Preparation method of high-strength, high-toughness and corrosion-resistant 7055 aluminum alloy medium-thickness plate

A high-strength, high-toughness, aluminum alloy technology, applied in the field of aluminum alloy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a high-strength, high-toughness, corrosion-resistant 7055 aluminum alloy medium-thick plate, comprising the following steps:

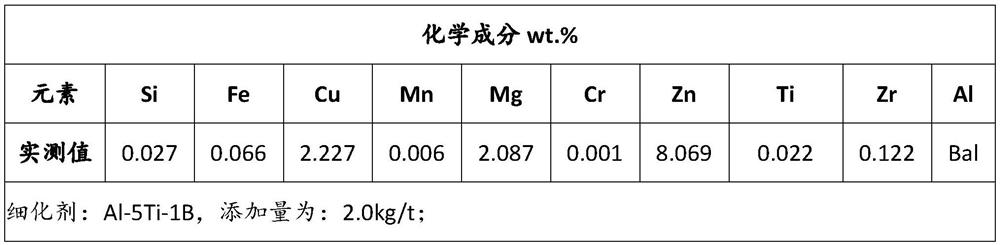

[0031] S1. Ingredients: Prepare aluminum alloy raw materials according to the following alloy elements and mass percentages

[0032]

[0033] The actual ratio of Zn to Mg is 3.87, and the ratio of Cu to Mg is 1.07;

[0034] S2. Smelting: Put the configured aluminum alloy raw materials into the melting furnace to melt into aluminum alloy melt, in which AlCu, AlZr, AlTi intermediate alloys, Mg ingots, and Zn ingots are added at a temperature between 720-760°C, and the melting is carried out after melting electromagnetic stirring;

[0035] S3. Casting: casting aluminum alloy melt into ingots, the casting temperature is controlled at 670-690°C, the measured hydrogen content: 0.097mL / 100gAl, the measured slag content: 18K / Kg, the crystallizer chooses a smaller size: 450mm×1580mm ;

[0036] S4. Homogenization: The ingot is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com