Aluminum oxide ceramic friction material prepared from aluminum profile industrial waste residue and preparation method thereof

A technology of alumina ceramics and industrial waste slag, which is applied in the field of preparing alumina ceramic friction materials from aluminum profile industrial waste slag, can solve the problems of high cation charge, high sintering temperature, and low diffusion coefficient, and achieve high activity, high mechanical strength, Good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

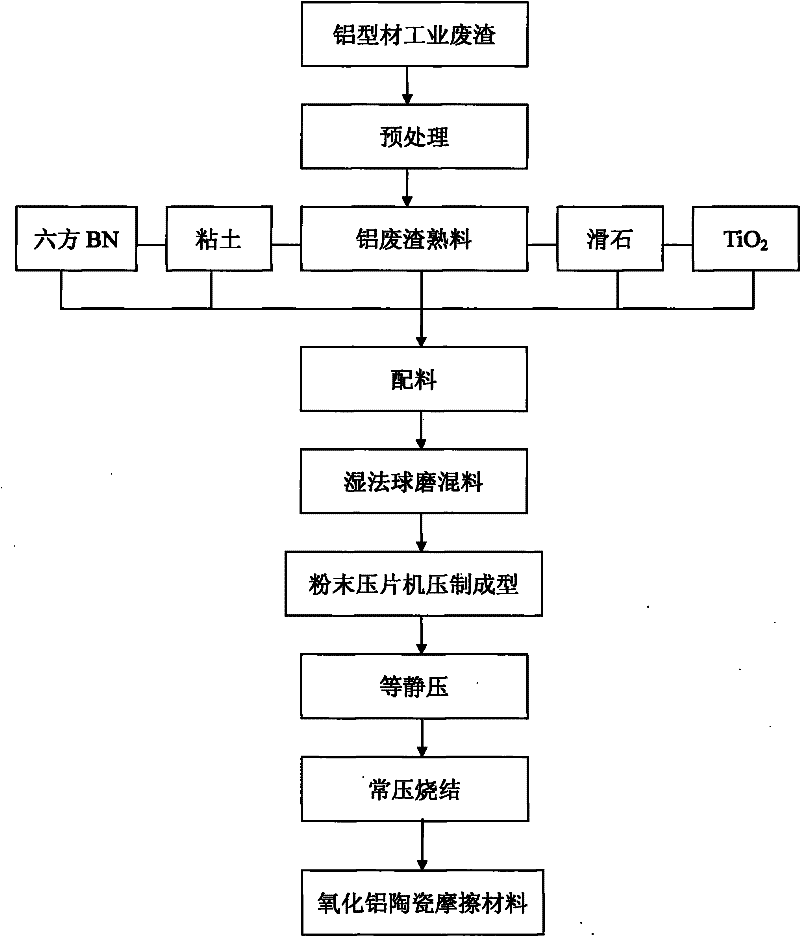

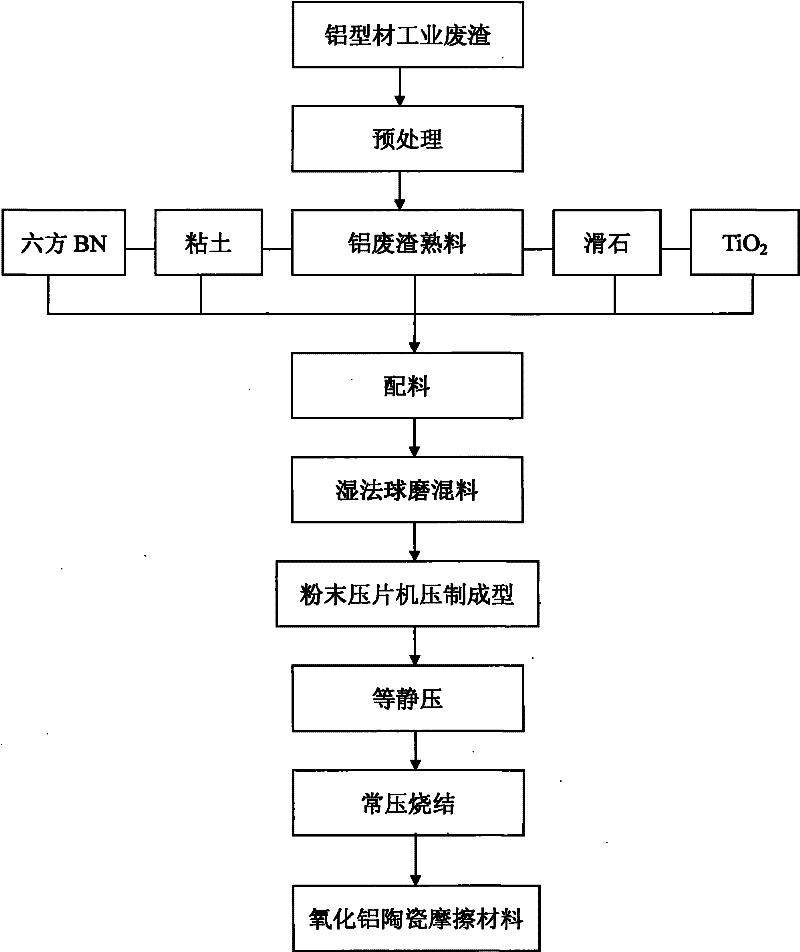

Method used

Image

Examples

Embodiment 1

[0029] Put 100g of aluminum profile industrial waste slag into a ball mill tank and carry out wet ball milling, according to the mass ratio of material: ball: water = 1: 2: 1 mixture (material refers to aluminum profile industrial waste, water is deionized water, and ball is alumina small balls), milled for 4 hours, filtered through a 250-mesh sieve, dried in a drying oven at 120°C, and then calcined in a high-temperature furnace at a temperature of 1000°C and a heating rate of 150°C / h , the holding time is 1h, after natural cooling, the calcined aluminum profile industrial waste slag clinker is obtained; the calcined aluminum profile industrial waste slag clinker is then subjected to wet ball milling, according to the mass ratio material: ball: water = 1: 2: 1 mixing, ball milling After 8 hours, pass through a 250 mesh sieve again, and then obtain the used aluminum waste slag clinker after drying the sieved slurry; according to the aluminum waste slag clinker: clay: talc: TiO ...

Embodiment 2

[0031] The present embodiment differs from Example 1 in that: according to aluminum waste slag clinker: clay: talc: TiO 2 : Hexagonal BN=75:15:4:2:4, batching. The alumina ceramic friction material prepared in this example has a bending strength of 224Mpa, a microhardness of 9.02Gpa, a friction coefficient of 0.675, and a wear rate of 6.81×10 -6 mm 3 (N·m) -1 .

Embodiment 3

[0033] The present embodiment differs from Example 1 in that: according to aluminum waste slag clinker: clay: talc: TiO 2 : Hexagonal BN=80:10:4:2:4, batching. The alumina ceramic friction material prepared in this example has a flexural strength of 258Mpa, a microhardness of 9.64Gpa, a friction coefficient of 0.642, and a wear rate of 6.03×10 -6 mm 3 (N·m) -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com