Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "High alumina content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid and high temperature resistant cement composites

InactiveUS20140047999A1Increase resistanceReduce resistanceSolid waste managementCement productionHigh resistanceSilicon dioxide

Process for production of acid and high temperature resistant cement composites, where the matrix is alkali activated F fly ash alone, F Fly ash combined with ground slag or ground slag alone. F-fly ash produces lower quality alkali activated cement systems. On the other hand the lack of calcium oxide results in very high resistance to medium and highly concentrated inorganic or organic acids. The high strength and low permeability of pure F-fly ash cement systems is achieved by using in the composition un-densified silica fume, the amorphous silicone dioxide obtained as by products in production of ferro-silicones. Precipitated nano-particle silica made from soluble silicates and nano-particle silica fume produced by burning silicon tetra chloride in the hydrogen stream.

Owner:RAZL IVAN

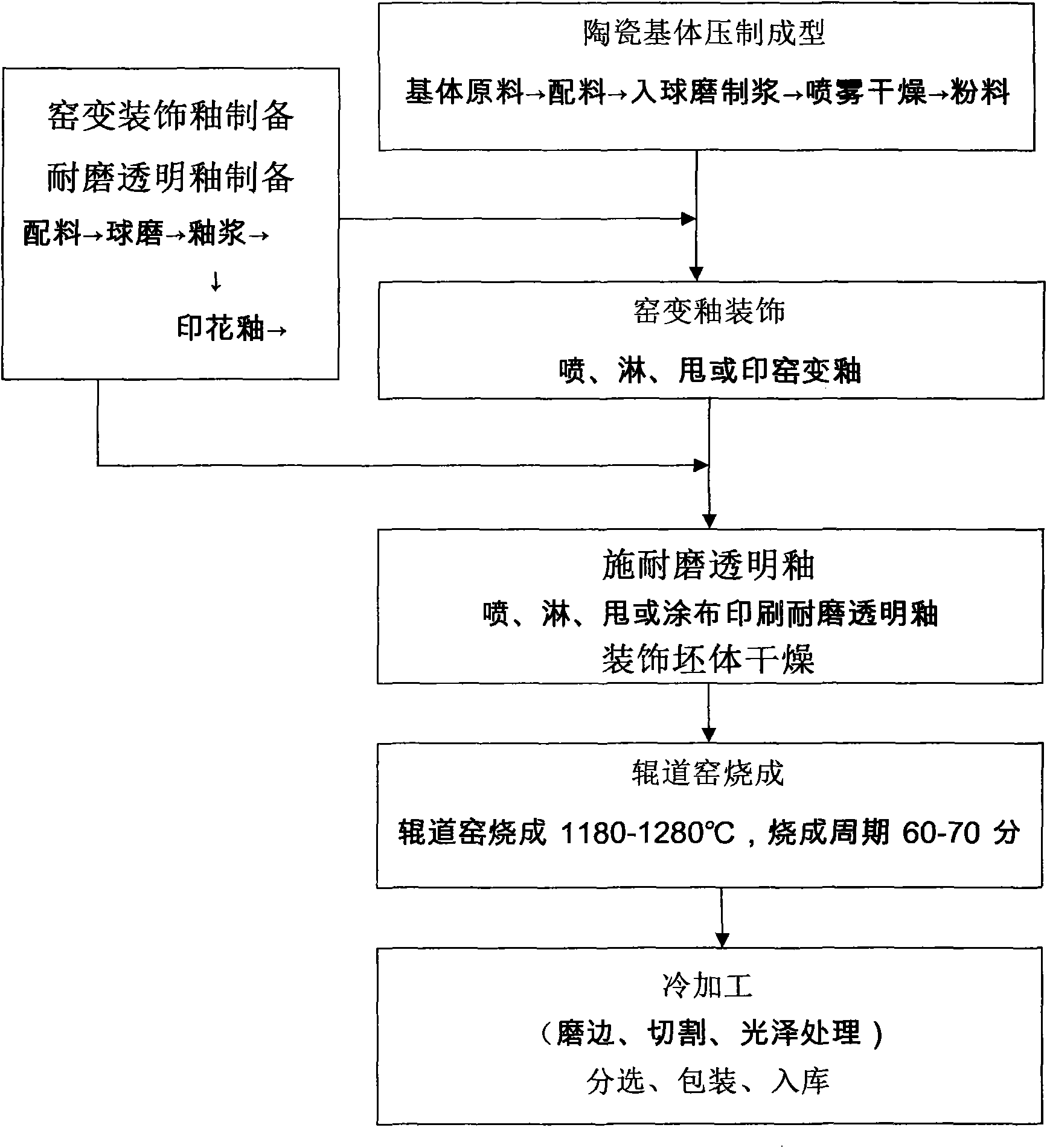

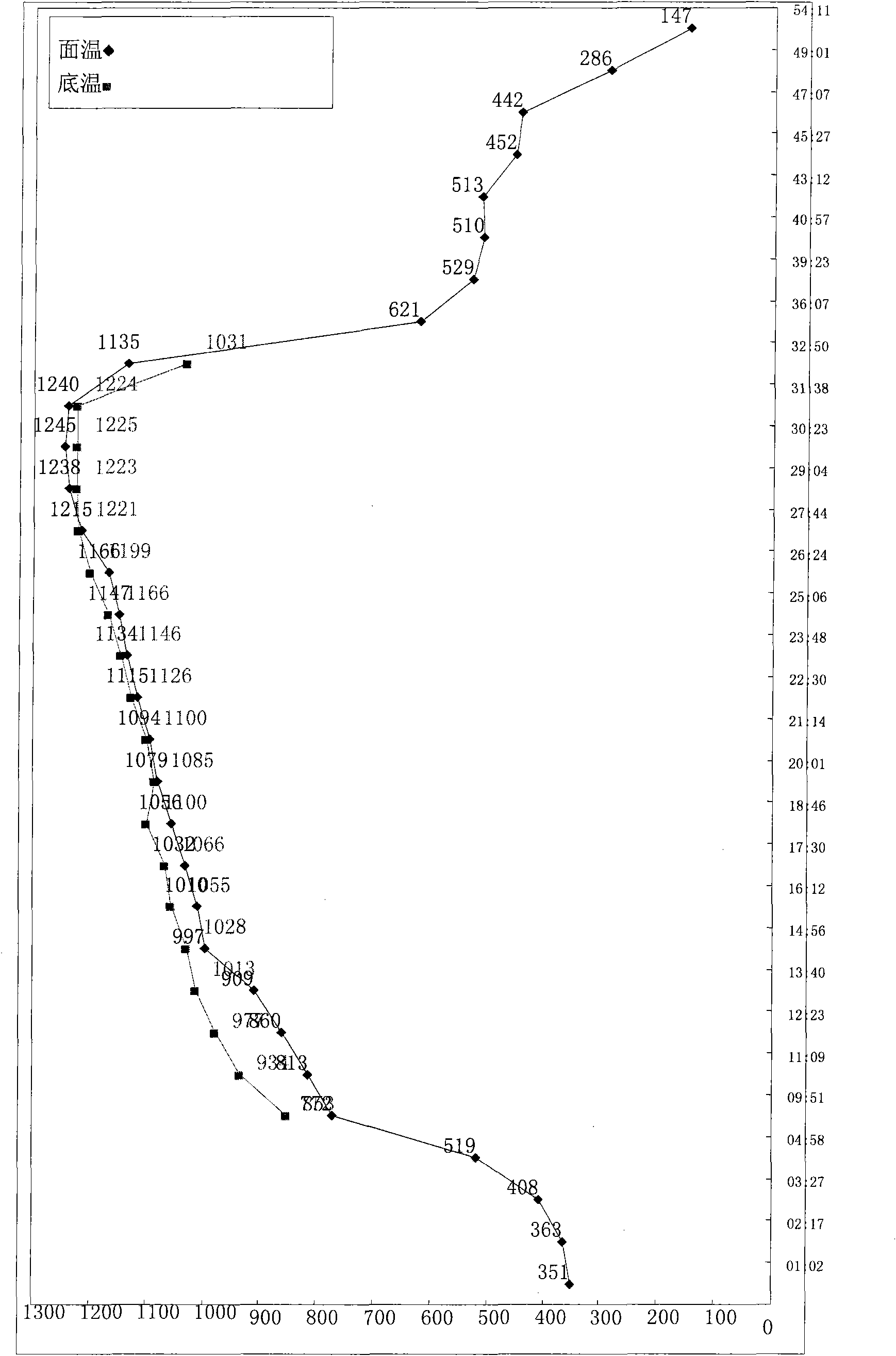

Furnace transmutation decoration glazed brick and production technology

The invention relates to a furnace transmutation decoration glazed brick and a production technique thereof. The furnace transmutation decoration glazed brick is prepared from the following componentsin percentage by weight: 10-30% of albite, 3-10% of spodumene, 5-10% of kaoline Al2O3.2SiO2.2H2O, 8-30% of zinc oxide ZnO, 3-10% of talc 3MgO.4SiO2.H2O, 0-20% of titanium TiO2, 3-10% of zirconite ZrSiO, and 1-10% of coloring metallic oxide MnO2, V2O5, Fe2O3 and CoO2. The production technique of the furnace transmutation decoration glazed brick comprises the following steps: (1) shaping the substrate of the furnace transmutation decoration glazed wall and floor bricks; (2) decorating the wall and floor brick substrate surface or anti-abrasion transparent glaze layers and drying; and (3) sintering the furnace transmutation decoration glazed wall and floor bricks once in a high-temperature roller kiln.

Owner:黄建平

Thin wall cordierite carrier for ceramic honeycomb catalyst and method for preparing the same

InactiveCN1827217AEasy alignmentSmall expansion coefficientCatalyst carriersCeramicwarePorosityCordierite

The invention relates to the improvement on the ceramic beehive catalyst carrier, especially providing a ceramic beehive catalyst carrier with high mechanical strength and lower expansion parameter and preparing method. The invention is characterized in that: said beehive catalyst carrier is the alumina micro powder in 12-15%WT whose average particle diameter is less than 2 micron; the sheet kaolin and / or clay micro powder in 43-47% whose average particle diameter is less than 2 micron, the sheet steatite micro powder in 33-37% whose average particle diameter is 5-15 micron, and the fuse quartz in 6-12% whose average particle diameter is less than 2 micron to be mixed, molded and baked to attain the cordierite whose total amount is 92-96%, wherein, the Al203, MgO and SiO2 are each in 36-37%, 13.0-14.0% and 50-52%. The invention adds surface active agent in the mixture when in preparation. The prepared beehive cordierite total amount with 600 hole / square inch can reach 92-96%, the expansion parameter can reach 0.8X10-6 / Deg. C (800Deg. C to room temperature), and the factor of porosity can reach 39-40%. The invention can reduce the ignition temperature 25-40Deg. C, and reduce the tail gas discharge of nitrogen oxygen compound and carbon monoxide of vehicle 5-10% to meet the demand of Europe III standard.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY +1

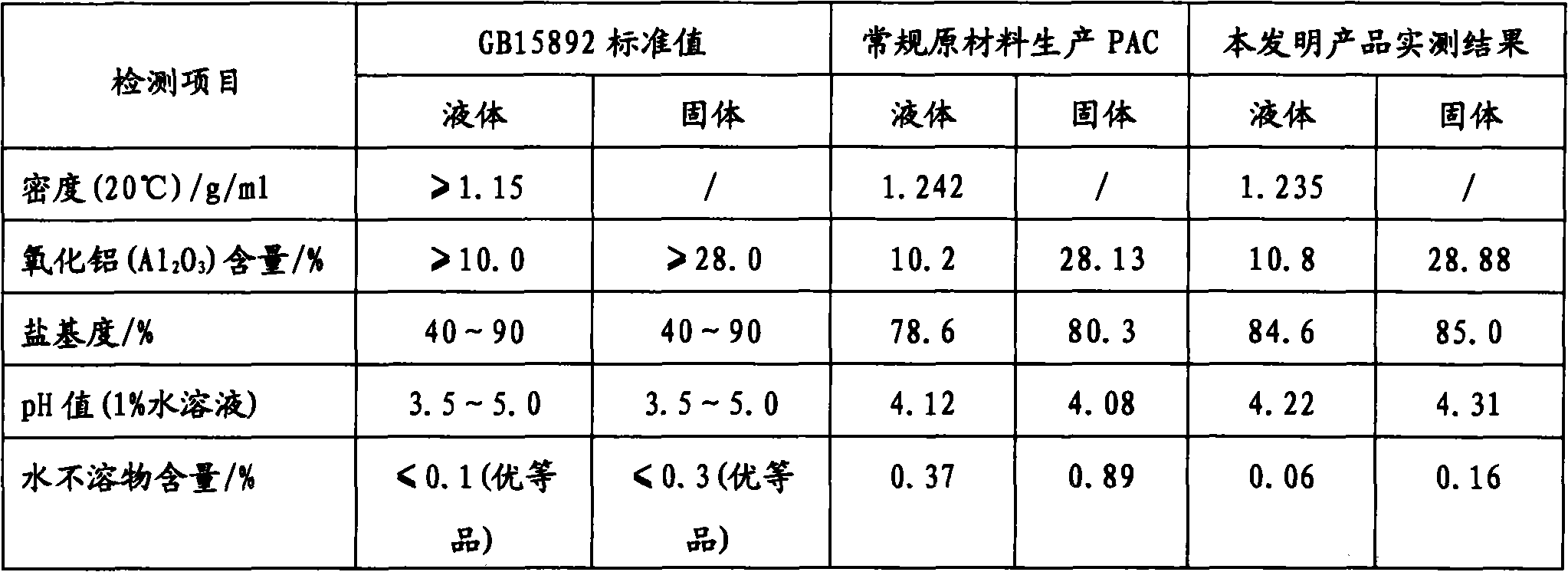

Method for secondary aluminum ash harmless use

InactiveCN109052445AHigh alumina contentIncrease contentAluminium chloridesCeramic materials productionBrickAluminium chlorohydrate

The invention discloses a method for secondary aluminum ash harmless use. The method comprises the following steps: mixing water with secondary aluminum ash, heating, stirring, leaching, and carryingout solid-liquid separation after water leaching so as to obtain primary filtrate and primary filter residues; heating and evaporating the primary filtrate so as to obtain a soluble salt; mixing the primary filter residues with an acid, heating and stirring to achieve leaching; after acid leaching, and carrying out solid-liquid separation so as to obtain secondary filtrate and secondary filter residues; manufacturing bricks with the secondary filter residues; adjusting the pH value of the secondary filtrate within 2.5-3.0; heating and aging the secondary filtrate after the pH value is adjusted, thereby obtaining aluminum polychlorid. By adopting the method, the aluminum element in secondary aluminum ash can be utilized to the maximum extent, aluminum nitride which is hard to react with theacid can be converted into aluminum hydroxide which is easy to react with the acid through high-temperature water leaching, dissolution of the aluminum element in the secondary aluminum ash can be improved, and the content of aluminum oxide in a prepared aluminum polychlorid product can be increased; in addition, a salt solvent and a nitrogen element in the secondary aluminum ash can be recycled,and damage of leaching residues upon the environment can be reduced.

Owner:CENT SOUTH UNIV

Method for producing polyaluminium chloride

ActiveCN102070170AReduce manufacturing costIn line with the environmental protection concept of energy saving and emission reductionAluminium chloridesWater/sewage treatment by flocculation/precipitationIngotPolyaluminium chloride

The invention relates to a method for producing polyaluminium chloride, which comprises the following steps: adding aluminum-containing waste residue into solution of hydrochloric acid and reacting at 90 to 120 DEG C and under a normal pressure for 3 to 5 hours; filtering, collecting mother solution, filling the mother solution into an acid-resistance and vapor-heated reactor with a stirring device, starting stirring, supplying a proper amount of water, starting to add calcium aluminate powder, and after the addition is finished, regulating the density of feed liquid to more than or equal to 1.20g / ml with water; and adding a synergist, heating and keeping the temperature between 90 and 120 DEG C, reacting at normal temperature for 3 to 5 hours, and obtaining finished liquid polyaluminium chloride. Compared with the prior art, the method, which uses aluminum-containing waste residue obtained after the neutralization of waste liquid from surface pickling of aluminum ingots and bands as raw material, reduces the manufacturing cost of polyaluminium chloride, recycles aluminum-containing waste residue and is in accordance with the environmental-protection concept of energy conservationand emission reduction.

Owner:蓝保(厦门)水处理科技有限公司

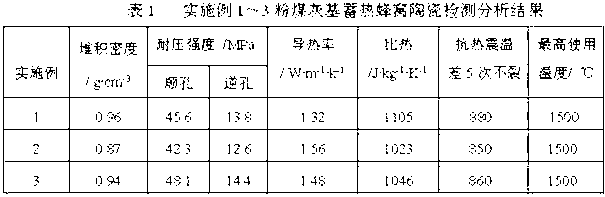

Pulverized fuel ash-based heat storage honeycomb ceramic and preparation method thereof

The invention belongs to the technical field of inorganic material, and particularly discloses a pulverized fuel ash-based heat storage honeycomb ceramic and a preparation method of the heat storage honeycomb ceramic. The pulverized fuel ash-based heat storage honeycomb ceramic is prepared by pulverized fuel ash, sintering aids, bonding agent, plasticizer, surface active agent and water, wherein the sum of the mass percent of the pulverized fuel ash and the sintering aids is 100%, the pulverized fuel ash accounts for 45-82%, and the sintering aids accounts for 18-55%; and the adding quantity of the bonding agent, the plasticizer, the surface active agent and the water is respectively 3-9%, 3-8%, 0.5-3% and 13-25% of the total quantity of the pulverized fuel ash and the sintering aids by mass percent. The pulverized fuel ash-based heat storage honeycomb ceramic takes the pulverized fuel ash as a base material, and the preparation method of the pulverized fuel ash-based heat storage honeycomb ceramic which is low in raw material cost, high in heat storage capacity, high in strength and good in thermal shock resistance is also disclosed.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Casting steel strip with low surface roughness and low porosity

InactiveUS20040177944A1High alumina contentAvoid increased oxygen levelsThin material handlingSquare MillimeterSurface roughness

A method of producing cast steel strip having low surface roughness and low porosity by casting with molten steel having a total oxygen content of at least about 70 ppm and a free oxygen content between 20 and 60 ppm, and a temperature that allows a majority of any oxide inclusions to be in a liquidus state. The total oxygen content may be at least 100 ppm and the the free oxygen content between 30 and 50 ppm. The steel strip produced by the method may have a per unit area density of at least about 120 oxide inclusions per square millimeter to a depth of about 2 microns from the strip surface.

Owner:NUCOR CORP

Method for preparing catalytic cracking catalyst containing pseudo-boehmite

ActiveCN105688977AIncrease contentLarge specific surface areaMolecular sieve catalystsIon exchangeBoehmite

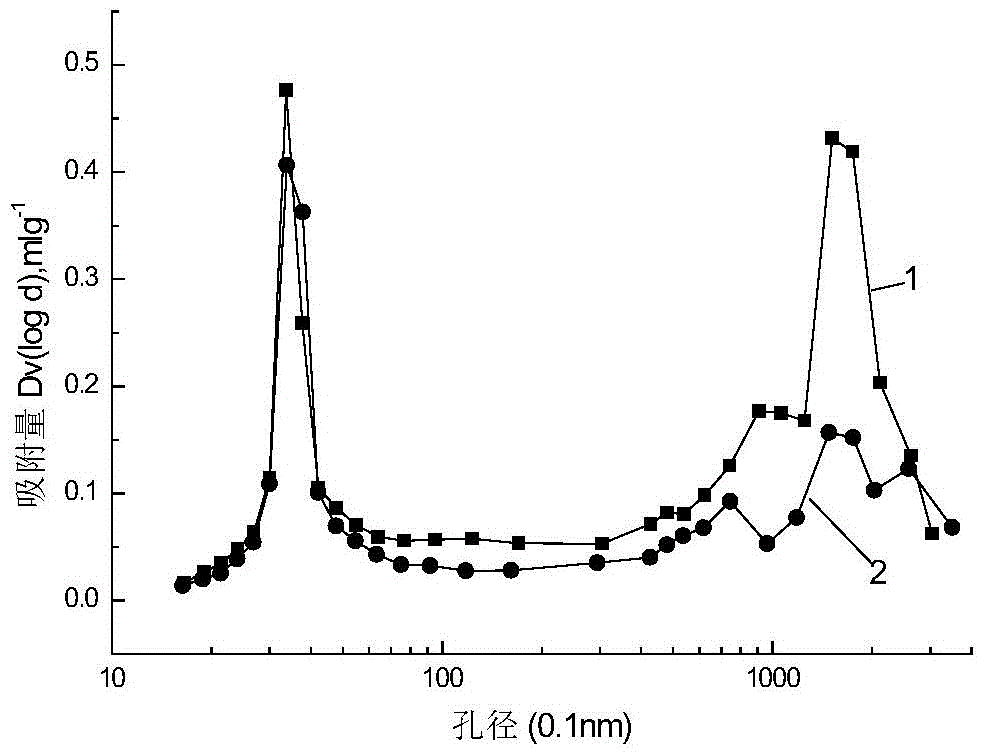

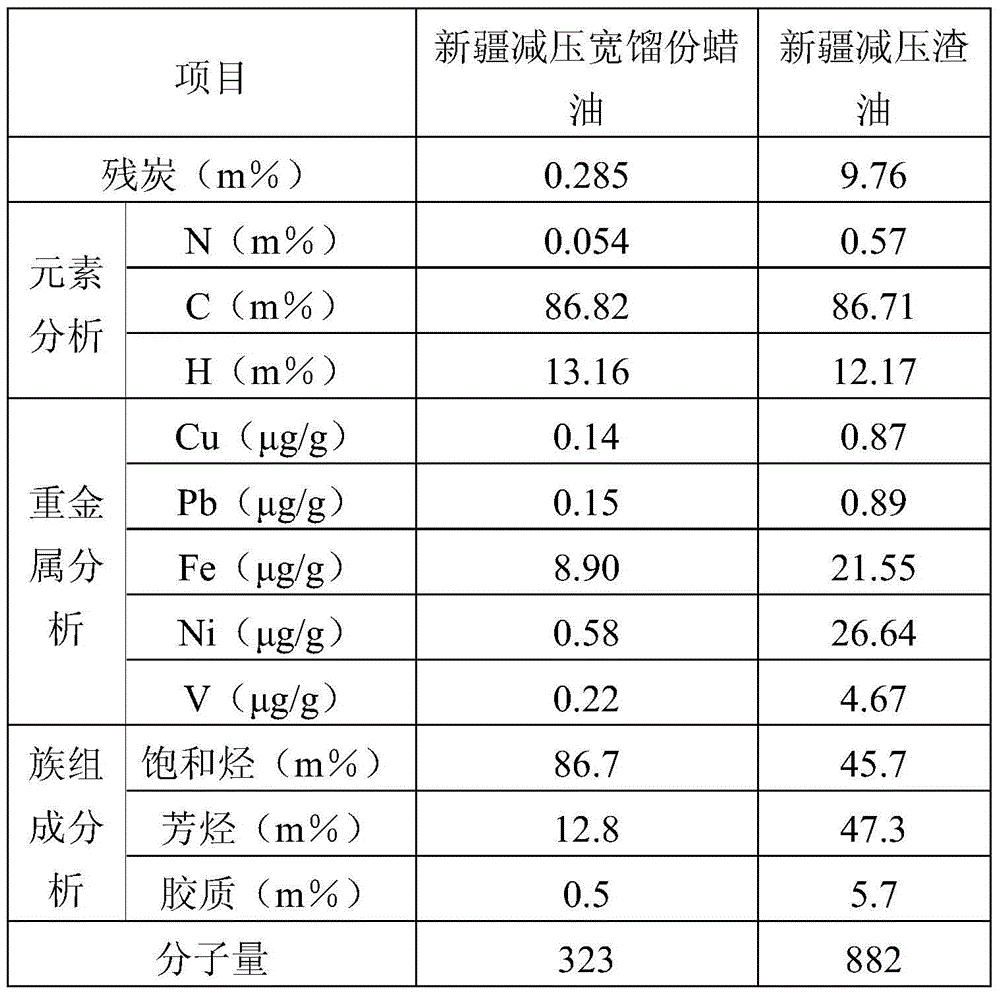

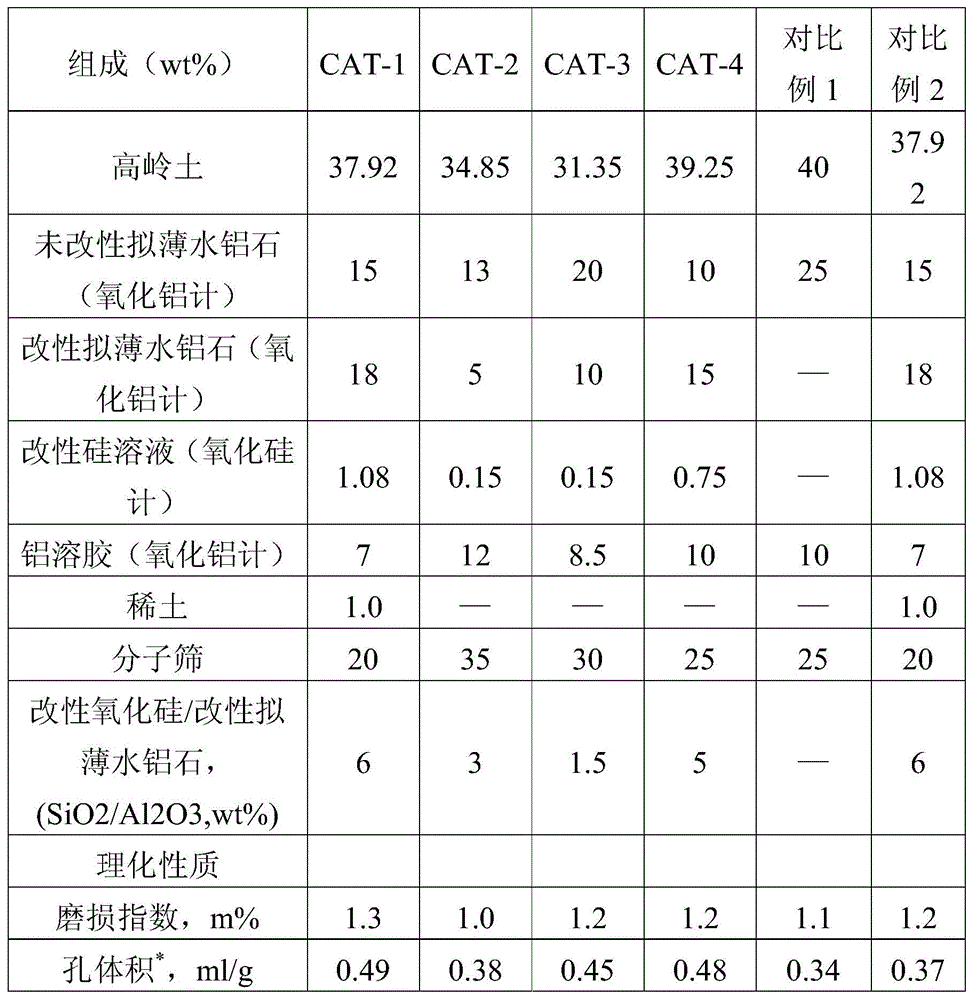

The invention discloses a method for preparing a catalytic cracking catalyst containing pseudo-boehmite.The method comprises the steps of mixing and stirring part of pseudo-boehmite and silica solution for over 15 min to prepare modified pseudo-boehmite A, the modified pseudo-boehmite A, residual pseudo-boehmite B and clay are mixed and pulped to prepare matrix size containing pseudo-boehmite, the matrix size and molecular sieve size are mixed, homogenized, formed and dried, and ion exchange is conducted to obtain the catalytic cracking catalyst, wherein the dry basis mass ratio of the modified pseudo-boehmite A to the residual pseudo-boehmite B is 0.2-2.5, and the add amount of silica solution is that SiO2 accounts for 0.5-8% of the dry basis weight of the modified pseudo-boehmite A.The catalyst prepared with the method has a high abrasion index, a large pore volume and high heavy oil conversion capacity and coke selectivity.

Owner:PETROCHINA CO LTD

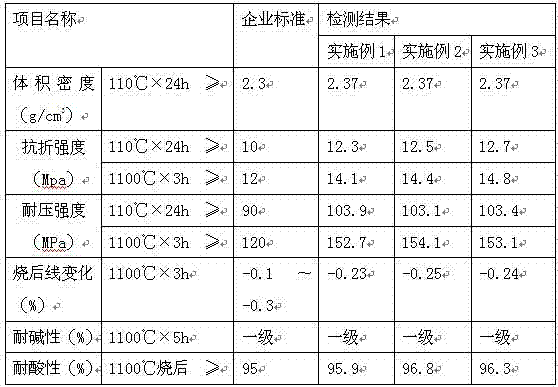

High intensity microporous mullite refractory aggregate and preparation method thereof

The invention relates to a high intensity microporous mullite refractory aggregate and a preparation method thereof. The technical solution thereof is: first using 50-70wt% of kaolin fine powder and 30-50wt% of active alpha-Al2O3 micropowder as raw materials, and additionally adding raw materials of 2-5wt% of dextrin, 1-5wt% of metal aluminum powder and 1-3wt% of carbon black for mixing evenly to obtain a mixture; evenly mixing the raw materials of 3-10wt% of alumina sol, 1-3wt% of silica sol, 0.5-1.0wt% of spodumene and 2-8wt% of water to prepare slurry; placing the mixture in a disk for pelleting, and spraying the slurry while pelleting to prepare particles with a particle size of 1-10mm; and naturally drying the particles, then drying same under the condition of 100-110 DEG C, then rising the temperature to 1200-1600 DEG C, maintaining the temperature for 2-4h, naturally cooling, and screening to prepare the high intensity microporous mullite refractory aggregate. The invention has characteristics of simple process and low preparation power consumption, and the prepared product has great compression strength, high using temperature, low volume density, and small heat conductivity coefficient.

Owner:ANHUI JINYAN GAOLING SCI & TECH CO LTD

Acid-resisting alkali-resisting refractory castable for garbage incinerator

InactiveCN103496994AGood chemical resistanceImproved thermal shock stabilityChromium trioxideMullite

The invention relates to a refractory castable, and particularly relates to an acid-resisting alkali-resisting refractory castable for a garbage incinerator. The acid-resisting alkali-resisting refractory castable comprises the following raw materials: low-iron sintered mullite, boron carbide powder, silicon carbide, pure calcium aluminate cement, chromium trioxide powder, alpha-Al2O3 fine powder, uf-SiO2, zirconium oxide, magnesium oxide, a water reducing agent, a retarder, an explosion-proof agent and the like. The acid-resisting alkali-resisting refractory castable for the garbage incinerator, provided by the invention, has the advantages of good chemical corrosion resistance, good thermal shock stability, high operating temperature and long service life.

Owner:宜兴市张泽浇注耐火材料有限公司

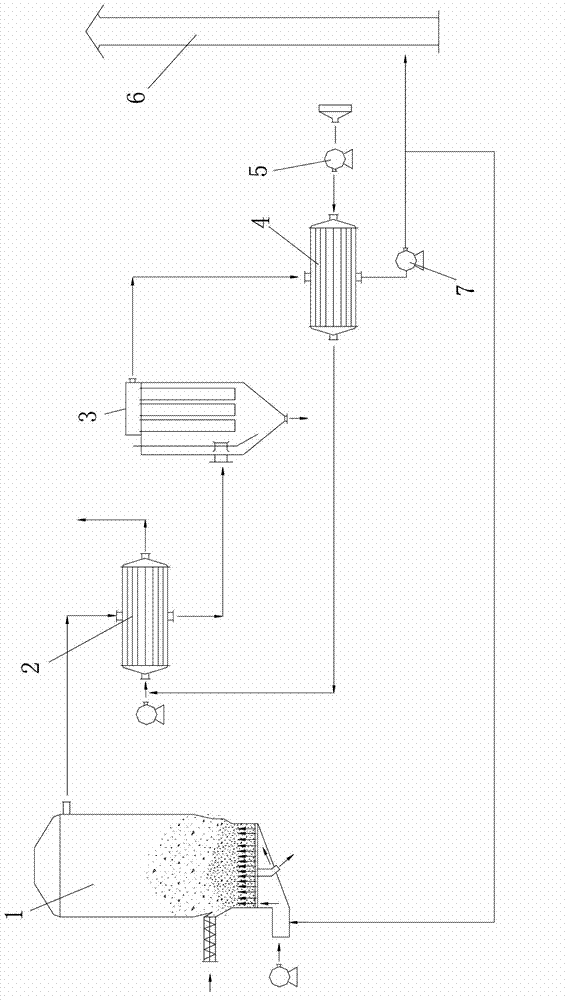

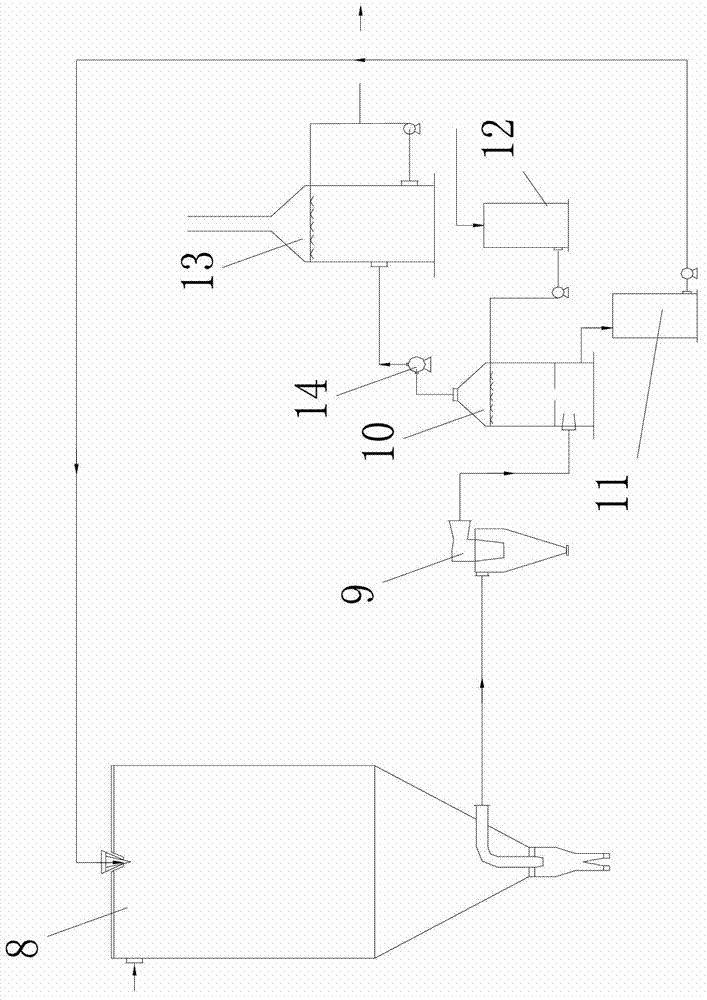

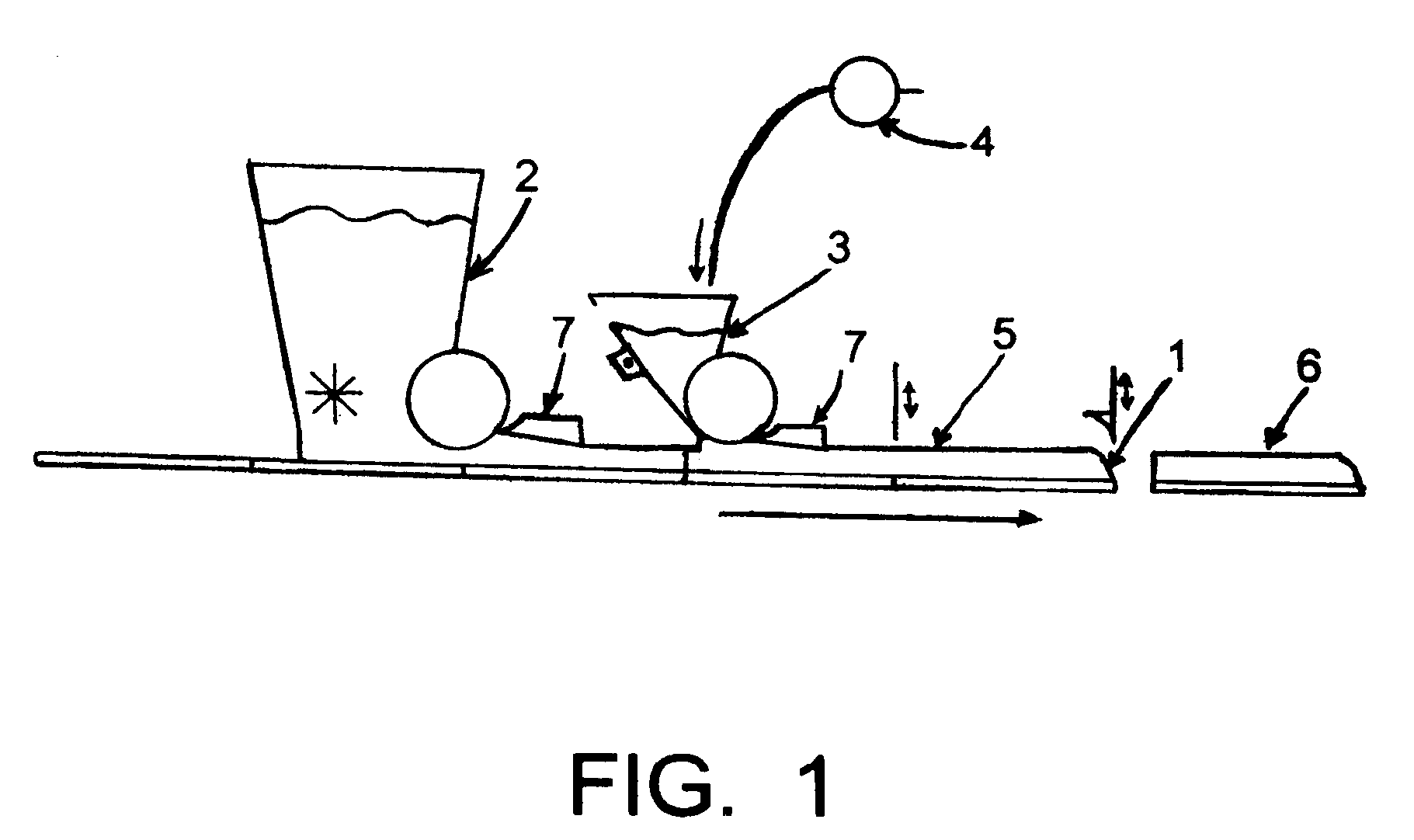

Device and method for dry and energy-saving production of polyaluminum chloride water purifying agent

ActiveCN102863061AImprove combustion efficiencyReduce the temperatureDrying gas arrangementsEnergy inputAir preheaterFlue gas

The invention discloses a device and a method for dry and energy-saving production of polyaluminum chloride water purifying agent. A furnace in fluid bed is used for heat supply, high-temperature flue gas generated by the furnace in fluid bed at 750-800 DEG C and air at the room temperature are subjected to secondary serial heat exchange, an air heat exchanger is used for further heating preheated air preheated to 70-75 DEG C by an air preheater to be at a temperature higher than 230 DEG C, the high-temperature flue gas is cooled to 200-230 DEG C after heat exchange by the air heat exchanger, the air at the room temperature is preheated to 70-75 DEG C by the air preheater, and the exhaust temperature of the flue gas is lowered to 100-120 DEG C. Polyaluminum chloride liquid supposed to enter a drying tower is subjected to negative-pressure spray concentration by dry tail gas with 0.5%-1.0% of drying powder and at the temperature of 105-120 DEG C, the tail gas is cooled to 70-80 DEG C while the 0.5%-1.0% of drying powder contained in the tail gas is absorbed by the polyaluminum chloride liquid, and the tail gas is exhausted after gas-liquid separation in an acid mist absorbing tower is completed. Therefore, the yield of a spray drying tower can be increased by about 5%, and comprehensive standard coal consumption for production of solid polyaluminum chloride per ton can be reduced by 60-90kg.

Owner:长沙天水环保科技有限公司

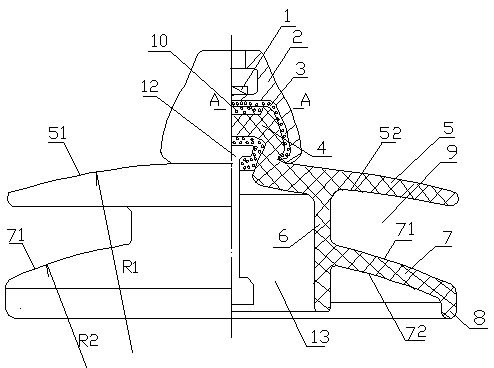

Electrolytic aluminum prebaked anode anti-oxidation insulating coating and preparation method thereof

ActiveCN110964352AHigh strengthHigh purityFireproof paintsAnti-corrosive paintsMetallurgyAluminium oxides

The invention provides an electrolytic aluminum prebaked anode anti-oxidation insulating coating. The electrolytic aluminum prebaked anode anti-oxidation insulating coating comprises the following components in percentage by mass: 60%-75% of a main component, 0.01%-5% of a secondary component, 24%-34% of a nano solvent binding phase and 0.01%-5% of a coating stabilizing phase, wherein the main component comprises amorphous aluminum oxide, nano-scale rho-Al2O3, nano-scale gamma-Al2O3 and nano-scale alpha-Al2O3. The insulating coating prepared by the invention can be cured at normal temperaturefor 6-8 hours after being sprayed to an anode by a spraying machine, the anode coating can form a compact net-shaped structure at the working temperature of 500-800 DEG C, the long-term tolerable temperature is over 900 DEG C, and the physical and chemical properties are stable.

Owner:CENT SOUTH UNIV +1

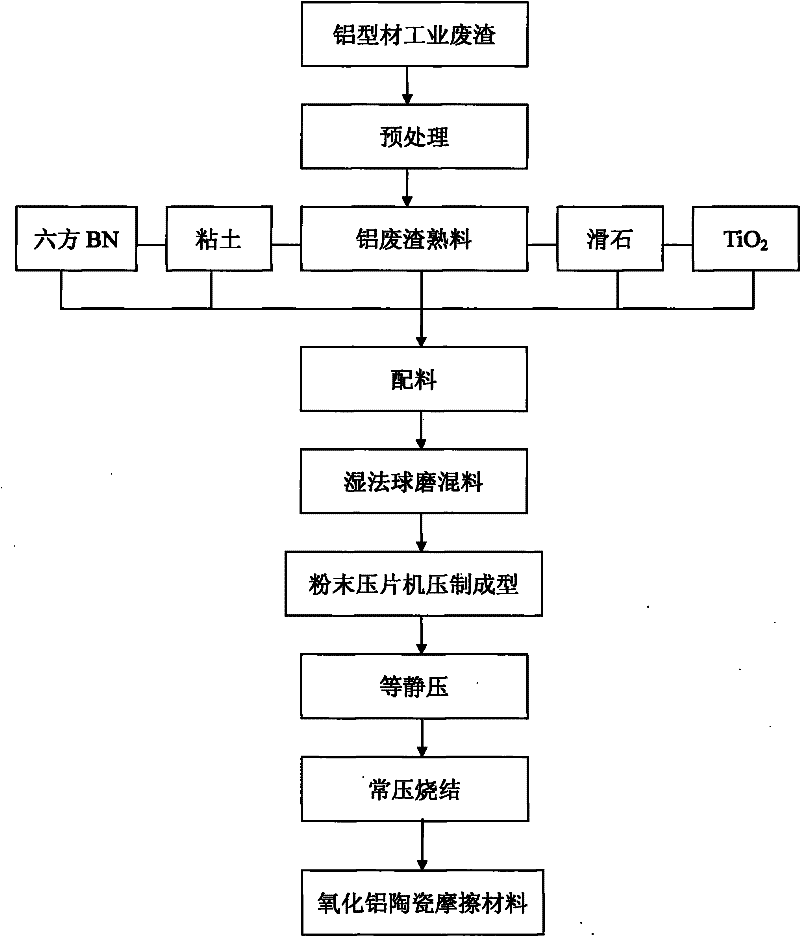

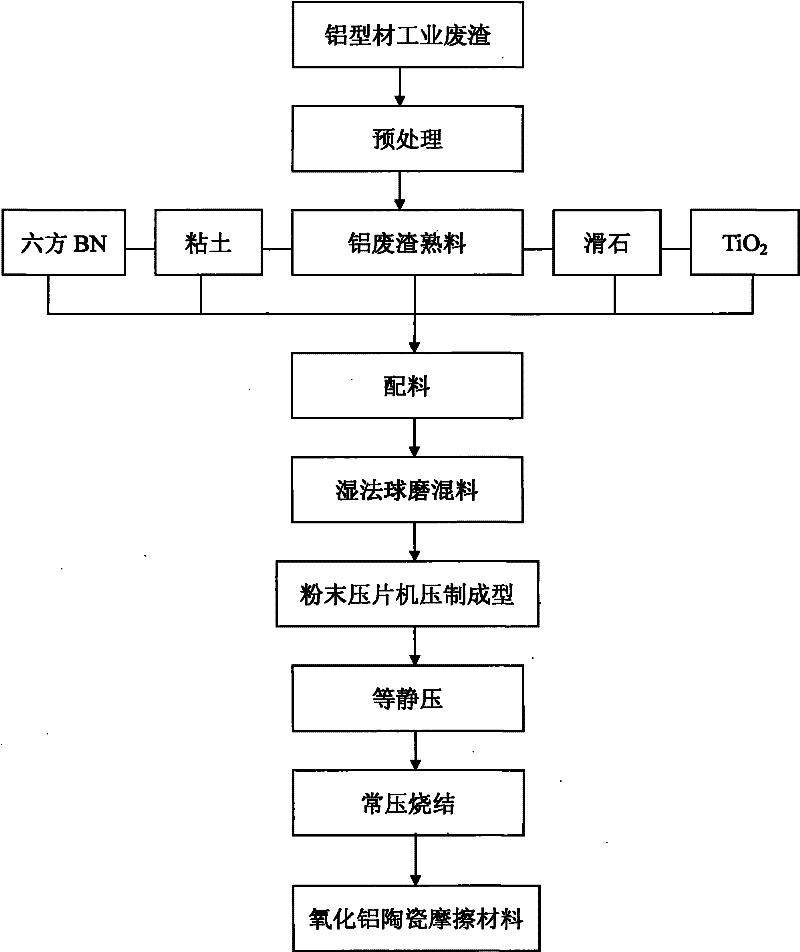

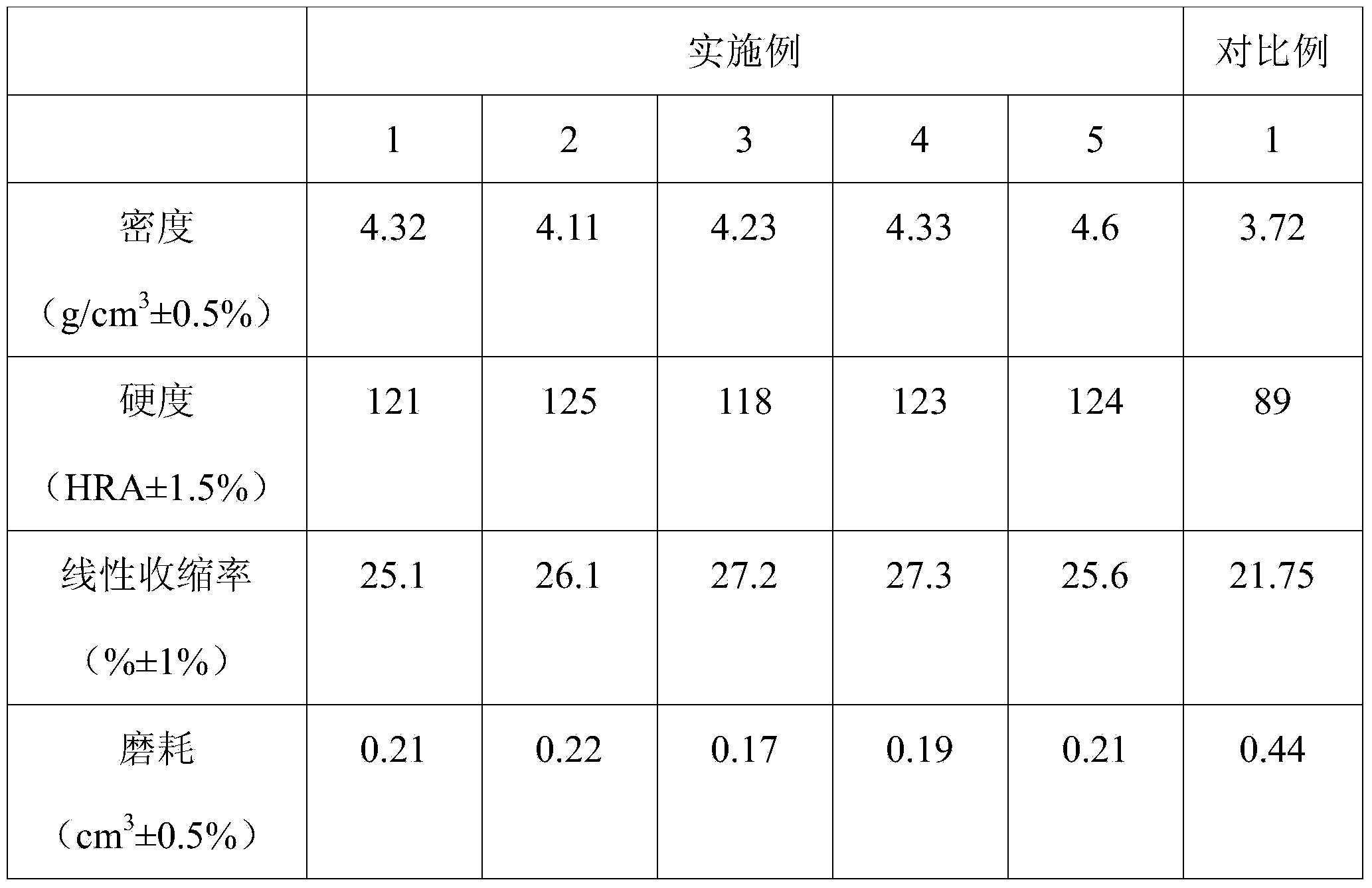

Aluminum oxide ceramic friction material prepared from aluminum profile industrial waste residue and preparation method thereof

The invention discloses a method for preparing an aluminum oxide ceramic friction material from aluminum profile industrial waste residue. The method comprises the following specific steps: (1) pretreating the aluminum profile industrial waste residue; (2) preparing the raw materials of the aluminum oxide ceramic friction material: preparing the raw materials, wherein the weight ratio of aluminum waste residue clinker to clay to talc to TiO2 to hexagonal boron nitride (BN) is (70-85):(5-20):(4-5):(1-2):4; performing the tertiary ball milling on the prepared raw materials, drying, and sieving with a 30-mesh sieve; (3) moulding the aluminum oxide ceramic friction material; and (4) sintering to obtain the aluminum oxide ceramic friction material. The friction material has the advantages of high mechanical strength and good friction and wear performance; the content of aluminum oxide in the aluminum profile industrial waste residue is up to 90%; the particles of the aluminum profile industrial waste residue are ultrafine and have high activity; and on the basis, a defined amount of sintering additive is added so as to effectively reduce the sintering temperature, save the energy and reduce the consumption.

Owner:SOUTH CHINA UNIV OF TECH

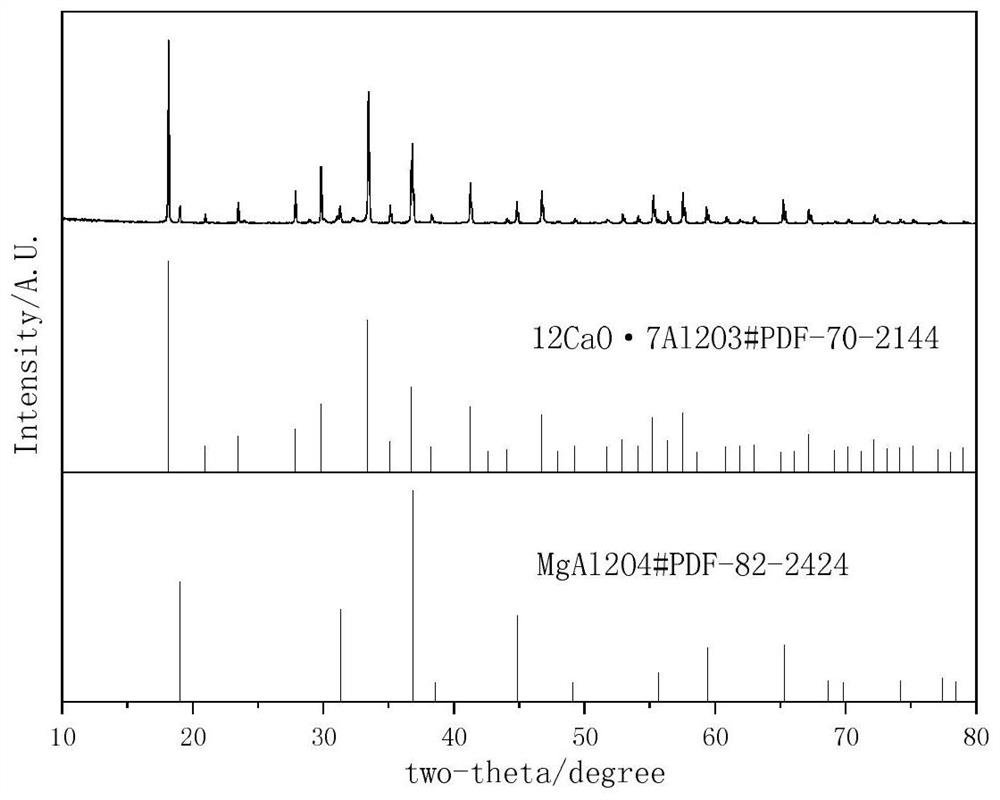

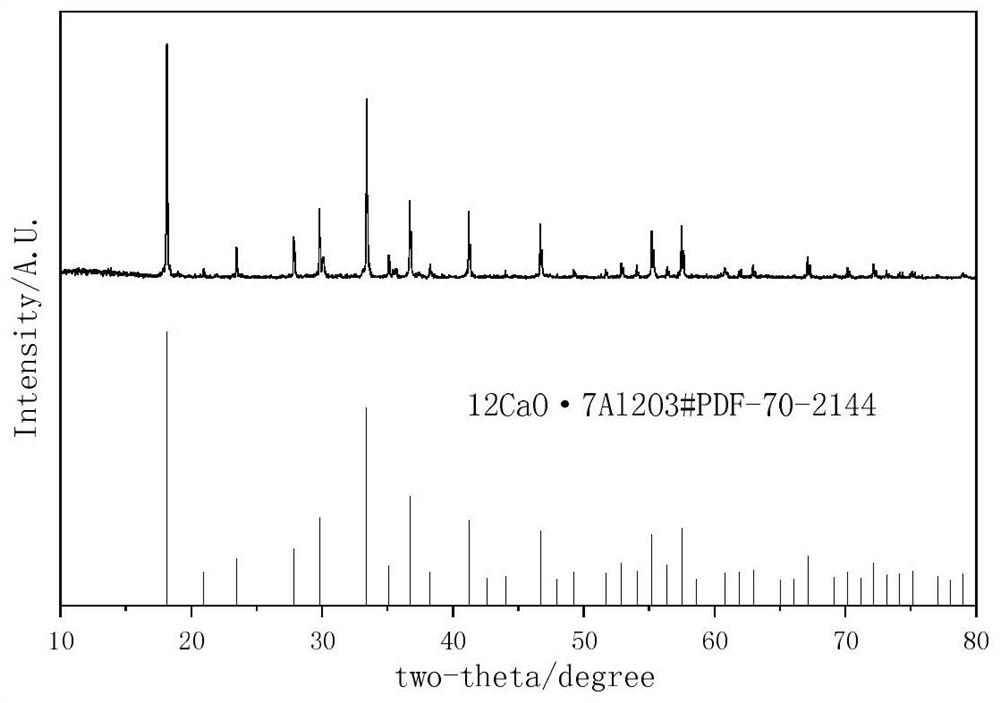

Method for preparing calcium aluminate by synergistic treatment of high-magnesium aluminum ash and fly ash

ActiveCN112607758AImprove decomposition rateIncrease spawn rateCalcium aluminatesAluminium silicatesCalcium aluminatesFly ash

The invention discloses a method for preparing calcium aluminate by synergistic treatment of high-magnesium aluminum ash and fly ash, which comprises the following steps: carrying out wet ball milling on high-magnesium aluminum ash, fly ash and quick lime, and sequentially carrying out washing, solid-liquid separation and roasting treatment on the ball-milled material to obtain a calcium aluminate product. According to the method, a calcium aluminate series product capable of being used for iron and steel smelting desulfurization is obtained by taking the aluminum ash generated in the aluminum smelting processing process as a raw material, so that the comprehensive utilization of hazardous wastes is realized, a relatively high economic value can be obtained, and the method is simple to operate and environment-friendly, and meets the industrial production requirements.

Owner:CENT SOUTH UNIV

Method of preparing light thermal insulation material by employing bauxite tailings

InactiveCN106830796ARealize resourcesHigh strengthCeramicwareThermal insulationUltimate tensile strength

The invention discloses a method of preparing a light thermal insulation material by employing bauxite tailings and relates to a comprehensive utilization method of bauxite tailings. The method is characterized by comprising the following steps of: adding the bauxite tailings into kaolin to calcined and reconstructed; and preparing the light thermal insulation material by taking the mixture as a raw material of the light thermal insulation material. The method disclosed by the invention makes full use of industrial solid wastes such as bauxite tailings, coal ash and flue gas desulfurization gypsum, and the material is low in cost, high in strength and good in thermal insulation property, and meanwhile, the requirement on SiO2 content is relatively low. The solid waste bauxite tailings can be scientifically utilized to realize reclamation of wastes, so that the method has far-reaching environmental-friendly meaning.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Emulsion polymer two-component compositions for fast curing cementitious waterproofing membranes

ActiveUS20170226013A1Extended opening timeFast curingSolid waste managementBuilding insulationsWaterproofingEmulsion

The present invention provides two-component compositions comprising a component A) one or more acrylic aqueous emulsion copolymer having a measured glass transition temperature (Tg) of from −20 to 0° C. and which is the copolymerization product of (i) from 60 to 89.9 wt. % of one or more nonionic (meth)acrylic monomers, (ii) from 10 to 40 wt. % of one or more vinyl aromatic monomers, (iii) from 0.1 to 2.0 wt. % of one or more monomers chosen from itaconic acid, methacrylic acid, amides of a,β-unsaturated C3 to C6 carboxylic acids, and mixtures thereof, all wt. %s of monomers based on the total monomer solids, wherein the aqueous emulsion copolymer has at least one residue of an ascorbic acid reducing agent or is the copolymerization product of a monomer (iii) comprising itaconic acid, and, a separate component B) comprising a fast curing dry mix powder composition of a hydraulic cement and a high alumina content cement.

Owner:DOW GLOBAL TECH LLC +2

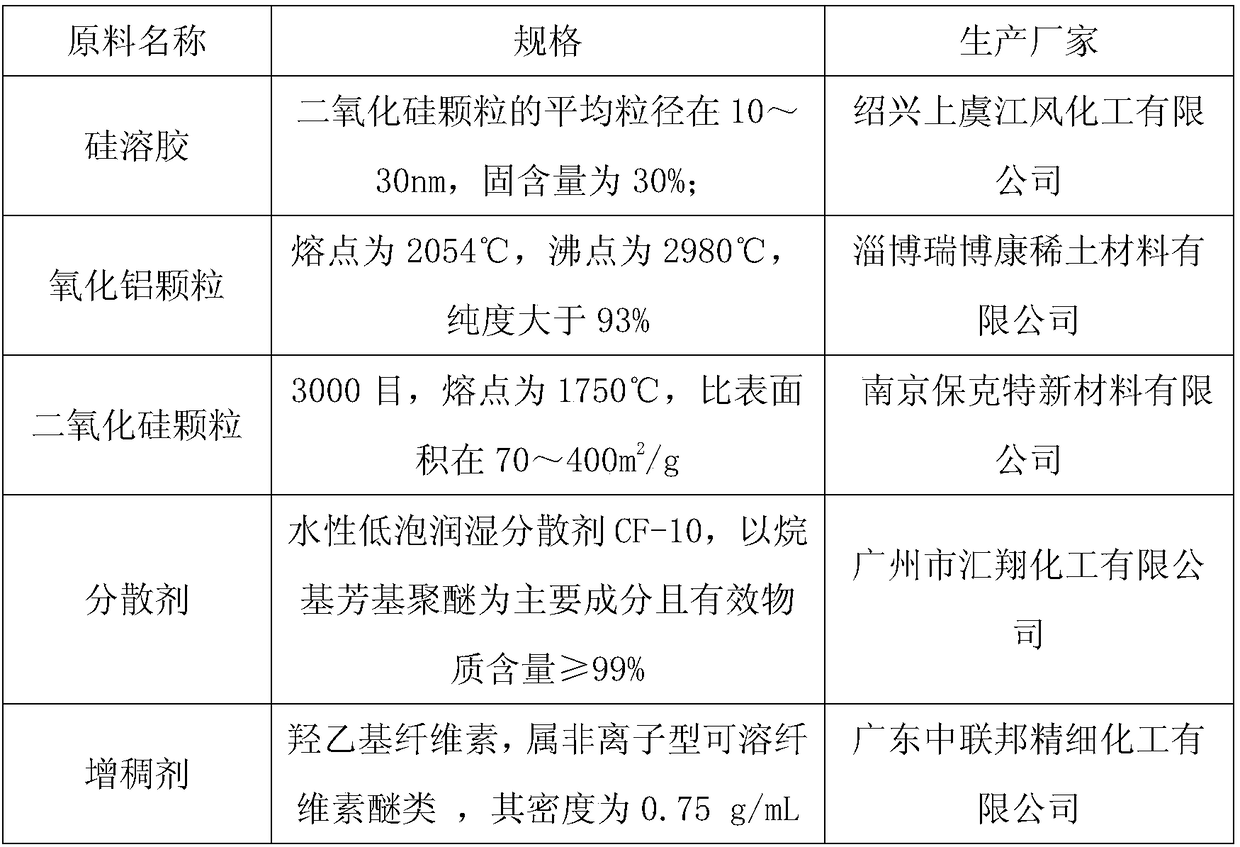

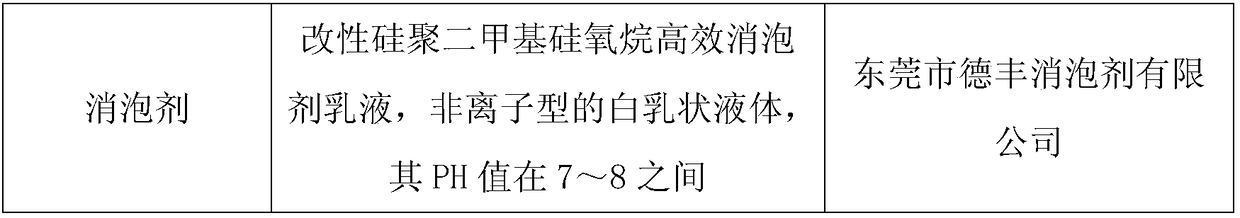

Sealing material used between coke oven protecting plate and oven door frame and preparation method

The invention provides a sealing material used between a coke oven protecting plate and an oven door frame. The sealing material is prepared from 100 parts by weight of a silica sol solution, 130-180parts by weight of aggregate and 15-17 parts by weight of an additive, wherein the aggregate is prepared from 45%-60% by mass of aluminium oxide particles, 20%-30% by mass of silicon dioxide particlesand 10%-35% by mass of talcum powder; the additive is prepared from a dispersant, a thickening agent and a water-based defoamer. The invention further provides a preparation method of the sealing material. The preparation method comprises steps as follows: firstly, the additive is added to the silica sol solution, the aggregate prepared from the aluminium oxide particles, the silicon dioxide particles and the talcum powder is added to a mixed solution and uniformly mixed, and the sealing material used between the coke oven protecting plate and the oven door frame is obtained. According to thesealing material, the coke oven protecting plate and the oven door frame can be sealed effectively, and the effect is remarkable; besides, construction is convenient, and labor intensity of an operator is greatly reduced.

Owner:SHANGHAI INST OF TECH

Preparation method of high-temperature structure and function integrated B4C (boron carbide)-enhanced Al (aluminum)-based neutron absorbing material

ActiveCN108130438AHigh alumina contentImprove sintering performanceNuclear energy generationReactor fuel elementsMicrometerStructure and function

The invention discloses a preparation method of a high-temperature structure and function integrated B4C (boron carbide)-enhanced Al (aluminum)-based neutron absorbing material, and belongs to the technical field of neutron absorbing materials and Al-based composite materials. The preparation method comprises the following steps of (1) pre-oxidizing the surface of superfine aluminum powder to increase the content of aluminum oxide; (2) uniformly mixing the superfine aluminum powder and micrometer-level B4C particles; (3) performing compression moulding on the powder, and sintering a pressed compact; (4) forging the sintered billet, extruding or rolling, so as to obtain a high-temperature structure and function integrated B4C / Al neutron absorbing profile or sheet. The preparation method hasthe advantages that in the final material, the aluminum oxide is distributed into crystal interfaces of material, and the pining is performed, so as to obviously enhance the high-temperature propertyof the material; by adding the B4C particles, the room-temperature and medium-temperature strengths can be further improved, and the neutron absorbing function is realized; the technology is simple and convenient and is easy to implement; the strength of the material at the room temperature to high temperature are higher than the actual use requirements, and the material can be applied to the storage and transportation of the spent fuel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ultrahigh-density ceramsite proppant and preparation method thereof

ActiveCN103242819AImproved and optimized particle gradationHigh bulk densityFluid removalManganeseUniform rotation

The invention discloses an ultrahigh-density ceramsite proppant and a preparation method thereof. The ultrahigh-density ceramsite proppant is prepared from the following ingredients in percentage by weight: 75-85% of bauxite, 5-18% of alumina micropowder, 1-4% of clay, 1-3% of manganese ore, 1-3% of silicon micropowder, 1-3% of limestone and 2-4% of high-ferrum bauxite. The preparation method comprises the steps of co-grinding all the ore raw materials according to a proportioning ratio into fine powder which has the 325-mesh sieve pass ratio of over 98%, adding the alumina micropowder and the silicon micropowder, mixing uniformly by using a ball mill, loading a mixture to a granulation pot, carrying out spraying granulation under the uniform rotation of the granulation pot, screening granules, drying the screened granules until the moisture content is not higher than 3%, loading the dried granules to a rotary kiln, and sintering for 0.5-1.5 h at the temperature of 1,320-1,380 DEG C, thereby preparing the ultrahigh-density ceramsite proppant. The ultrahigh-density ceramsite proppant disclosed by the invention is stable in performance and low in production cost, and meets the national oil and gas industry standards.

Owner:渑池德惠石油支撑剂有限公司

Emulsion Polymer Two-Component Compositions For Fast Curing, Flexible Cementitious Waterproofing Membranes

The present invention provides two-component compositions for making a waterproofing membrane comprising as component A) one or more acrylic aqueous emulsion copolymerization product (copolymer) of (i) from 60 to 89.9 wt. % of one or more nonionic (meth)acrylic monomers, preferably, butyl acrylate, methyl acrylate or ethylhexyl (meth)acrylate, (ii) from 10 to 40 wt. % of one or more vinyl aromatic monomers, (iii) from 0.1 to 2.0 wt. % of one or more amide functional acrylic monomer, and mixtures thereof with itaconic acid or methacrylic acid, wherein the emulsion copolymer has at least one residue of an ascorbic acid reducing agent and of t-butyl hydroperoxide and has less than 40 ppm or, preferably, less than 20 ppm, or more preferably, less than 10 ppm, of residual (meth)acrylamide.

Owner:DOW GLOBAL TECH LLC +1

Sanitary shale ceramic and preparation method thereof

The invention discloses a sanitary shale ceramic and a preparation method thereof. The blank of the sanitary shale ceramic comprises the following raw materials: 10-20wt% of Boai clay, 5-15wt% of bauxite, 5-15wt% of white gangue, 5-15wt% of ash waste rock, 1-5wt% of Yuan'an clay, 5-15wt% of black mud, 5-40wt% of shale, 10-20wt% of quartz and 5-25wt% of feldspar. As shale is adopted as a main raw material, the sanitary ceramic with excellent properties are made, the material cost is effectively reduced, meanwhile the product quality is ensured, the sintering temperature is low in the preparation process, energy consumption is effectively reduced, and the production cost is reduced.

Owner:四川金辉卫浴洁具有限公司

Method for preparing beta-type aluminum hydroxide

InactiveCN101182021AHigher than the surfaceHigh alumina contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateCarbon dioxide

The invention relates to a preparation method of Beta-type aluminum hydroxide, which is used for preparing the Beta-type aluminum hydroxide. Sodium aluminate solution is used as raw material, neutralized by feeding carbon dioxide and then is treated with filtering washing and drying to obtain the Beta-type aluminum hydroxide product. The preparation method is characterized in that Beta-type aluminum hydroxide seeds are added before the carbon dioxide is fed so as to produce the Beta-type aluminum hydroxide product with high purity and large specific surface area; in addition, the method has simple production technology, easy control of particle size and easy manipulation of the operation process.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Intensified lime-sintering method for preparing alumina clinker by adopting medium or high-grade alumyte

InactiveCN101555031AWide variety of sourcesSolve the problems that have always existed in the extraction of aluminaAluminium oxides/hydroxidesRed mudMaterials science

The invention discloses an intensified lime-sintering method for preparing alumina clinker by adopting medium or high-grade alumyte. The method includes the following steps: the medium or high-grade alumyte is mixed with calcium oxide, with the calcium-aluminium molar weight ratio ranging from 1.3 to 1.5; and the alumina-contained clinker can be obtained after the mixture is sintered for 30 to 90 minutes at a temperature ranging from 1270 DEG C to 1310 DEG C. The invention adopts an intensified lime-sintering method, i.e., the alumyte is added with calcium oxide. Compared with soda lime sintering method, the invention has the advantages that raw materials are broad in source, the clinker is dispensed with alkali, carbon seed pregnant liquor is not sintered, the alkali is circulated only in wet processing step, and dry sintering method with lower alkali consumption and lower energy consumption can be adopted. Besides, the invention also solves the difficulties that the clinker has high content of alumina, thinning of red mud dissolved from the clinker is serious, and the red mud is poor in settling property. The method, which is simple but has ideal using effect, solves the difficulties existing in the method of extracting alumina from medium or high-grade alumyte.

Owner:GUIZHOU NORMAL UNIVERSITY

Manufacture method of high-strength disc porcelain insulator

ActiveCN108538526AHigh tensile strengthImprove flexural strengthInsulatorsChina clayUltimate tensile strength

The invention discloses a high-strength disc porcelain insulator. The high-strength disc porcelain insulator comprises an insulator body, a steel cap and a steel pin, wherein the steel cap and the steep pin are in gluing connection with two ends of the insulator body through gluing layers; the insulator body of the high-strength disc porcelain insulator comprises a core head, a core bar, an upperskirt and a lower skirt, and is prepared from 20wt%-40wt% of calcined bauxite, 20wt%-40wt% of clay, 10wt%-15wt% of Nankeng china clay from Pingxiang, 5wt%-10wt% of tungsten pit mud from Yichun, 10wt%-20wt% of feldspar, 3wt%-5wt% of Dazhang clay from Liling and 3wt%-5wt% of black clay from Guangdong through mixing, dehydration clay squeezing, vacuum pugging, blank forming, fettling sintering, glazing, firing and gluing. Through structural and shape improvement, raw material selection and formula and process adjustment, skirt surfaces are processed by reasonably selecting raw materials with specific performance on the premise that material cost is not increased and a product does not get hard or brittle, and mechanical strength and various electrical properties of the insulator body are improved.

Owner:江西省萍乡市玻瓷高压绝缘子有限公司

Rhenium recovery from used reductive amination catalysts

ActiveUS20150087837A1Robust to reductive aminationImprove the immunityChemical recyclingFilter regenerationRheniumAqueous solution

The present invention provides techniques that selectively recover Re from reductive amination catalysts. In particular, the present invention allows Re to be recovered selectively relative to Ni, Co, and / or Cu, and particularly Ni, that are often present on reductive amination catalysts. The present invention uses a combination of oxidation and extraction techniques to selectively recover Re relative to Ni, Co, and / or Cu. Advantageously, the recovery is selective even when using aqueous solutions for extraction.

Owner:DOW GLOBAL TECH LLC

Alumina ceramic material and preparation method thereof

The invention provides an alumina ceramic material which uses high-alumina fly ash, light calcium carbonate and magnesium carbonate as raw materials. The preparation method comprises the following steps: firstly, performing pre-desilicification and acid activation pretreatment on the high-alumina fly ash to improve the alumina content in the high-alumina fly ash; then, ball-milling the high-alumina fly ash, the light calcium carbonate, the magnesium carbonate, water, a dispersing agent and a binding agent, drying, and grinding, so as to obtain powder; sieving and deironing the powder, adding a release agent, uniformly mixing, then pressing into a green body, and performing pressurization high-temperature sintering on the green body, so as to obtain the alumina ceramic material. According to the method, no other additional aluminium sources are needed, and the sintering temperature is obviously reduced during the preparation process, so that the cost is reduced; moreover, the method is high in parameter controllability and high in repeatability, and the prepared products are good in consistency, high in abrasion resistance and high in stability.

Owner:江苏龙欧新型建材科技有限公司

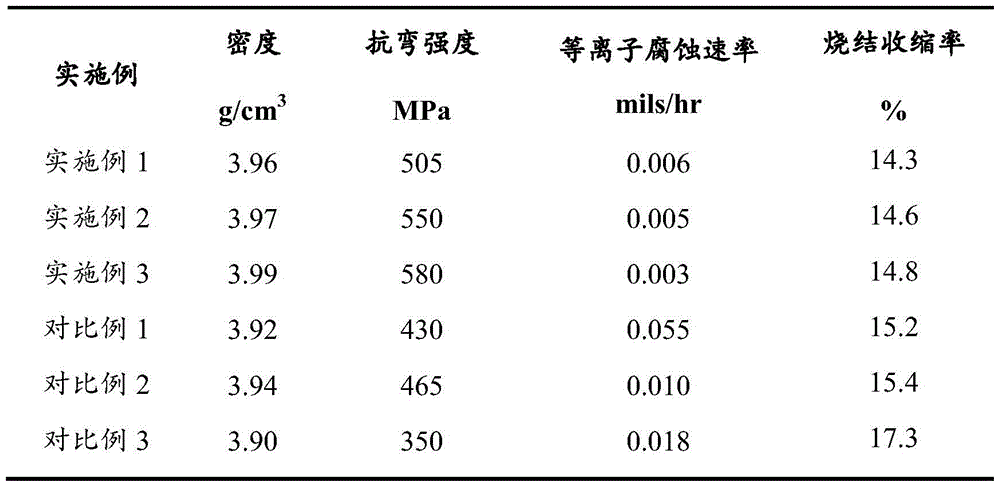

Plasma etching resistant ceramic body and manufacturing method thereof, and plasma etching device

ActiveCN105777079ALow glass contentImprove plasma corrosion resistanceCompression moldingHigh density

The invention discloses a plasma etching resistant ceramic body and a manufacturing method thereof, and a plasma etching device. The plasma etching resistant ceramic body is obtained by carrying out compression molding forming treatment of an alumina powder and then sintering, wherein the alumina powder contains inevitable impurity composition, and the mass content of the impurity composition is not more than 0.001%. The plasma etching resistant ceramic body has high plasma corrosion resistance, and the preparation method can make the prepared plasma etching resistant ceramic body have the advantages of high plasma corrosion resistance, stable size and high density. An etching chamber of the plasma etching device is internally provided with an alumina ceramic component which is formed by the plasma etching resistant ceramic body. Therefore, the alumina ceramic component has good plasma corrosion resistance, the yield of wafers obtained from etching is high, and the service life of the alumina ceramic component is effectively prolonged.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

Pseudo boehmite preparation method

InactiveCN107352565AHigh crystallinityHigh alumina contentPhysical/chemical process catalystsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSalt solutionFilter cake

The present invention discloses a pseudo boehmite preparation method, and relates to a method for preparing pseudo-boehmite by using a FCC spent catalyst. The preparation method comprises: A) adding a FCC spent catalyst to an acid solution, uniformly mixing and stirring, carrying out a reaction for 1-8 h at a temperature of 50-90 DEG C, filtering, washing, and collecting the filtrate to obtain an acid reaction liquid; B) adding the acid reaction liquid obtained in the step A) to an alkali solution, carrying out a complete reaction, filtering, and washing, wherein the obtained filtrate is a metaaluminate solution; C) mixing the filtrate obtained in the step B) and an aluminum salt solution, adjusting the pH value of the system to 7.5-12, and aging for 2-12 h at a temperature of 60-100 DEG C under a stirring state to obtain a reaction product; and D) filtering the reaction product obtained in the step C), carrying out water washing, drying the filter cake, and crushing to obtain the pseudo boehmite. According to the present invention, the new technical route is provided for the preparation of the high added-value pseudo boehmite from the FCC spent catalyst, and the environmental pollution caused by the FCC spent catalyst can be solved.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

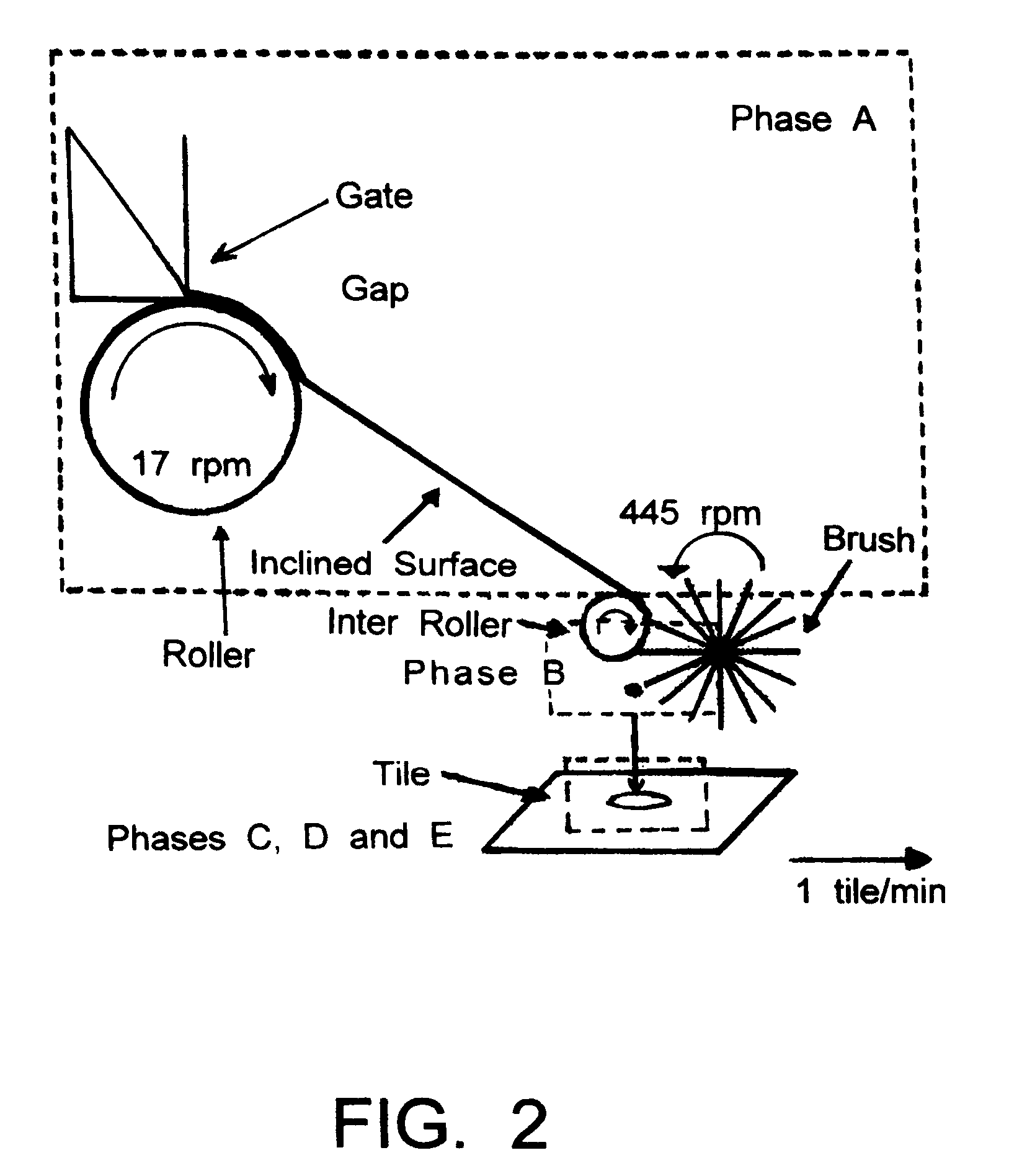

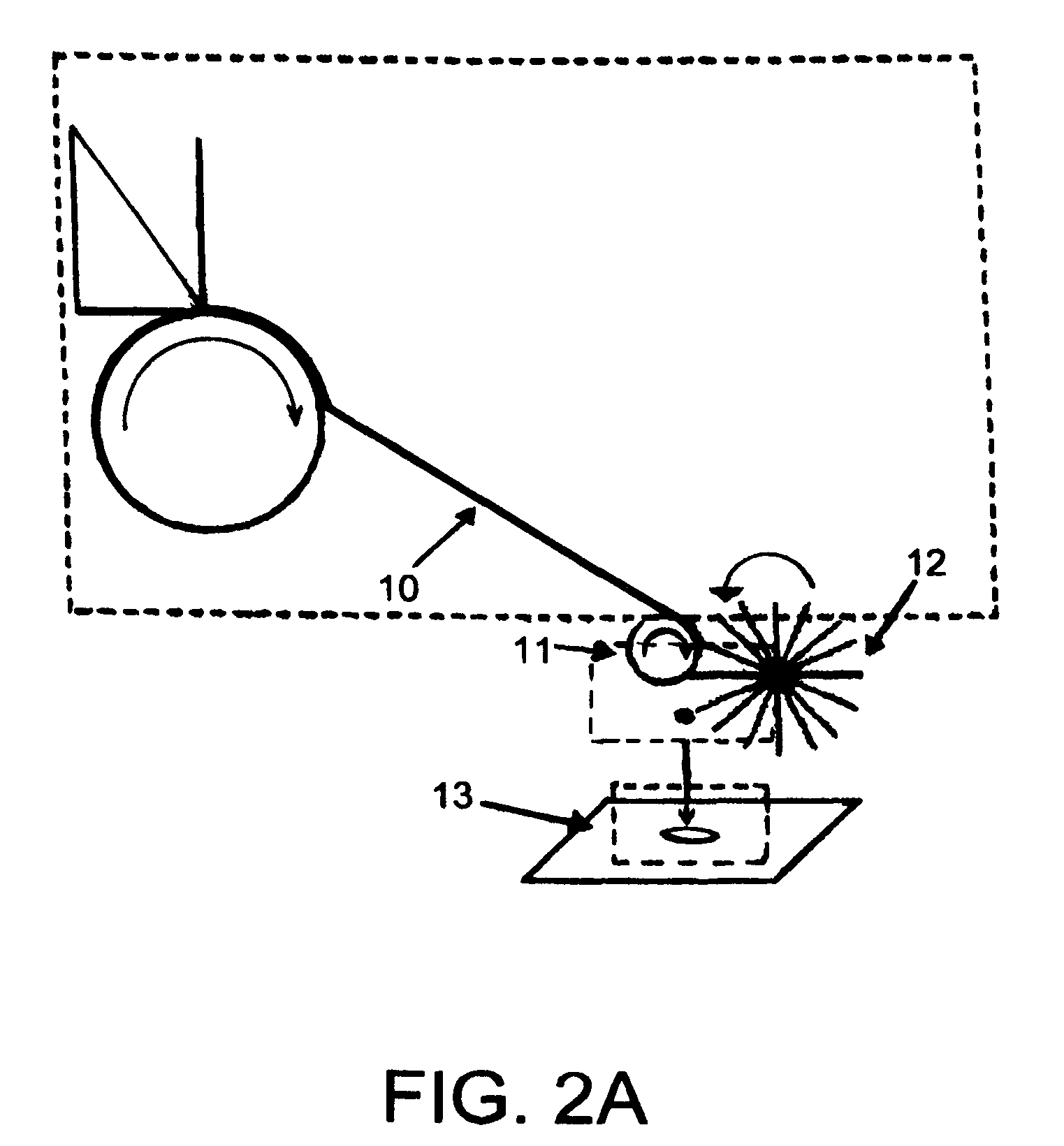

Roofing tile with enhanced surface durability and processes for manufacturing the roofing tile

InactiveUS20090075059A1Increased durabilityReduces water demandRoof covering using tiles/slatesSolid waste managementRoof tileTrademark

A new roofing tile with enhanced surface durability and processes for manufacturing the same. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:MONIER TECHN CENT

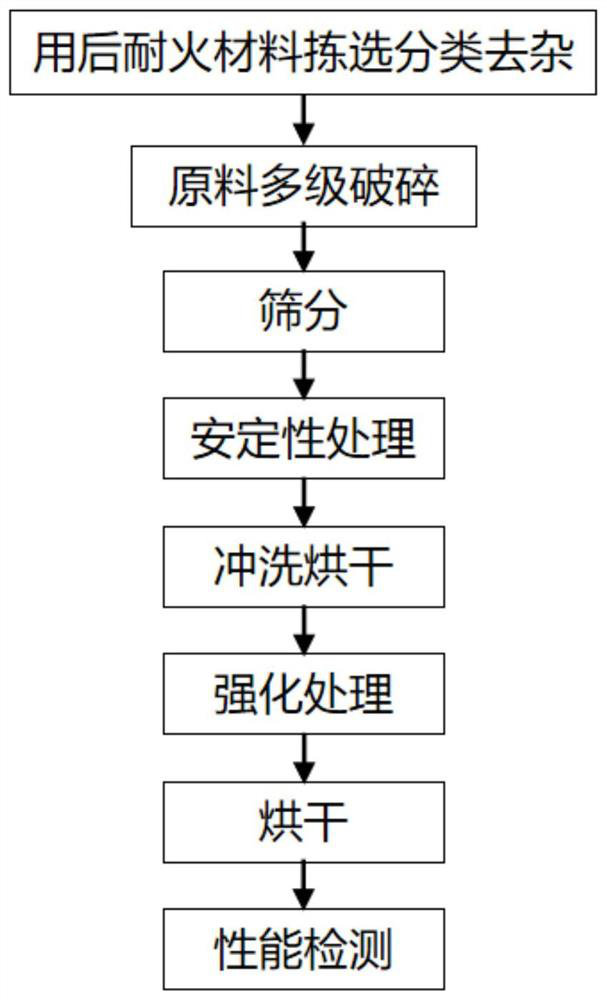

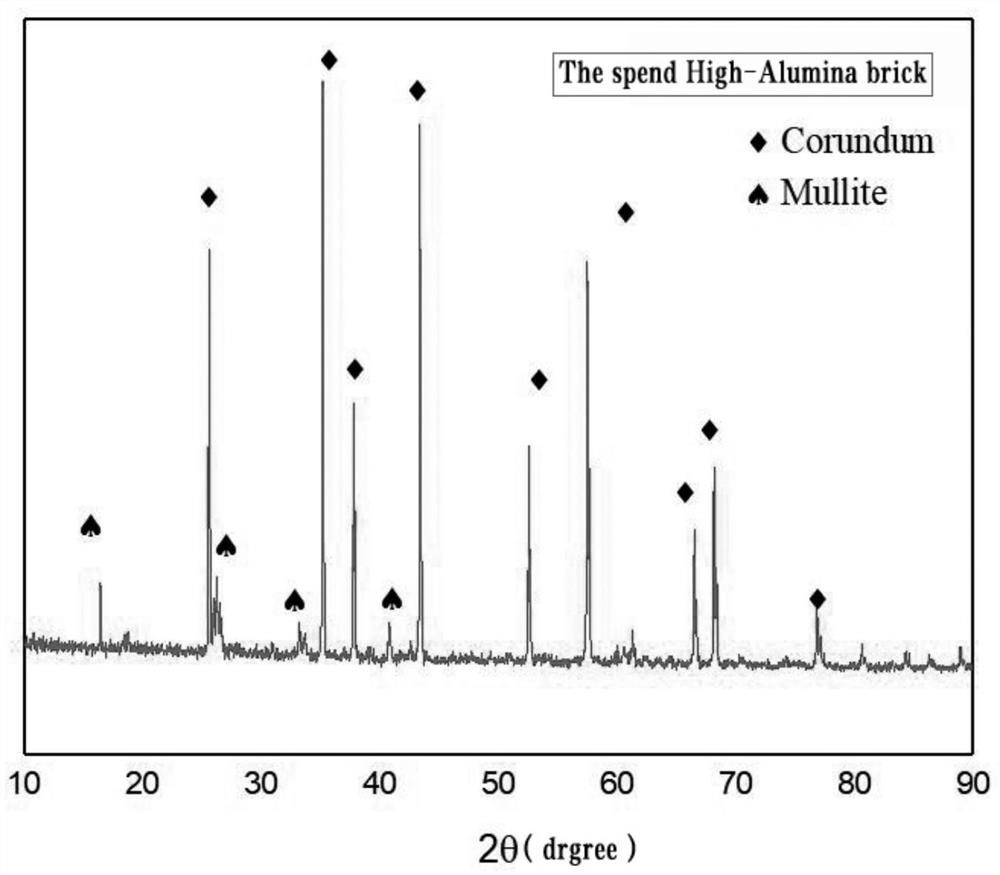

High-wear-resistance anti-skid pavement aggregate, pavement and preparation method

InactiveCN111718143AIncrease added valueAchieve protectionSolid waste managementCarbide siliconBrick

The invention discloses a high-wear-resistance anti-skid pavement aggregate, a pavement and a preparation method. The high-wear-resistance anti-skid pavement aggregate is obtained by taking a waste refractory material as a raw material and carrying out sorting, crushing, screening, soaking and strengthening treatment on the waste refractory material, and the waste refractory material comprises a waste high-alumina refractory material and a waste silicon mullite brick. Main phases in the waste high-alumina refractory material are corundum, mullite and quartz, wherein the mass percentage of Al2O3 is greater than or equal to 60%; main phases in the waste silicon mullite brick are corundum, mullite, silicon carbide and quartz, wherein the mass percentage of Al2O3 is greater than or equal to 55%. The waste is high in alumina content, high in hardness and strength and good in wear resistance, and compared with a process of treating the waste to prepare a refractory material, the process is simple and low in cost.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com