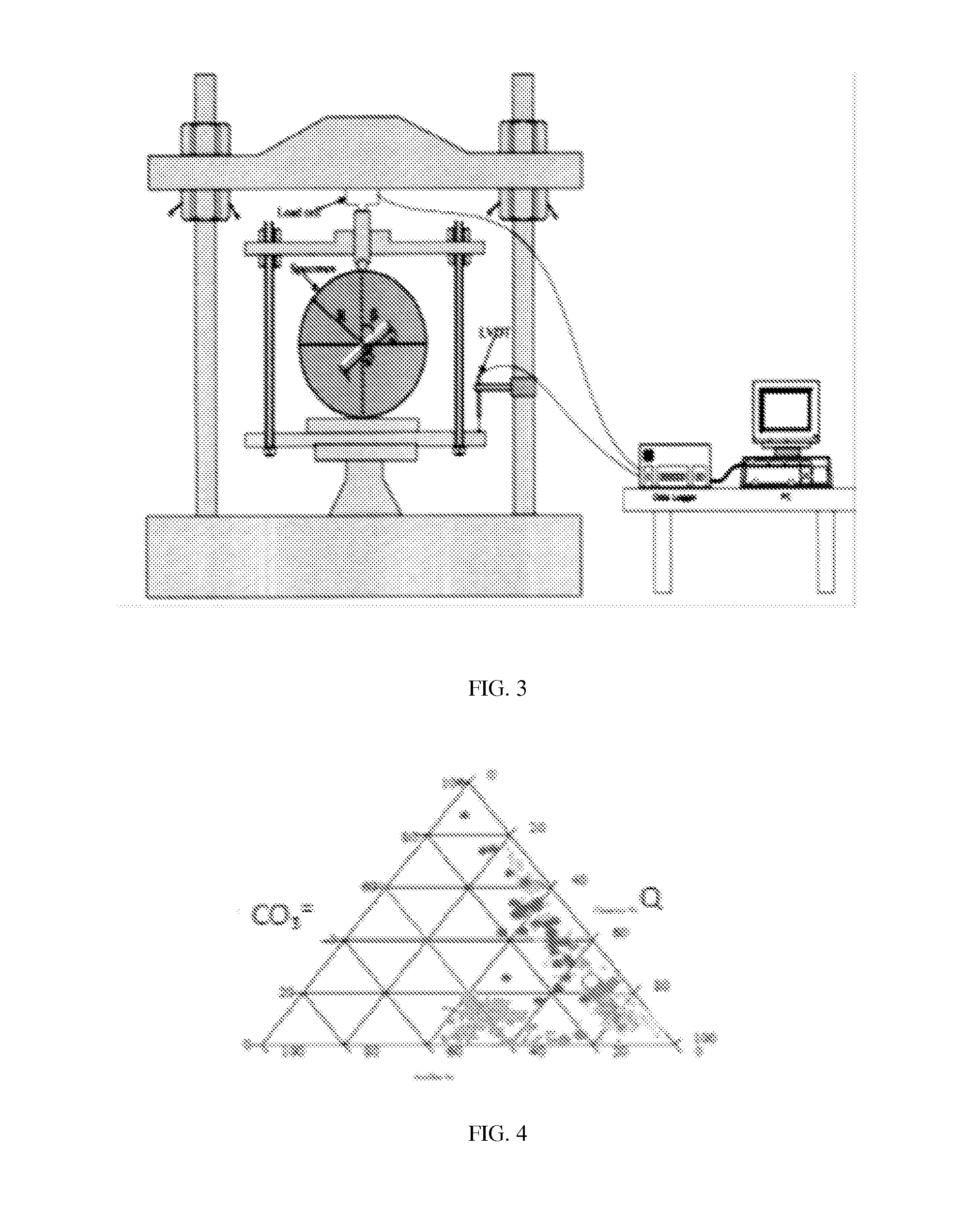

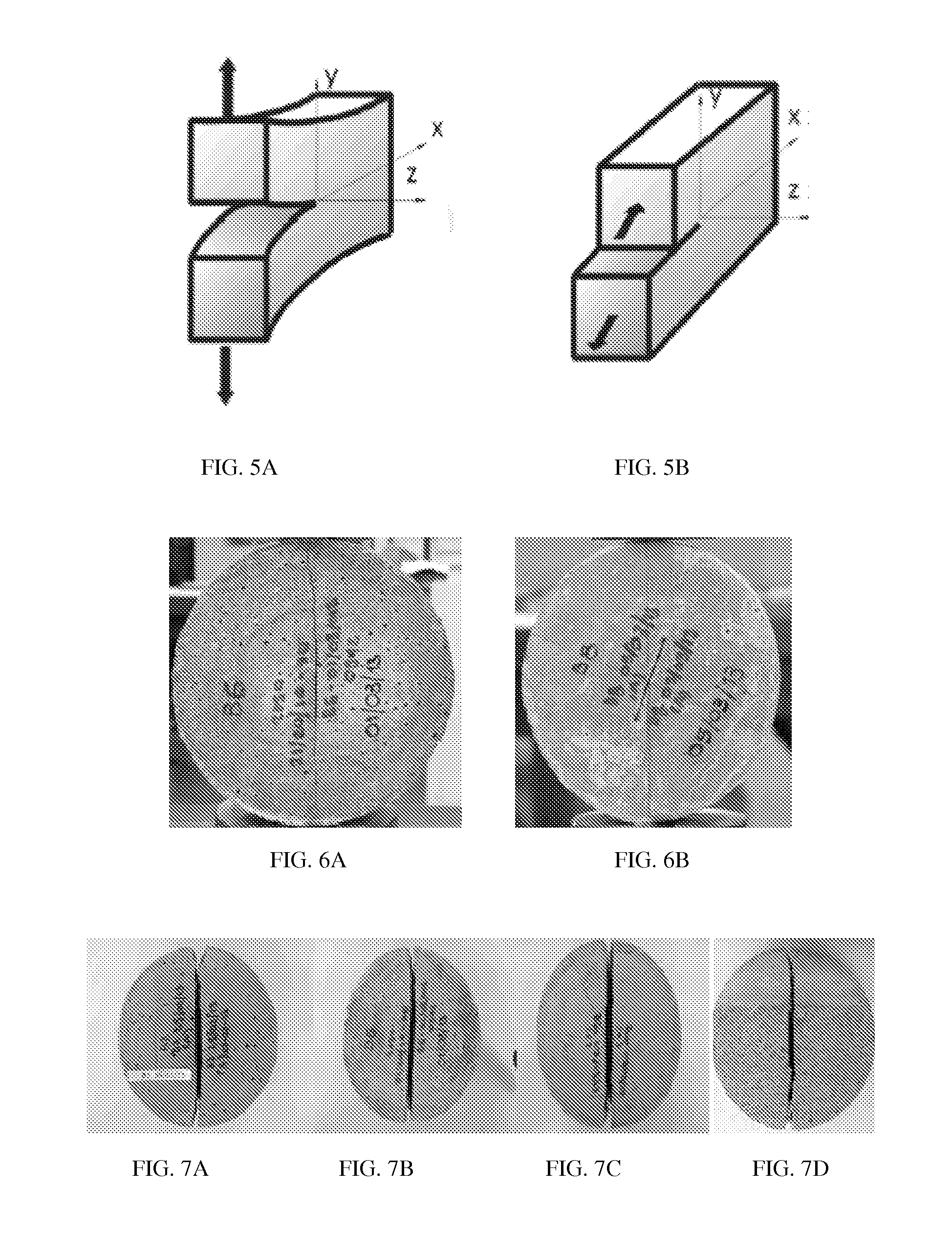

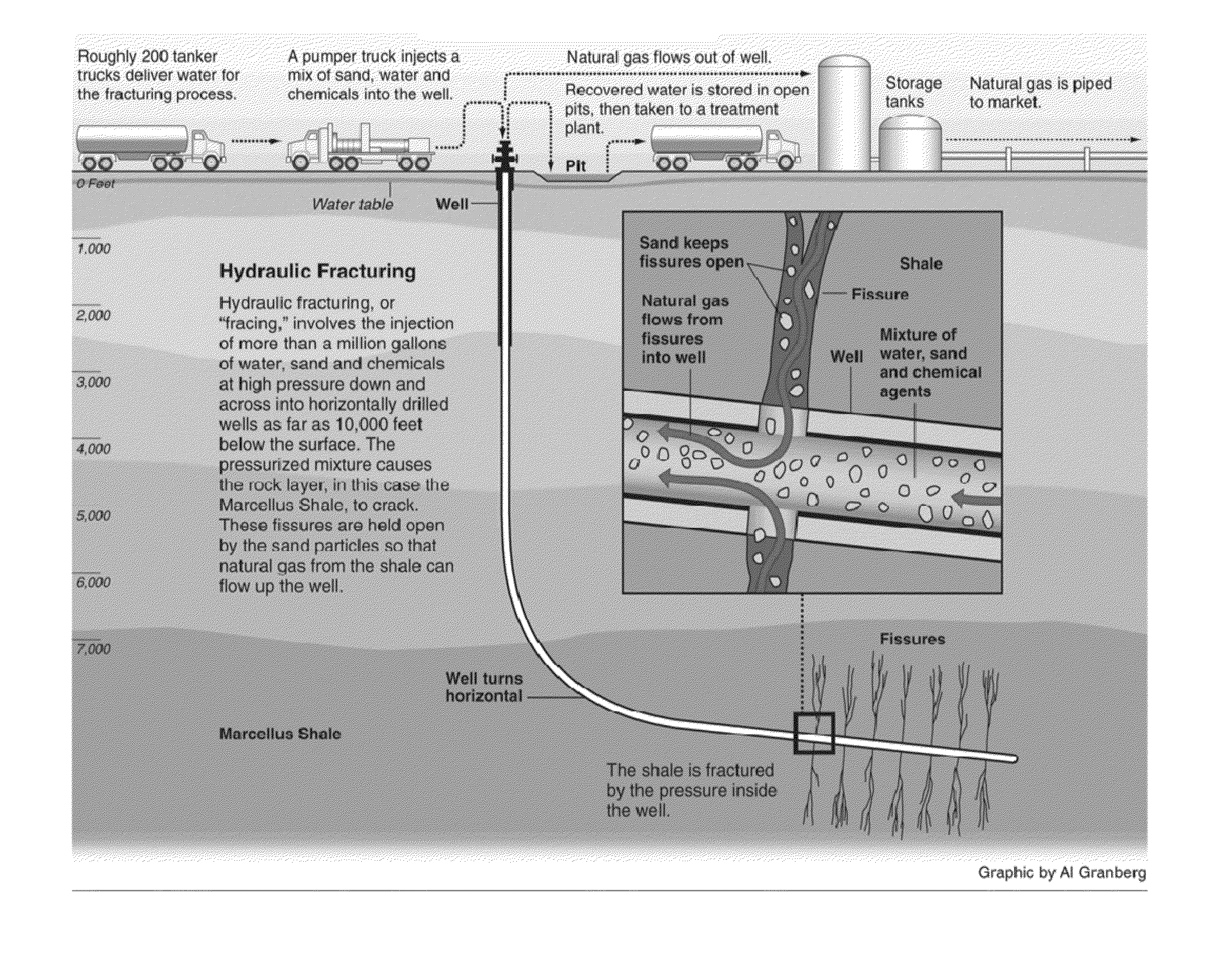

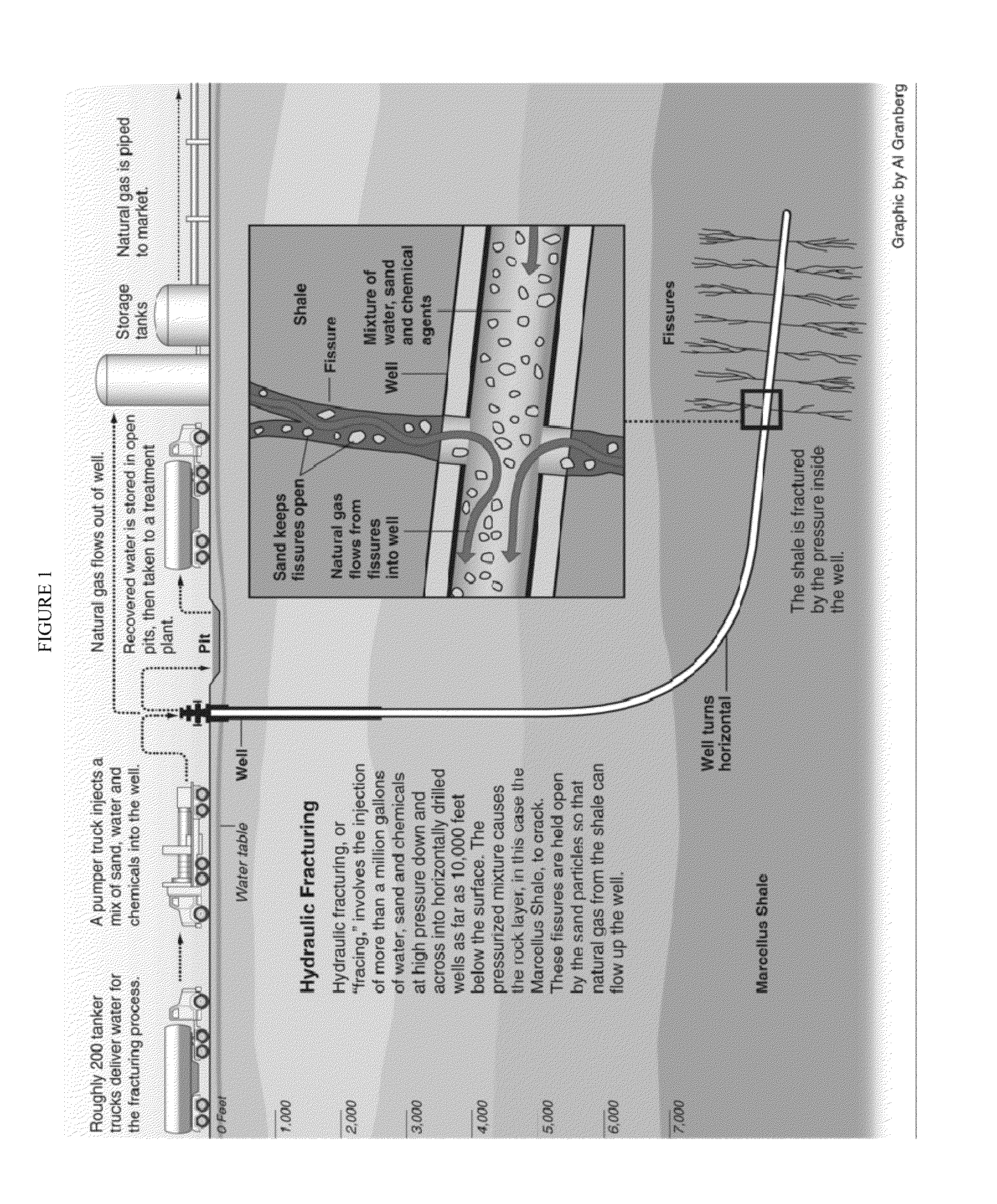

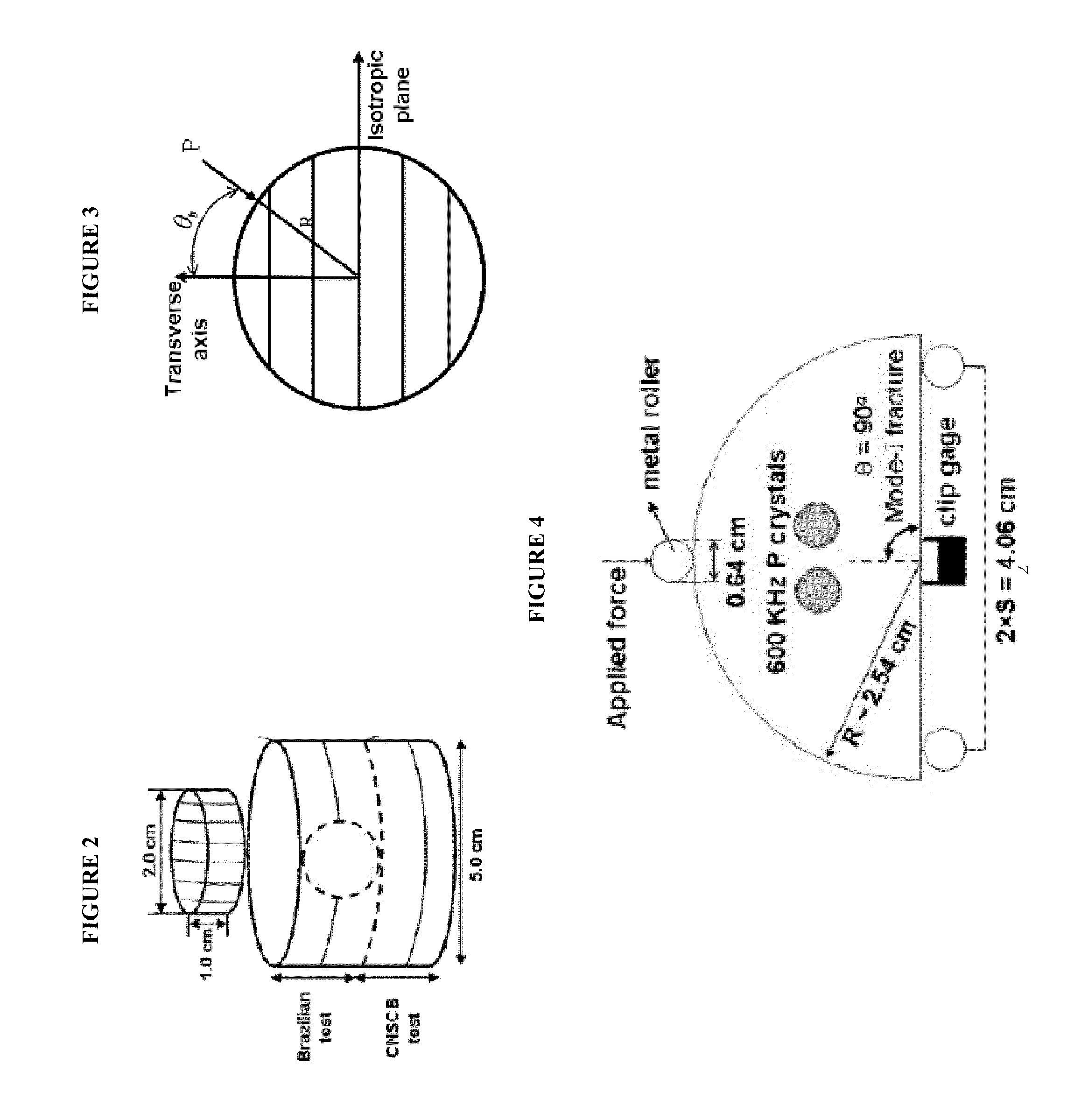

Pretreatment of Subterranean Formations for Dendritic Fracturing

InactiveUS20160237338A1Produced in advanceLow fracture toughnessCleaning apparatusFluid removalOxidizing agentFracture toughness

Provided are methods for pretreating a subterranean formation that include introducing into at least a portion of the subterranean formation: a first composition containing an oxidant in an aqueous base; and a second composition containing an acid and a compound that generates a non-oxygen gas upon reaction with the oxidant. Pretreating a subterranean formation according to these methods reduces the fracture toughness of the rock and establishes conditions favoring the growth of dendritic fracture.

Owner:YPF TECHA

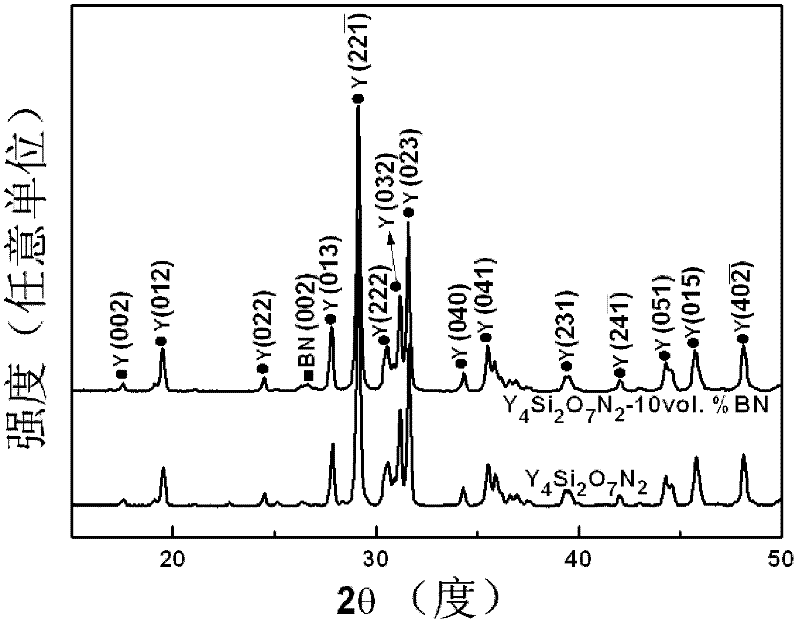

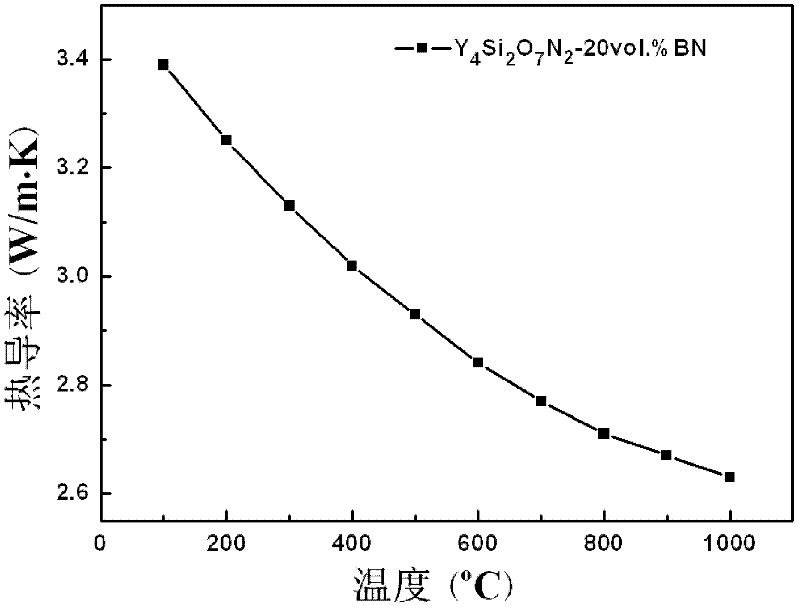

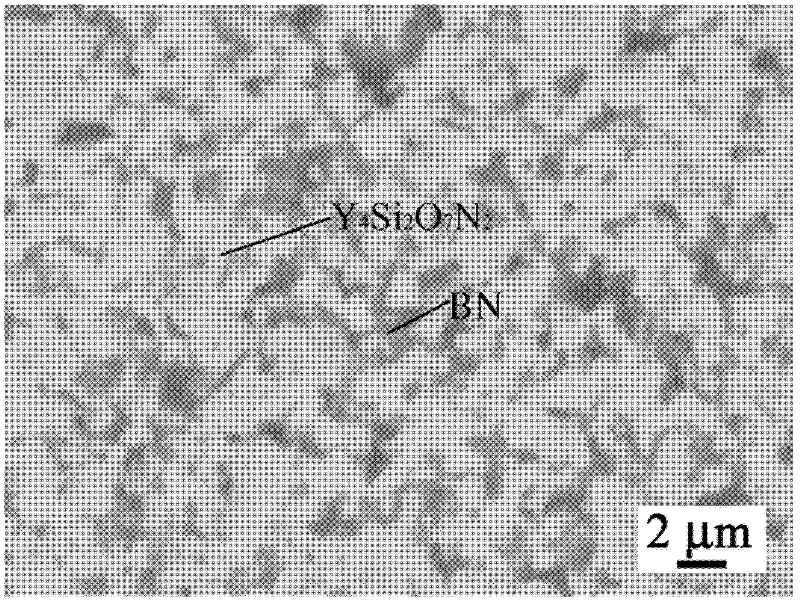

In-situ preparation method for Y4Si2O7N2-BN ceramic base composite materials

The invention relates to the field of ceramic base composite materials, in particular to an in-situ preparation method for Y4Si2O7N2-BN ceramic base composite materials. The composite materials consist of two phases: Y4Si2O7N2 and BN, wherein the content of the BN in the composite materials is 5 to 95 percent through being metered in percentage by volume, and the balance is the Y4Si2O7N2. Yttriumoxide powder, silicon oxide powder, silicon nitride powder and BN powder are used as raw materials, material powder carries out ball milling for 1 to 24 hours, the materials are charged into a graphite mold after being baked and sieved, the cold pressing is carried out at 10 to 15MPa, then, the temperature is raised to 1500 to 1700 DEG C at a temperature rise velocity of 5 to 40 DEG C / min in a hot pressing furnace by using nitrogen gas as protection atmosphere, the temperature is preserved for 0.5 to 1 hour, then, the temperature is raised to 1800 to 2100 DEG C at a temperature rise velocity of 5 to 40 DEG C / min, the temperature is preserved for 1 to 3 hours, and the hot pressing pressure is 10 to 40 MPa. The Y4Si2O7N2-BN ceramic base composite materials with high purity, good density, high intensity and low heat conductivity can be sintered through hot pressing in a short time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Geomechanical weakening with surface acting agents

InactiveUS20140367110A1Reduce pressureIncrease fracture bifurcation indexFluid removalDrilling compositionActive agentHydraulic fracturing

Owner:CONOCOPHILLIPS CO

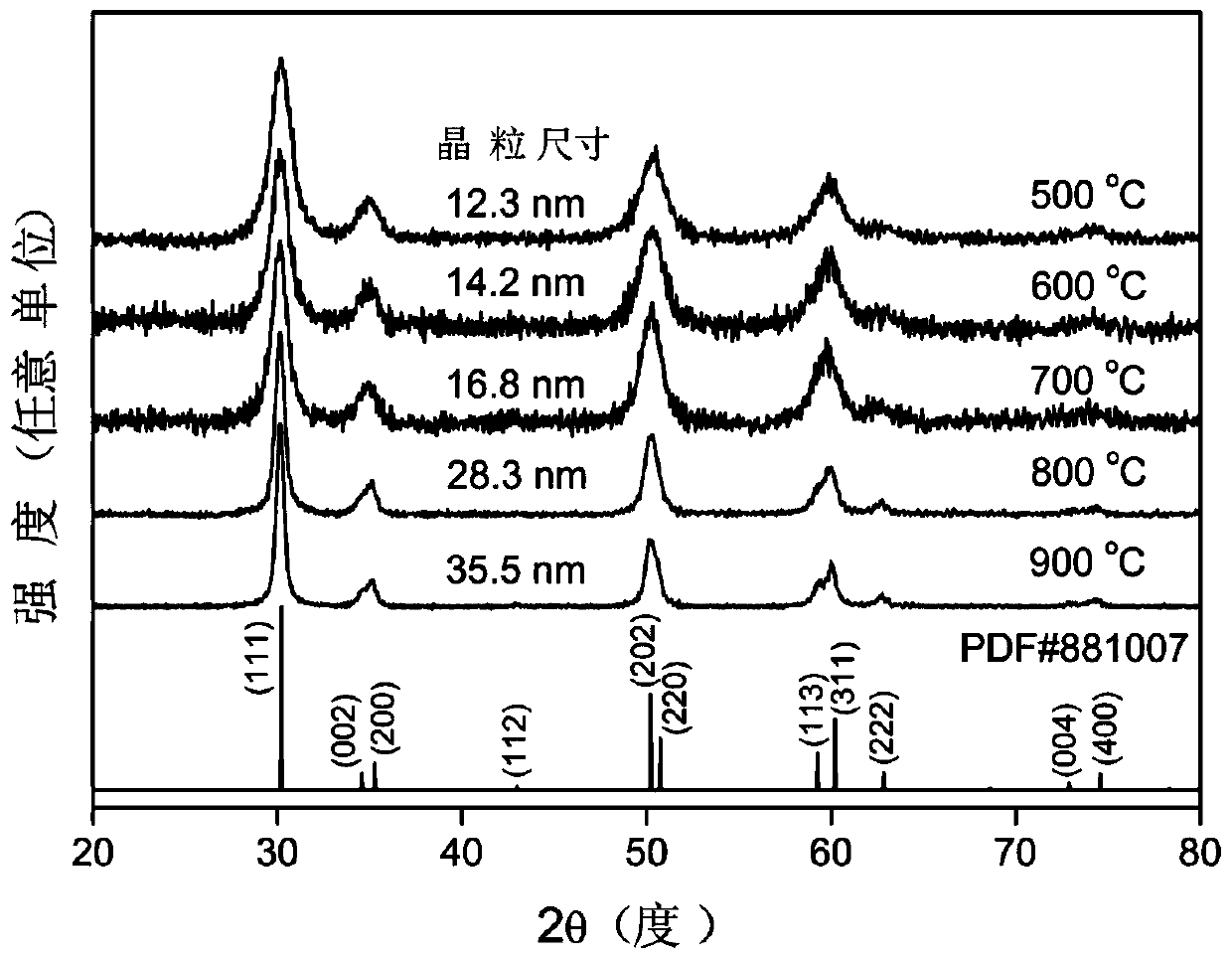

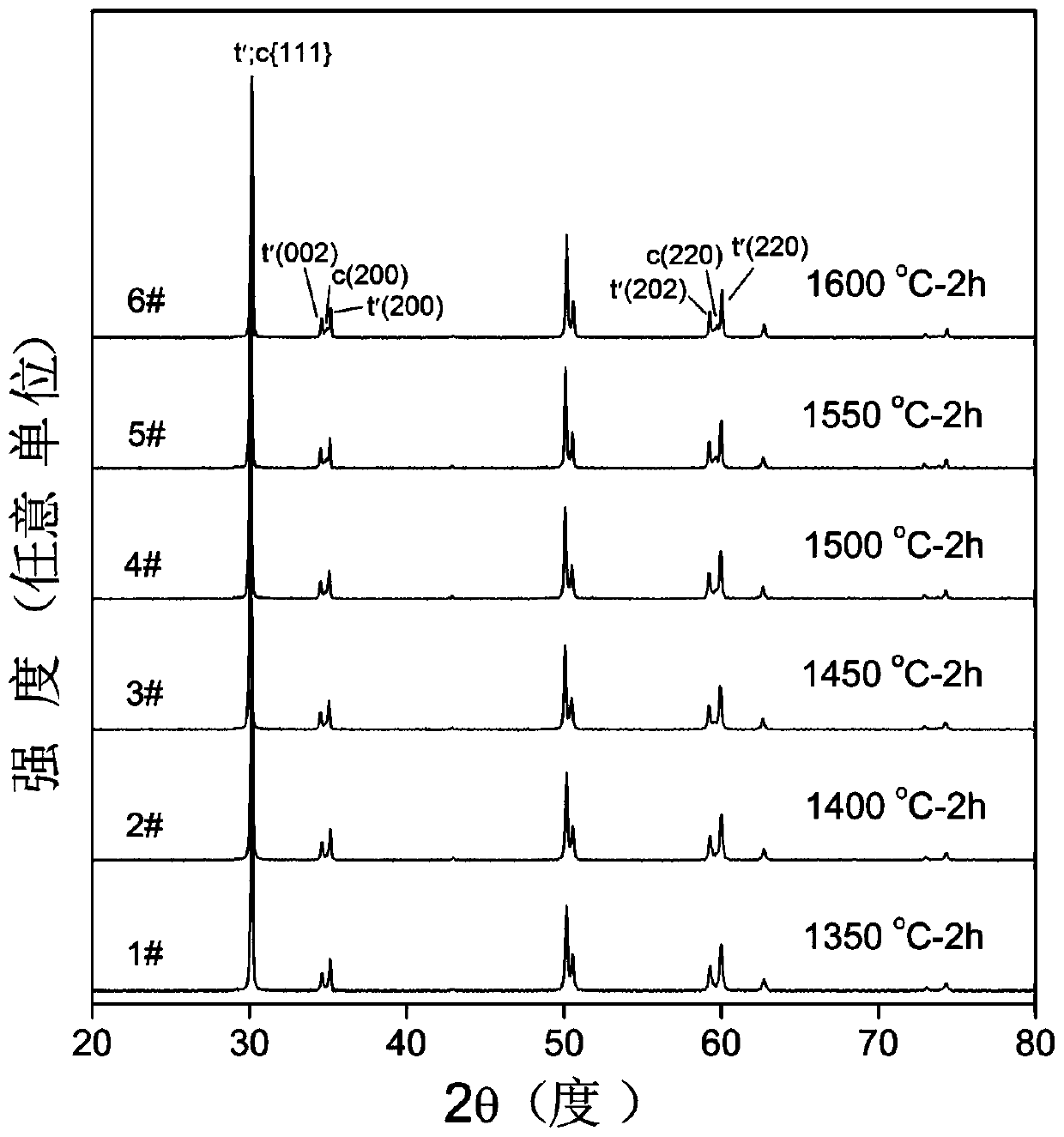

High toughness yttrium oxide stabilized tetragonal zirconia material unaffected by sintering and preparation method thereof

ActiveCN110104681AHighlight substantiveWide sintering temperature rangeZirconium oxidesHydrolysisYttrium

Belonging to the field of zirconia ceramics, the invention relates to a high toughness yttrium oxide stabilized tetragonal zirconia material unaffected by sintering and a preparation method thereof. The high toughness yttrium oxide stabilized tetragonal zirconia (3Y-TZP) material unaffected by sintering has a particle size of 100nm-900nm, no monoclinic phase, a sintered density of 5.63 g / cm<3>-6.05g / cm<3>, and a relative density of 92.6%-99.5%. Compared with similar technologies, the method provided by the invention enables uniform reaction of the raw materials at atomic scale, and avoids hydrolysis of zirconium ions, so that the starting raw materials have no monoclinic phase; the sintering temperature range is wide from 1350DEG C to 1550DEG C, and the sintering process becomes simple; and the toughness is relatively high, and does not decrease significantly along with the sintering time and temperature.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

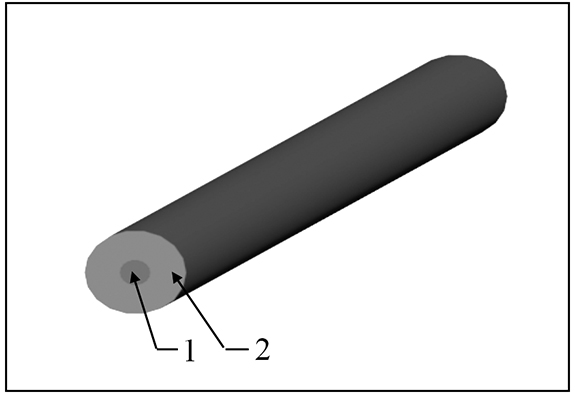

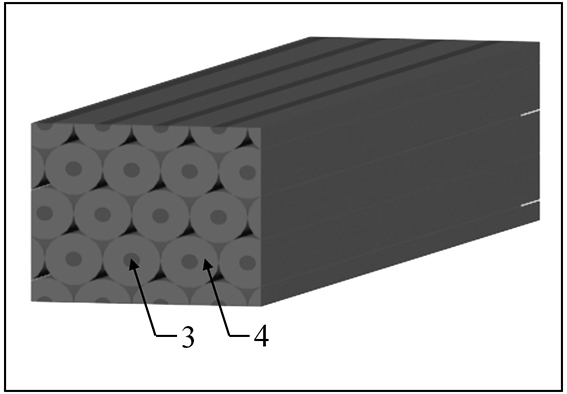

Method for preparing exoskeleton structure fiber monolith zirconium carbide ceramic through wet spinning and co-extrusion

The invention provides a method for preparing exoskeleton structure fiber monolith zirconium carbide ceramic through wet spinning and co-extrusion. The method is characterized by comprising the following steps of: (1) adding a curing agent and a plasticizer into an organic solvent and stirring for dissolving the curing agent and the plasticizer, respectively adding ceramic powder of a fibrous monolith precursor cell and ceramic powder of a cell interface layer, uniformly stirring to form two spinneret slurries with different components, pouring the spinneret slurries into different injectors,and spraying the spinneret slurries into a gel tank through a co-extrusion spinneret under mechanical pressure to obtain an exoskeleton structure fibrous monolith precursor; (2) carrying out warm-pressing molding; (3) carrying out vacuum degreasing; and (4) carrying out hot pressing sintering to obtain the exoskeleton structure fiber monolith zirconium carbide ceramic, the fracture toughness of which can reach 8MPa. M<1 / 2> or above. According to the obtained exoskeleton structure fiber monolith zirconium carbide ceramic, the toughening mode in which strong and weak layers of a biomimetic material are alternately arranged is reserved, meanwhile, the three-dimensional communication structure of a weak material is changed, and the fracture toughness and the oxidation ablation resistance of the material are synergistically improved.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com