High-wear-resistance anti-skid pavement aggregate, pavement and preparation method

A high wear-resistant, aggregate technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of undiscovered waste refractory materials, etc., to achieve environmental protection, high hardness and strength, alumina high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

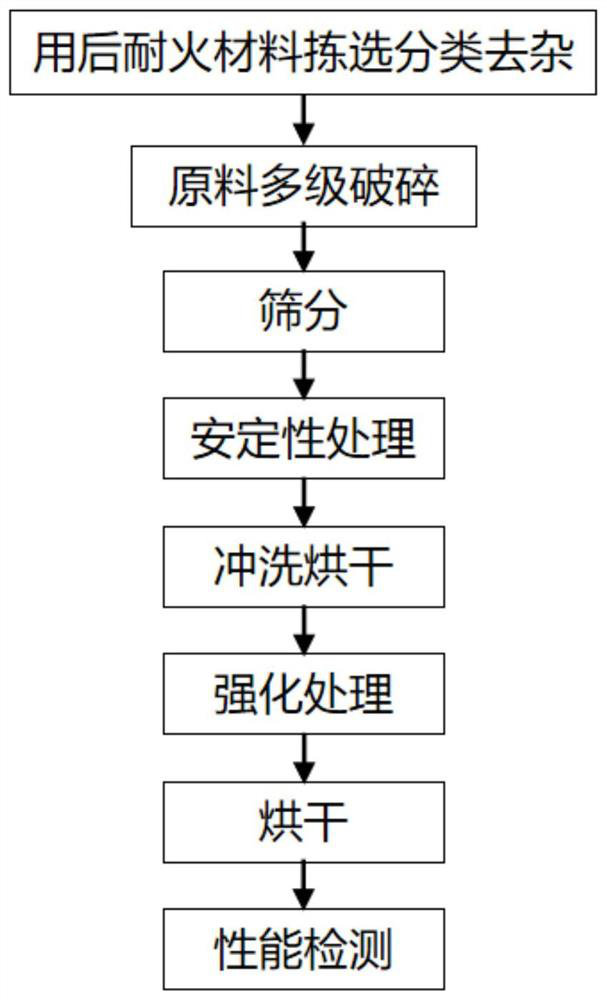

[0034] The preparation method of the high wear-resistant and anti-skid pavement aggregate of the present invention comprises using waste refractory materials as raw materials, sorting, crushing, sieving, soaking and strengthening treatment of the waste refractory materials, and specifically includes the following steps:

[0035] Step 1: Sorting the waste refractory materials and stacking them according to the different alumina content of the waste refractory materials. During the sorting process, remove the sticky slag layer, reaction layer and metamorphic layer of the waste refractory materials to obtain recyclable refractory materials;

[0036] Step 2: Use a crusher to crush the recyclable refractory materials that are stacked in batches to obtain the initial recycled aggregate; multi-stage crushing can control the content of aggregate needle flakes, and finally obtain 0-3mm, 3-5mm, 5-10mm , 10-20mm, 20-30mm regenerated refractory aggregates with different particle size distr...

Embodiment 1

[0041] This embodiment proposes a high wear-resistant and anti-skid pavement aggregate, road surface and preparation method. The high wear-resistant and anti-skid aggregate uses regenerated waste refractory aggregates as raw materials, and crushes, screens, soaks and strengthens waste refractory materials. obtained after processing.

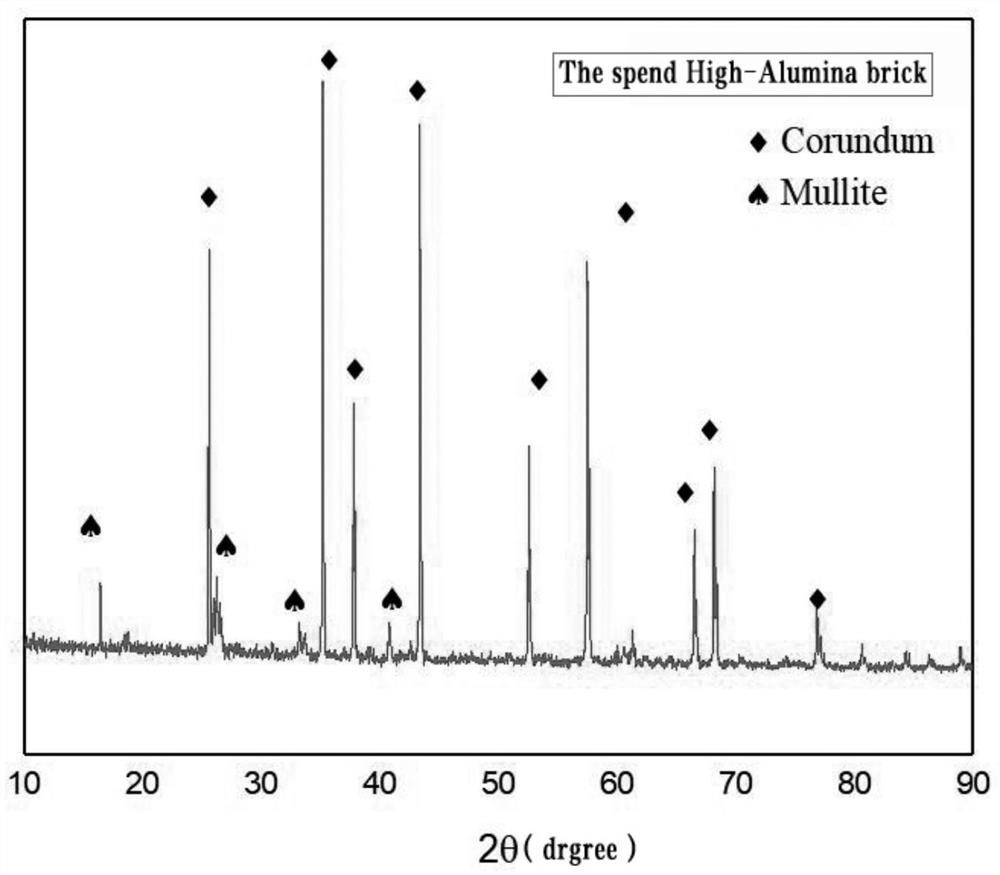

[0042] The waste and old refractory materials in this embodiment include waste and old high-alumina refractory materials. The main phases of the waste and old high-alumina refractory materials are corundum, mullite and a small amount of quartz. The XRD results are shown in the attached figure 2 Shown, in mass percent, where Al 2 o 3 The content is 80%.

[0043] This embodiment also discloses a method for preparing high wear-resistant and anti-skid pavement aggregates, which specifically includes the following steps:

[0044] Step 1: Sorting the waste refractory materials and stacking them according to the different alumina content of the wast...

Embodiment 2

[0054] Same as Example 1, but different from Example 1, the waste refractories used in this example are waste silica bricks. The main phases in waste silica-molybricks are corundum, mullite, silicon carbide and a small amount of quartz. The XRD results are shown in the attached image 3 Shown, in mass percent, where Al 2 o 3 The content is 70%. The drying process is 110°C for 24h. The well-mixed aggregates are kept at 120°C for 18 hours for curing.

[0055] In this embodiment, the performance of the obtained high wear-resistant and anti-skid aggregate is tested. The prepared high wear-resistant and anti-skid aggregate has an aggregate polishing value of 55BPN; Los Angeles abrasion loss is 15.21%; aggregate crushing value is 12.01% ;Aggregate Vickers hardness is 1124.62HV 10

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com