Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

169 results about "Calcium phosphate cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

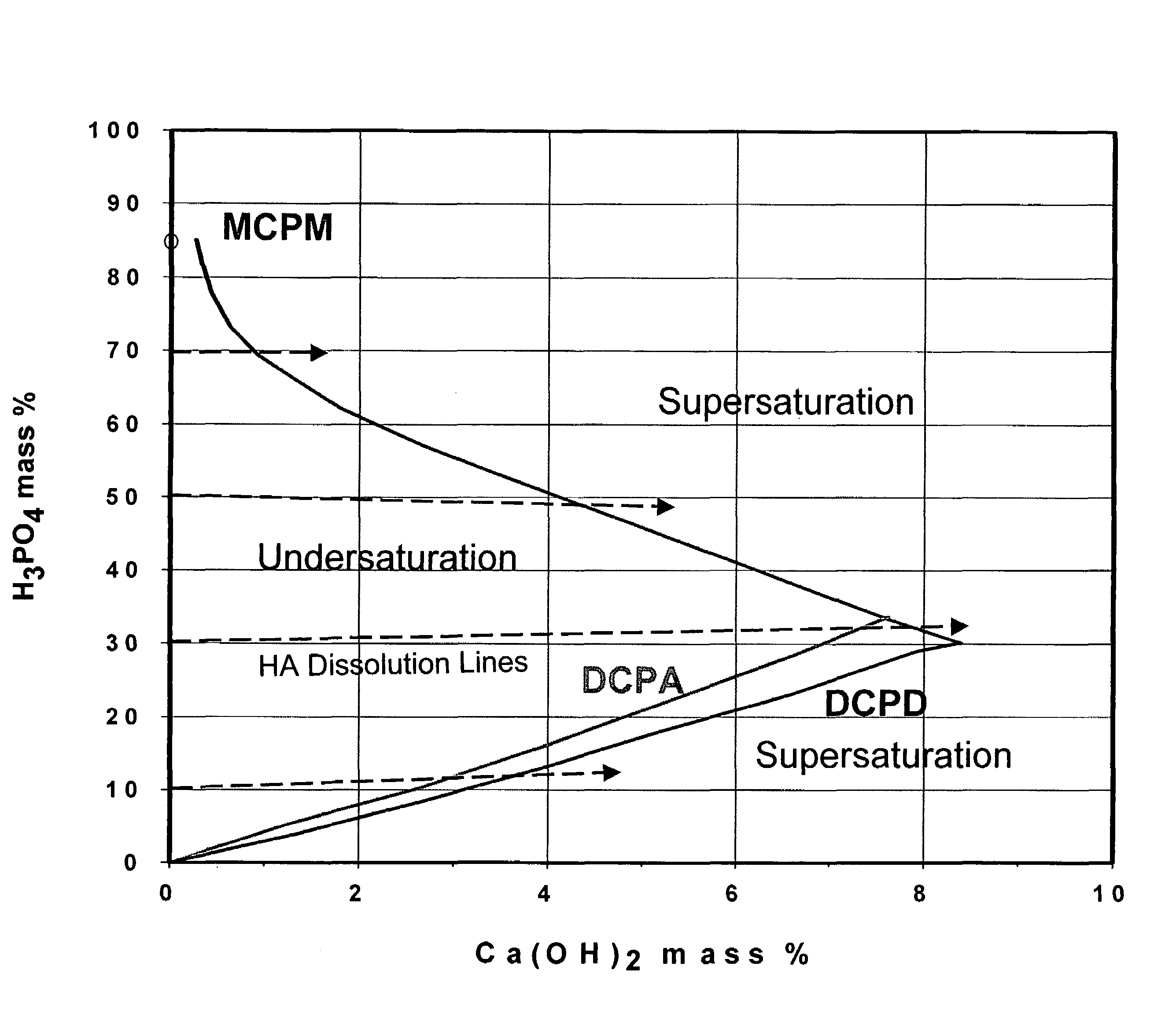

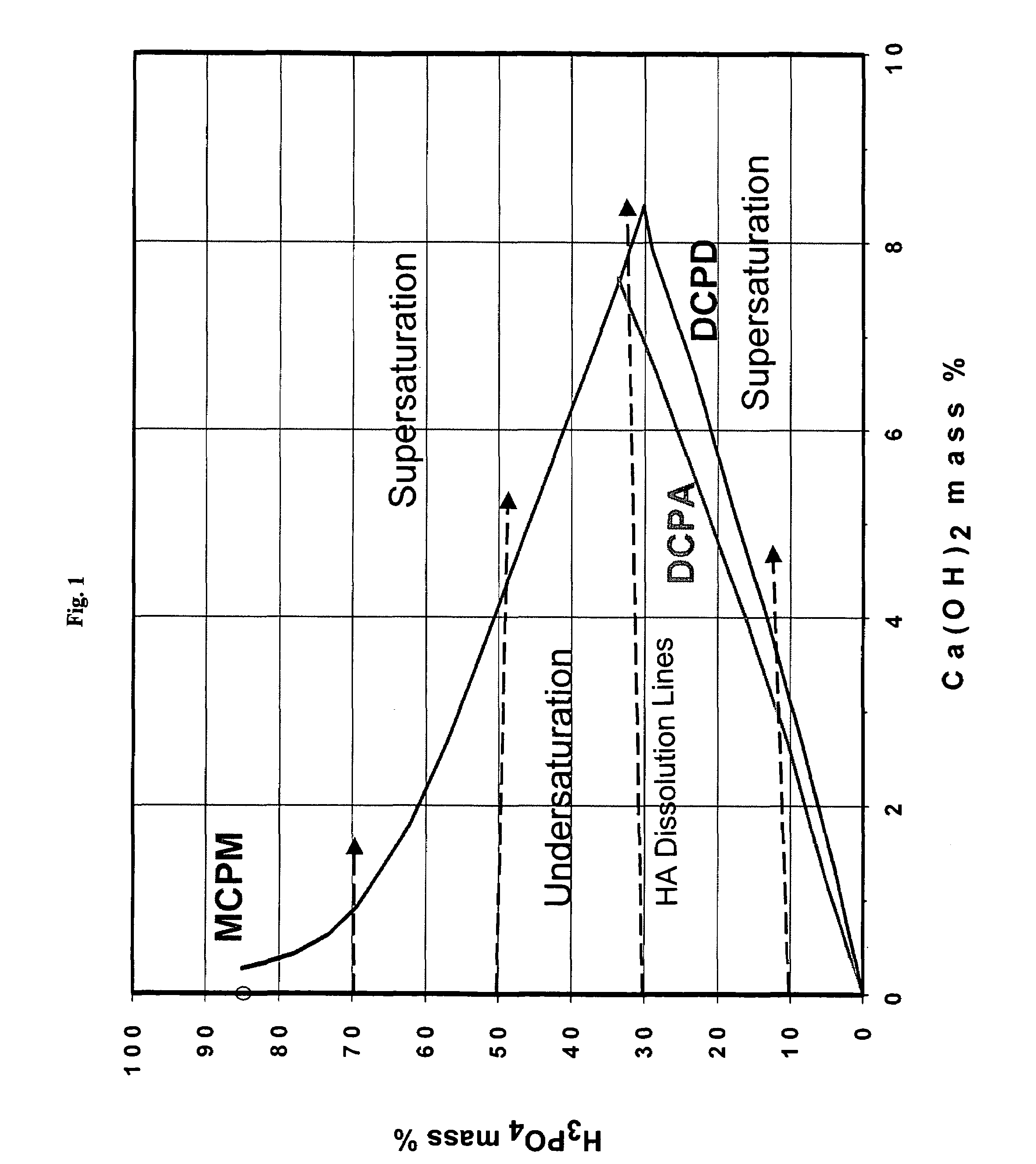

Calcium phosphate cement (CPC) is a breakthrough of biomaterials aimed for the reconstruction of bone defect. Upon mixing its powder phase with its liquid phase, it sets to form apatite or dicalcium phosphate dihydrate.

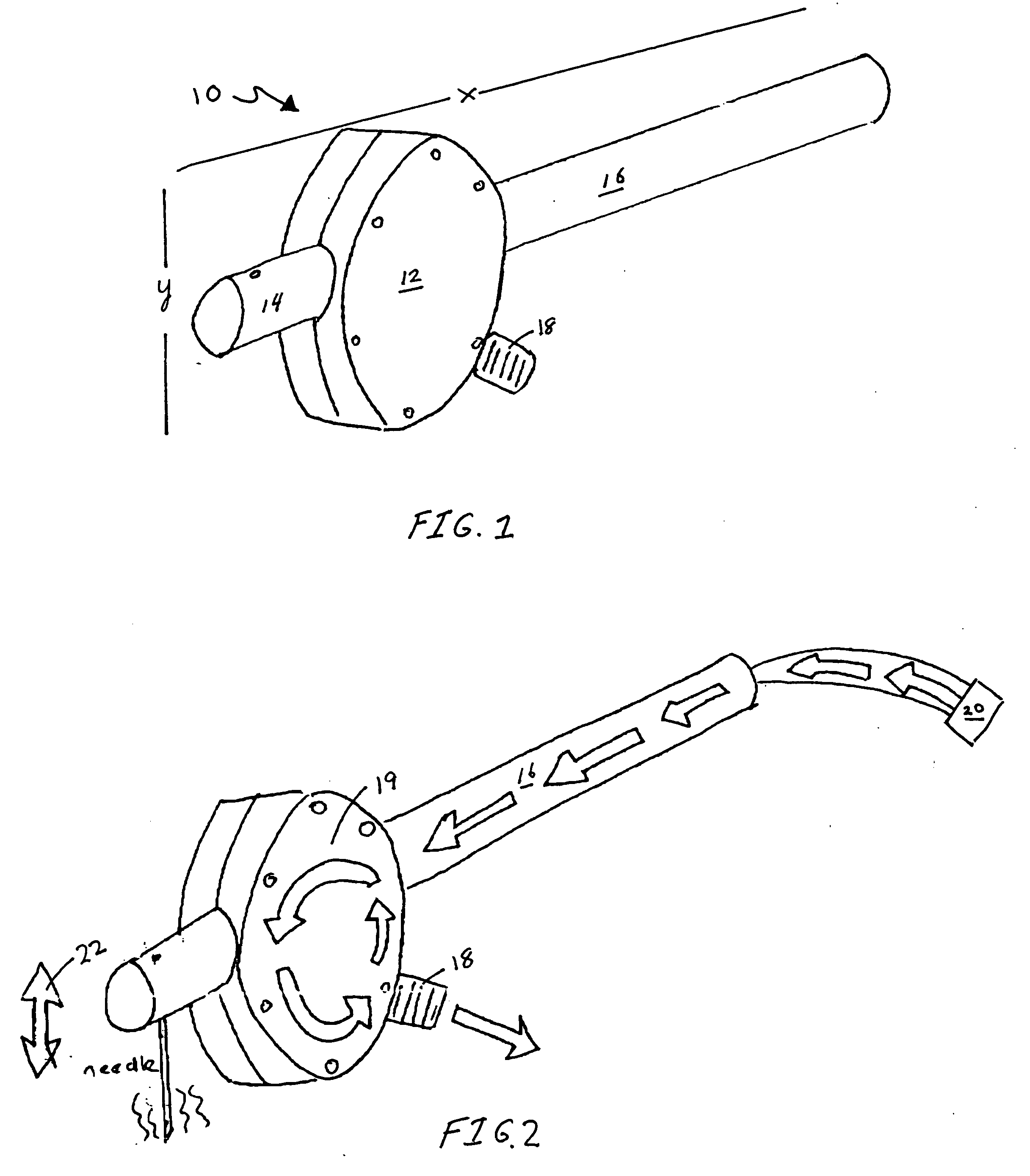

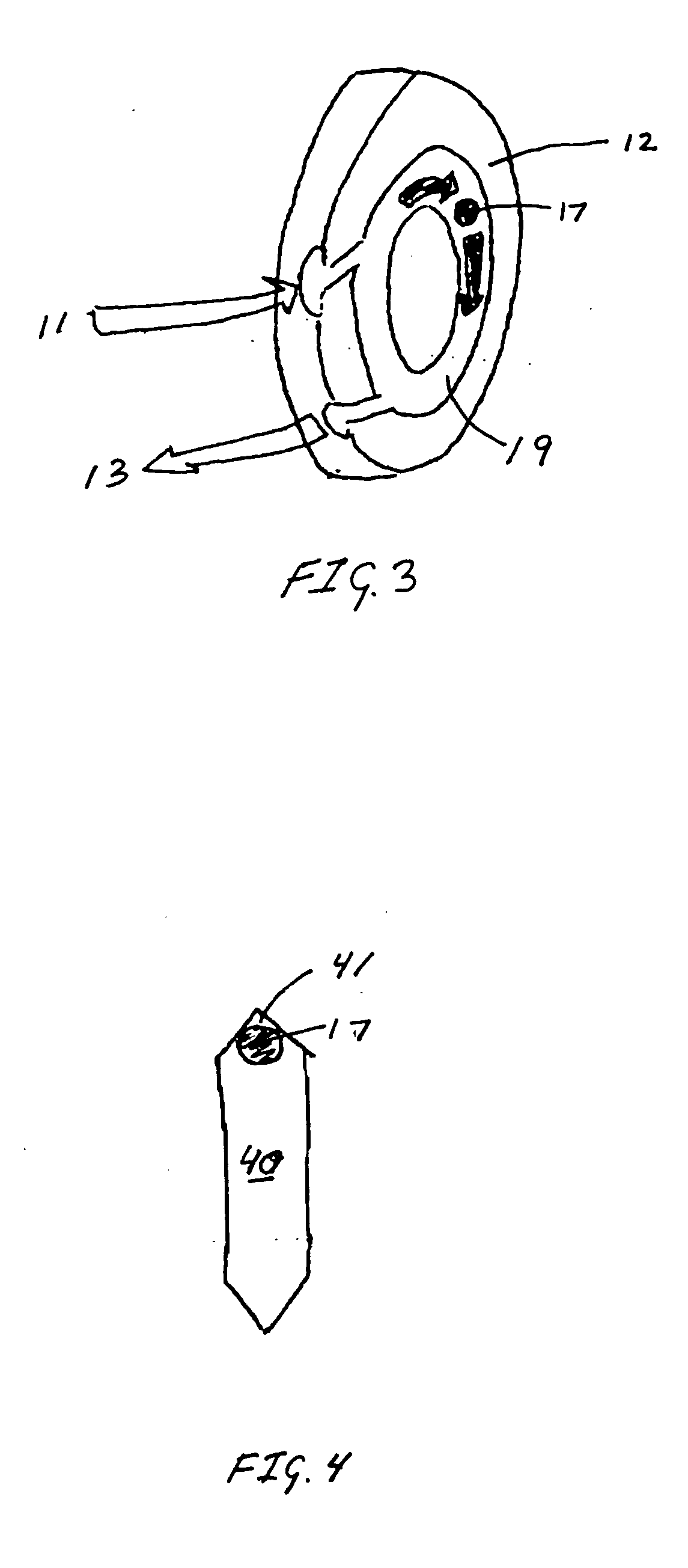

Methods and devices for the preparation, storage and administration of calcium phosphate cements

InactiveUS6149655AStable reductionPromote resultsLiquid surface applicatorsShaking/oscillating/vibrating mixersCalcium biphosphatePhosphoric acid

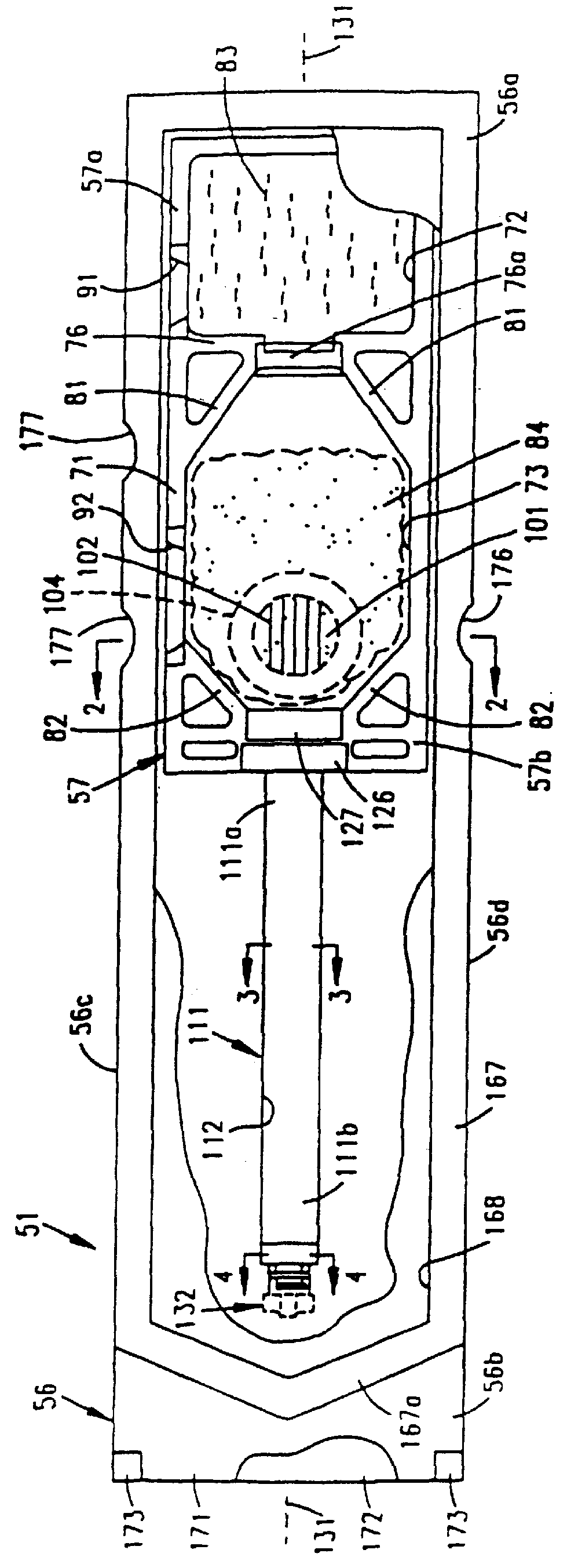

A system is provided for the storage, preparation and administration of calcium phosphate cements. The subject invention provides a storage means for storing a two component calcium phosphate cement having a liquid component and a dry component. Also provided is a preparation means for combining the two components of the cement while present in the storage means. The subject invention further provides a means for administering the prepared cement to a physiological site. The subject devices and methods find use in a variety of applications where the introduction of a flowable material capable of setting to a solid calcium phosphate mineral to a physiological site is desired, including dental and orthopedic applications.

Owner:NORIAN CORP

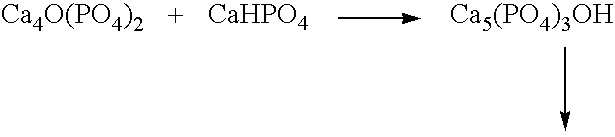

Process for producing fast-setting, bioresorbable calcium phosphate cements

InactiveUS6379453B1Improve biological activityOther chemical processesDentistry preparationsSeed crystalCalcium phosphate cement

Owner:CALCITEC

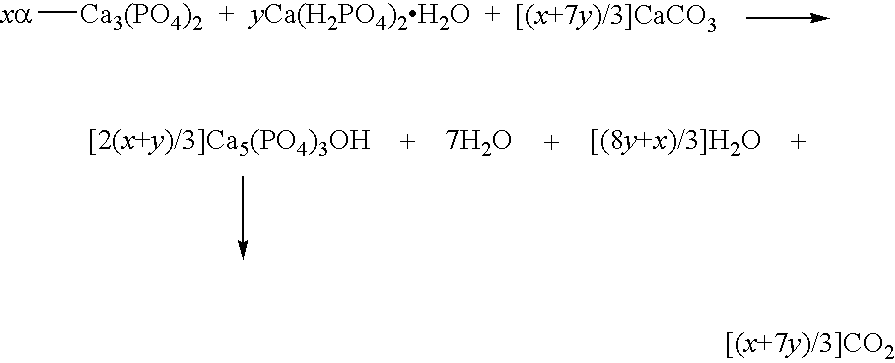

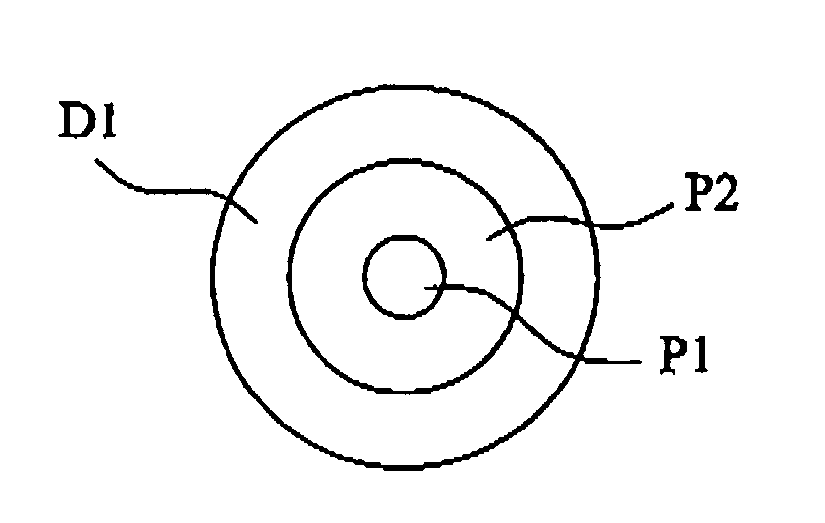

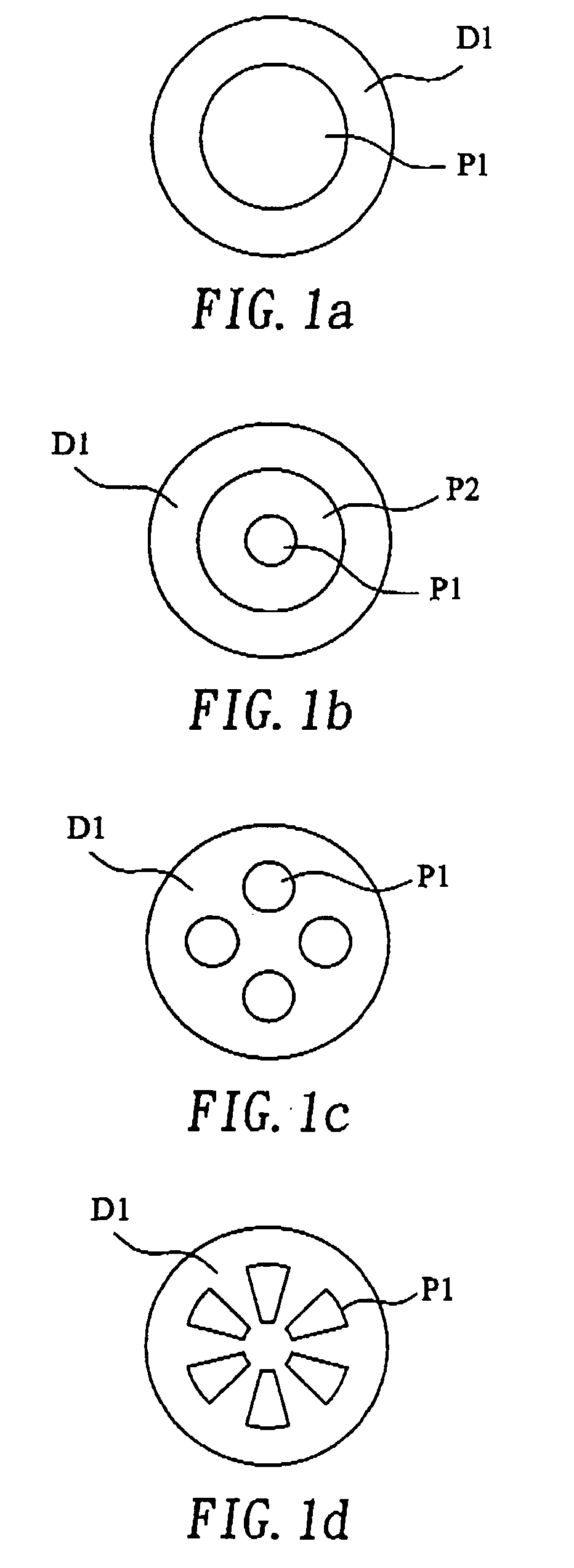

Dual function prosthetic bone implant and method for preparing the same

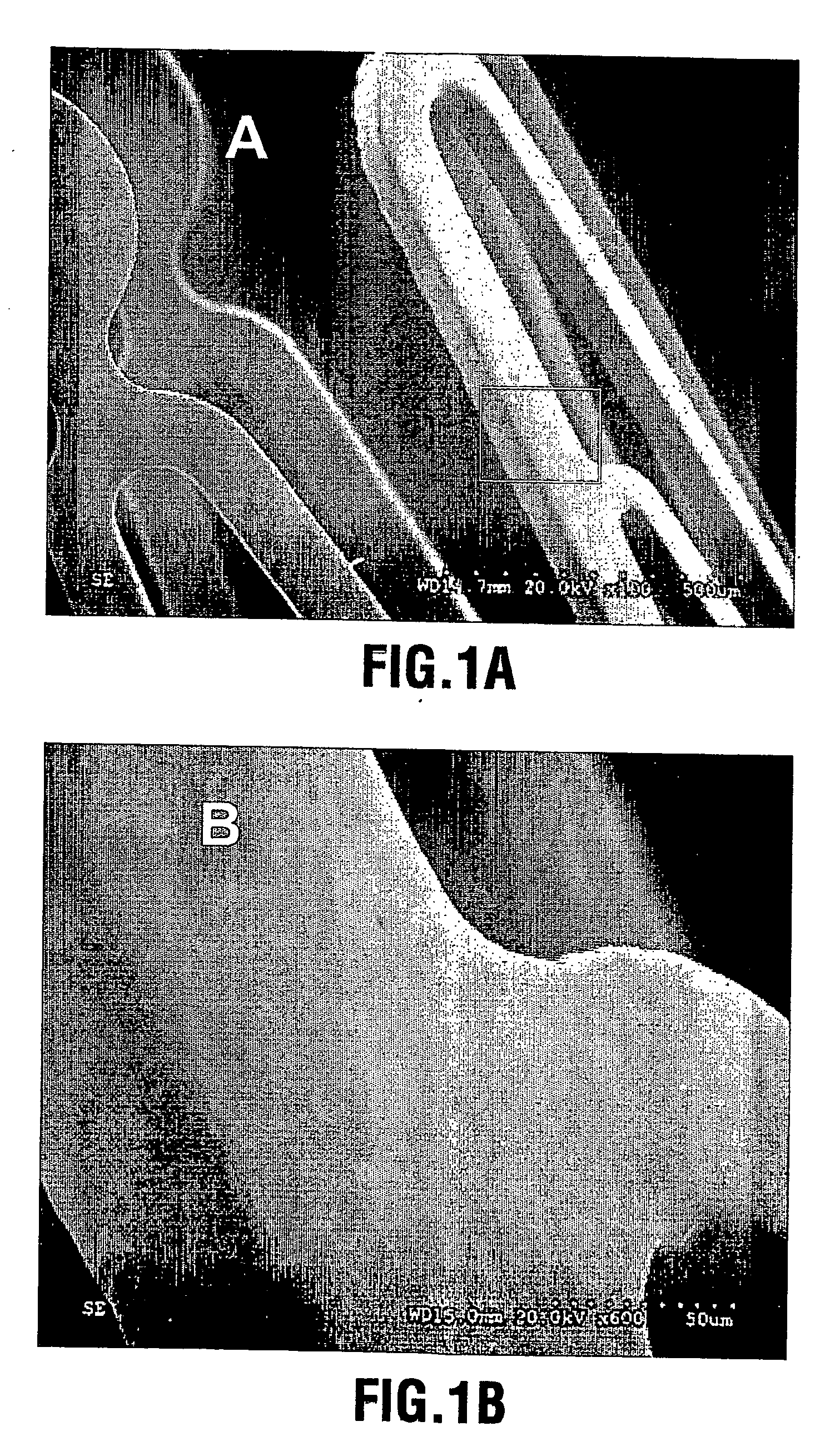

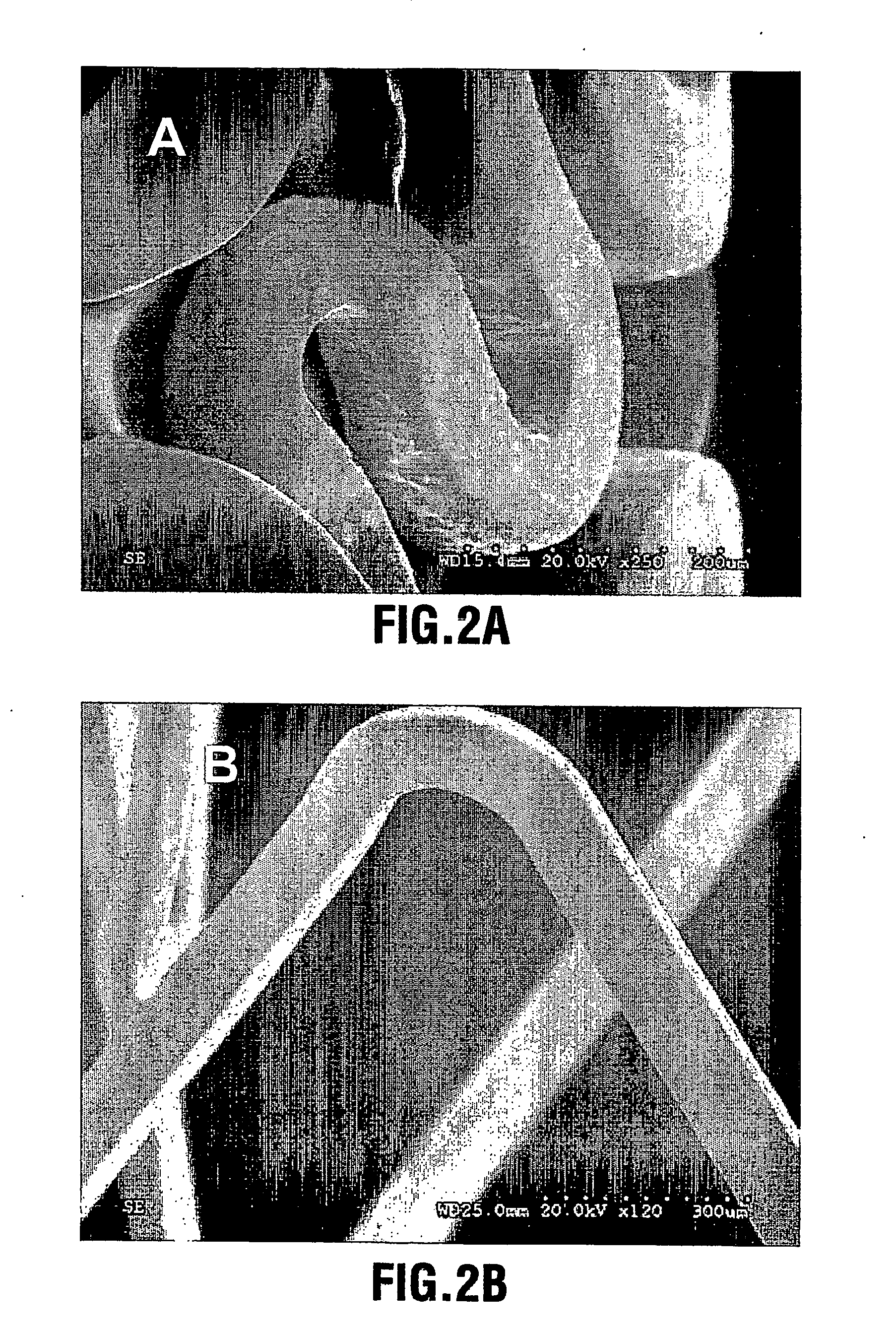

InactiveUS6994726B2Penetrate fastHigh compressive strengthBone implantWood working apparatusBone implantBody fluid

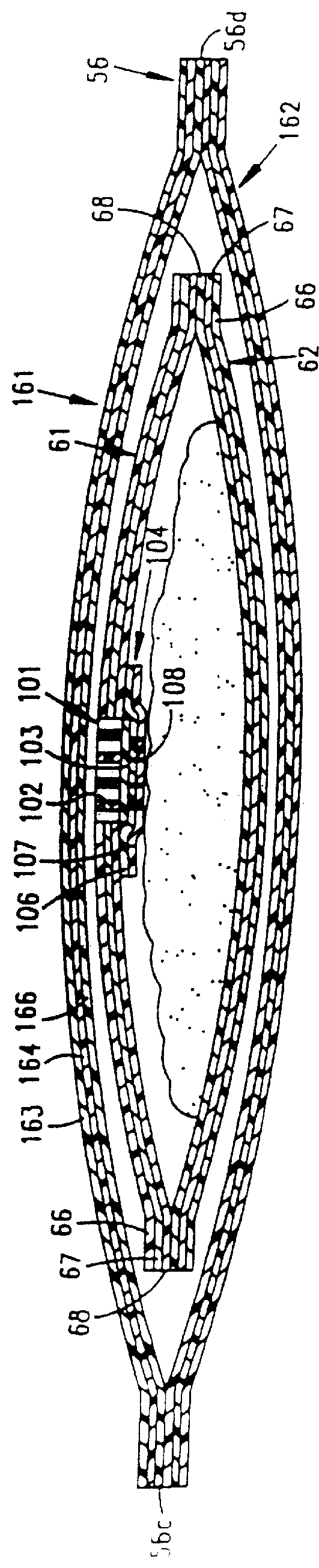

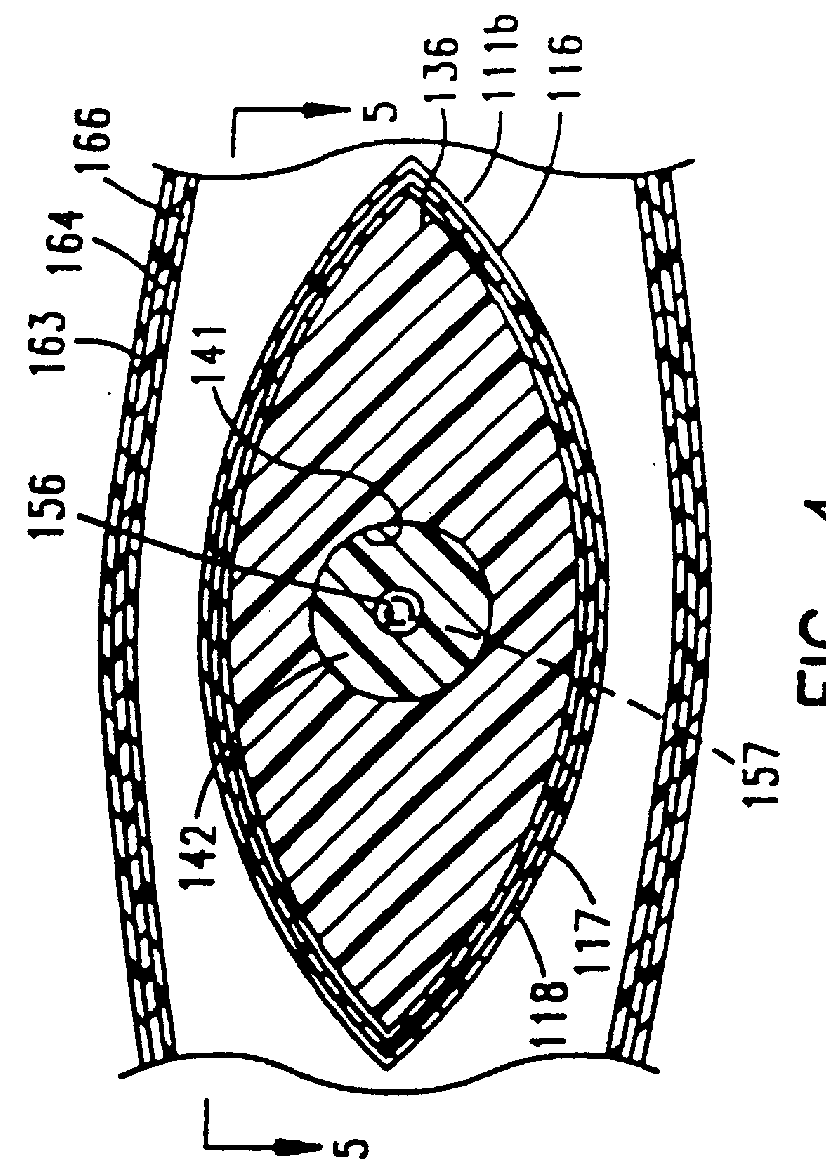

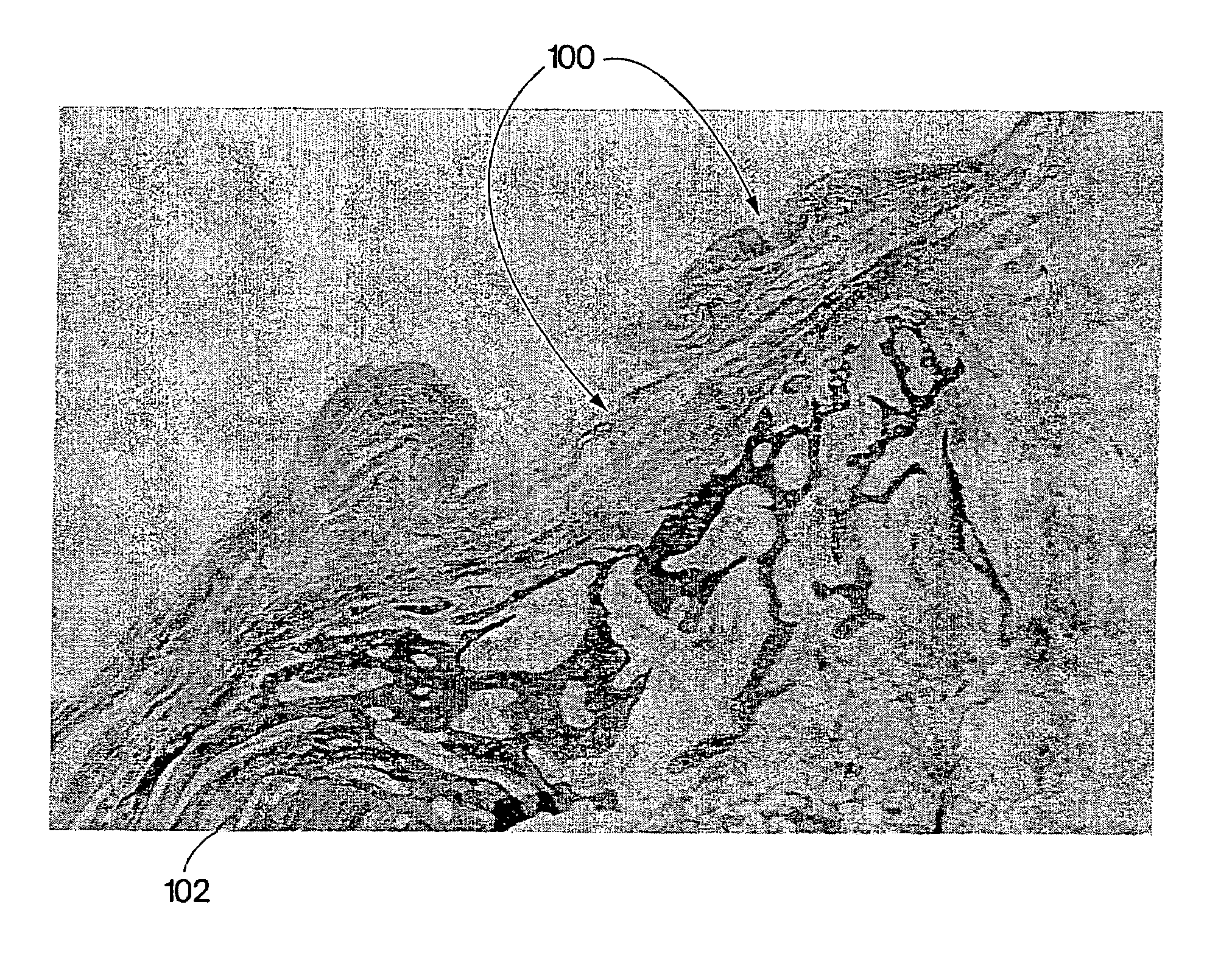

The present invention discloses a prosthetic bone implant made of a hardened calcium phosphate cement having an apatitic phase as a major phase, which includes a dense cortical portion bearing the majority of load and a porous cancellous portion allowing a rapid blood / body fluid penetration and tissue ingrowth.

Owner:CALCITEC

Calcium phosphate cement composition and a method for the preparation thereof

ActiveUS6929692B2Good water solubilityIncreased formationOther chemical processesBone implantChemical synthesisCalcium biphosphate

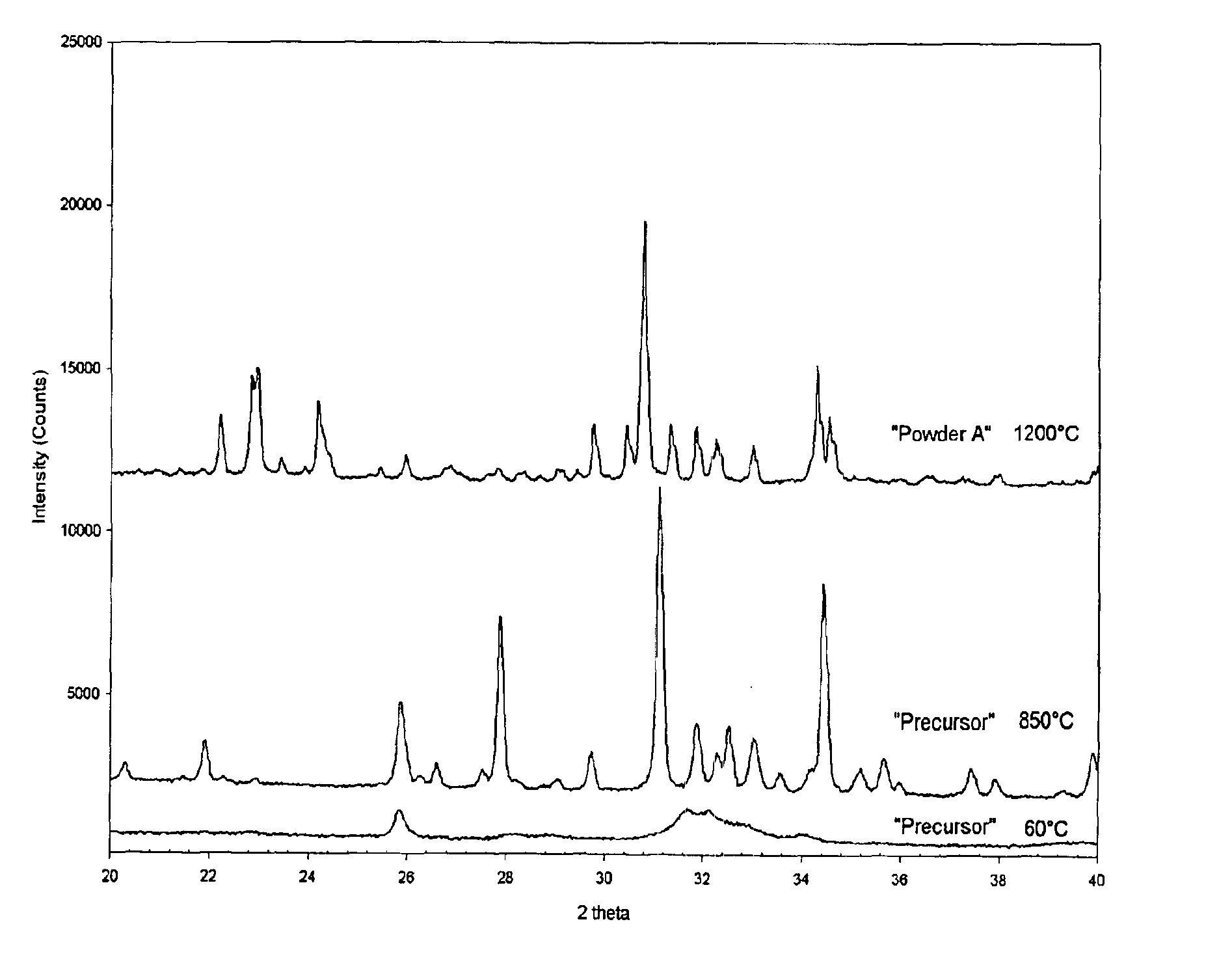

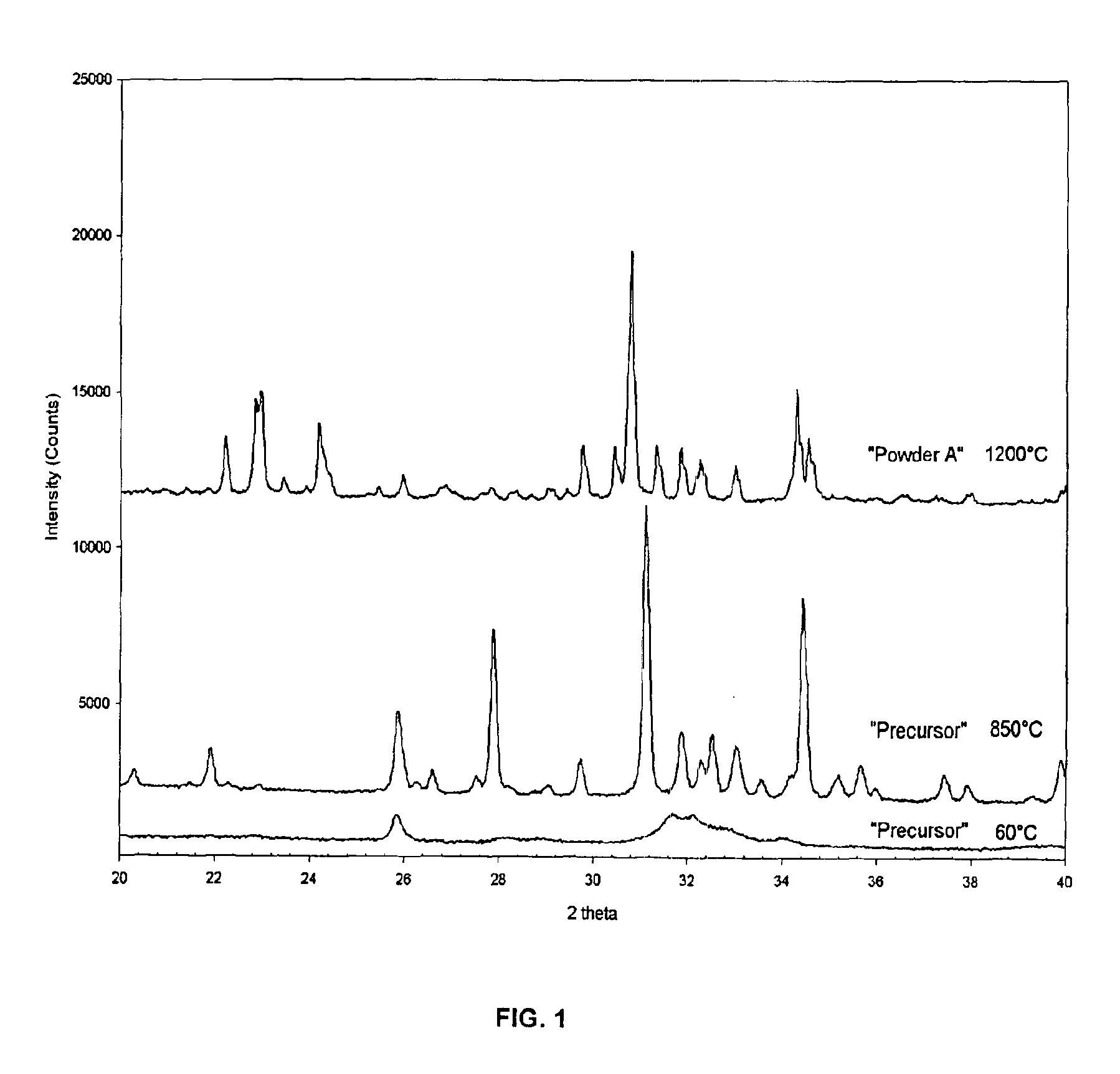

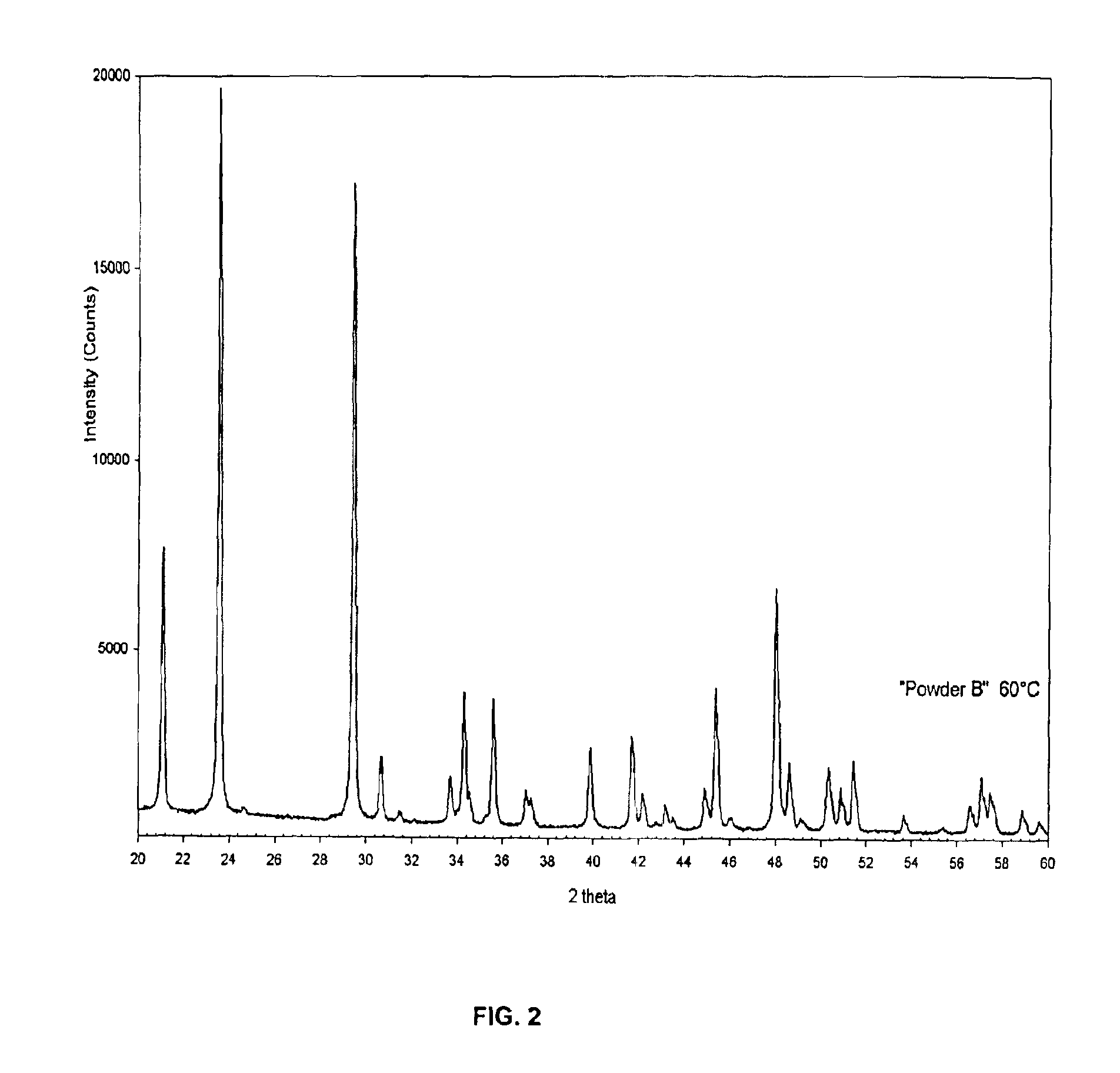

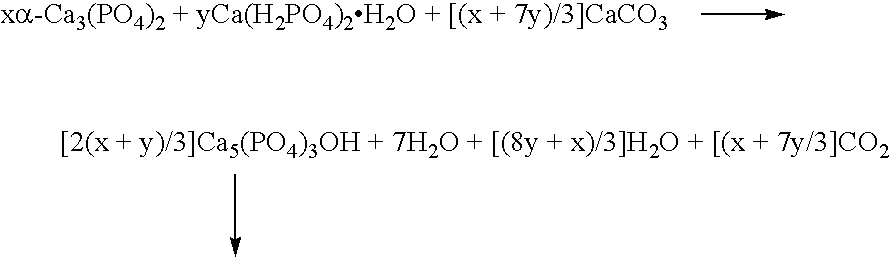

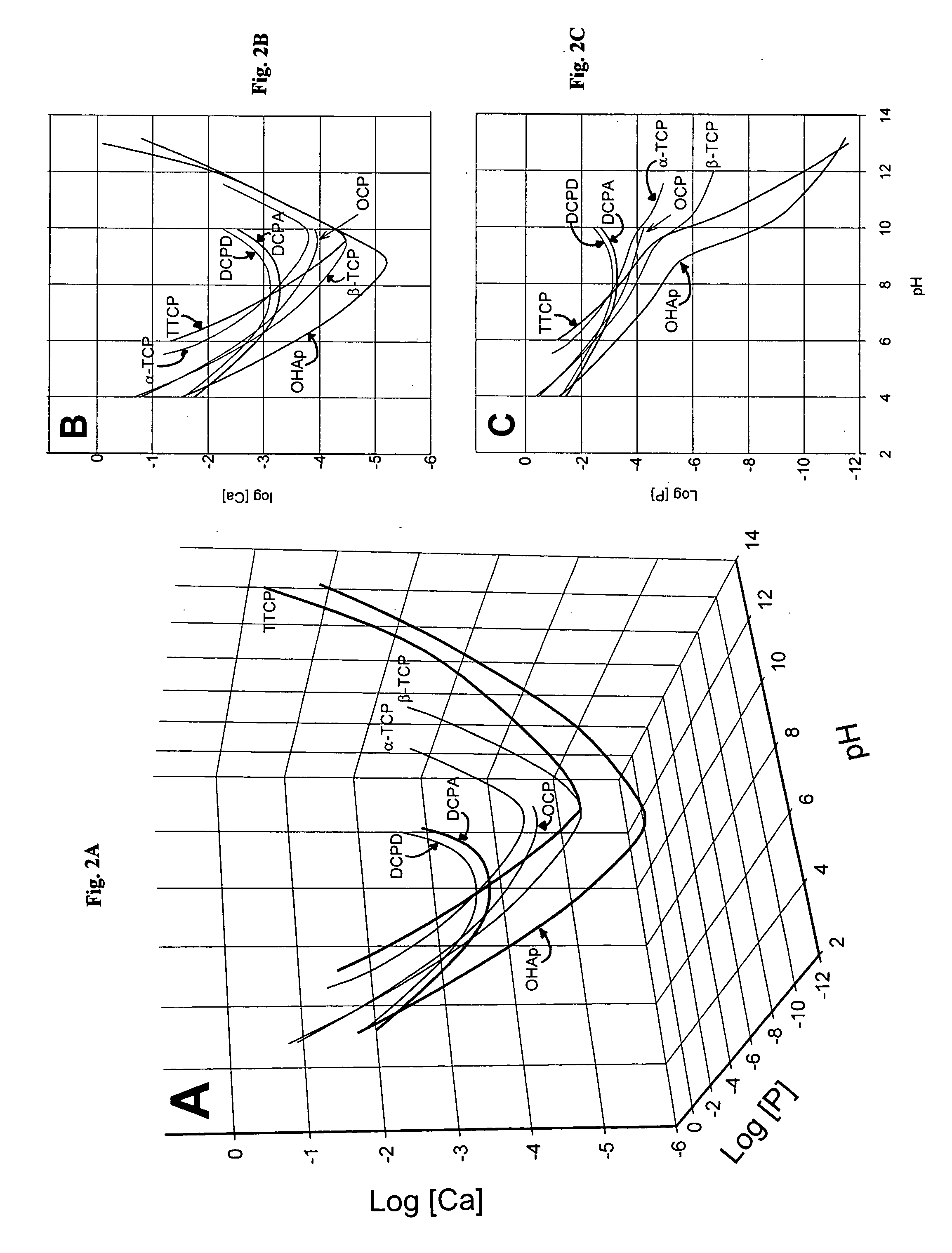

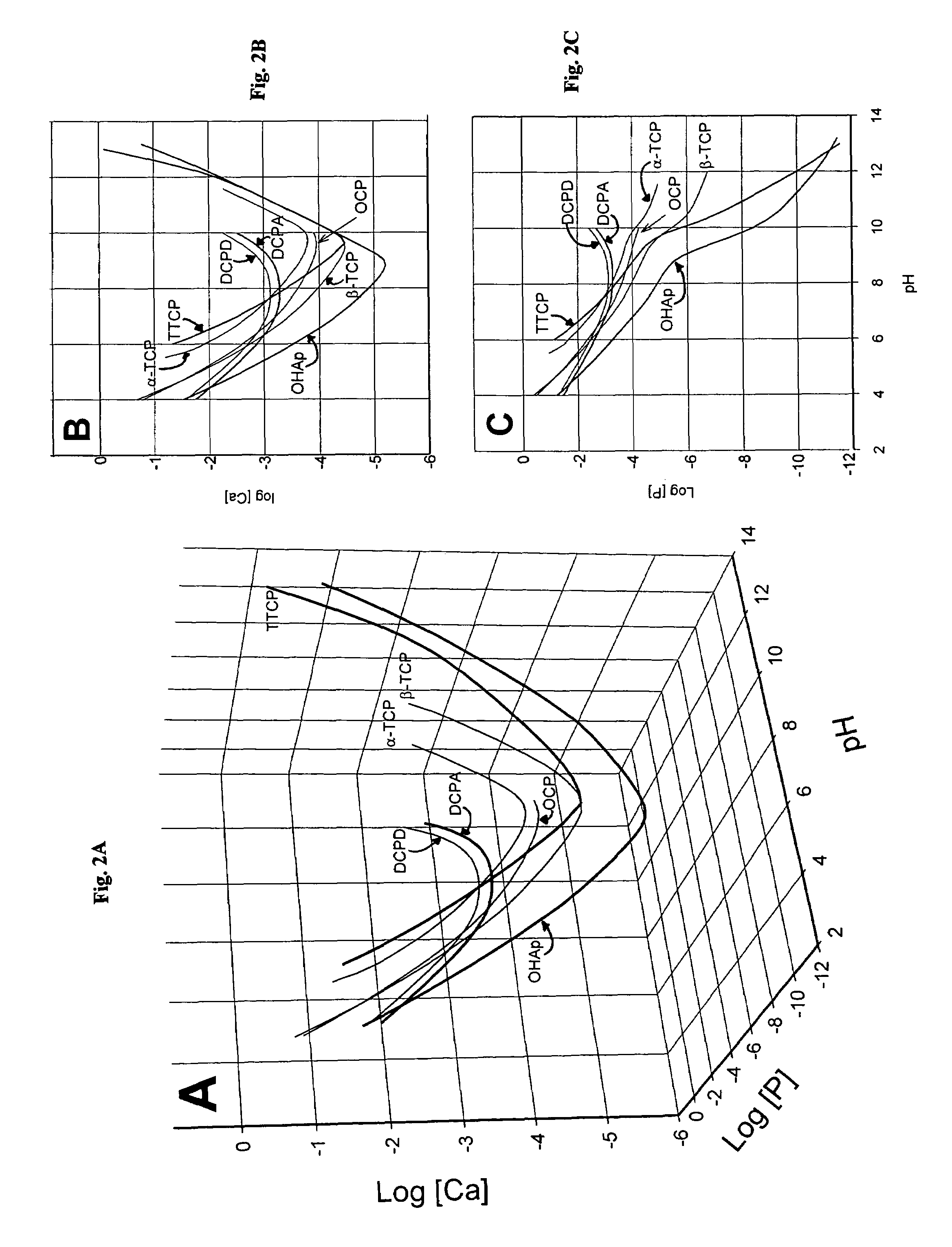

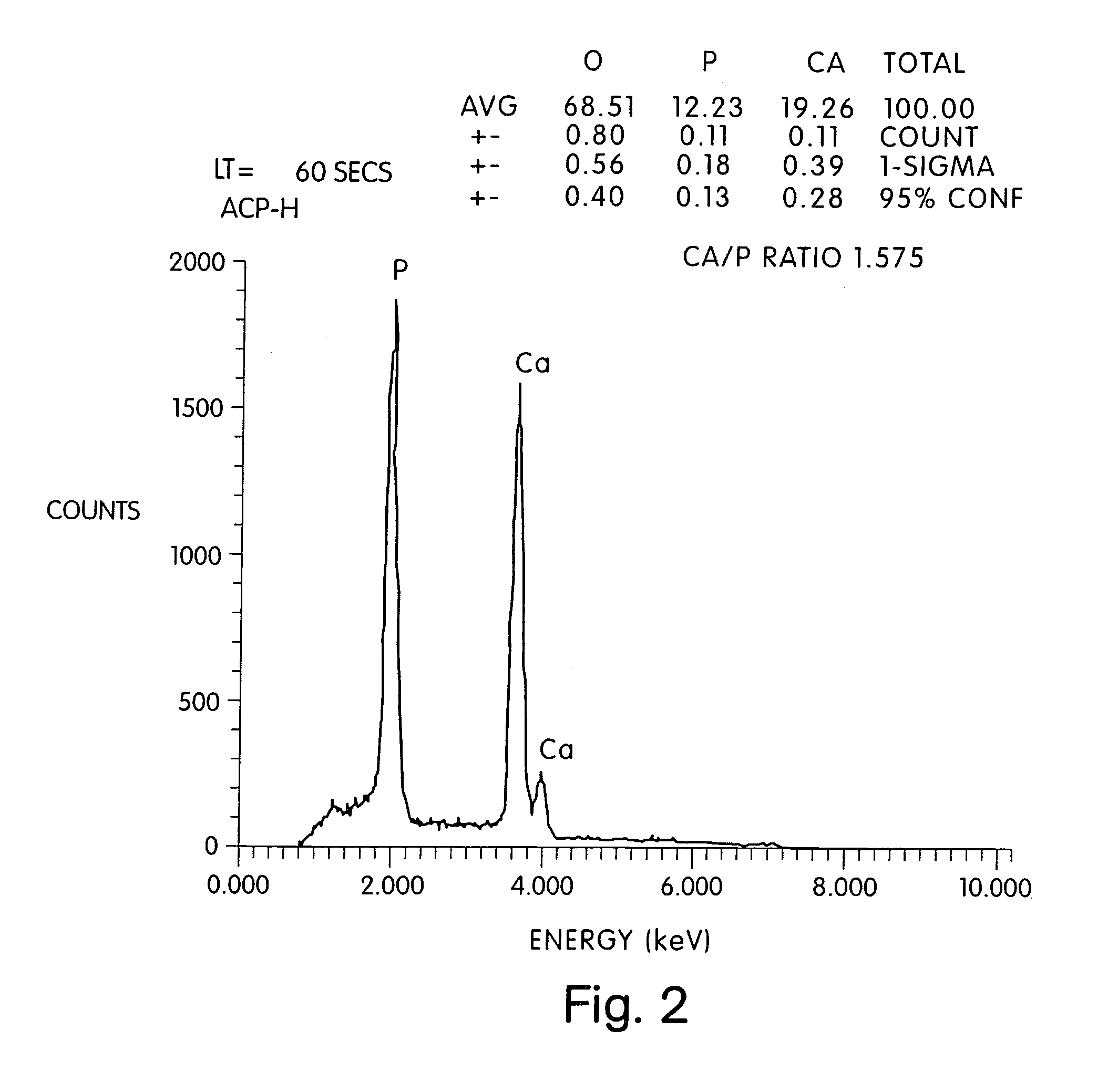

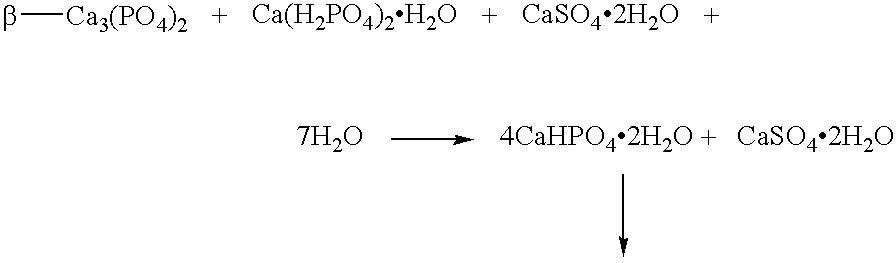

The invention describes a new calcium phosphate cement powder, whose composition can best be described over the Ca / P molar ratio range of 1.35 to 1.40, most preferably 1.39, and whose two components were prepared by wet chemical synthesis procedures. One component is chemically-synthesized, bi-phasic alpha-TCP (Ca3(PO4)2, 95 wt %)+HA (Ca10(PO4)6(OH)2, 5 wt %) powder, while the second component is again a chemically-synthesized, single-phase DCPD (CaHPO4·2H2O) powder. A setting solution (Na2HPO4·2H2O) is used to form a self-setting calcium phosphate cement from the powder mixture. This cement can be used as bone filler or bone substitute in applications, which require higher rates of resorption.

Owner:DR AHMET CUNEYT TAS

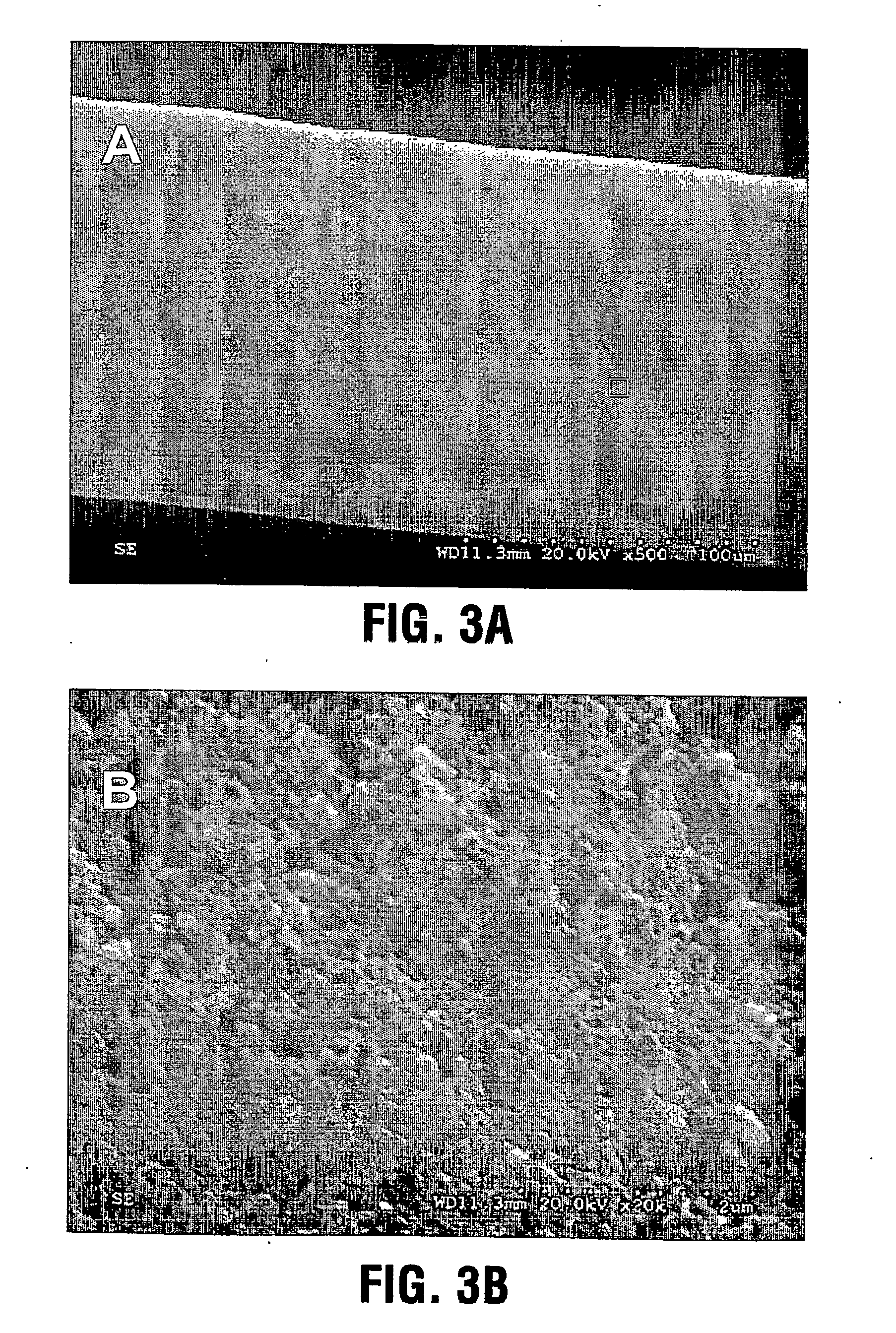

Calcium phosphate coated implantable medical devices and processes for making same

InactiveUS20060134160A1Reduce porosityControlled release rateBiocideInorganic phosphorous active ingredientsCalcium phosphate coatingCardiovascular stent

This invention relates to novel calcium phosphate-coated implantable medical devices and processes of making same. The calcium-phosphate coatings are designed to minimize the immune response to the implant (e.g. restenosis in stenting procedures) and can be used to store and release a medicinally active agent in a controlled manner. Such coatings can be applied to any implantable medical devices and are useful for a number of medical procedures including (but not limited to) balloon angioplasty in cardiovascular stenting, ureteral stenting and catheterisation. The calcium phosphate coatings can be applied to a substrate as one or more coatings by a sol-gel deposition process, an aerosol-gel deposition process, a biomimetic deposition process, a calcium phosphate cement deposition process, an electro-phoretic deposition process or an electrochemical deposition process. The coating can contain and elude a drug in an engineered manner.

Owner:THE UNIV OF BRITISH COLUMBIA

Method of preparing a poorly crystalline calcium phosphate and methods of its use

InactiveUS7517539B1Readily injectableHigh strengthBiocideSurgical adhesivesOsteoporotic boneIntervertebral spaces

The present invention provides a novel process for producing a calcium phosphate cement or filler which hardens in a temperature dependent fashion in association with an endothermic reaction. In the reaction a limited amount of water is mixed with dry calcium phosphate precursors to produce a hydrated precursor paste. Hardening of the paste occurs rapidly at body temperature and is accompanied by the conversion of one or more of the reactants to poorly crystalline apatitic calcium phosphate. The hardened cements, fillers, growth matrices, orthopedic and delivery devices of the invention are rapidly resorbable and stimulate hard tissue growth and healing. A composite material is provided including a strongly bioresorbable, poorly crystalline apatitic calcium phosphate composite and a supplementary material. The supplementary material is in intimate contact with the hydroxyapatite material in an amount effective to impart a selected characteristic to the composite. The supplemental material may be biocompatible, bioresorbable or non-resorbable. A method for treating a bone defect also is provided by identifying a bone site suitable for receiving an implant, and introducing a strongly resorbable, poorly crystalline apatitic calcium phosphate at the implant site, whereby bone is formed at the implant site. The implant site may be a variety of sites, such as a tooth socket, non-union bone, bone prosthesis, an osteoporotic bone, an intervertebral space, an alveolar ridge or a bone fracture.

Owner:LIFE SCI ENTERPRISES

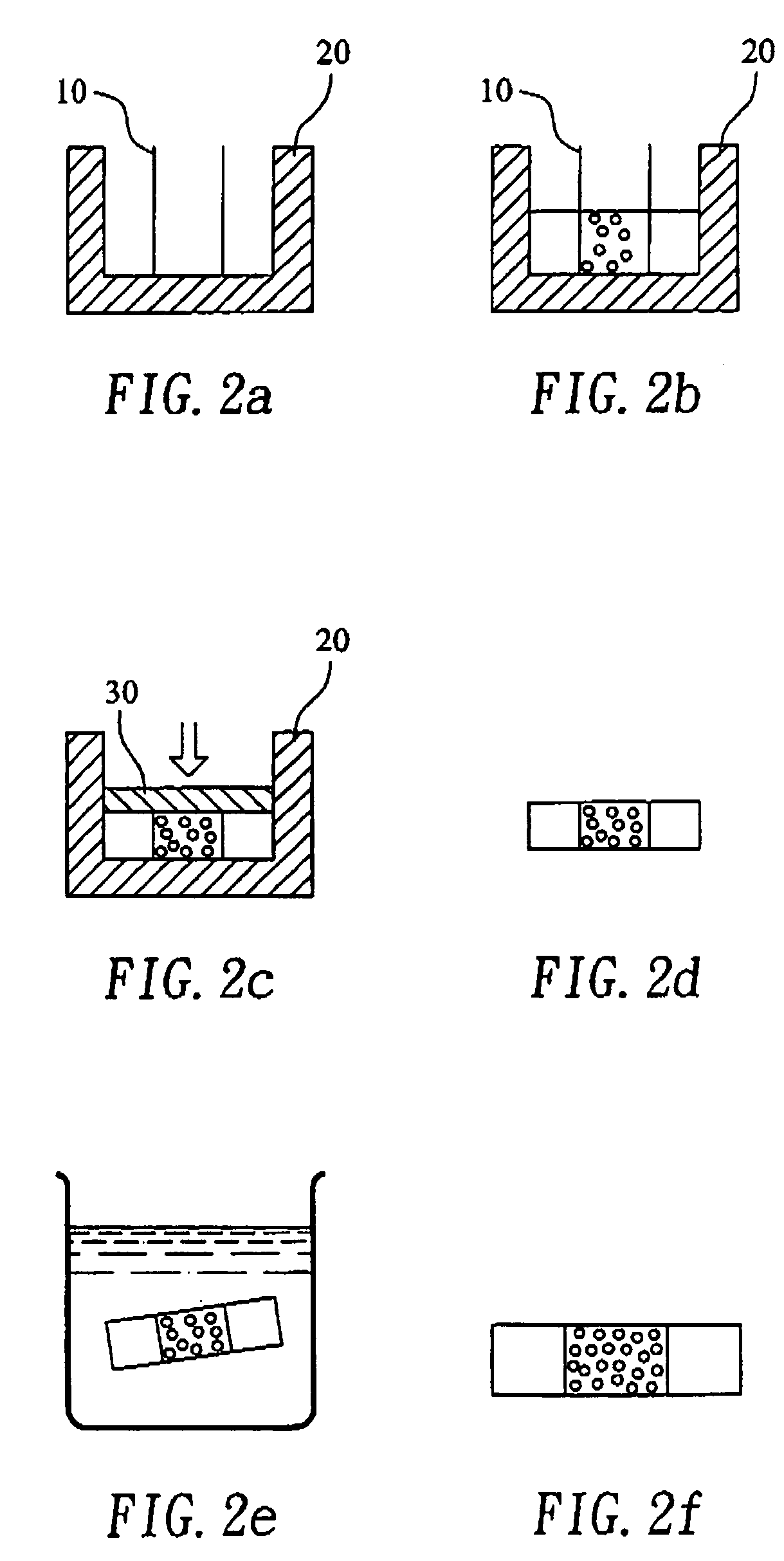

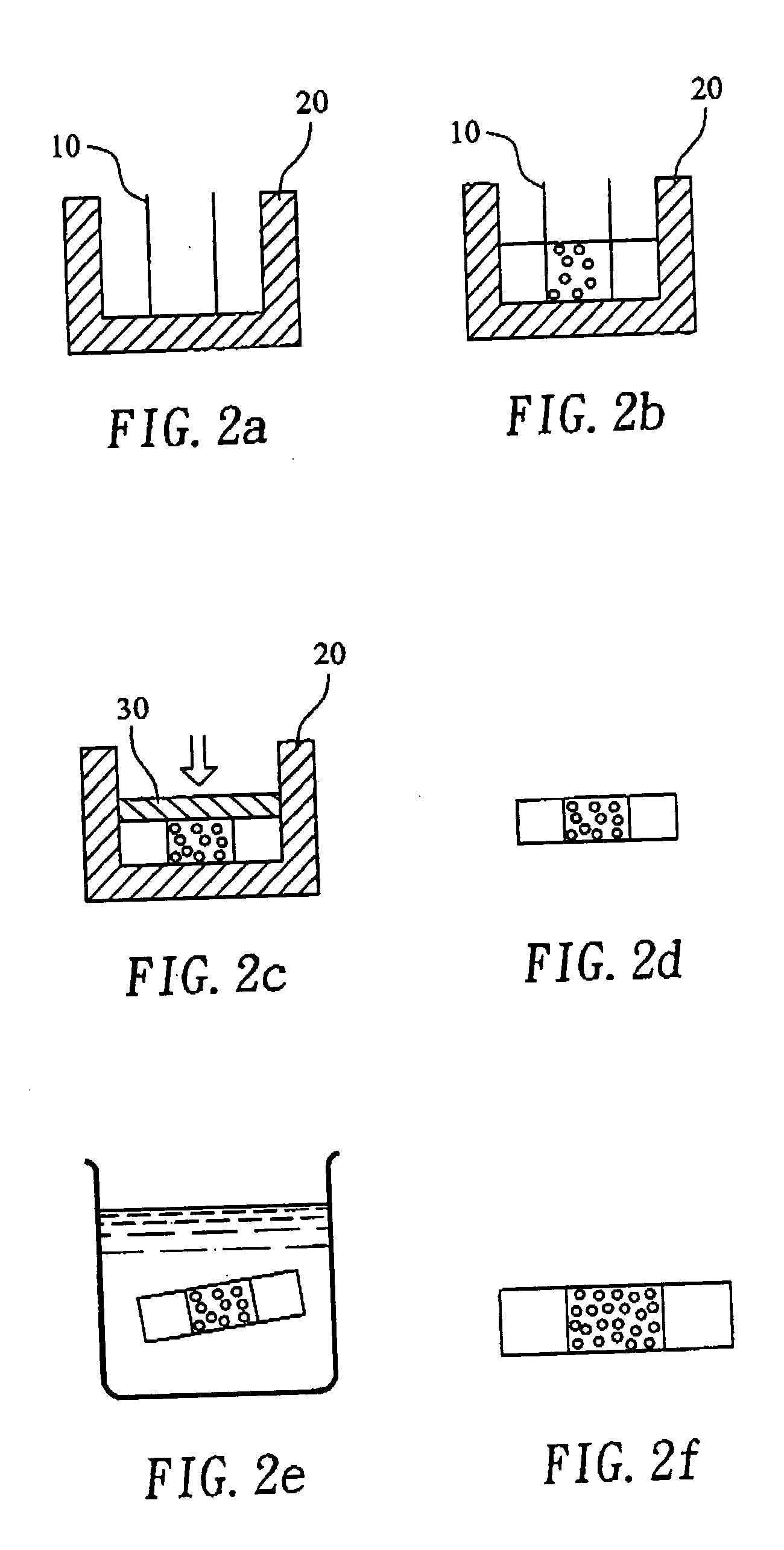

Method for making a porous calcium phosphate article

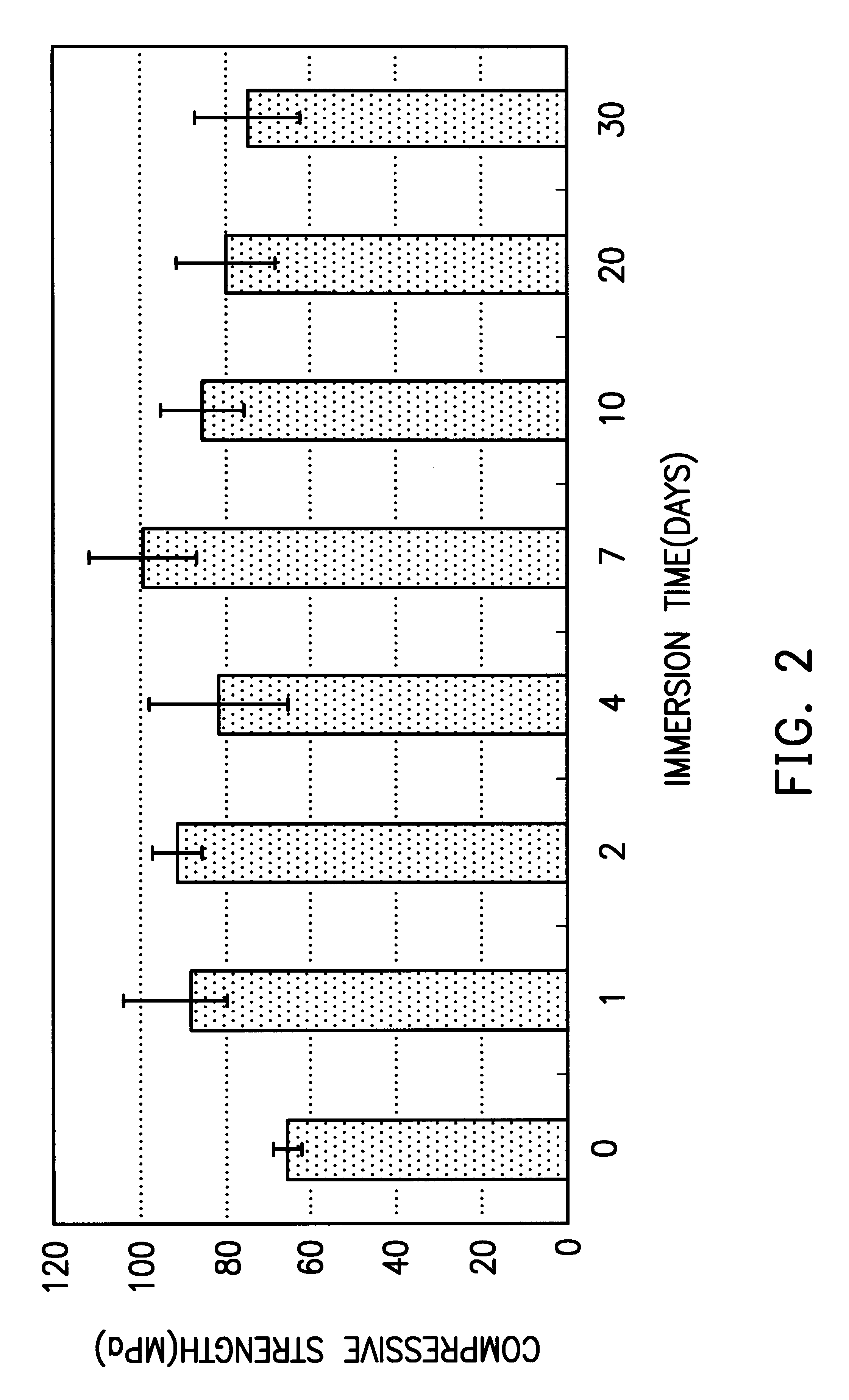

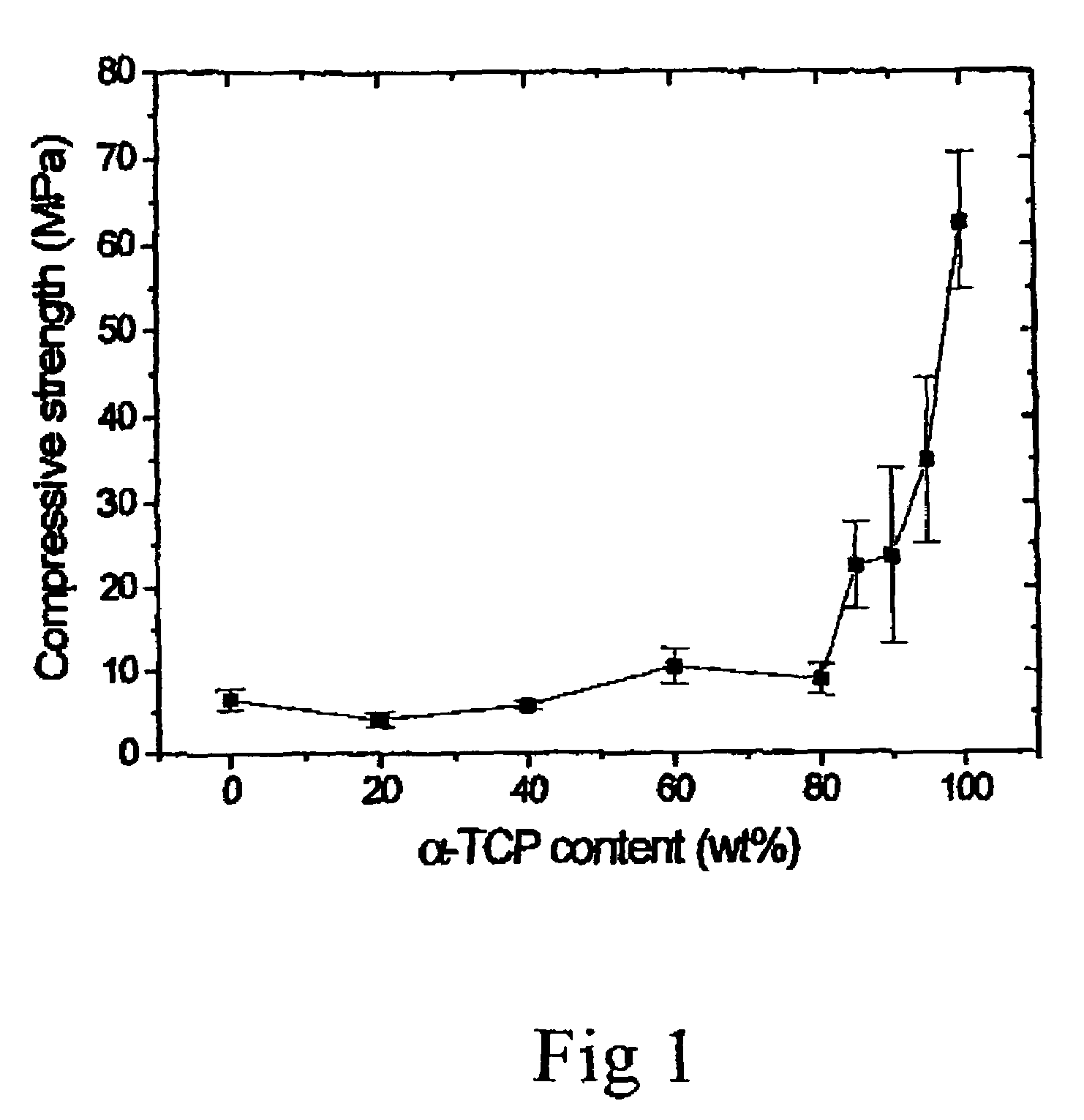

InactiveUS20050184417A1Improves bioresorbabilityPretreated surfacesCeramic shaping apparatusCalcium biphosphateCompressive strength

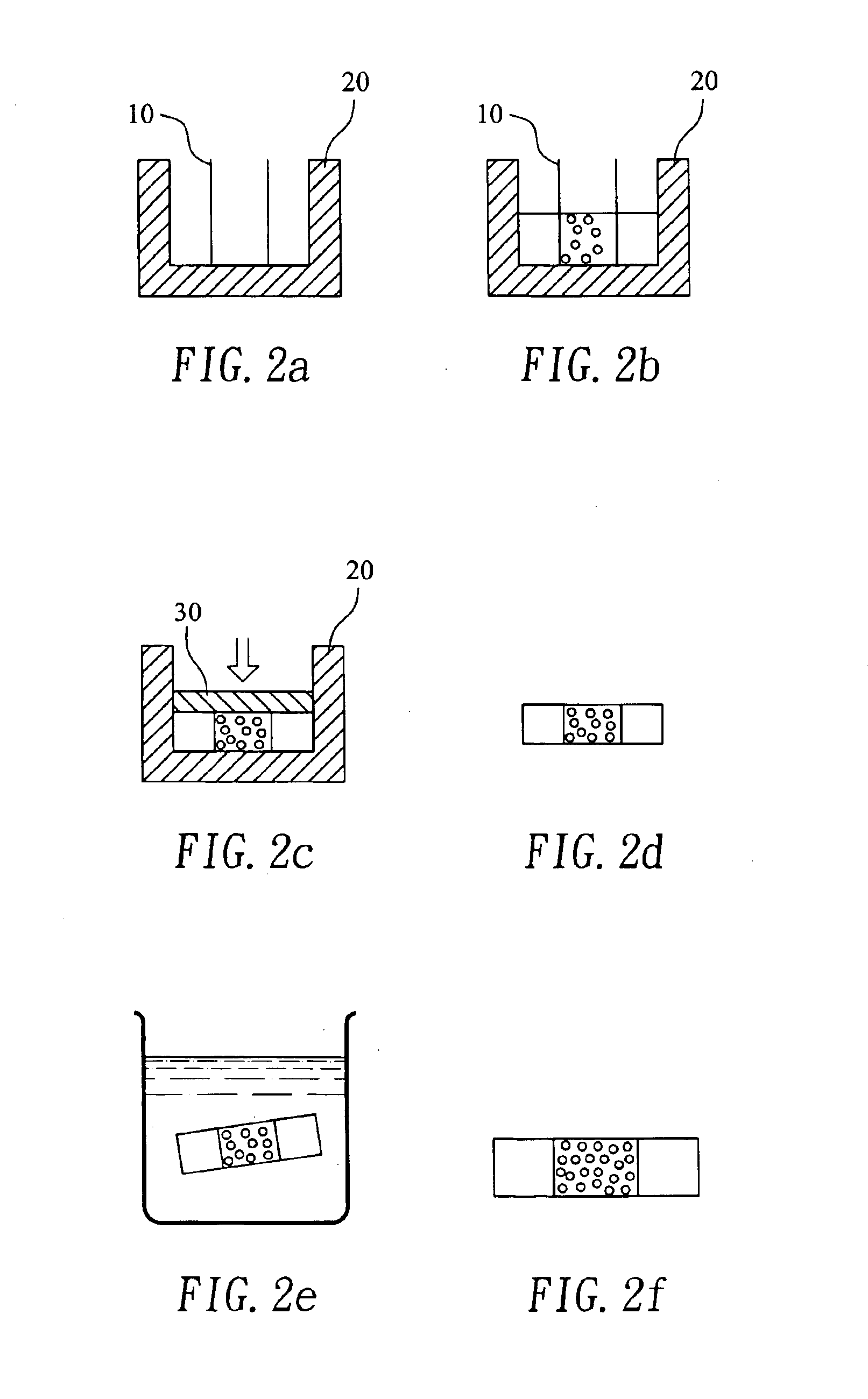

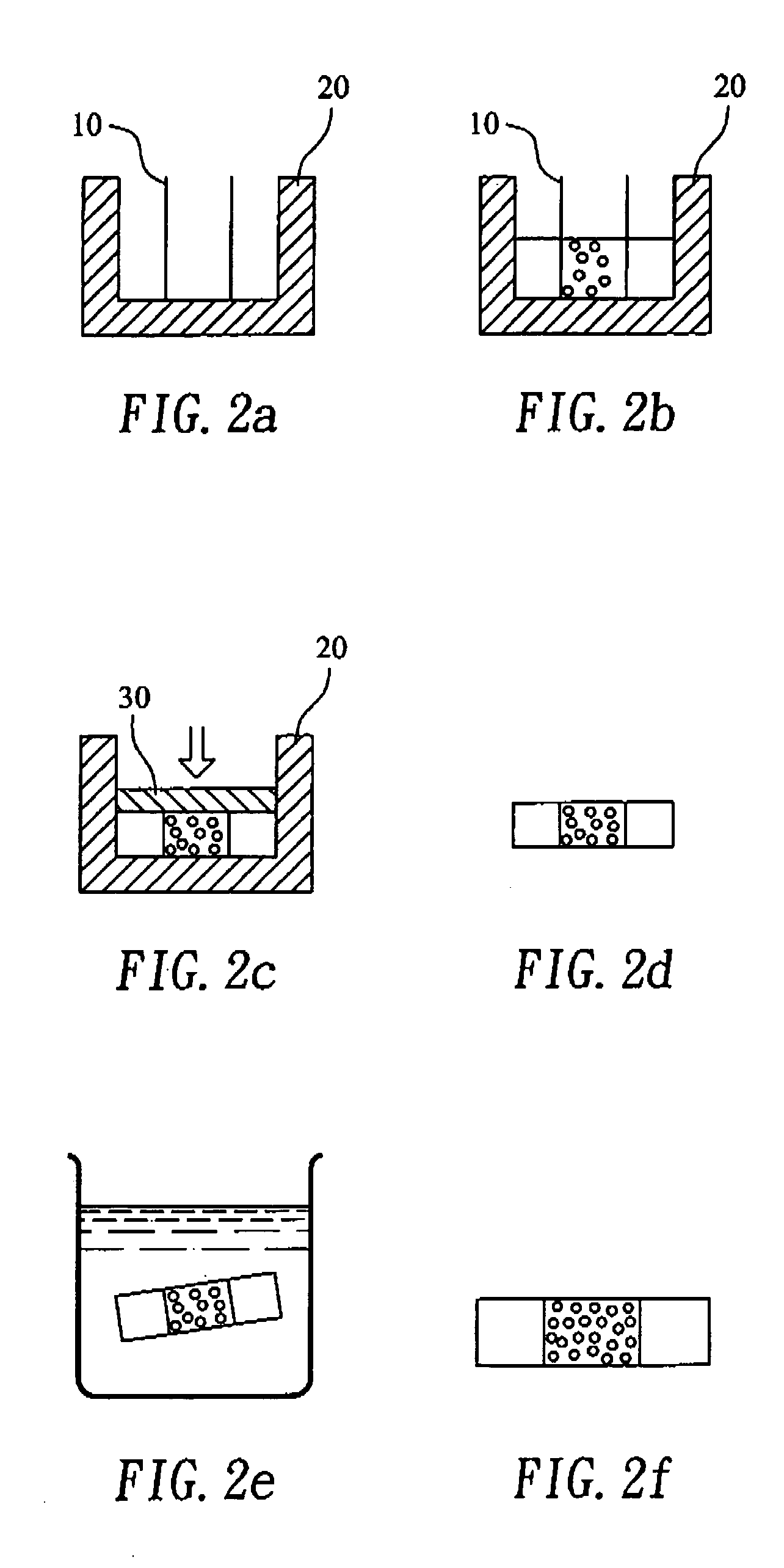

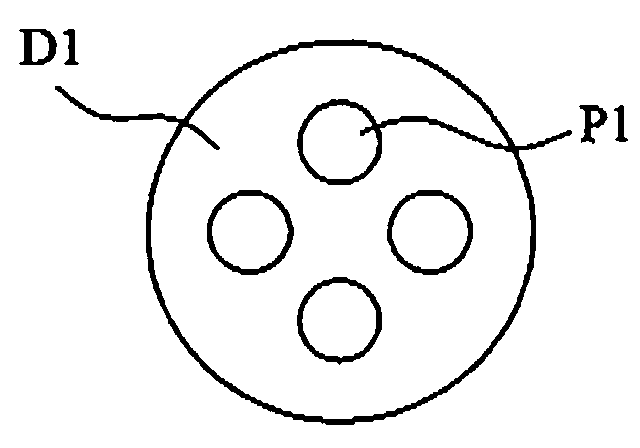

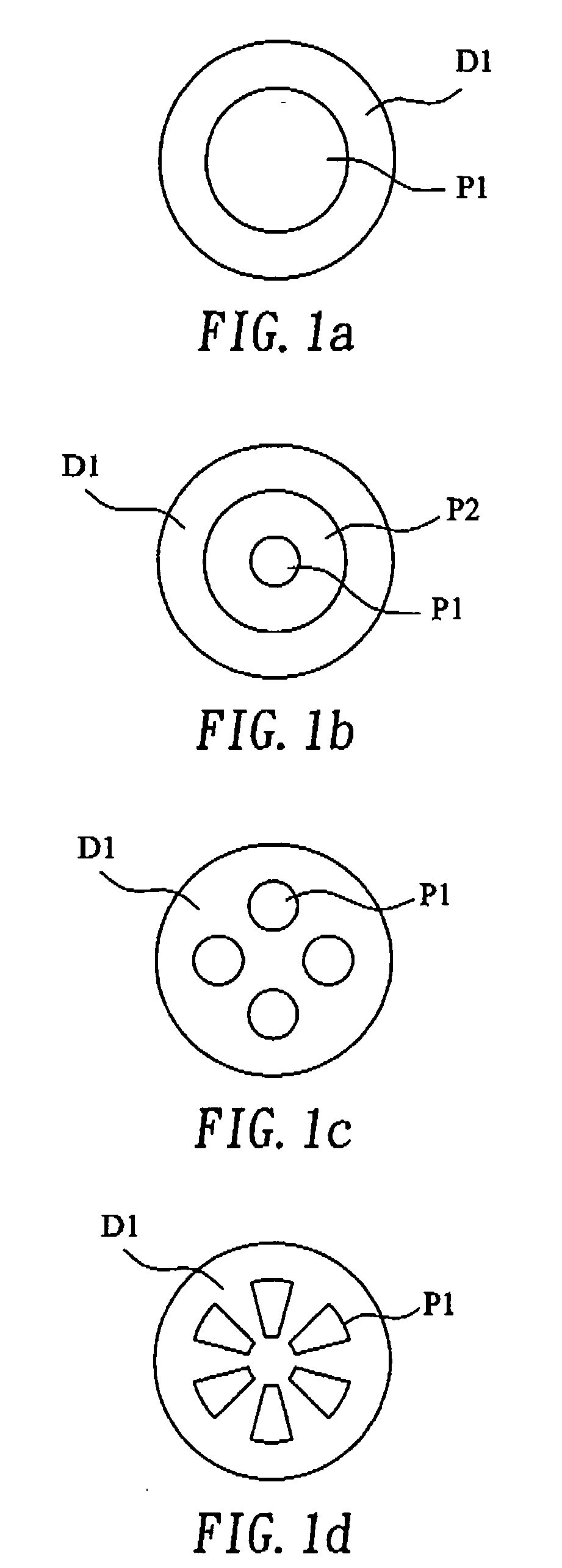

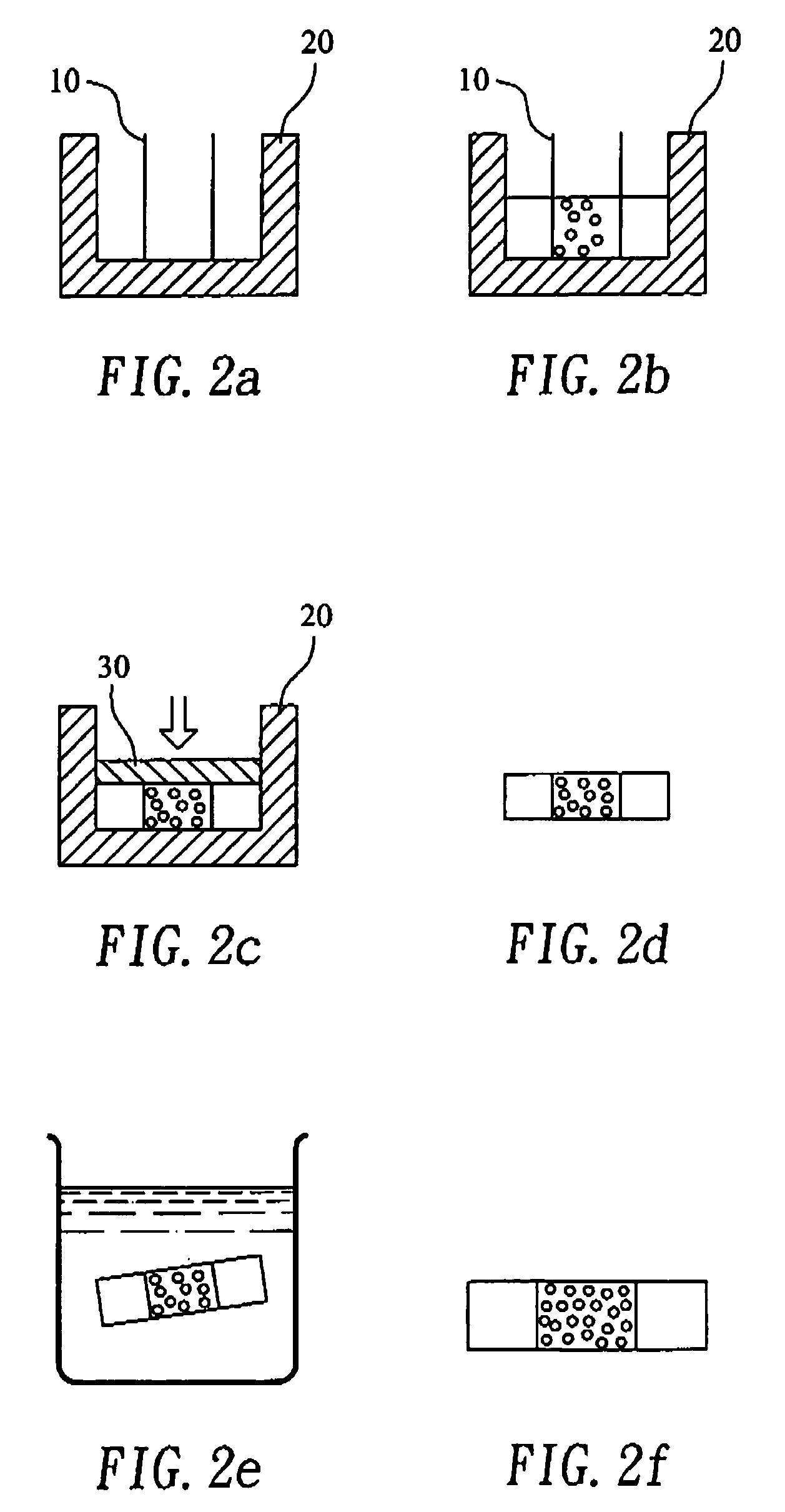

The present invention discloses a method for making a porous calcium phosphate article including i) preparing a shaped article from a paste containing a calcium phosphate cement, a pore-forming powder and a setting liquid; ii) immersing the shaped article in an immersing liquid for a period of time so that the pore-forming powder is dissolved in the immersing liquid, creating pores in said shaped article; and iii) removing the resulting porous shaped article from the immersing liquid, wherein the resulting porous shaped article has an improved compressive strength. The porous shaped calcium phosphate article of the present invention may be used as a tissue-engineered scaffold, medical implant or a reinforcing constituent of a composite.

Owner:CALCITEC

Method for making a porous calcium phosphate article

InactiveUS20050186354A1Improves bioresorbabilityBiocideInorganic phosphorous active ingredientsCalcium biphosphateCompressive strength

The present invention discloses a method for making a porous calcium phosphate article including i) preparing a shaped article from a paste containing a calcium phosphate cement, a pore-forming powder and a setting liquid; ii) immersing the shaped article in an immersing liquid for a period of time so that the pore-forming powder is dissolved in the immersing liquid, creating pores in said shaped article; and iii) removing the resulting porous shaped article from the immersing liquid, wherein the resulting porous shaped article has an improved compressive strength. The porous shaped calcium phosphate article of the present invention may be used as a tissue-engineered scaffold, medical implant or a reinforcing constituent of a composite.

Owner:CALCITEC

Pasty or liquid multiple constituent compositions for injectable calcium phosphate cements

InactiveUS20040244651A1Simple actionImpairment of mechanical propertyImpression capsSurgical adhesivesCalcium biphosphateInjectable bone

The invention concerns injectable bone filling cements, in particular hydraulic calcium phosphate cements, the latter being prepared from at least two initial liquid or pasty constituents comprising each a species reactive in solution or in suspension, the solidification process being initiated when said constituents are being mixed.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Rapid-hardening calcium phosphate cement compositions

InactiveUS20050074415A1Resist erosionEasy and fast setupCosmetic preparationsBiocideCalcium biphosphateApatite

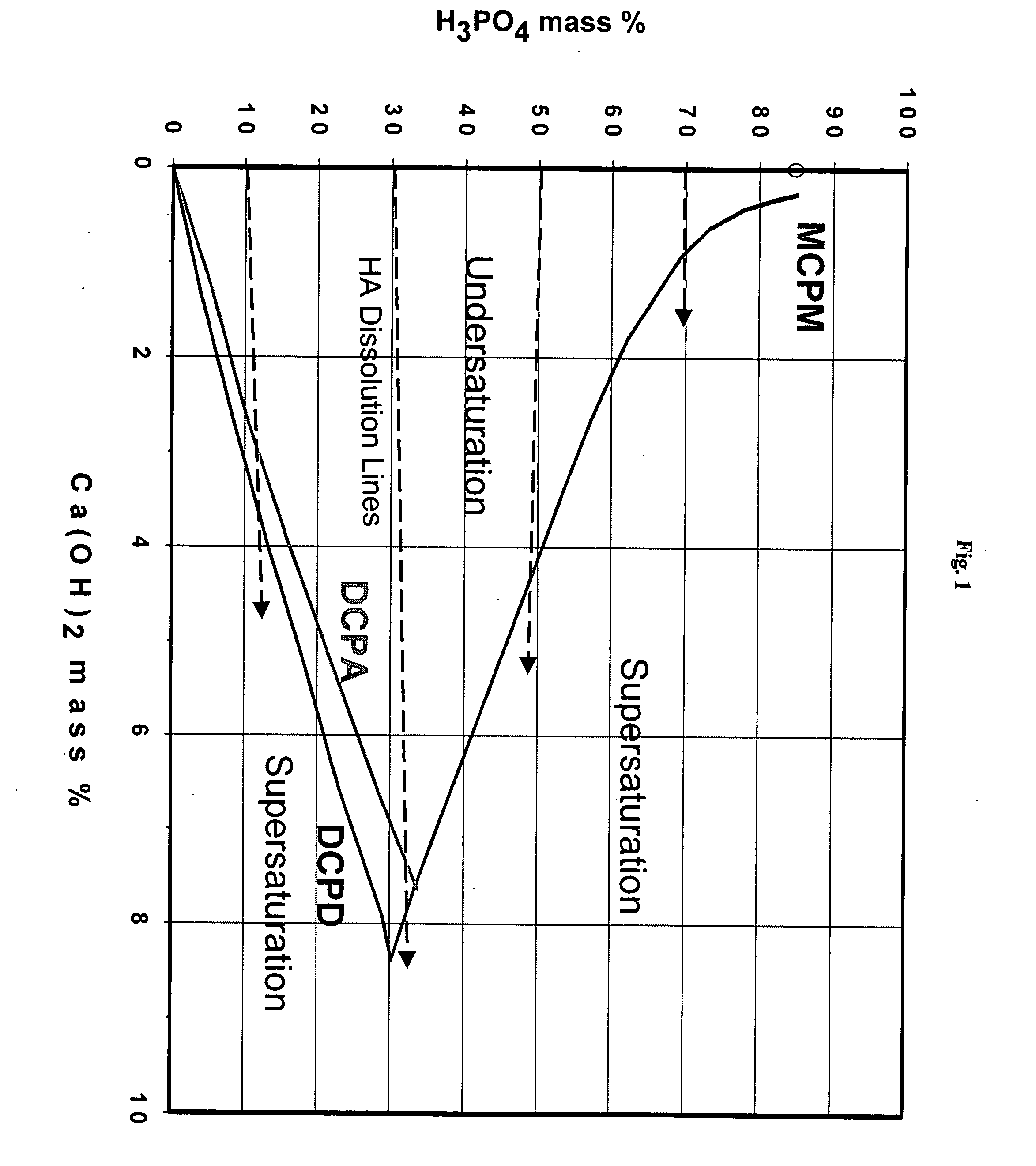

A bone or dental implant material in the form of a paste includes a mixture of calcium phosphate and / or calcium-containing powders and a solution that is (1) an acidic calcium phosphate solution saturated with respect to one or more calcium phosphate compounds, (2) a concentrated acid solution, or (3) salt solutions with a cationic component other than calcium. The paste is stable, resistant to washout and will form hydroxyapatite and harden relatively rapidly to a cement.

Owner:ADA FOUND

Method for making a porous calcium phosphate article

InactiveUS20050186353A1Improves bioresorbabilityPharmaceutical containersPretreated surfacesCalcium biphosphateCompressive strength

The present invention discloses a method for making a porous calcium phosphate article including i) preparing a shaped article from a paste containing a calcium phosphate cement, a pore-forming powder and a setting liquid; ii) immersing the shaped article in an immersing liquid for a period of time so that the pore-forming powder is dissolved in the immersing liquid, creating pores in said shaped article; and iii) removing the resulting porous shaped article from the immersing liquid, wherein the resulting porous shaped article has an improved compressive strength. The porous shaped calcium phosphate article of the present invention may be used as a tissue-engineered scaffold, medical implant or a reinforcing constituent of a composite.

Owner:CALCITEC

Magnesium phosphate cement based rapid repair mortar and preparation method thereof

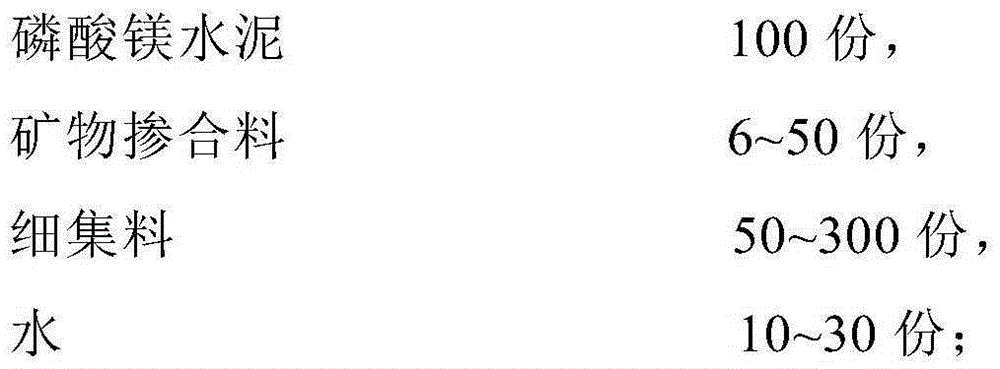

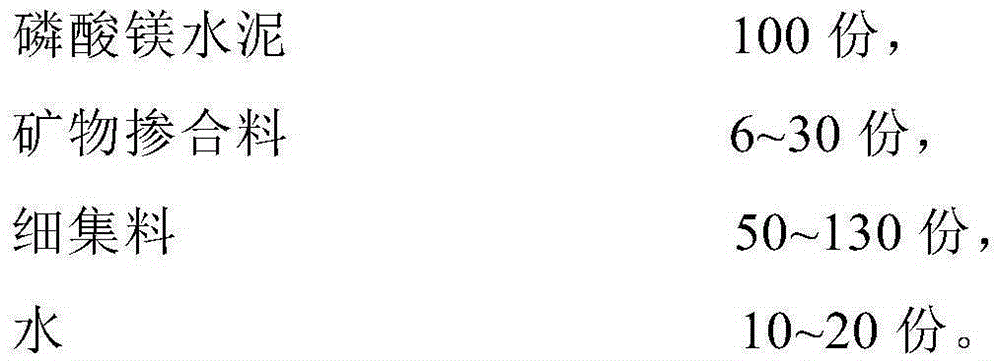

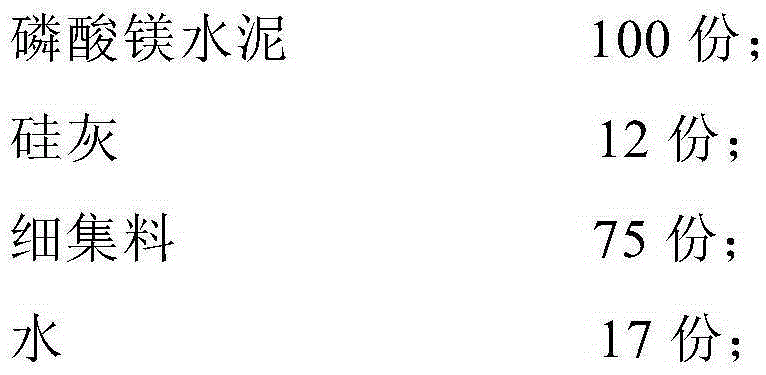

ActiveCN105272138AGuaranteed water resistanceImprove performance indicatorsMagnesium phosphateMagnesium orthophosphate

The invention relates to a magnesium phosphate cement based rapid repair mortar and a preparation method thereof. The rapid repair mortar includes the following components by weight: 100 parts of magnesium phosphate cement, 6-50 parts of a mineral admixture, 50-300 parts of fine aggregate, and 10-30 parts of water. The magnesium phosphate cement is obtained by mixing of, by weight, 60-70 parts of metal oxide powder, 20-28 parts of phosphate, 3-6 parts of a retarder and 4-6 parts of a coagulation regulating component. The magnesium phosphate cement based rapid repair mortar is prepared by adopting magnesium phosphate cement as the cementing material, adopting dipotassium phosphate for coagulation regulating modification, and using sand as the fine aggregate, then adding a proper amount of mineral admixture, and performing mixing with water. Compared with the prior art, the magnesium phosphate cement based rapid repair mortar provided by the invention has the advantages of controllable coagulation time, high bonding strength, good stability and high water resistance, etc.

Owner:TONGJI UNIV

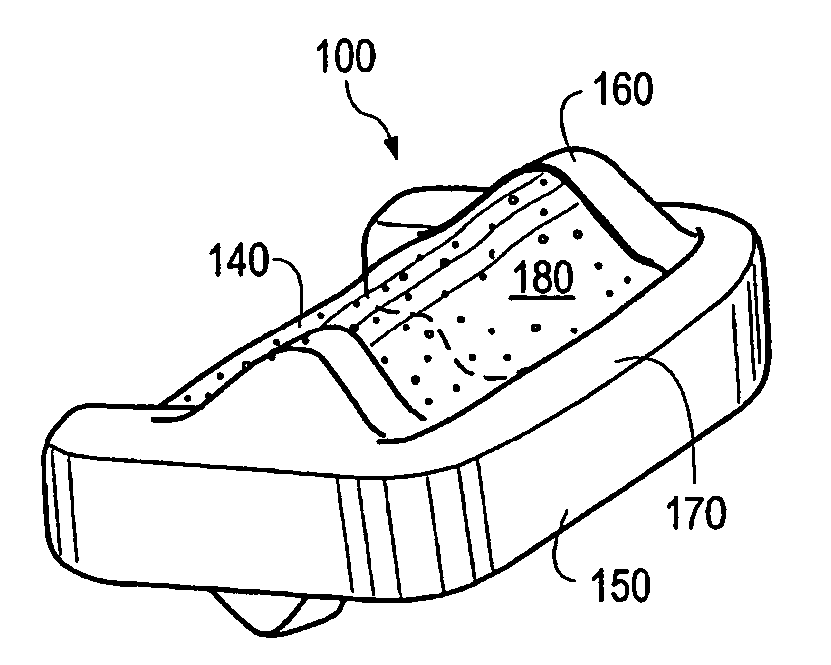

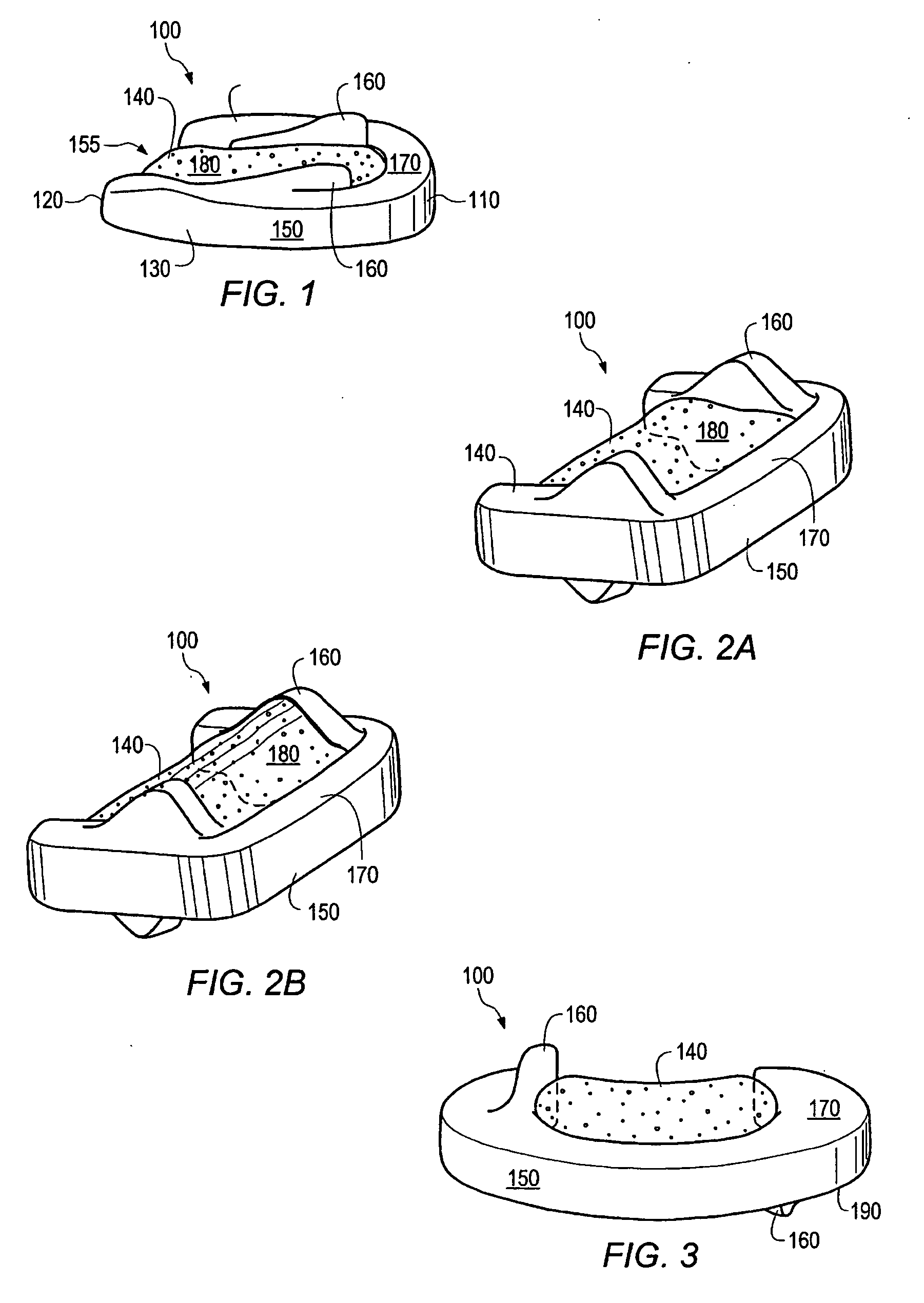

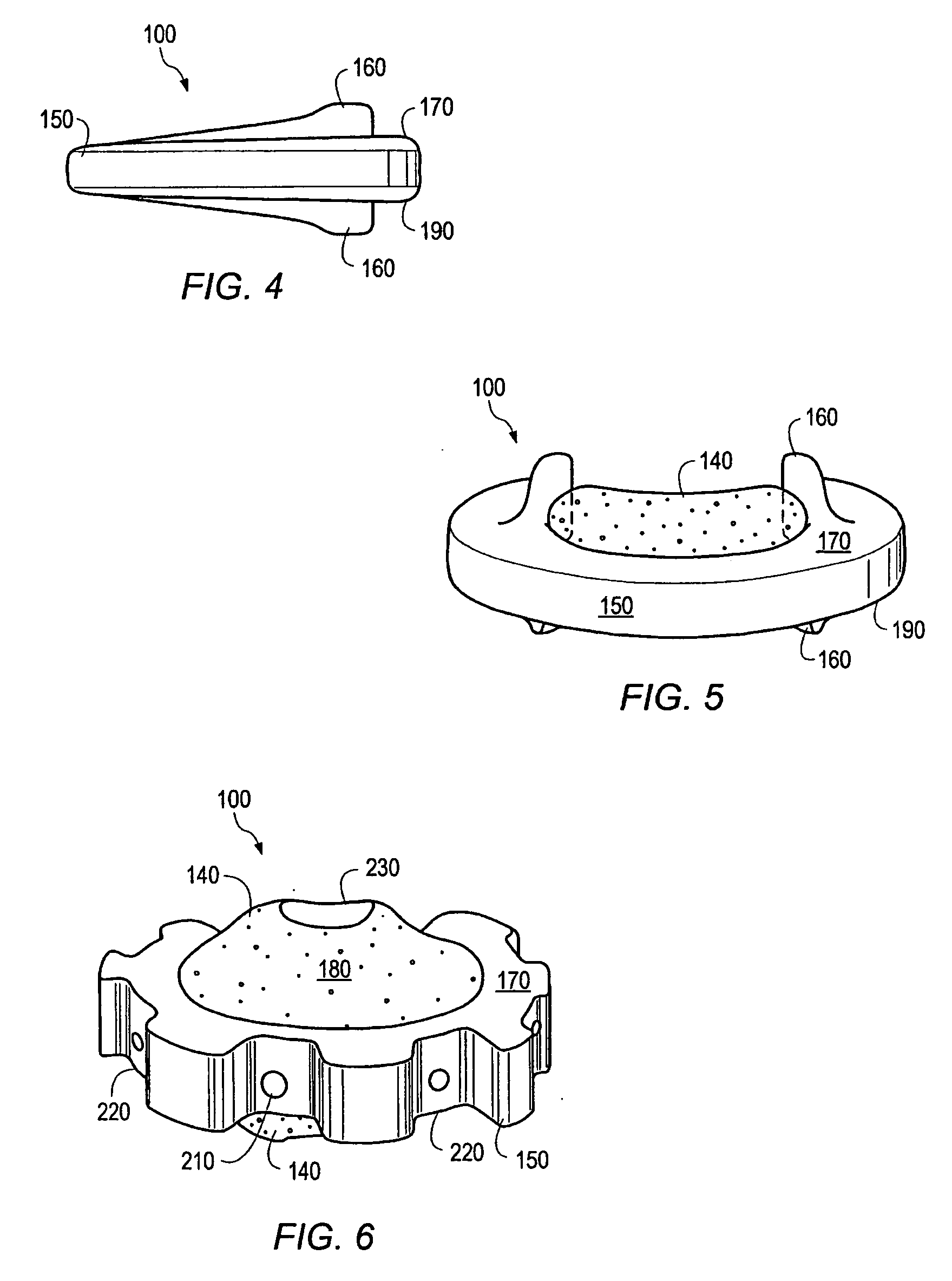

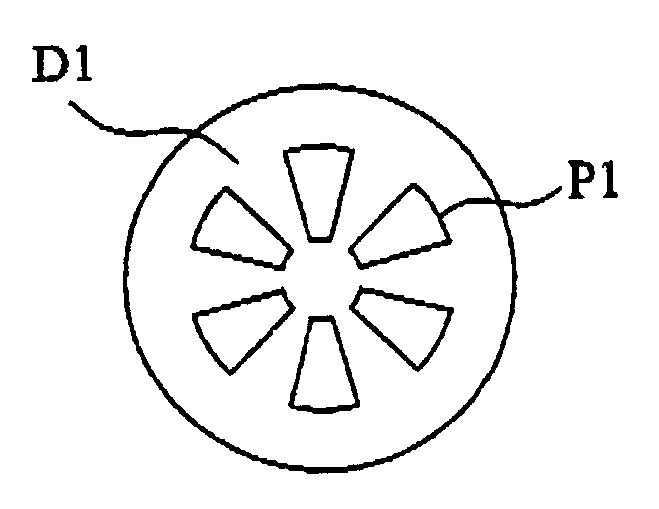

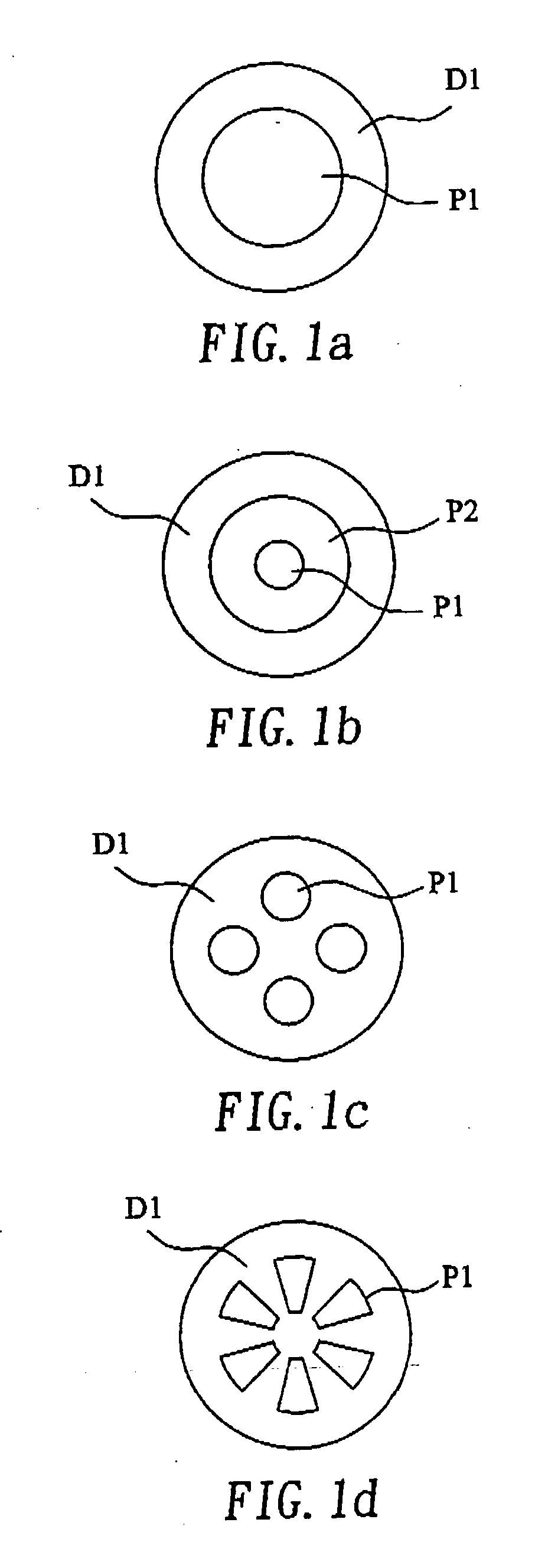

Hardened calcium phosphate cement bone implants

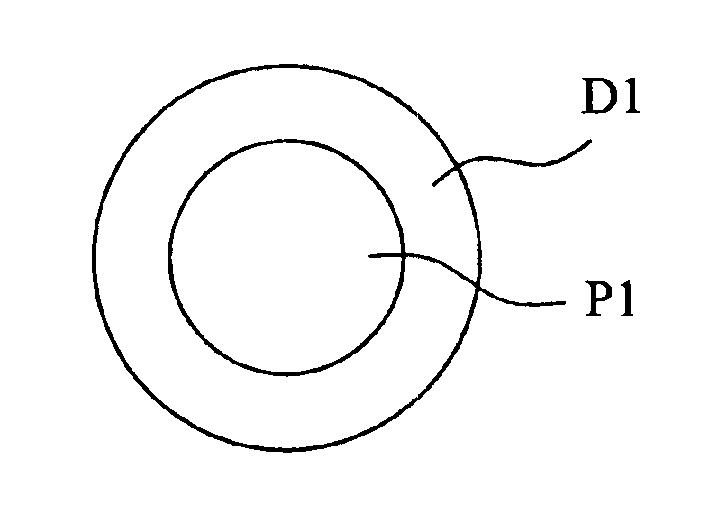

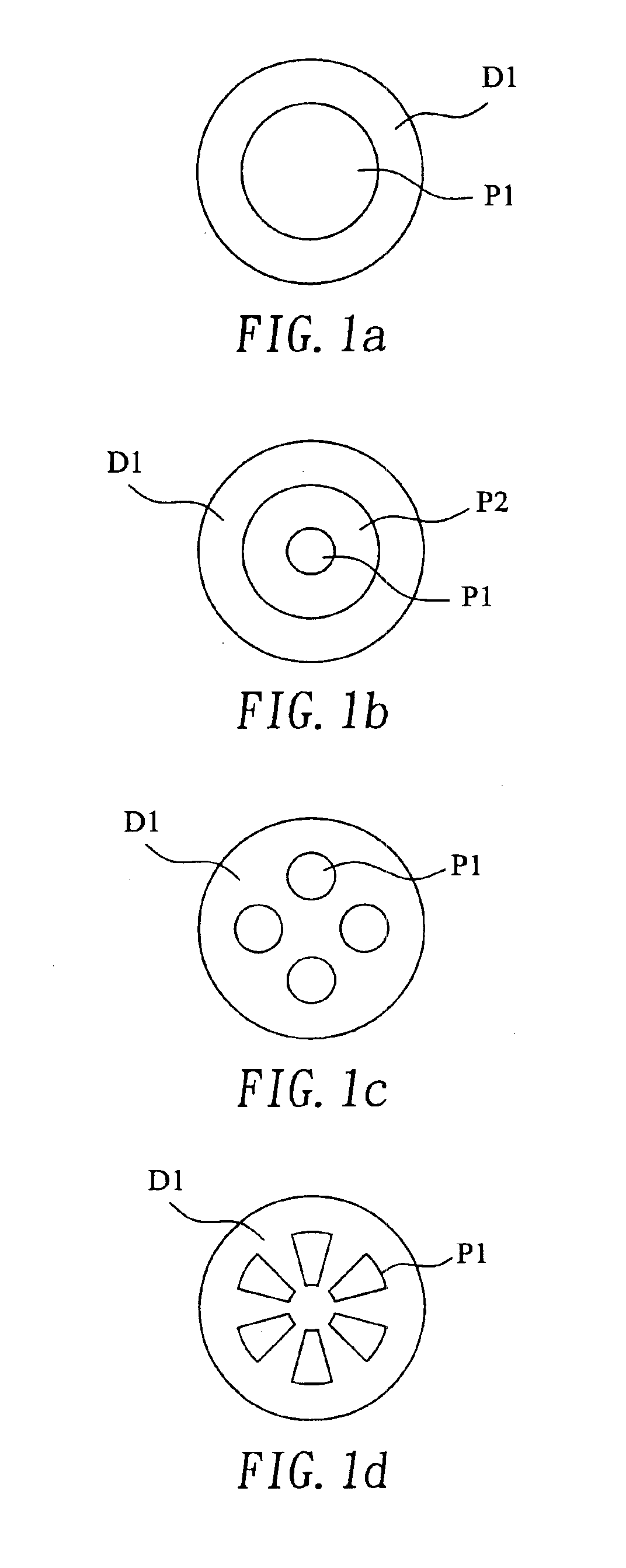

In some embodiments, an implant may include a porous component and a load bearing component at least partially surrounding the porous component. The porous component has a porosity that is greater than the porosity of the load bearing component. One or more protrusions may be present on the load bearing component. The porous component and / or a load bearing component may be at least partially composed of calcium phosphate.

Owner:CALCITEC

Preparation method of an in situ pore-forming self-setting calcium phosphate composite tissue engineering scaffold

The invention discloses a making method of composite tissue engineering rack of original poring self-solidifying calcium phosphate, which comprises the following steps: placing porous rack of calcium phosphate cement into drier to dry; immersing porous rack into macromolecular solution; extracting into vacuum for 0.5-6h; injecting macromolecular material into the pore of porous rack of calcium phosphate cement; drying the surface of porous rack through filter paper; pre-freezing under -60- -4 deg.c for 1-48h; drying the frozen material to do multiple injections until the pore is filled with cement; obtaining the product.

Owner:SOUTH CHINA UNIV OF TECH

Method for making a porous calcium phosphate article

InactiveUS20050186449A1Improves bioresorbabilityLayered productsPretreated surfacesCalcium biphosphateCompressive strength

The present invention discloses a method for making a porous calcium phosphate article including i) preparing a shaped article from a paste containing a calcium phosphate cement, a pore-forming powder and a setting liquid; ii) immersing the shaped article in an immersing liquid for a period of time so that the pore-forming powder is dissolved in the immersing liquid, creating pores in said shaped article; and iii) removing the resulting porous shaped article from the immersing liquid, wherein the resulting porous shaped article has an improved compressive strength. The porous shaped calcium phosphate article of the present invention may be used as a tissue-engineered scaffold, medical implant or a reinforcing constituent of a composite.

Owner:CALCITEC

Method for making a porous calcium phosphate article

InactiveUS20050184418A1Improves bioresorbabilityPretreated surfacesCeramic shaping apparatusCalcium biphosphateCompressive strength

The present invention discloses a method for making a porous calcium phosphate article including i) preparing a shaped article from a paste containing a calcium phosphate cement, a pore-forming powder and a setting liquid; ii) immersing the shaped article in an immersing liquid for a period of time so that the pore-forming powder is dissolved in the immersing liquid, creating pores in said shaped article; and iii) removing the resulting porous shaped article from the immersing liquid, wherein the resulting porous shaped article has an improved compressive strength. The porous shaped calcium phosphate article of the present invention may be used as a tissue-engineered scaffold, medical implant or a reinforcing constituent of a composite.

Owner:CALCITEC

Rapid-hardening calcium phosphate cement compositions

InactiveUS7294187B2Easy and fast setupShorten hardening timeBiocideCosmetic preparationsCalcium biphosphateApatite

Owner:ADA FOUND

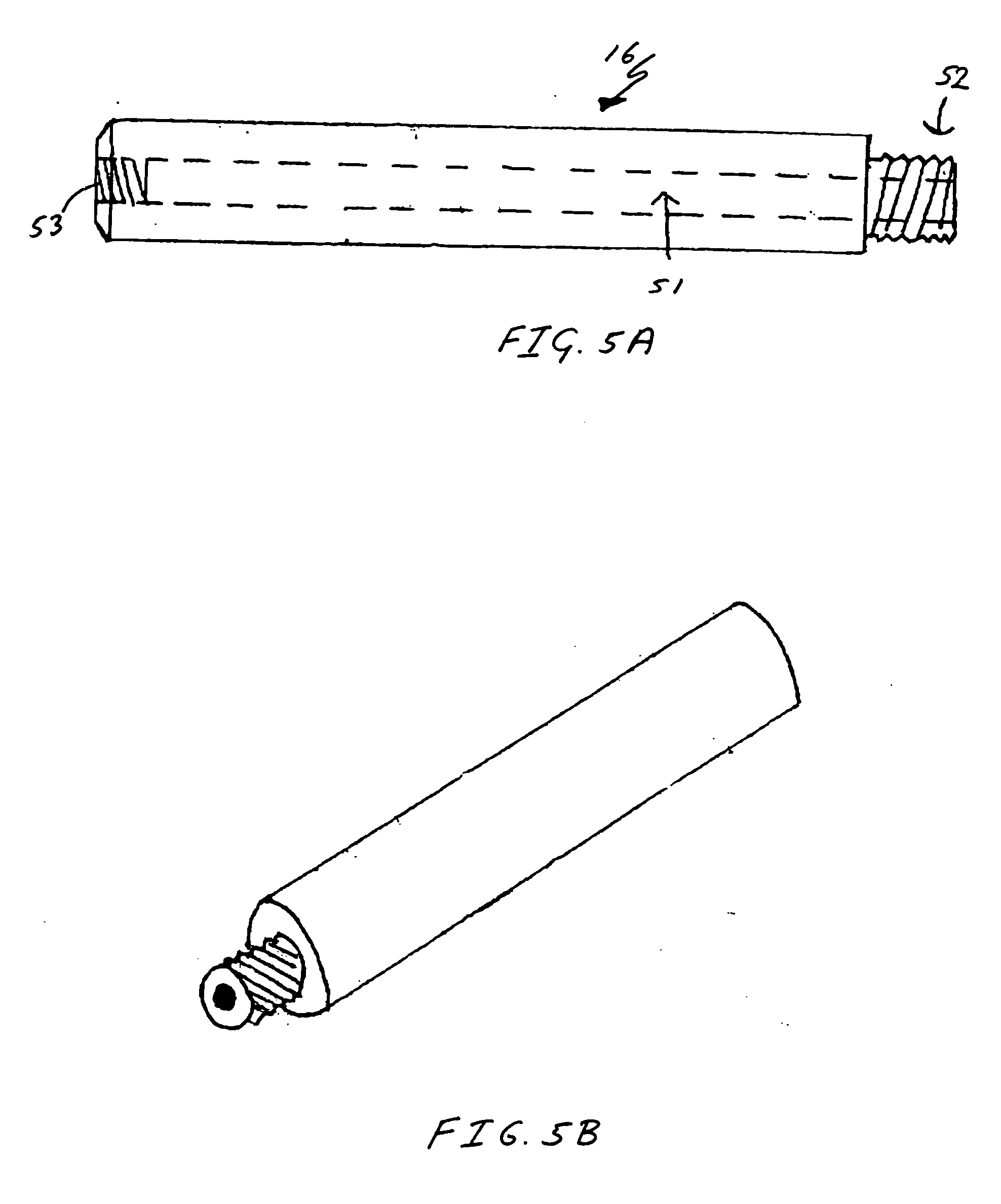

Methods and devices for delivering orthopedic cements to a target bone site

InactiveUS20050058717A1BiocideInorganic phosphorous active ingredientsSubject matterBiomedical engineering

Methods and devices are provided for delivery an orthopedic, e.g., calcium phosphate cement to a target bone site. In practicing the subject methods, a flowable cement composition is delivered to a target bone site in conjunction with vibration. Also provided are the devices that deliver a flowable cement to a target bone site according to the subject methods. Introducing a flowable cement to a target bone site in conjunction with vibration in accordance with the subject methods provides for highly controlled penetration of the delivered cement throughout the target bone site without the use of substantial pressure. The subject devices and methods find use in a variety of different applications, and are particularly suited for use in applications where a calcium phosphate cement is to be delivered to cancellous tissue, e.g., as found in a vertebral body.

Owner:SKELETAL KINETICS

Composition for an injectable bone mineral substitute material

InactiveUS7417077B2High mechanical strengthHigh viscosityBiocidePowder deliveryCalcium biphosphateInjectable bone

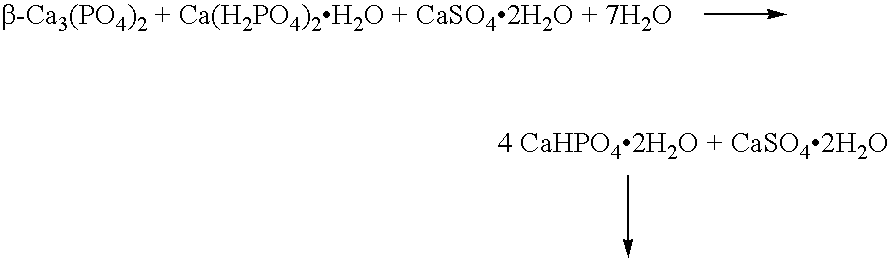

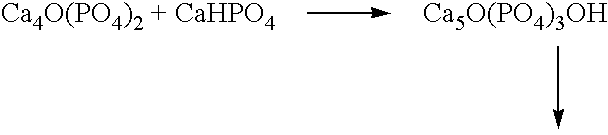

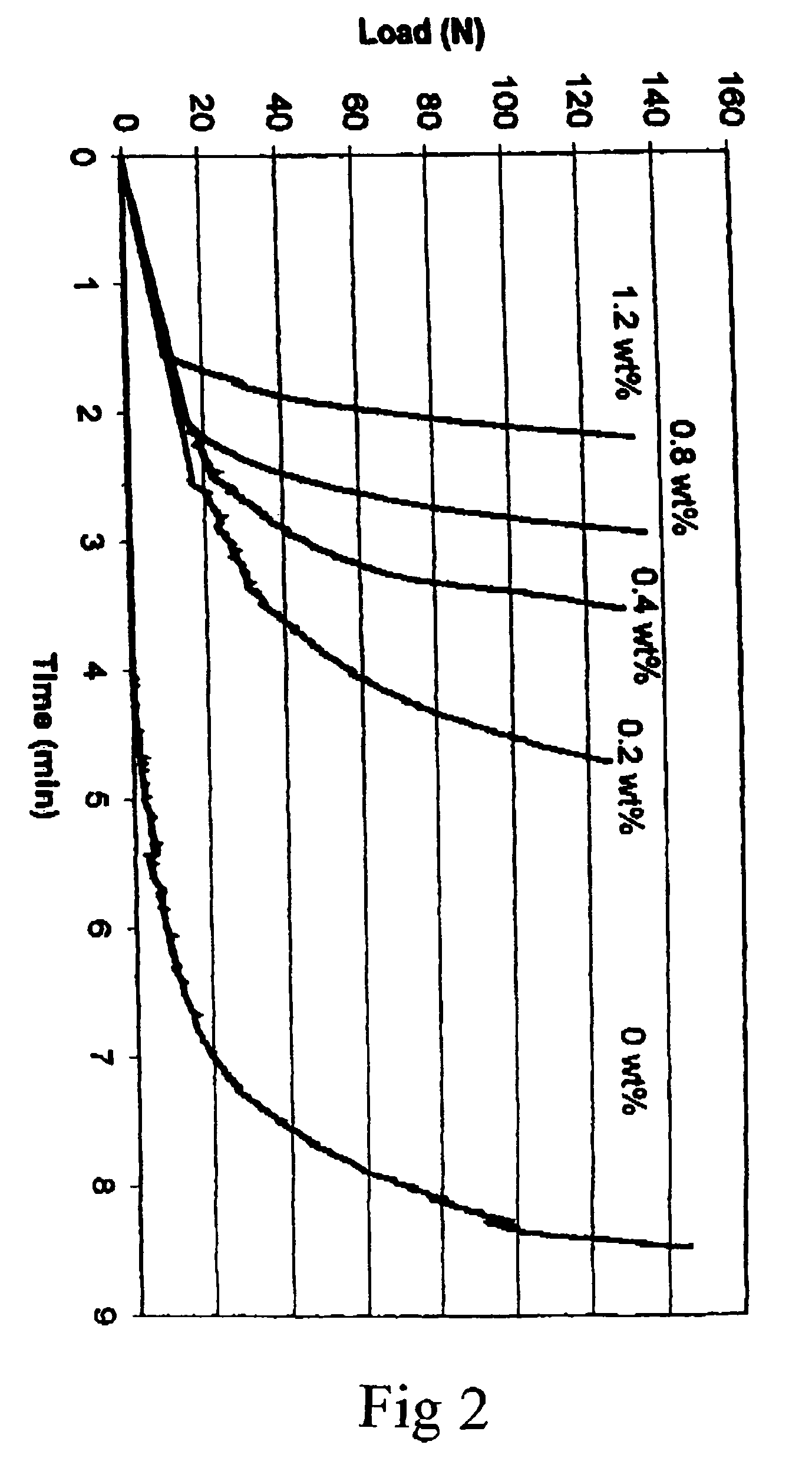

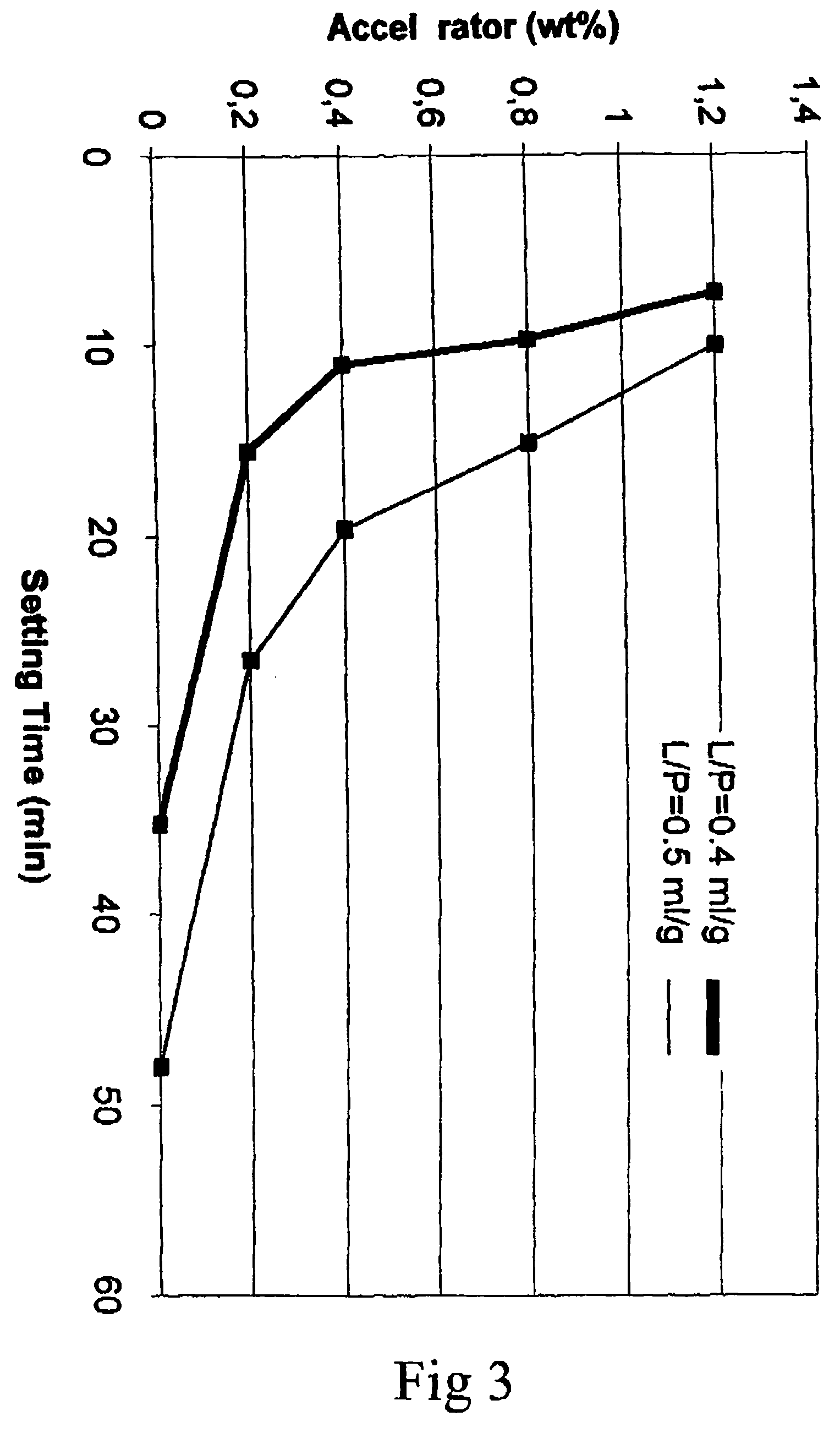

The invention refers to an injectable composition for a bone mineral substitute material, which comprises a dry powder mixed with an aqueous liquid. The powder comprises a first reaction component comprising a calcium sulphate hemihydrate with the capability of being hardened to calcium sulphate dihydrate when reacting with said aqueous liquid; a second reaction component, which comprise a calcium phosphate with the capability of being hardened to a calcium phosphate cement when reacting with said aqueous liquid; and at least one accelerator for the reaction of said first and / or second reaction component with said aqueous liquid. A method of producing an injectable bone mineral substitute material is also provided, wherein the composition is mixed in a closed mixing and delivery system for delivery.

Owner:BONE SUPPORT

Method of increasing working time of tetracalcium phosphate cement paste

InactiveUS20050069479A1Convenience to workHigh compressive strengthImpression capsPhosphatesPhosphoric acidCement paste

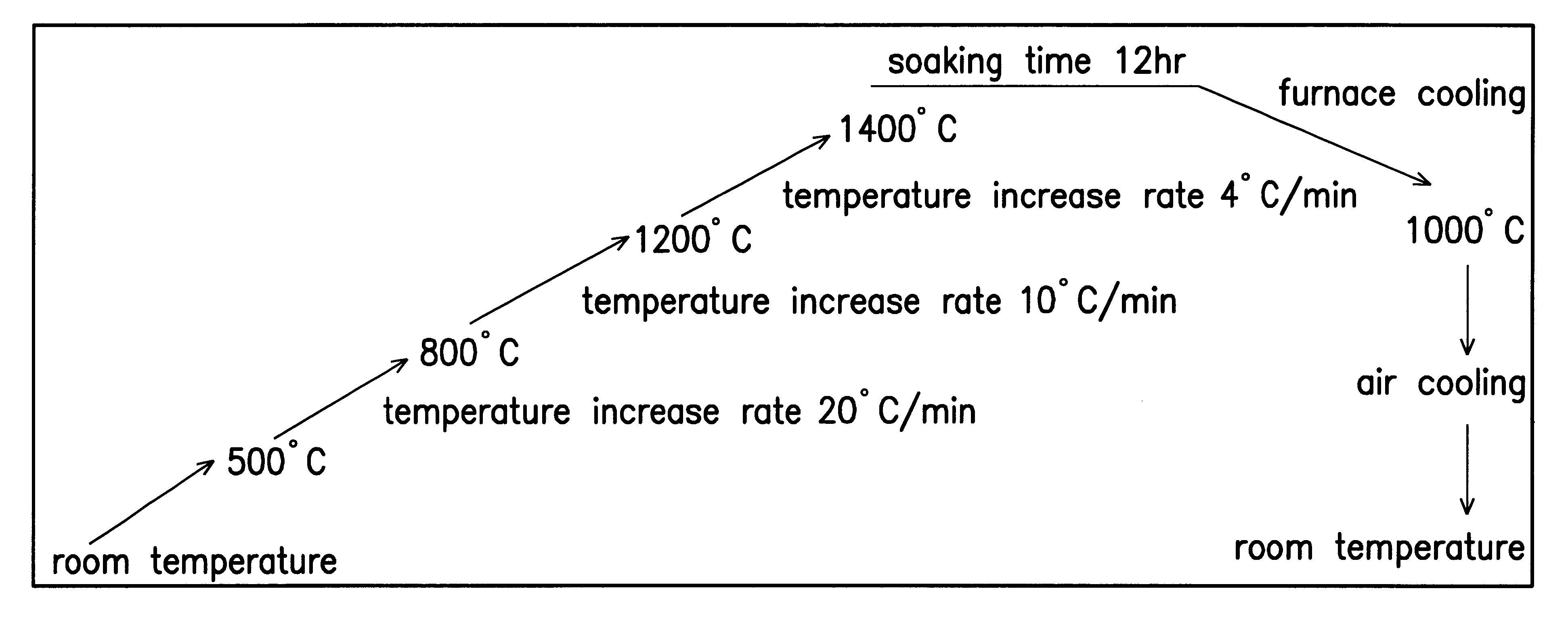

A method for increasing working time / setting time of monolithic tetracalcium phosphate (TTCP) cement paste formed by mixing a TTCP powder with an aqueous solution, which includes heating the TTCP powder, prior to the mixing, so that the TTCP powder is maintained at a temperature of 50-350° C. for a period of time which is greater than one minute, and that a TTCP cement paste formed by mixing the resulting heated TTCP powder with the aqueous solution has a prolonged working time in comparison with that formed by mixing TTCP powder that has not been subjected to such heating with the aqueous solution.

Owner:CALCITEC

Medicine controlled functional cement with calcium phosphate being as framework and its preparation method

A calcium phosphate cement with the function of controlling medicine release for repairing dysostosis, treating osteomyelitis and preventing infection and recurrence of osteoma is prepared from porous calcium phosphate cement and medicine capsules containing antibacterial medicine, antineoplastic medicine, anti-flammatory antalgic medicine, antituberculosis, etc. Its advantages are slow medicinesreleasing, and high curative effect.

Owner:EAST CHINA UNIV OF SCI & TECH

Pasty or liquid multiple constituent compositions for injectable calcium phosphate cements

The invention concerns injectable bone filling cements, in particular hydraulic calcium phosphate cements, the latter being prepared from at least two initial liquid or pasty constituents comprising each a species reactive in solution or in suspension, the solidification process being initiated when said constituents are being mixed.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Dual function prosthetic bone implant and method for preparing the same

InactiveUS20050267589A1Rapid blood/body fluid penetrationRapid tissue ingrowthBone implantWood working apparatusMedicineApatite

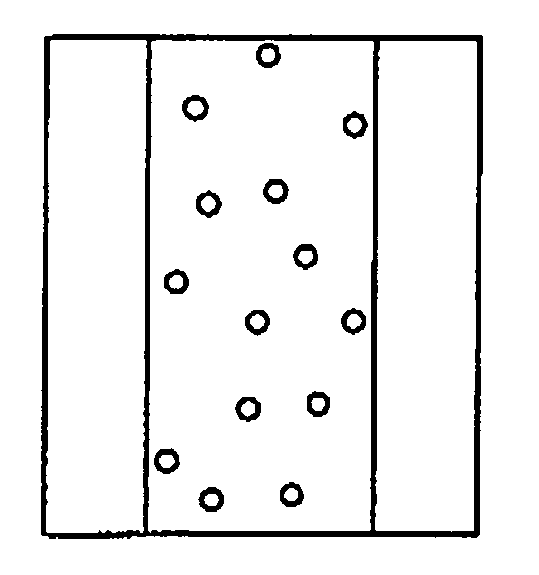

The present invention discloses a prosthetic bone implant made of a hardened calcium phosphate cement having an apatitic phase as a major phase, which includes a dense cortical portion bearing the majority of load and a porous cancellous portion allowing a rapid blood / body fluid penetration and tissue ingrowth.

Owner:CALCITEC

Dual function prosthetic bone implant and method for preparing the same

InactiveUS20050267588A1Rapid blood/body fluid penetrationRapid tissue ingrowthBone implantWood working apparatusApatiteBone implant

The present invention discloses a prosthetic bone implant made of a hardened calcium phosphate cement having an apatitic phase as a major phase, which includes a dense cortical portion bearing the majority of load and a porous cancellous portion allowing a rapid blood / body fluid penetration and tissue ingrowth.

Owner:CALCITEC

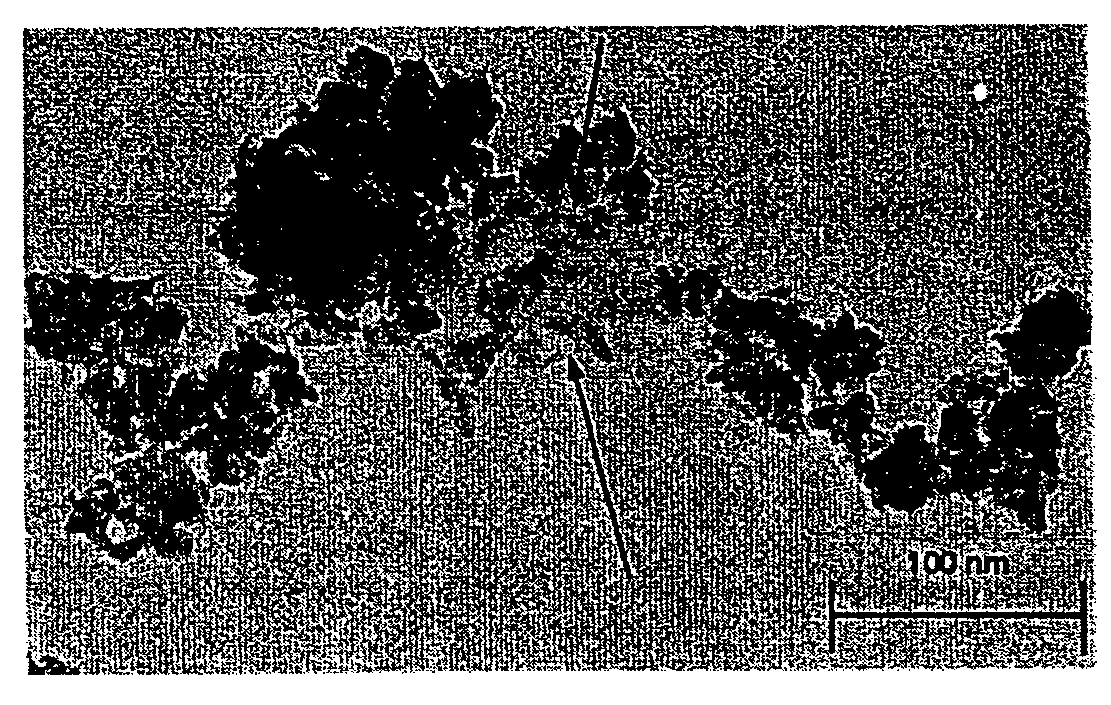

Injectable calcium phosphate cements and the preparation and use thereof

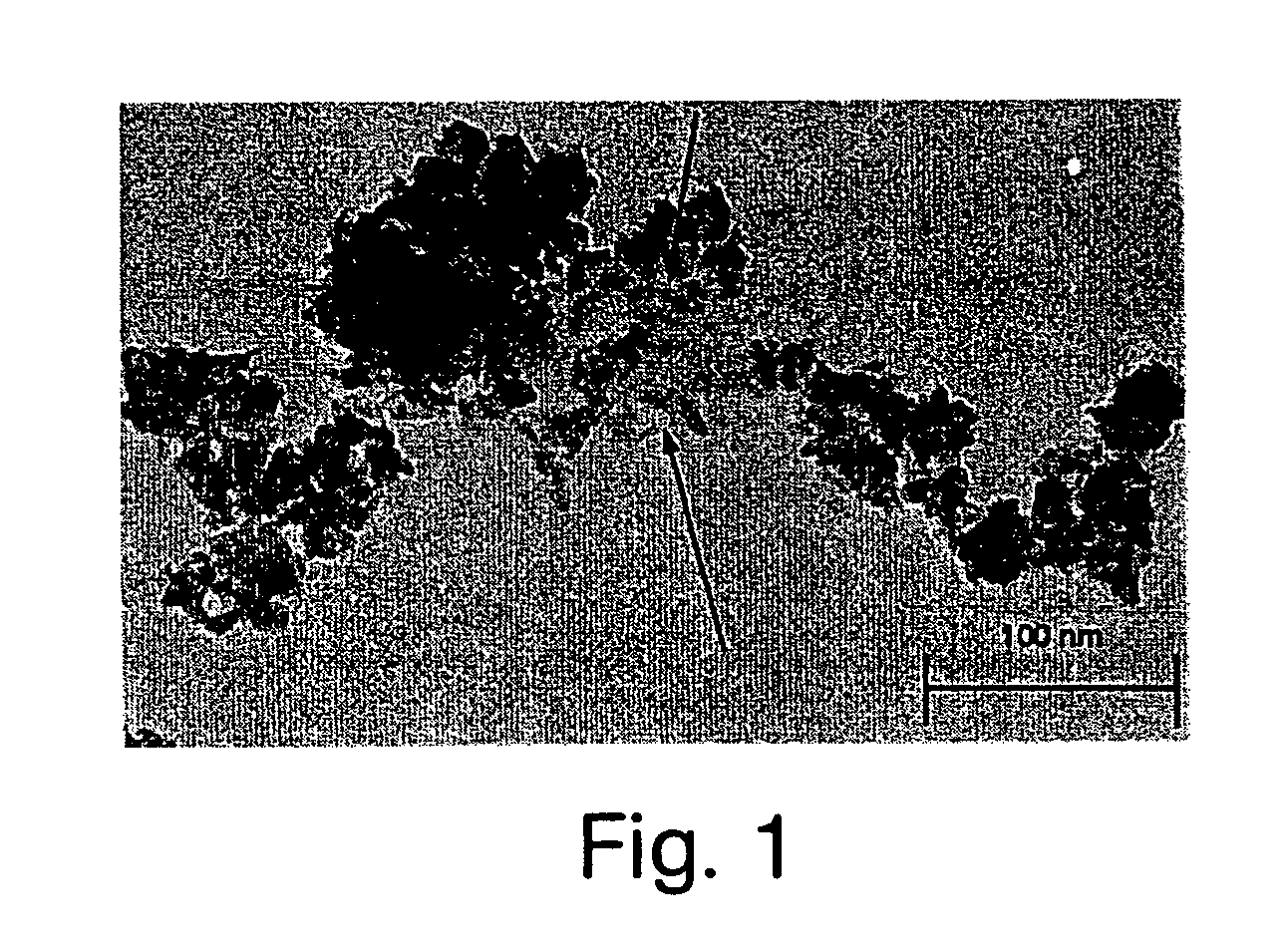

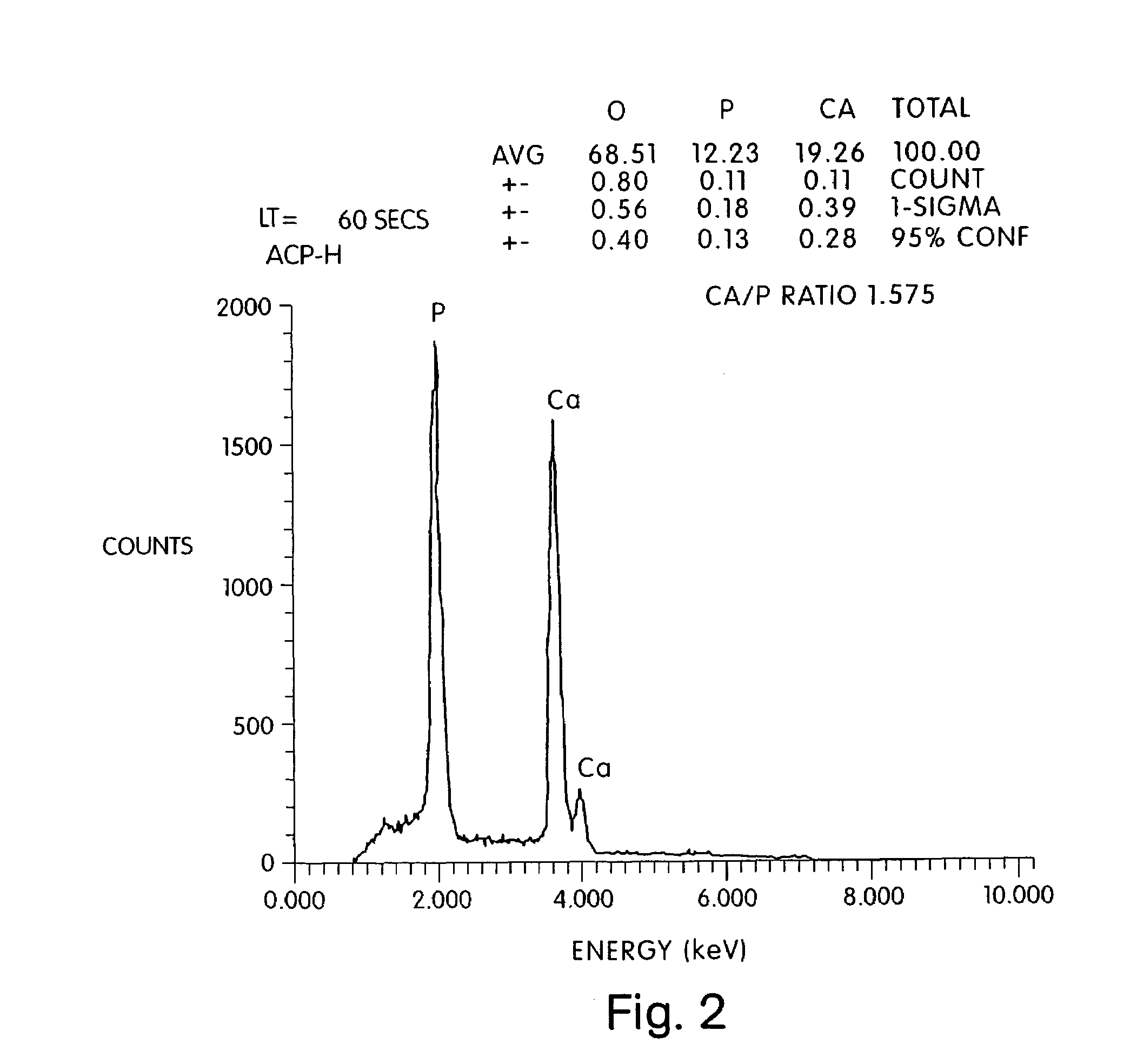

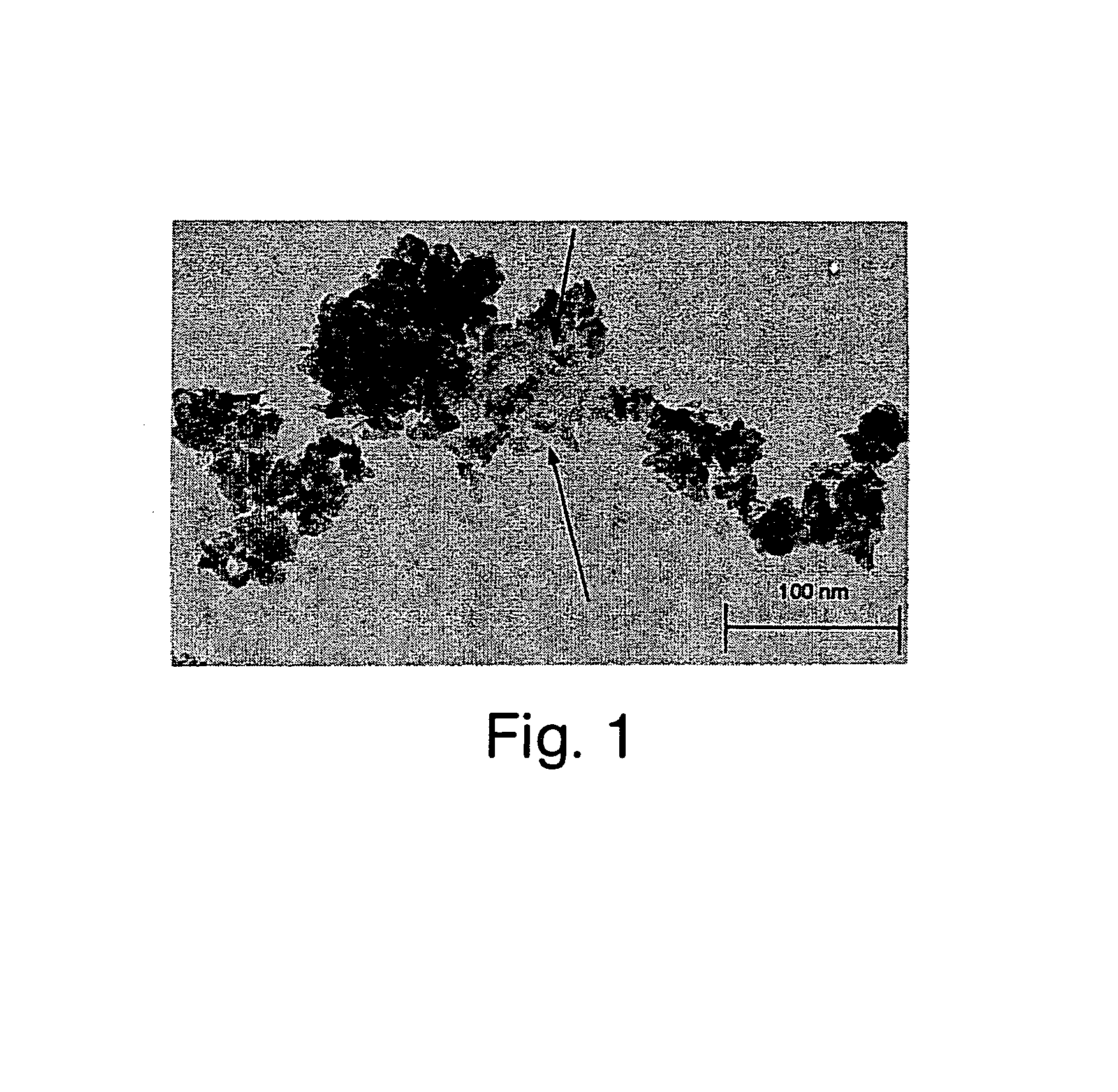

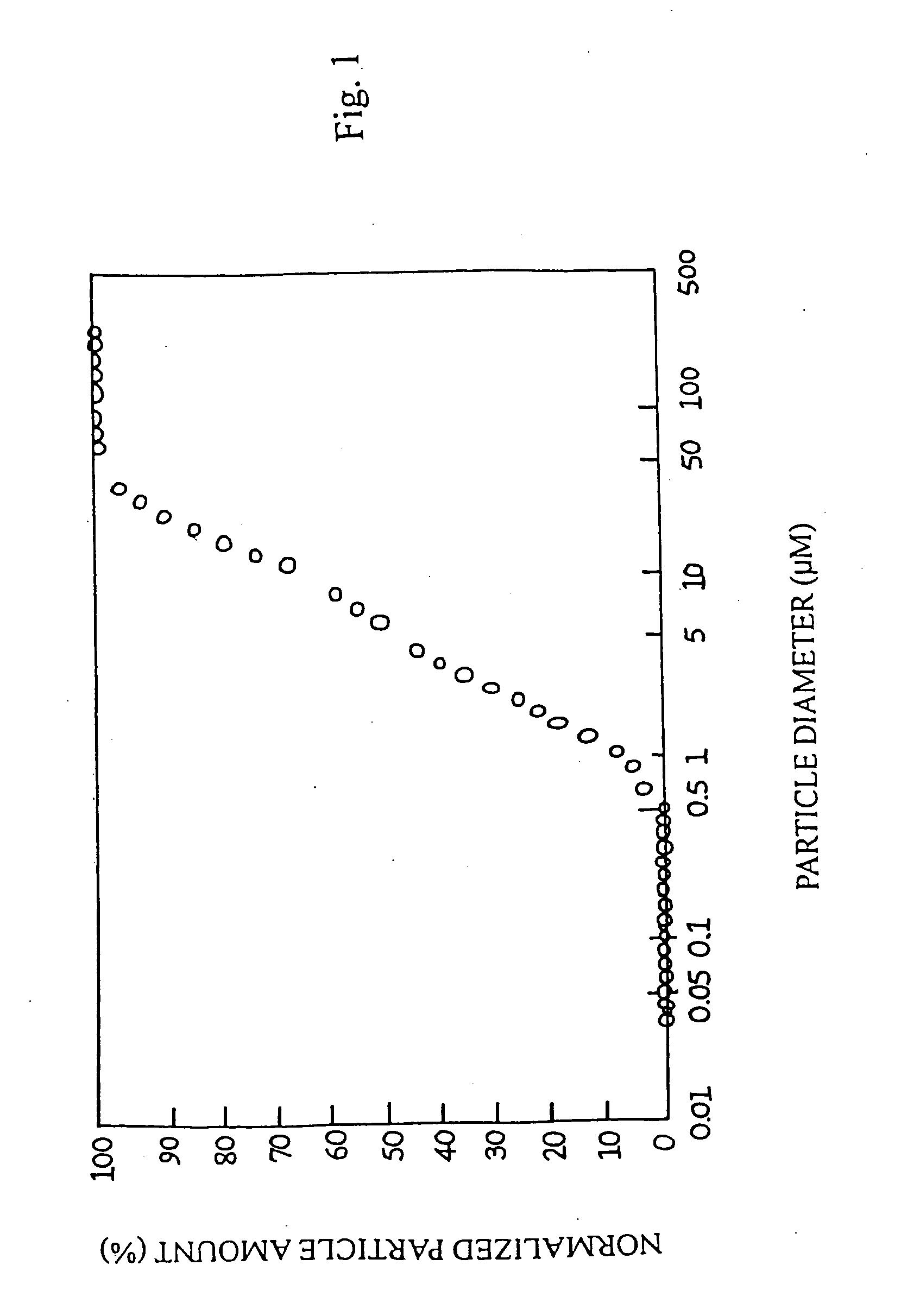

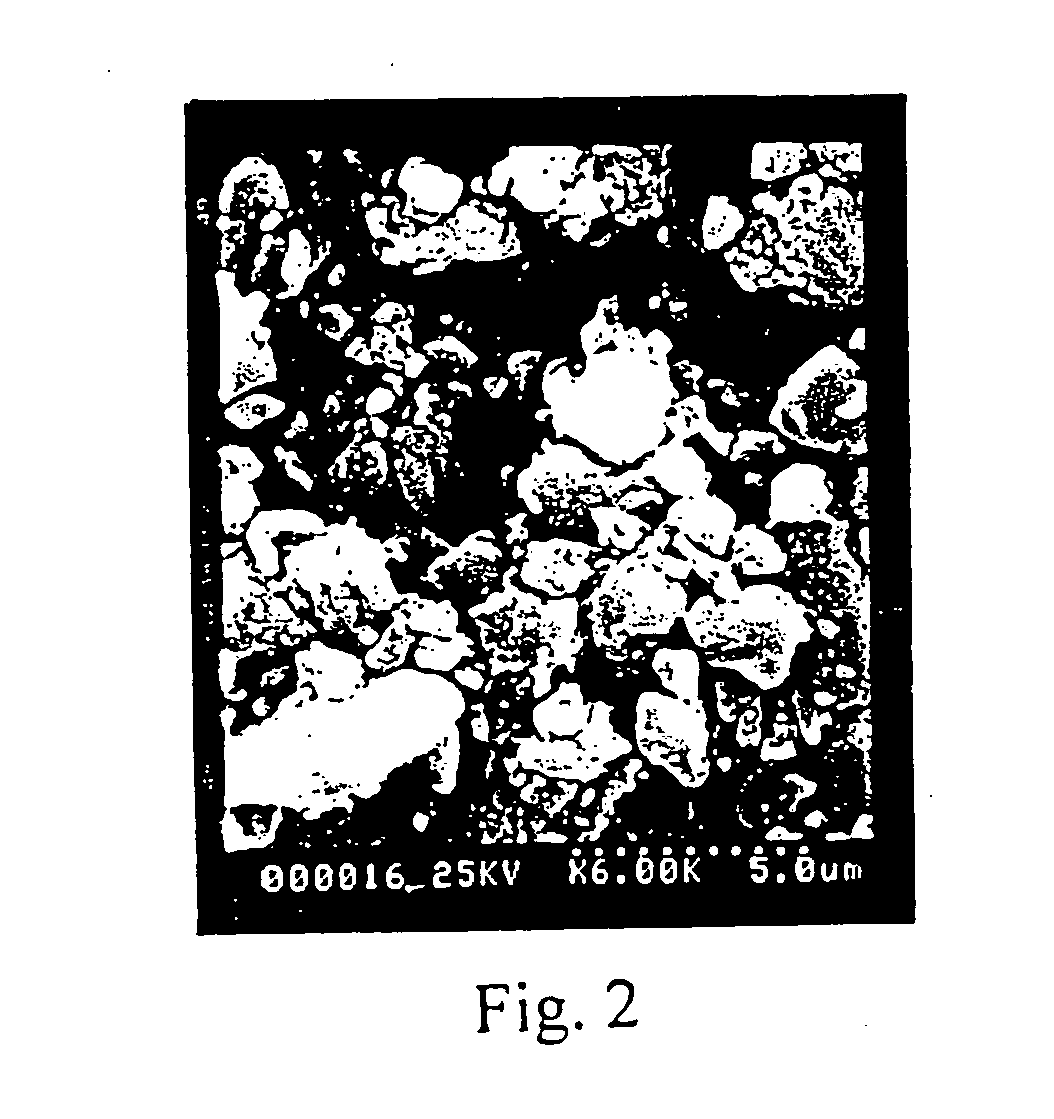

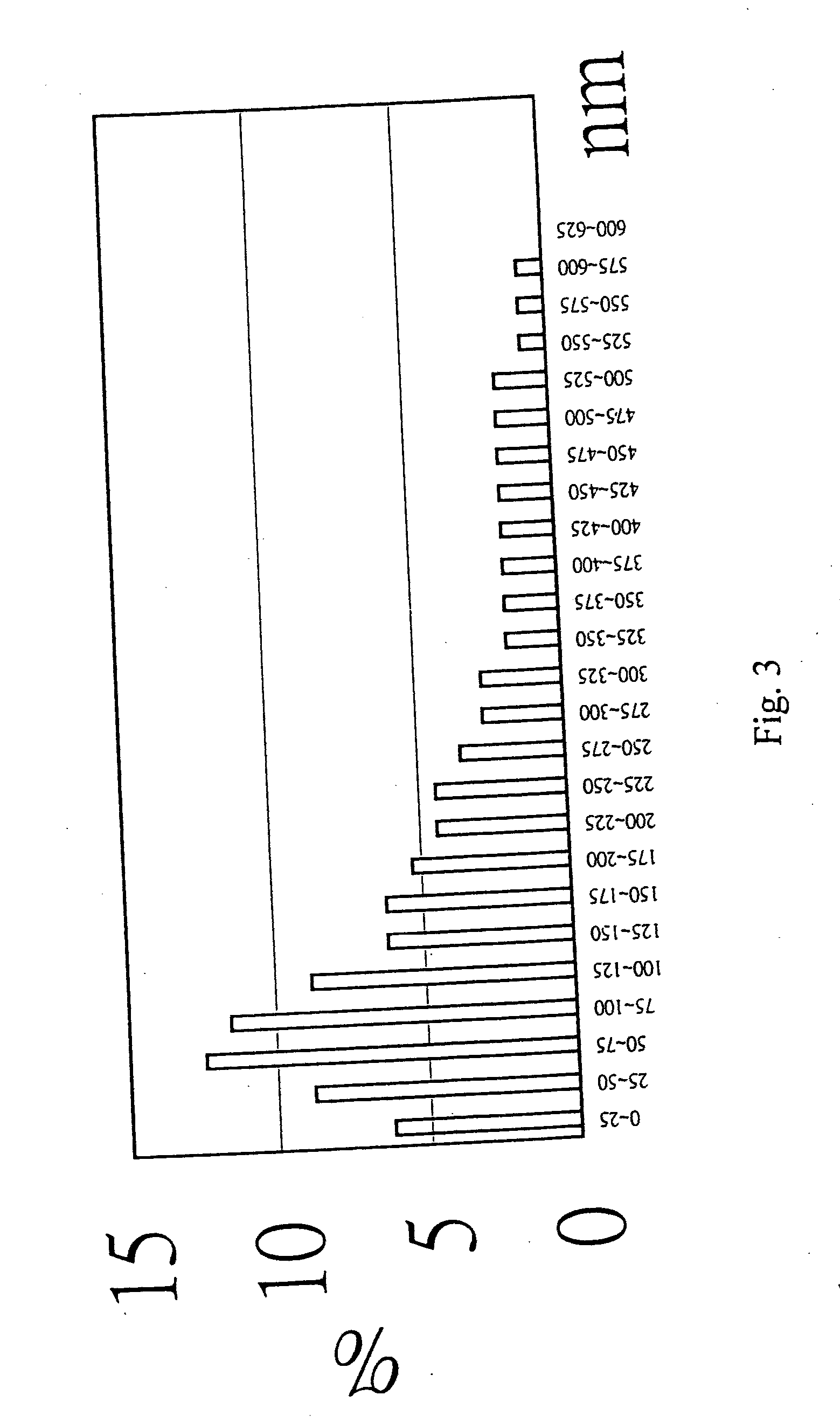

A calcium phosphate cement suitable for use in dental and bone prosthesis is disclosed, which include calcium phosphate particles having a diameter of 0.05 to 100 microns, wherein said calcium phosphate particles on their surfaces have whiskers or fine crystals having a width ranging from 1 to 100 nm and a length ranging from 1 to 1000 nm.

Owner:CALCITEC

Dual function prosthetic bone implant and method for preparing the same

InactiveUS20050267593A1Rapid blood/body fluid penetrationRapid tissue ingrowthBone implantWood working apparatusMedicineApatite

The present invention discloses a prosthetic bone implant made of a hardened calcium phosphate cement having an apatitic phase as a major phase, which includes a dense cortical portion bearing the majority of load and a porous cancellous portion allowing a rapid blood / body fluid penetration and tissue ingrowth.

Owner:CALCITEC

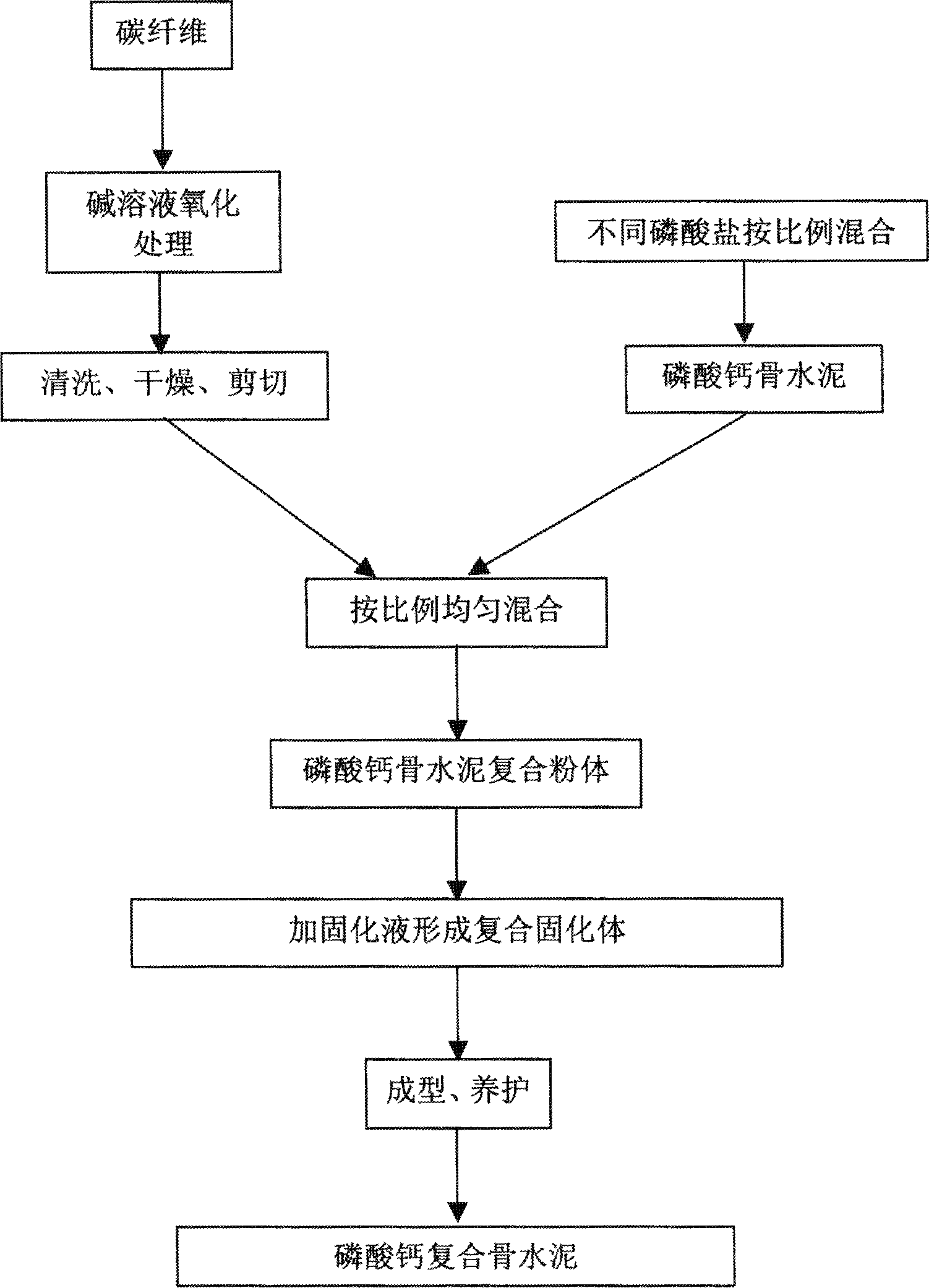

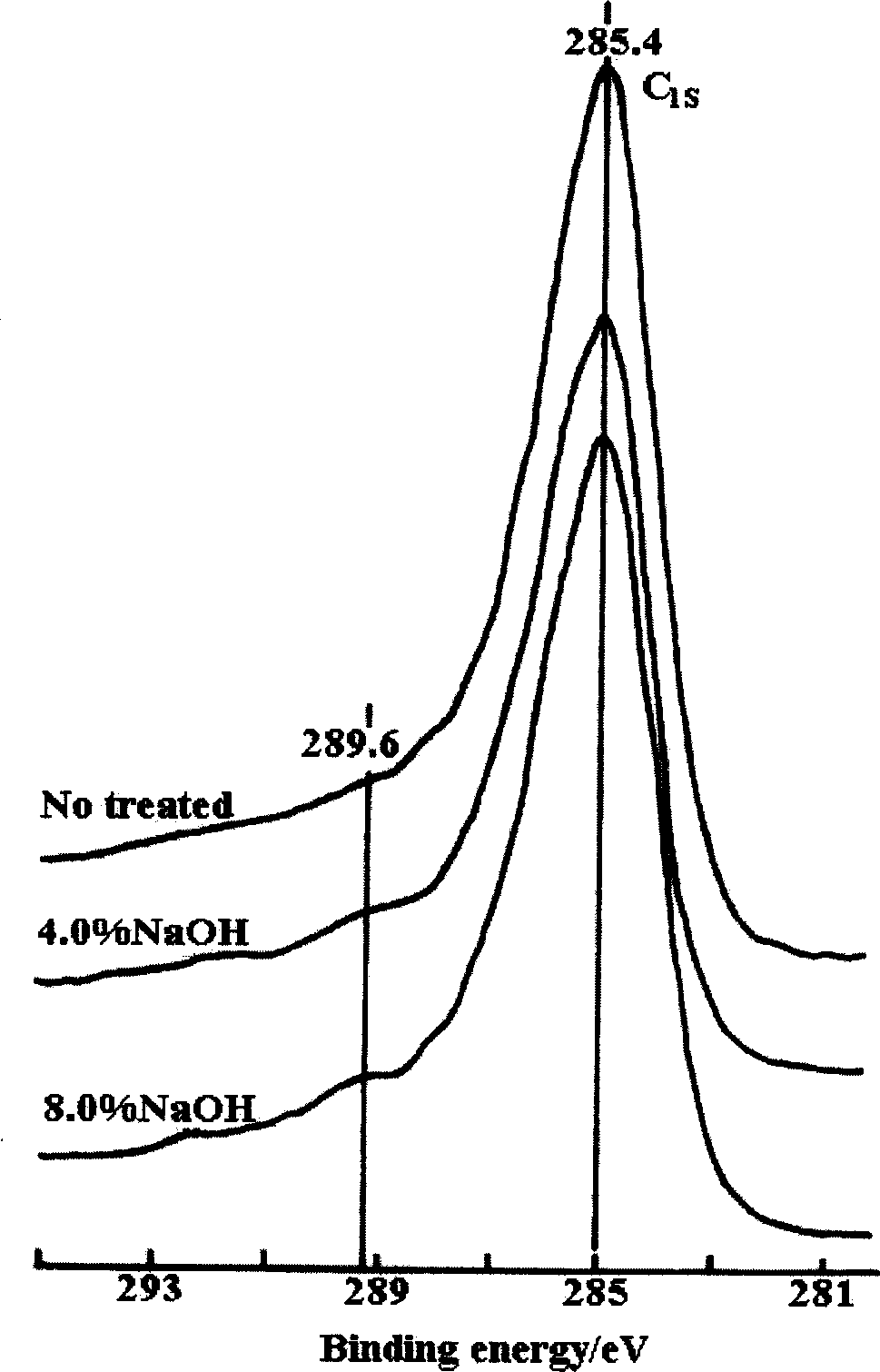

Preparation method of calcium phosphate composite bone cement

A composite calcium phosphate cement for preparing artificial bone is prepared through immersing carbon fibres in NaOH solution, heating at 70-90 deg.C for 2-3 hr, flushing, drying, shearing short, proportionally mixing it with calcium phosphate cement, stirring to obtain composite powder, proportionally mixing it with solidifying liquid, stirring, moulding and curing.

Owner:WUHAN UNIV OF TECH

Self-foaming cement for void filling and/or delivery systems

A self-foaming bone cement is described herein. In one variation, the bone cements include a self setting calcium phosphate cement formulation which when cured, forms macroscopic pores of varying sizes and densities with sufficient surface area to provide substantial regions for bone turnover.

Owner:KYPHON +1

Dual function prosthetic bone implant and method for preparing the same

InactiveUS20050267587A1Rapid blood/body fluid penetrationRapid tissue ingrowthBone implantWood working apparatusMedicineApatite

The present invention discloses a prosthetic bone implant made of a hardened calcium phosphate cement having an apatitic phase as a major phase, which includes a dense cortical portion bearing the majority of load and a porous cancellous portion allowing a rapid blood / body fluid penetration and tissue ingrowth.

Owner:CALCITEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com