Method for preparing exoskeleton structure fiber monolith zirconium carbide ceramic through wet spinning and co-extrusion

A technology of structural fiber and exoskeleton, which is applied in the field of preparation of ultra-high temperature ceramics, can solve the problems of poor toughness, poor ablation resistance, and difficulty in forming fiber monolithic precursors of zirconium boride ultra-high temperature ceramics, so as to improve the anti-oxidation performance , Improve interface bonding, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

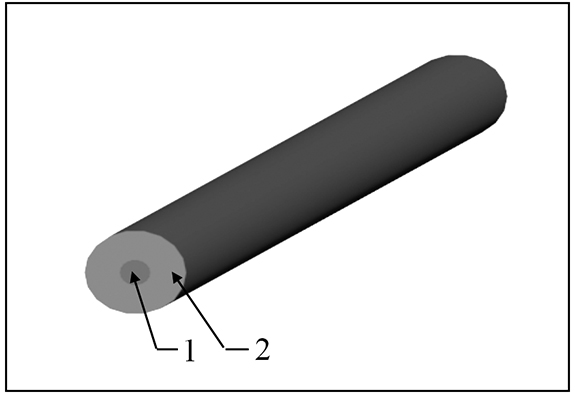

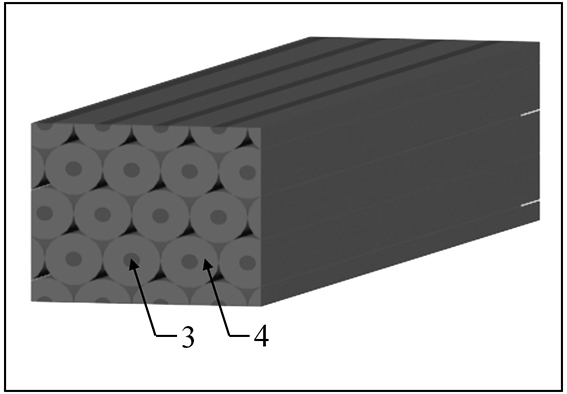

[0032] 1. Preparation of fiber monolithic precursor cell body spinneret: First, stir and dissolve 20 grams of polyvinyl butyral and 20 grams of polyethylene glycol in 200 grams of absolute ethanol, and then add the ceramic fiber monolithic precursor cell body Powder, the ceramic powder of the fiber monolithic precursor body is made of 70 grams of boron nitride powder and 30 grams of zirconium carbide powder according to the mass percentage of 70%: 30%. Stir evenly to make the fiber monolithic precursor body spray silk liquid;

[0033] 2. Prepare the spinneret for the interface layer of the fiber monolithic precursor cell body: first stir and dissolve 10 grams of polyvinyl butyral and 10 grams of polyethylene glycol in 100 grams of absolute ethanol, and then add the fiber monolithic precursor cell body The ceramic powder of the interface layer, the ceramic powder of the fiber monolith precursor cell body interface layer is made of 70 grams of zirconium carbide powder and 30 gra...

Embodiment 2

[0039] 1. Preparation of fiber monolithic precursor cell body spinneret: first stir and dissolve 30 grams of polyvinyl butyral and 30 grams of polyethylene glycol in 300 grams of absolute ethanol, and then add the ceramic fiber monolithic precursor cell body Powder, the ceramic powder of the fiber monolithic precursor body is made of 90 grams of boron nitride powder and 10 grams of zirconium carbide powder according to the mass percentage of 90%: 10%. Stir evenly to make the fiber monolithic precursor body spray silk liquid;

[0040] 2. Prepare the spinneret for the interfacial layer of the fiber monolithic precursor cell body: first stir and dissolve 20 grams of polyvinyl butyral and 20 grams of polyethylene glycol in 200 grams of absolute ethanol, and then add the fiber monolithic precursor cell body The ceramic powder of the interface layer, the ceramic powder of the fiber monolith precursor cell body interface layer is made of 90 grams of zirconium carbide powder and 10 gr...

Embodiment 3

[0046] 1. Preparation of fiber monolithic precursor cell body spinneret: first stir and dissolve 25 grams of polyvinyl butyral and 25 grams of polyethylene glycol in 250 grams of absolute ethanol, and then add the ceramic fiber monolithic precursor cell body Powder, the ceramic powder of the fiber monolithic precursor body is made of 80 grams of boron nitride powder and 20 grams of zirconium carbide powder according to the mass percentage of 80%: 20%, and stirred evenly to make the fiber monolithic precursor body spray silk liquid;

[0047] 2. Prepare the spinneret for the interface layer of the fiber monolithic precursor cell body: first stir and dissolve 15 grams of polyvinyl butyral and 15 grams of polyethylene glycol in 150 grams of absolute ethanol, and then add the fiber monolithic precursor cell body The ceramic powder of the interface layer, the ceramic powder of the fiber monolith precursor cell body interface layer is made by mixing 80 grams of zirconium carbide powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com