Device and method for dry and energy-saving production of polyaluminum chloride water purifying agent

A technology of polyaluminum chloride and water purifier, applied in aluminum chloride, dry gas layout, aluminum halide, etc., can solve the problems of coal combustion utilization rate of only about 85%, thermal efficiency of only 65%, and too high requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

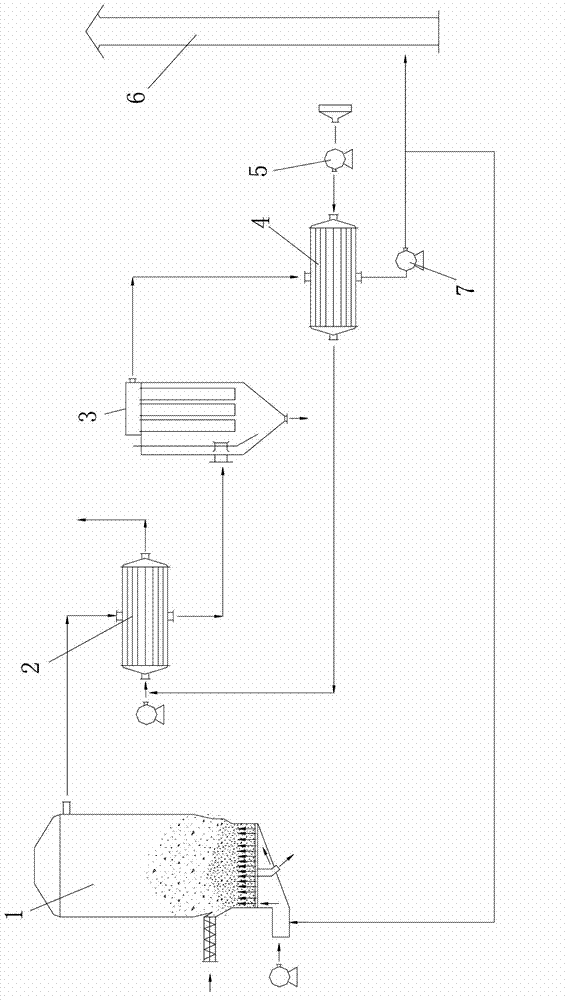

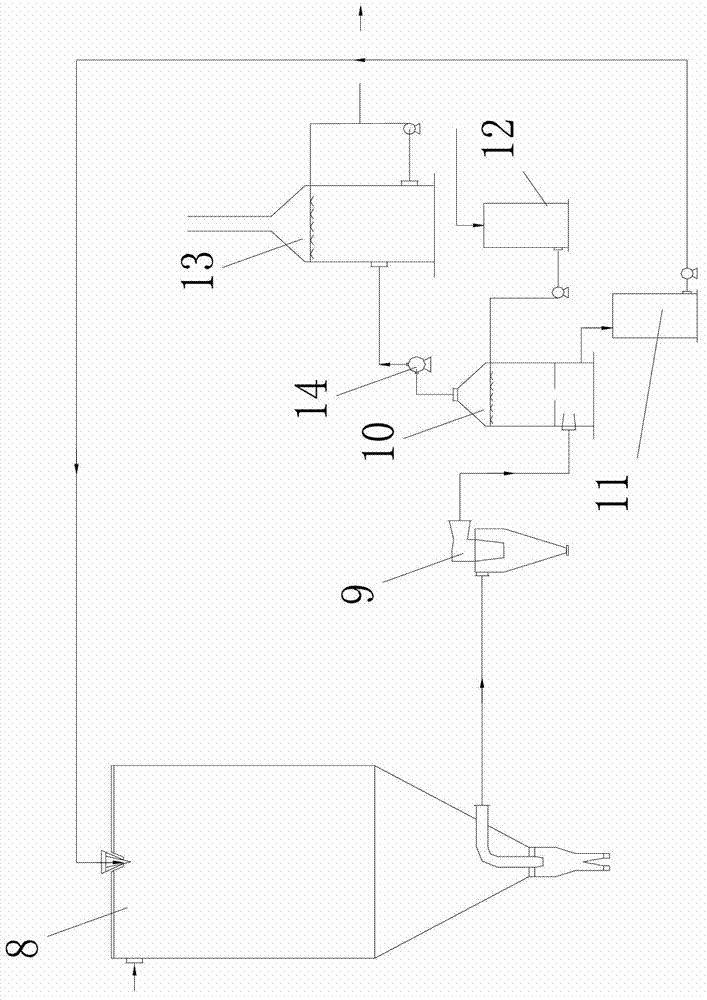

Image

Examples

Embodiment 1

[0030] Using aluminum hydroxide, calcium aluminate and hydrochloric acid as raw materials, add 1000Kg of aluminum hydroxide, 4000kg of 31% hydrochloric acid and 2500kg of water into a 10000L enamel reaction kettle, and react under 0.2MPa pressure for 2 hours, then cool down to 100°C, add 1000kg of calcium aluminate was reacted for another 1.5 hours, and then filtered to obtain liquid polyaluminum chloride with an alumina content of 13.5%. The liquid polyaluminum chloride with an alumina content of 13.5% is used as raw material for spray drying. The flue gas temperature at the outlet of the fluidized fluidized furnace is 750°C-800°C. After the second heat exchange, the flue gas temperature decreases by 100°C-120°C. After the second heat exchange, it is heated to 250°C-260°C as dry hot air. After the hot air passes through the drying tower to dry the material, the temperature of leaving the drying tower is 110°C-118°C. The tail gas at this temperature is used as the pre-drying co...

Embodiment 2

[0032] Using aluminum hydroxide and hydrochloric acid as raw materials, add 3600Kg of aluminum hydroxide, 7600kg of 31% hydrochloric acid and 500kg of water in a 10000L enamel reaction kettle, and react at a pressure of 0.4MPa for 4 hours, then cool down to 100°C, and filter to obtain the content of alumina It is 18.0% liquid polyaluminum chloride. The liquid polyaluminum chloride with an alumina content of 18.0% is used as raw material for spray drying. The flue gas temperature at the outlet of the fluidized fluidized furnace is 750°C-800°C. After the second heat exchange, the flue gas temperature decreases by 100°C-120°C. After the second heat exchange, it is heated to 230°C-240°C as dry hot air. After the hot air passes through the drying tower to dry the material, the temperature of leaving the drying tower is 105°C-110°C. The tail gas at this temperature is used as the pre-drying concentration tower. Hot air can increase the liquid polyaluminum chloride with alumina conte...

Embodiment 3

[0034] Using bauxite, calcium aluminate and hydrochloric acid as raw materials, add bauxite 2300kg, 31% hydrochloric acid 4000kg and water 2500kg in a 10000L reaction tank, react at 100°C for 3 hours, add calcium aluminate 1000kg, and then react for 1.5 hour, then filtered to obtain aluminum oxide content of 13.5% of the liquid polyaluminum chloride. The liquid polyaluminum chloride with an alumina content of 13.5% is used as raw material for spray drying. The flue gas temperature at the outlet of the fluidized fluidized furnace is 750°C-800°C. After the second heat exchange, the flue gas temperature decreases by 100°C-120°C. After the second heat exchange, it is heated to 250°C-260°C as dry hot air. After the hot air passes through the drying tower to dry the material, the temperature of leaving the drying tower is 110°C-118°C. The tail gas at this temperature is used as the pre-drying concentration tower. Hot air can increase the liquid polyaluminum chloride with alumina con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com