Low-temperature high-toughness hot rolled H-shaped steel with yield strength being 500MPa and preparation method thereof

A yield strength, H-beam technology, applied in the field of metallurgy, can solve the problem that hot-rolled H-beam cannot meet high strength, high toughness and uniform section performance at the same time, and achieves the matching of strength and toughness, and improves welding performance and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

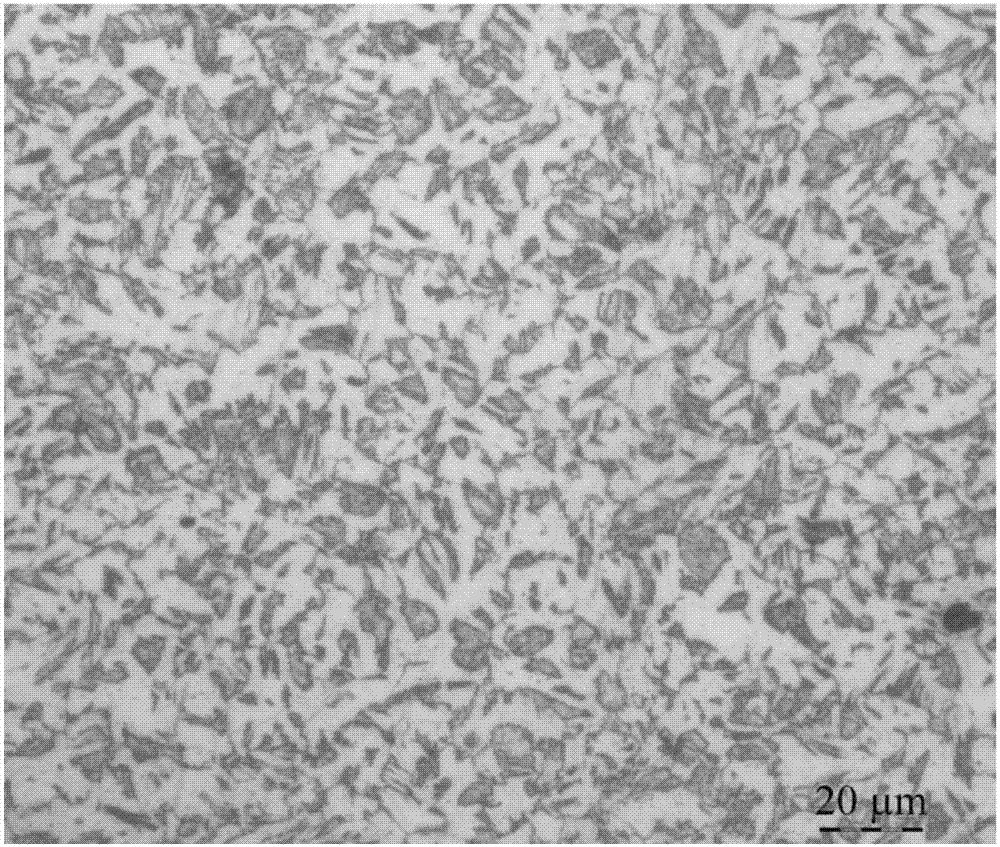

Image

Examples

Embodiment 1

[0029] A low-temperature high-toughness hot-rolled H-shaped steel with a yield strength of 500 MPa and its production process. The chemical composition of the H-shaped steel according to the present invention is (%) by weight: C: 0.16, Si: 0.25, Mn: 0.7, P: 0.018 , S: 0.010, Nb: 0.015, B: 0.0025, and the rest are Fe and unavoidable impurities.

[0030] The H-shaped steel production process is as follows: taking the specification H200x200x9x15 as an example, the casting slab with the above composition is heated to 1240°C through a heating furnace, and kept for 120 minutes. The final rolling temperature of the universal rolling mill is 940°C. The cut-to-length H-beam is treated with two-stage rapid electromagnetic induction heating. In the first stage, the H-beam is preheated from room temperature to 620°C, and the second stage is immediately heated to 850°C. Then, the H-beam flange and After the web was quenched and cooled at 40°C / s to room temperature, it was rapidly heated to...

Embodiment 2

[0033] A low-temperature high-toughness hot-rolled H-shaped steel with a yield strength of 500 MPa and its production process. The chemical composition of the H-shaped steel according to the present invention is (%) by weight: C: 0.10, Si: 0.30, Mn: 1.55, P: 0.013 , S: 0.009, Nb: 0.035, B: 0.0010, and the rest are Fe and unavoidable impurities.

[0034] The H-beam production process is as follows: taking the specification H200x200x9x15 as an example, the cast slab with the above composition is heated to 1260°C in a heating furnace and kept for 125 minutes. The final rolling temperature of the universal rolling mill is 1000°C. The cut-to-length H-beam is treated with two-stage rapid electromagnetic induction heating. In the first stage, the H-beam is preheated from room temperature to 650°C, and the second stage is immediately heated to 880°C. Then, the H-beam flange and After the web was quenched and cooled at 60°C / s to room temperature, it was rapidly heated to 620°C for temp...

Embodiment 3

[0037] A low-temperature high-toughness hot-rolled H-shaped steel with a yield strength of 500 MPa and its production process. The chemical composition of the H-shaped steel according to the present invention is (%) by weight: C: 0.12, Si: 0.45, Mn: 1.25, P: 0.023 , S: 0.005, Nb: 0.020, B: 0.0018, and the rest are Fe and unavoidable impurities.

[0038] The H-beam production process is as follows: taking the specification H200x200x9x15 as an example, the cast slab of the above composition is heated to 1200°C through a heating furnace, and kept for 140 minutes. The final rolling temperature of the universal rolling mill is 970°C. The cut-to-length H-beam is treated with two-stage rapid electromagnetic induction heating. In the first stage, the H-beam is preheated from room temperature to 600°C, and the second stage is immediately heated to 830°C. Then, the H-beam flange and After the web was quenched and cooled at 30°C / s to room temperature, it was rapidly heated to 580°C for t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com