Preparing method for ultra-fine high-purity Ti2AlNb alloy powder

A technology of alloy powder and purity, which is applied in the field of preparation of ultra-fine high-purity Ti2AlNb-based alloy powder to achieve the effect of high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

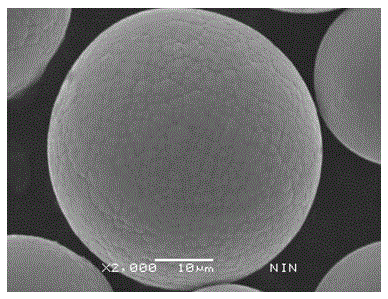

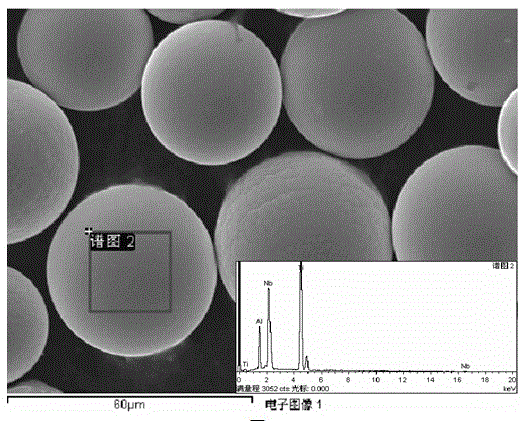

Image

Examples

Embodiment 1

[0024] A kind of ultra-fine high-purity Ti 2 The preparation method of AlNb alloy powder comprises the following steps:

[0025] 1) According to Ti 2 The composition of AlNb-based alloys is ingredients, Ti: 47.1wt%, Al: 10.6wt%, Nb: 41.3wt%, Mo: 1.0wt%, and smelted into Ti 2 AlNb alloy rods.

[0026] 2) For smelted Ti 2 AlNb alloy rods are processed by fine turning. The processed electrode rods are: diameter 95mm, length 1000mm, roundness deviation 0.01mm, straightness deviation 0.06mm / m, roughness 0.48μm;

[0027] 3) Load the electrode rod into the reaction chamber, and vacuum the reaction chamber to 5*10 -3 Pa, fill the reaction chamber with helium, so that the pressure in the chamber is 0.5MPa, and the oxygen content in the atmosphere is 0.001wt%;

[0028] 4) The power of the plasma gun of PREP powder making equipment is 300kW. The plasma torch contains tungsten cathode and copper anode. The electrode rod is not used as an electrode. The plasma heats the end of the ele...

Embodiment 2

[0033] A kind of ultra-fine high-purity Ti 2 The preparation method of AlNb alloy powder comprises the following steps:

[0034] 1) According to Ti 2 The composition of AlNb-based alloy is ingredients, Ti: 39.64wt%, Al: 9.64wt%, Nb: 30.16wt%, Ta: 20.56wt%, and smelted into Ti 2 AlNb alloy rod;

[0035] 2) For smelted Ti 2 The AlNb alloy rod is processed by finishing turning. The processed electrode rod is: 15mm in diameter, 110mm in length, 0.05mm in roundness deviation, 0.02mm / 110mm in straightness deviation, and 1.34μm in roughness;

[0036] 3) Load the electrode rod into the reaction chamber, and evacuate the reaction chamber to 8*10 -3 Pa, fill the reaction chamber with a mixed gas of helium and argon, so that the pressure in the chamber is 0.08MPa, and the oxygen content in the atmosphere is 0.089wt%;

[0037] 4) The power of the plasma gun of PREP milling equipment is 100kW. The plasma torch contains tungsten cathode and copper anode. The electrode rod is not used a...

Embodiment 3

[0042] A kind of ultra-fine high-purity Ti 2 The preparation method of AlNb alloy powder comprises the following steps:

[0043] 1) According to Ti 2 The composition of AlNb-based alloy is ingredients, Al: 10.08wt%, Nb: 44.35wt%, Ti: 45.57wt%, and smelted into Ti 2 AlNb alloy rod;

[0044] 2) For smelted Ti 2 AlNb alloy rods are processed by finish turning. The processed electrode rods are: diameter 55mm, length 650mm, roundness deviation 0.035mm, straightness deviation 0.04mm / 650mm, roughness 1.02μm;

[0045] 3) Load the electrode rod into the reaction chamber, and evacuate the reaction chamber to 3*10 -3 Pa, fill the reaction chamber with argon, so that the pressure in the chamber is 0.7MPa, and the oxygen content in the atmosphere is 0.03wt%;

[0046] 4) The power of the plasma gun of PREP powder making equipment is 200kW. The plasma torch contains tungsten cathode and copper anode. The electrode rod is not used as an electrode. The plasma heats the end of the electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com