Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "No need to break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

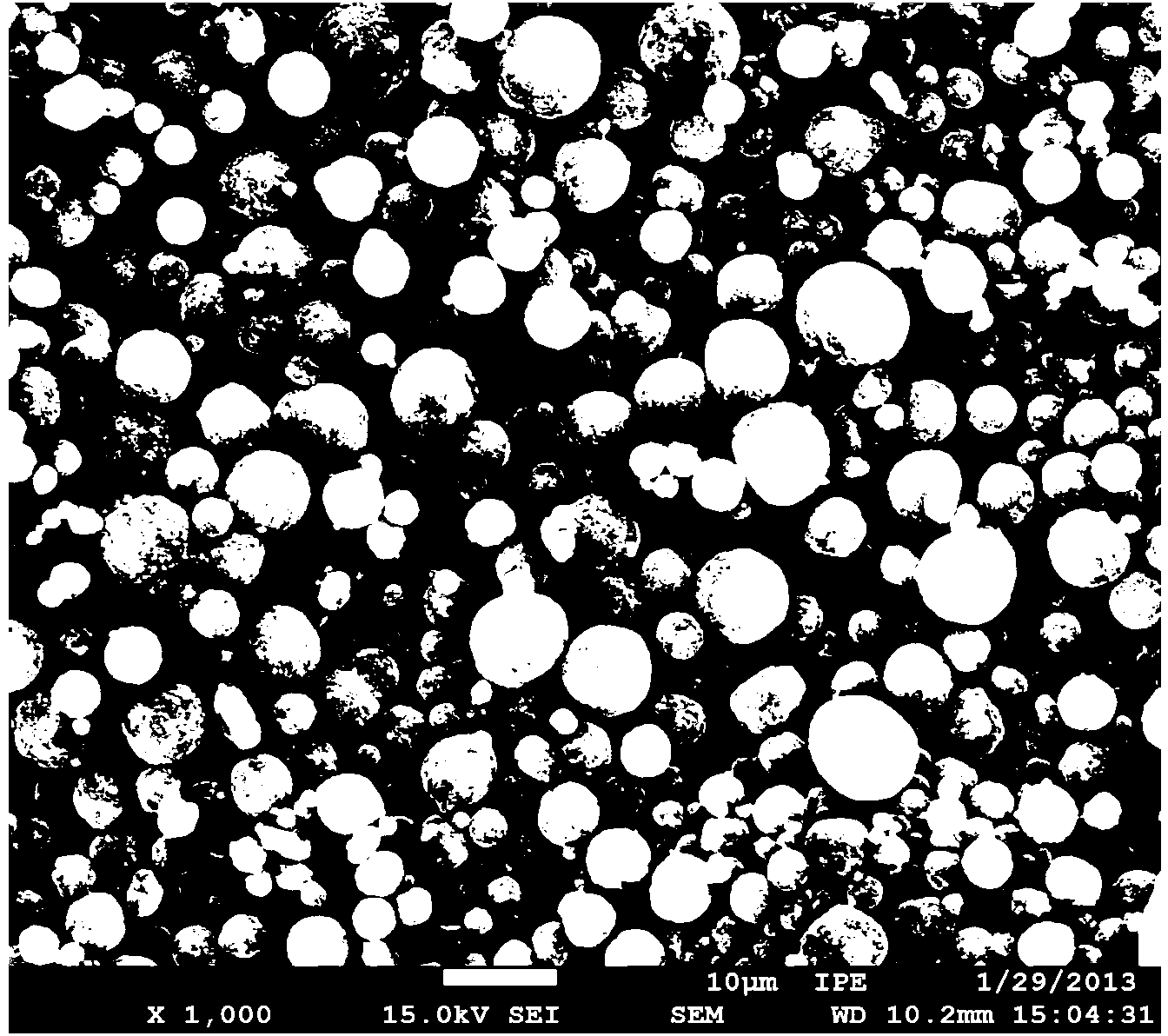

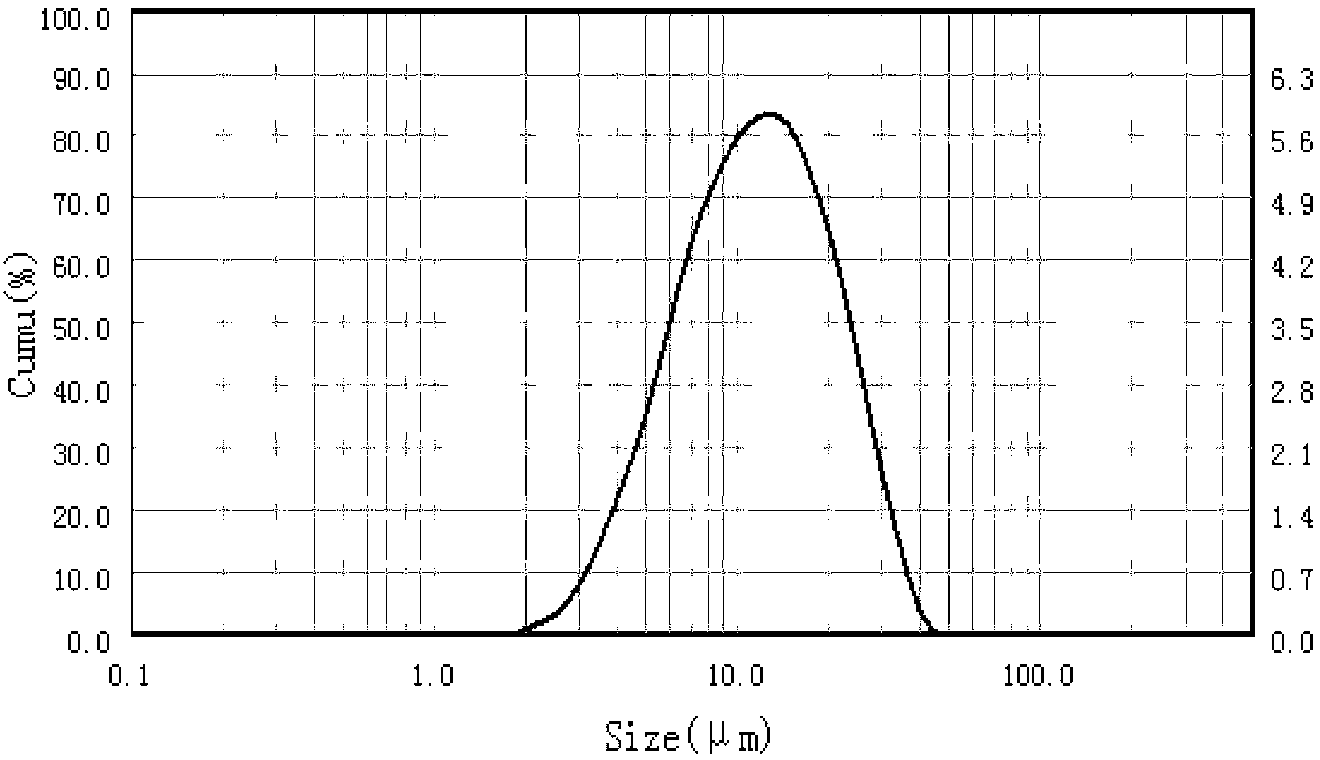

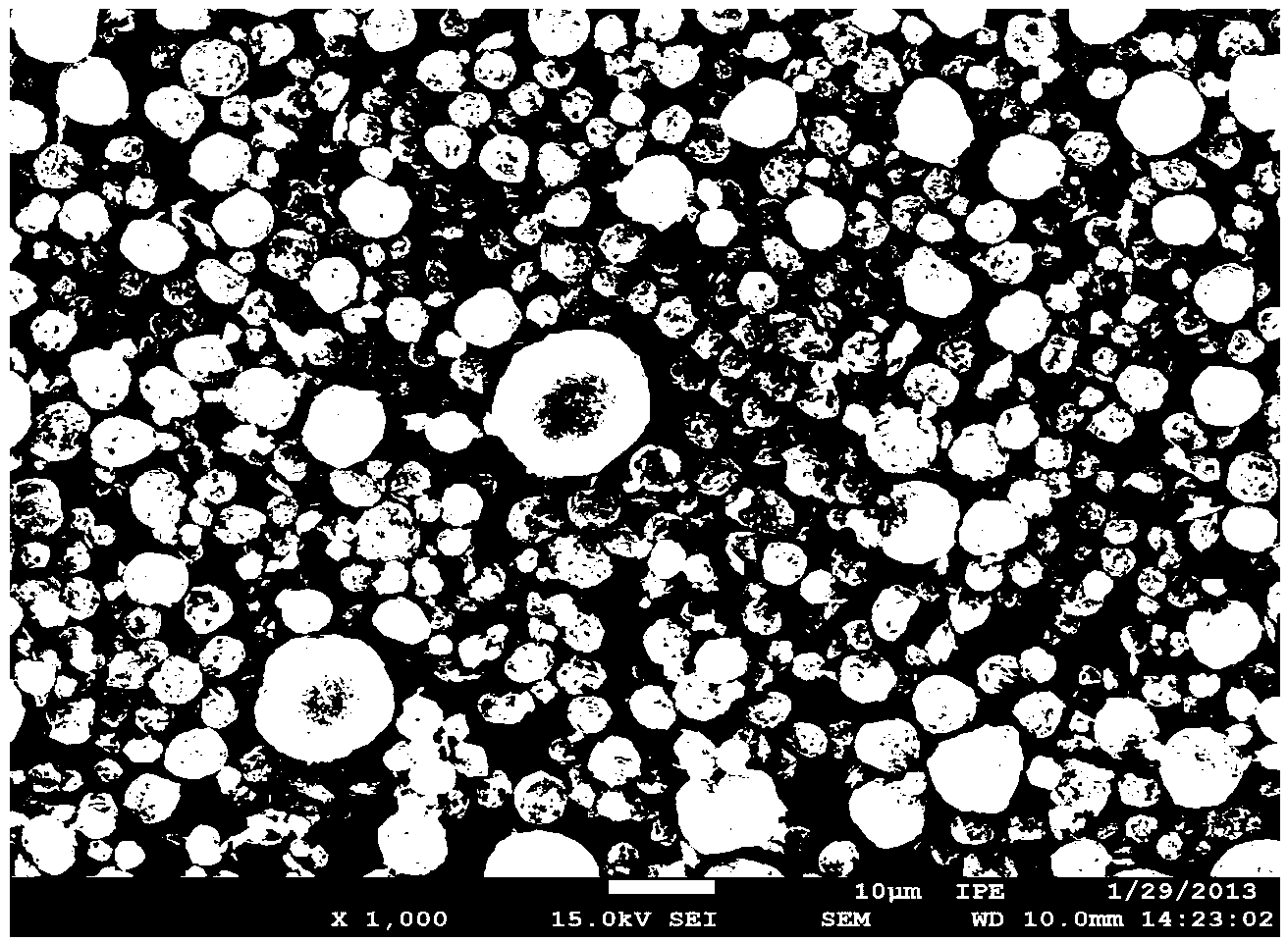

Carbon/carbon composite microsphere material, production method and lithium ion battery

ActiveCN103214245ASmall specific surface areaHigh strengthMaterial nanotechnologyCell electrodesSolventCarbon black

The invention relates to a carbon / carbon composite microsphere material, a production method and a lithium ion battery. The carbon / carbon composite microsphere material is prepared through the following steps of: grinding petroleum coke, needle coke or other soft carbon materials into particles which are less than 2 microns in granularity, and mixing the particles with a binding agent, carbon black and a solvent by a certain proportion to obtain a slurry; carrying out spray-balling and drying to obtain an initial composite microsphere, and implementing heat treatment in the atmosphere of an inert gas to obtain the carbon / carbon composite microsphere material. The carbon / carbon composite microsphere material disclosed by the invention has a good sphericity degree and a proper microporous channel, the microsphere material, serving as a negative electrode material of a lithium ion battery, is well compatible with an electrolyte solution, and simultaneously, the microsphere material has a relatively high specific capacity and an excellent circulating performance. The preparation process is environmental-friendly, simple in process, low in cost and easy for industrial promotion.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

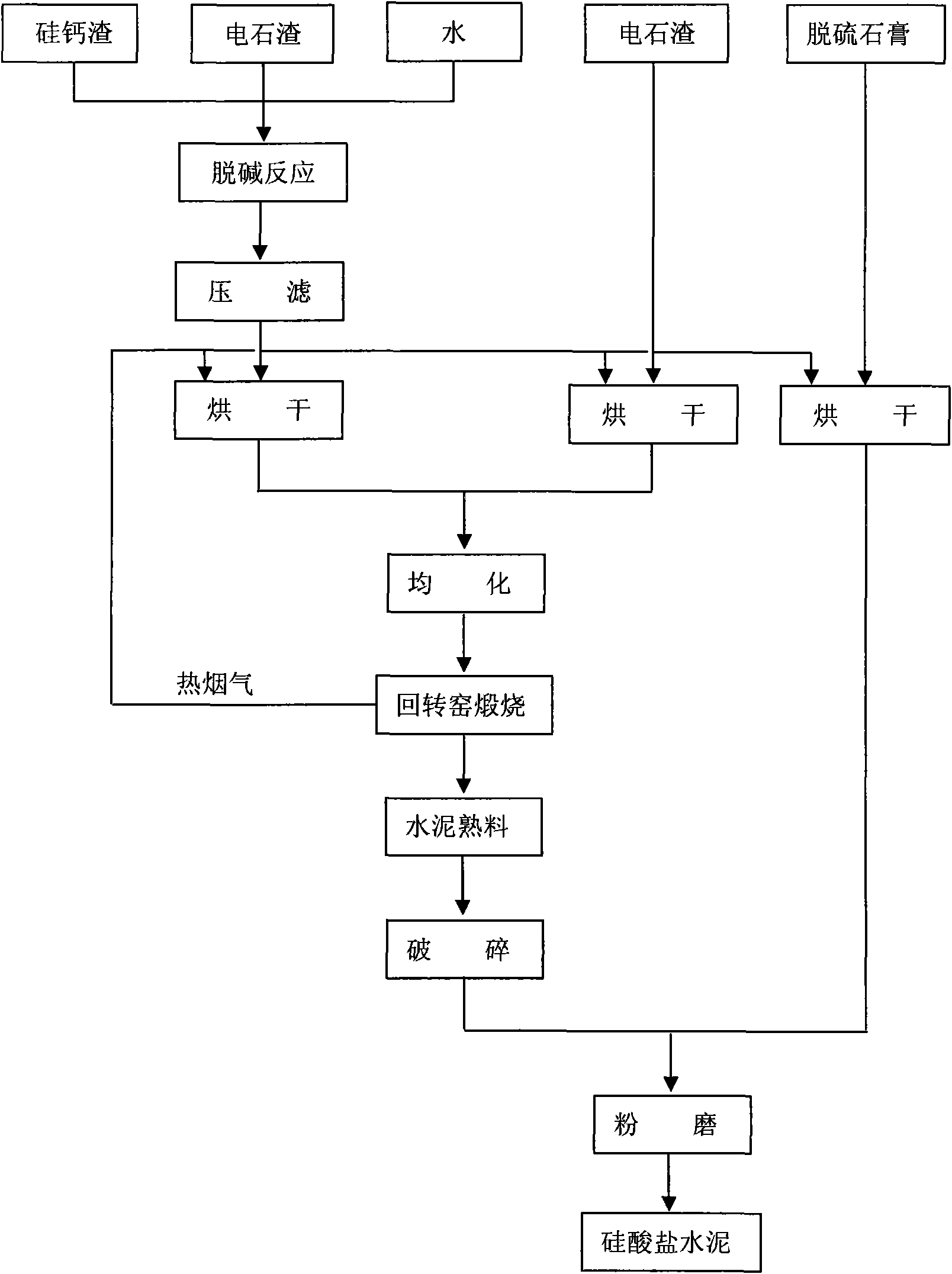

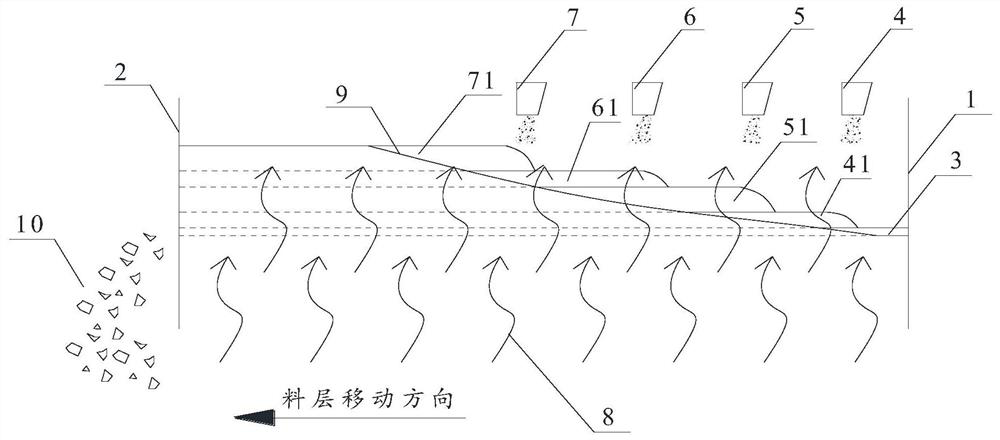

Method for producing silicate cement by using silico-calcium dregs and carbide dregs

InactiveCN101591150AReduce contentMeet the requirements of alkali contentCement productionCalcinationMaterials science

The invention provides a method for producing silicate cement by using silico-calcium dregs and carbide dregs, relating to the technical field of building materials. The method has the following steps: 1. adding carbide dregs and water into silico-calcium dregs followed by dealkalization and carrying out pressure filtering and drying on the dealkalized silico-calcium dregs if the alkali content in the silico-calcium dregs is high, or directly drying the silico-calcium dregs if the alkali content in the silico-calcium dregs is low; and drying the carbide dregs and desulfurated plaster respectively; 2. dosing and homogenizing the dealkalized silico-calcium dregs and carbide dregs after drying; 3. sending the homogenized crude materials into a rotary kiln for high temperature calcinations and obtaining the cement clinker after cooling; and 4. smashing the cement clinker and sending the smashed cement clinker and the dried desulfurated plaster into a cement grinding mill for grinding to prepare the silicate cement. Compared with the prior art, the method of the invention is simple in process, low in investment, low in production cost, low in energy consumption, and stable in the prepared silicate cement performance.

Owner:TONGFANG ENVIRONMENT

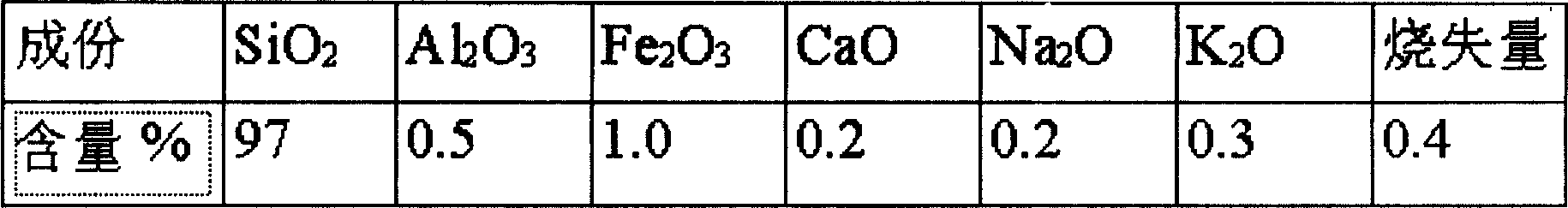

Method for fabricating sanitary ceramics by using waste sand of quartz

The present invention relates to a method for producing sanitary ceramics by using waste quartz sand. Its main raw materials including waste quartz sand, violet wook knot, clay, raw material, feldspar, waste ceramics, talcum and electrolyte, and its production process includes the procedures of breaking, ball-grinding, injection-forming, glazing and baking to obtain finished product.

Owner:宜昌长江陶瓷有限责任公司

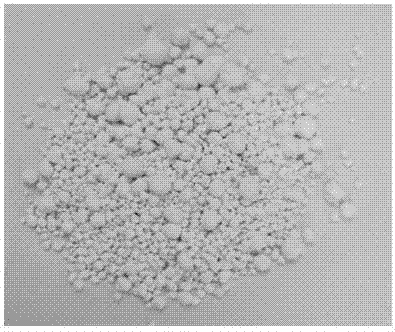

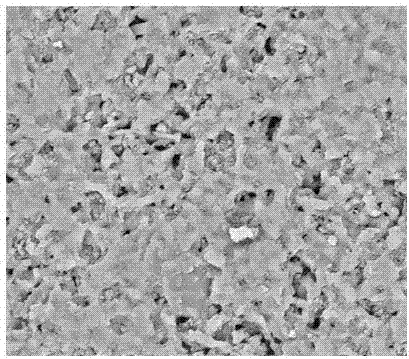

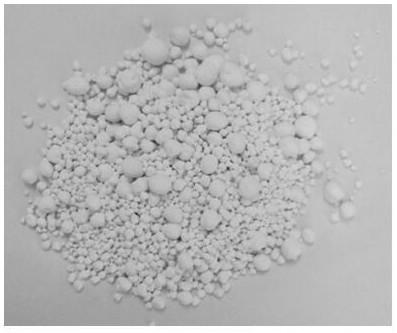

High intensity microporous mullite refractory aggregate and preparation method thereof

The invention relates to a high intensity microporous mullite refractory aggregate and a preparation method thereof. The technical solution thereof is: first using 50-70wt% of kaolin fine powder and 30-50wt% of active alpha-Al2O3 micropowder as raw materials, and additionally adding raw materials of 2-5wt% of dextrin, 1-5wt% of metal aluminum powder and 1-3wt% of carbon black for mixing evenly to obtain a mixture; evenly mixing the raw materials of 3-10wt% of alumina sol, 1-3wt% of silica sol, 0.5-1.0wt% of spodumene and 2-8wt% of water to prepare slurry; placing the mixture in a disk for pelleting, and spraying the slurry while pelleting to prepare particles with a particle size of 1-10mm; and naturally drying the particles, then drying same under the condition of 100-110 DEG C, then rising the temperature to 1200-1600 DEG C, maintaining the temperature for 2-4h, naturally cooling, and screening to prepare the high intensity microporous mullite refractory aggregate. The invention has characteristics of simple process and low preparation power consumption, and the prepared product has great compression strength, high using temperature, low volume density, and small heat conductivity coefficient.

Owner:ANHUI JINYAN GAOLING SCI & TECH CO LTD

Production method of sea-buckthorn pure fruit juice primary pulp

The invention relates to a production method of fruit juice primary pulp, and specifically provides a production method of sea-buckthorn pure fruit juice primary pulp which is high in juice yield, high in soluble solid content and high in nutrition content and has no tannin bitter. The production method comprises the following processing steps of: removing fruits: shearing and selecting sea-buckthorn with branches by manpower, then quickly freezing, and after the temperature of the center of the fruit reaches (-18) DEG C, removing fruits by a fruit remover; pre-treating: removing leaves by a winnower, removing crushed branches by using a rotary fish-scale-sieve sieving machine; cleaning by using a fruit cleaner and removing sand by using sand removing equipment; immersing for 1-3min in 0 DEG C dewatering ripening solution and then draining, and unfreezing in microwave unfreezing equipment; and finally spraying by clear water at 0-5 DEG C so as to finish secondary cleaning and draining; and juice processing: breaking and pulping the sea-buckthorn, separating juice by using a juice separator, filtering impurities by using a juice primary filter, carrying out solid-liquid separation by using a horizontal spiral separator and a disc-type separator, degassing, sterilizing and sterilely filling, so as to obtain the sea-buckthorn pure fruit juice primary pulp.

Owner:华池县甘农生物科技有限公司

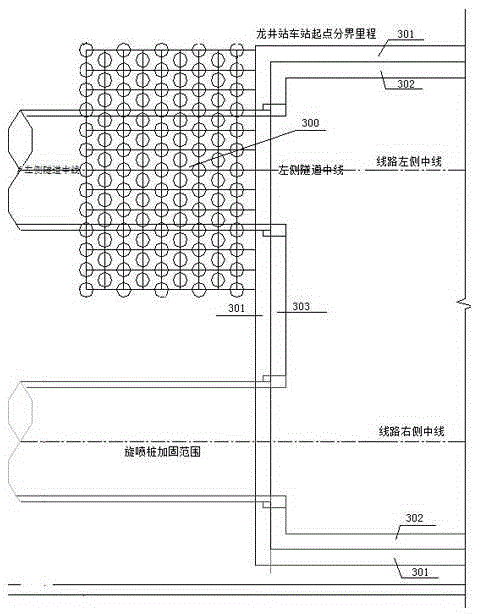

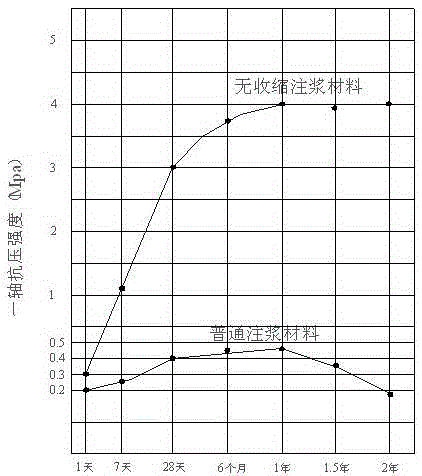

Application of WSS construction method in shield end reinforcement of water-rich sand layer

InactiveCN105971637AWide formation adaptabilitySpecial soil consolidation effectUnderground chambersDrainageSlurryEngineering

The invention provides an application of a WSS construction method in shield tool changing reinforcement of a water-rich sand layer. A WSS construction method grouting technology is characterized in that an underground drill rig is used for deep- hole grouting and reinforcement and solution-type grout composed of a solution A and a solution B is used firstly for back grouting and soil body drainage, so that soil body impermeability can be enhanced; and after completion of the back grouting construction of a whole reinforcement body with application of the solution-type grout composed of the solution A and the solution B, turbid-type grout composed of the solution A and a solution C is used for forward grouting and soil body solidification, so that physical natures of the original soil body can be changed and compressive strength of the soil body is increased. Finally, a soft soil layer (which is mainly composed of sandy soil, gravelly clayey soil and sand layers) becomes a soil body with the high impermeability, the high compressive strength and high stability. Hence, concrete grouting inspection and tool replacement become more convenient.

Owner:RANKEN RAILWAY CONSTR GROUP

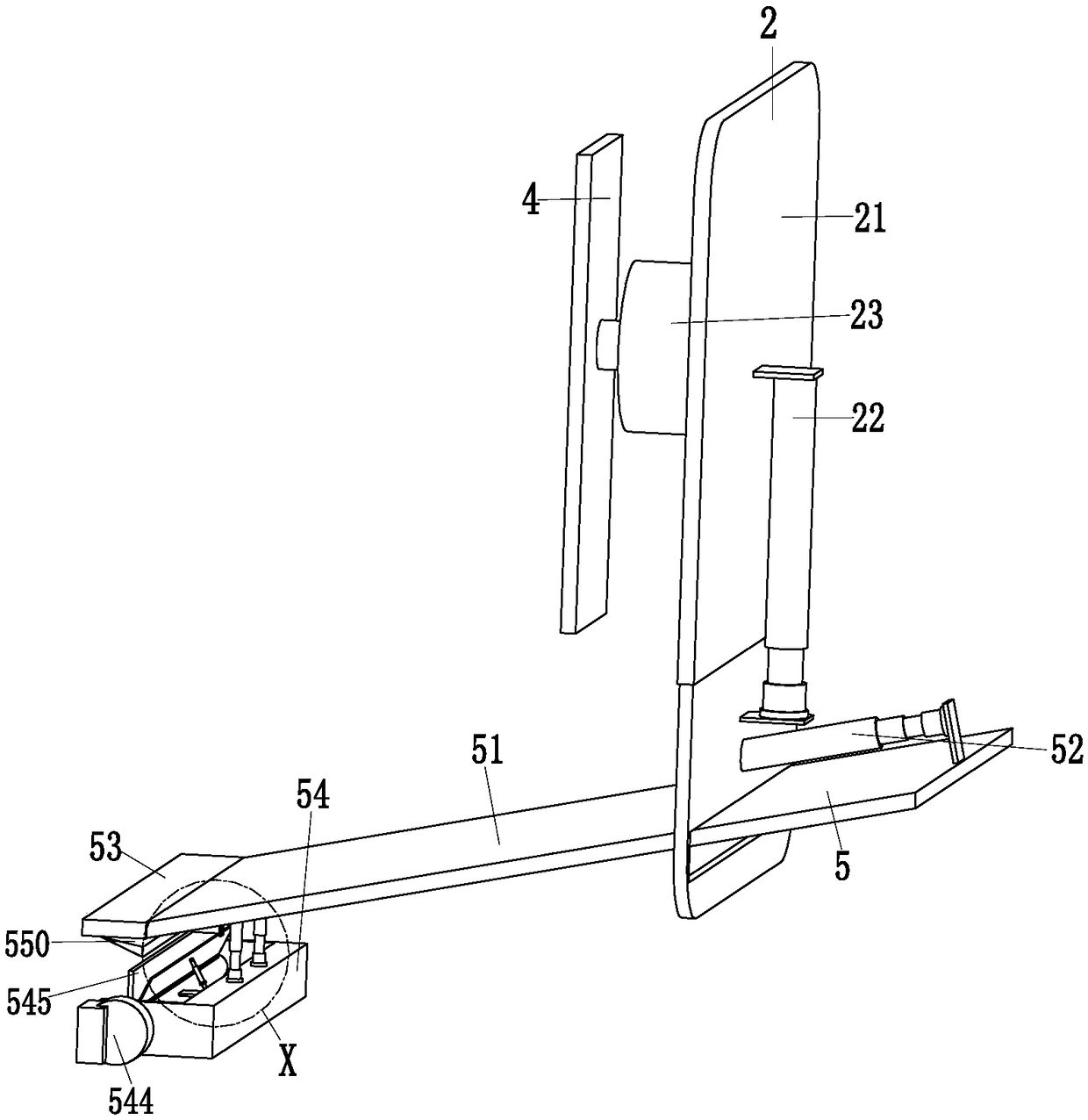

Construction robot for environment-friendly wall decorations

The invention relates to a construction robot for environment-friendly wall decorations, which comprises an adjusting device, a telescopic device, a connecting plate, a cutting device, a dual-purposedevice and a shearing device, wherein the telescopic device is installed on the front side of the upper end of the adjusting device, and the shearing device is installed at the lower end of the telescopic device, the connecting plate is installed at the front end of the telescopic device, the shearing device is installed at the upper end of the connecting plate, and the dual-purpose device is installed at the lower end of the connecting plate. The invention can solve the existing problems: in case of seaming anti-mold wallpapers, personnel are required to push the excess paper material betweenthe two wallpapers into a convex shape by means of a ruler, and then cut the paper material with a cutter, and a plurality of people are needed to cooperate; in case of cutting, a manual cutting is not flush, and the cutting is not complete, and the wallpapers may be pulled and damaged or stretched due to personnel not pressing the wallpapers stable; and in case of cutting the redundant wallpaperat the skirting line, as the skirting line is too low, the personnel will have difficulties to cut even the personnel bend down, thereby resulting in a long time consumption, a large labor intensityand a low efficiency etc.

Owner:浙江金果知识产权有限公司

Application of WSS construction method in shield tool changing reinforcement of water-rich sand layer

InactiveCN105971638AEasy to adjustHigh strengthUnderground chambersTunnel liningSlurryCompressive strength

Provides an application of WSS construction method in the reinforcement of shield tunneling in water-rich sand layer. The grouting process of WSS construction method adopts tunnel drilling rig to carry out deep hole grouting reinforcement. The slurry is used to drain the soil to improve the impermeability of the soil; when the whole solidification is completed by the solution-type slurry backward grouting composed of liquid A and liquid B, the suspension composed of liquid A and liquid C is used again. The forward grouting of the type slurry is used to consolidate the soil, change the physical properties of the original soil and improve the compressive strength of the soil, and finally make the weak soil layer (mainly sandy, gravel-cohesive soil and sand layer) impermeable. Soil with high resistance, high compressive strength and high stability is convenient for opening inspection and tool replacement.

Owner:RANKEN RAILWAY CONSTR GROUP

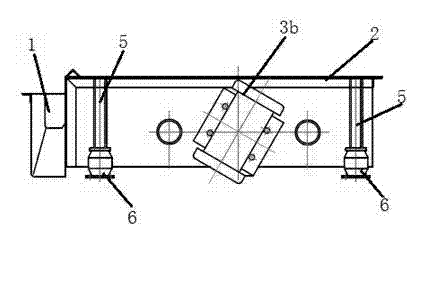

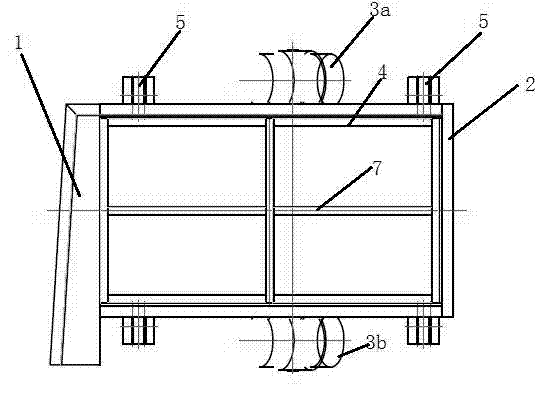

Water-coal-slurry vibrating screen

InactiveCN102641839ASolve the function of buffering and vibration isolationPlay the role of shock absorberSievingScreeningCoal slurryPhysics

The invention discloses a water-coal-slurry vibrating screen, comprising a block discharging groove, a screen body and vibrating excitation source, wherein the block discharging groove is arranged on one end of the screen body; a vibrating groove body and a stainless steel trapezoid bar sieve net are arranged in the screen body; the vibrating excitation source is two vibrating motors mounted on two sides of the screen body respectively; the two vibrating motors are started simultaneously and has inverse rotating directions; four angle arms of the screen body are provided with a support base; and the bottom part of the support base is provide with a rubber spring. According to the invention, the water-coal-slurry vibrating screen is characterized by stable working, high screening efficiency, adjustable amplitude, low power consumption, small volume, light weight, small noise, long service life, convenient maintenance and convenient preservation.

Owner:江阴市东发机械设备制造有限公司

Preparation method of MgO-CaO-ZrO2 sand

The invention relates to a preparation method of MgO-CaO-ZrO2 sand. The preparation method comprises the following steps: carrying out heat treatment on dolomite ore and magnesite ore, hydrating, sieving with a 0.2 mm sieve, drying a filter body obtained by sieving, and grinding to 200 meshes or below to obtain MgO-CaO2 powder; placing MgO-CaO powder and Zr(OH)4 sol in a mixer to be evenly mixed,conducting ball pressing after mixing, and drying till the moisture is smaller than 1%; and finally, placing the mixture in a kiln to be calcined, and obtaining the MgO-CaO-ZrO2 sand. The MgO-CaO-ZrO2sand prepared by the preparation method disclosed by the invention is good in hydration resistance, high in refractoriness, high in thermal stability and strong in alkaline slag corrosion resistance,has a purification effect on molten steel, and is an ideal raw material for preparing high-grade materials such as magnesium-calcium refractory materials and ceramics.

Owner:海城市军刚中档镁砂有限公司

Method for preparing cupric oxide powder by oxygenizing raw copper powder

The invention provides a method for preparing cupric oxide powder by oxidizing crude copper powder, which relates to a method for preparing the cupric oxide powder that is used in powder metallurgy and is applicable to the method for producing the cupric oxide powder by taking the crude copper powder generated by electrolytic copper powder as raw material. The method is characterized in that ammonium nitrate is added into the crude copper powder, evenly mixed and then calcined to obtain the cupric oxide powder. By the method of the invention, the crude copper powder is not agglomerated during calcinations, the content of cupric oxide in the cupric oxide powder is more than 99 percent, the crude copper powder is quite porous after calcinations and needs not to be smashed, which can be packaged after being screened. The method of the invention is easy to operate and has obvious oxidation effect.

Owner:JINCHUAN GROUP LIMITED

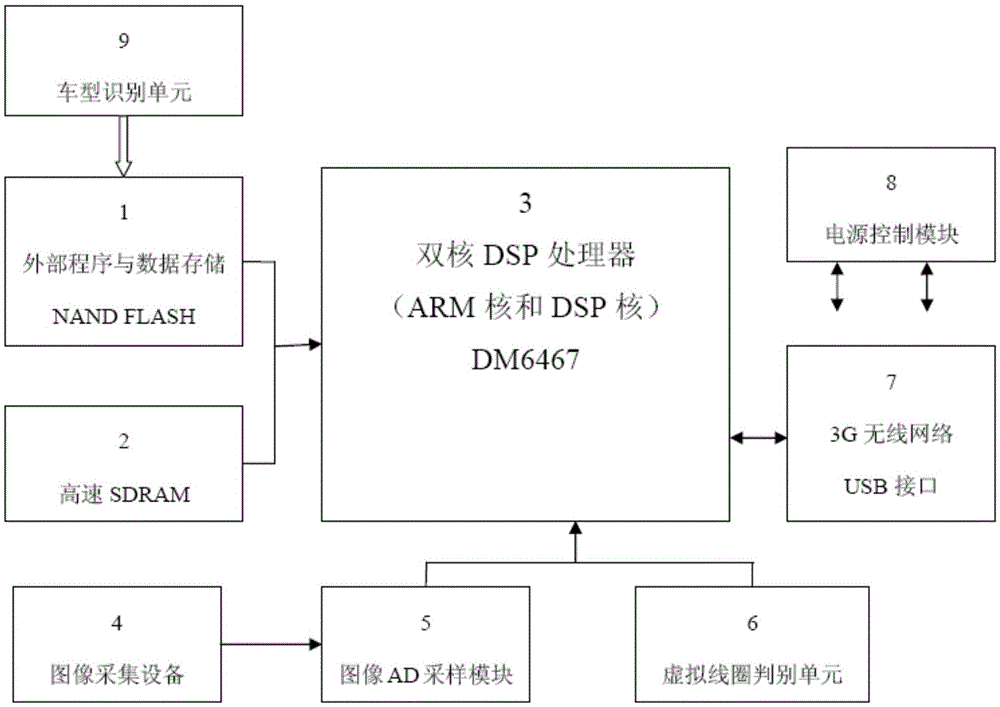

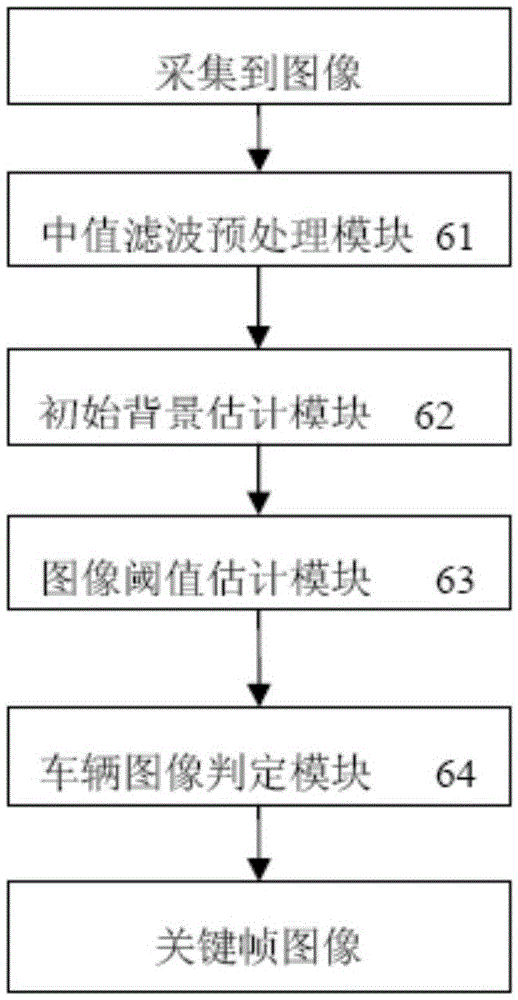

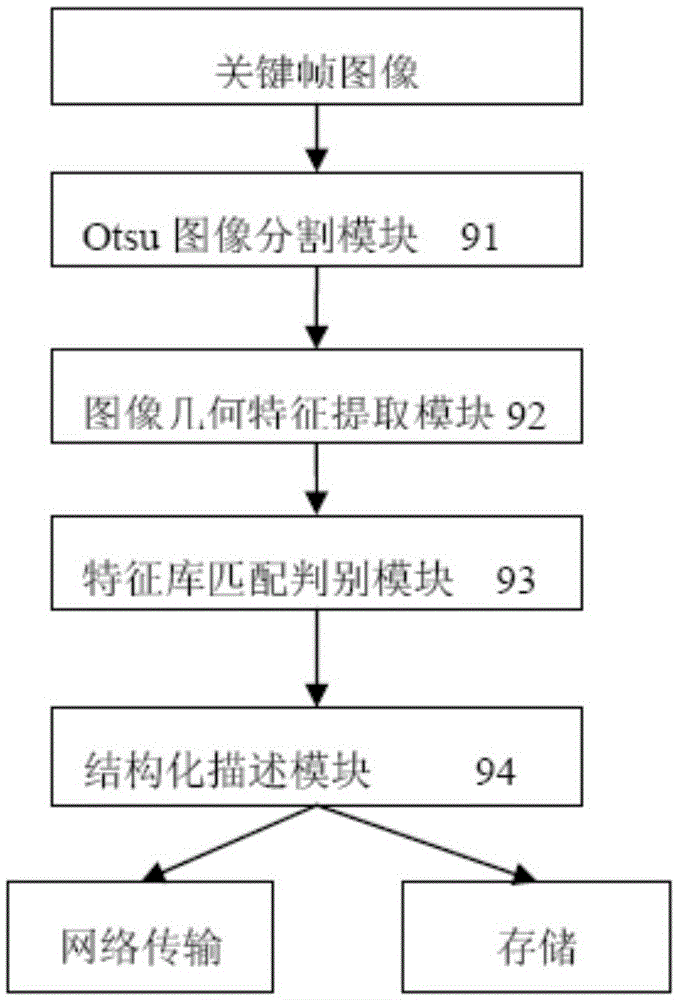

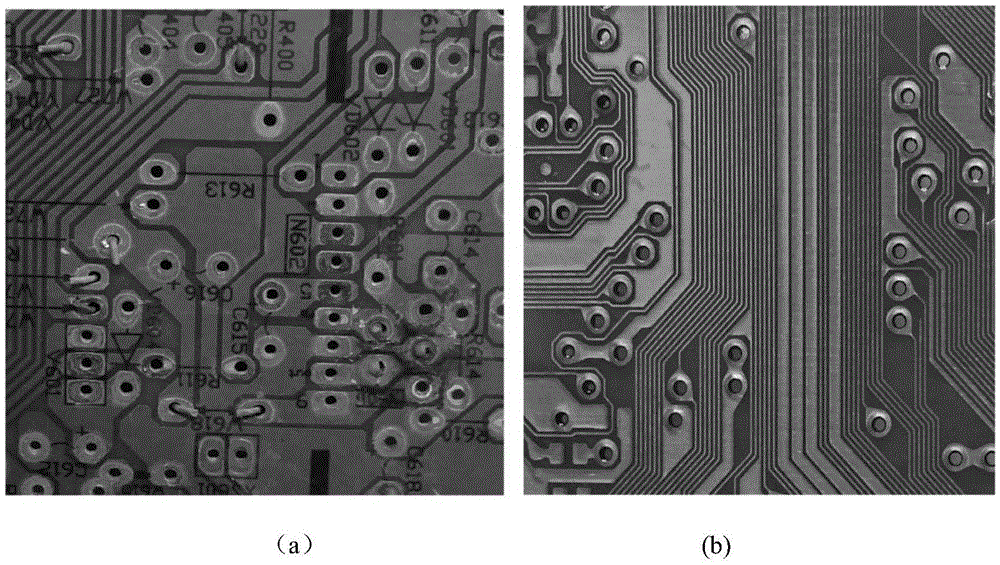

Embedded type vehicle type recognition system based on virtual coil

ActiveCN103473933ANo need to breakPromote smart applicationsRoad vehicles traffic controlVideo monitoringDual core

The invention discloses an embedded type vehicle type recognition system based on a virtual coil. The embedded type vehicle type recognition system comprises an external program and data memorizer, an external high-speed dynamic memorizer SDRAM, an image collecting device, an image AD sampling module, a power source control module, a dual-core DSP digital signal processor chip, a virtual coil distinguishing unit and a vehicle type recognition unit. The image AD sampling module is used for acquiring the video image date provided by the image collecting device. The dual-core DSP digital signal processor chip is used for calling the virtual coil distinguishing unit to carry out virtual coil distinguishing on the collected video image to select the keyframe image emerging when a vehicle appears. The dual-core DSP digital signal processor chip is used for calling the vehicle type recognition unit to carry out vehicle type recognition calculation on the keyframe image. The embedded type vehicle type recognition system can extract characteristic values about the vehicle from the video image information and carry out structuring description with the cooperation with the virtual coil, the type of the vehicle in the video image can be recognized, and a video monitoring system can be applied and managed intelligently and conveniently.

Owner:THE THIRD RES INST OF MIN OF PUBLIC SECURITY

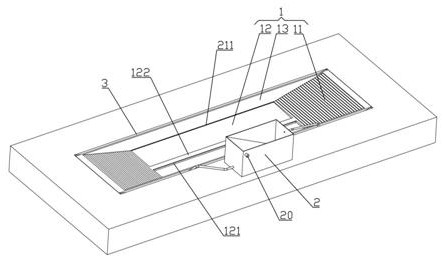

Automatic desilting finished vehicle washing pool and construction method thereof

PendingCN114575445AReduce wasteShorten the construction periodCesspoolsArtificial islandsSludgeProcess engineering

The invention relates to the technical field of vehicle washing device construction, in particular to an automatic desilting finished vehicle washing pool and a construction method thereof. The finished product car washing pool comprises a car washing pool body and a settling tank, the settling tank is connected with the car washing pool body through a pipeline, a sludge tank is arranged in the middle of a bottom plate of the car washing pool body, the two ends of the sludge tank are connected with the settling tank through pipelines, and a dredging pump is installed on the pipeline, communicated with the settling tank, of the tail end of the sludge tank. The device can be repeatedly used, reduces the problem of material waste, can be immediately put into use after installation, has no complicated process, can greatly shorten the construction period, uses high-pressure water to clean wheels, has a cleaning effect more remarkable than that of a traditional car washing pool cleaning mode, realizes full-automatic flushing and desilting, can be unattended, reduces the manual maintenance cost, and is suitable for large-scale popularization and application. And after being used, the building block can be directly transferred to other places for use without being broken, and less building waste is generated.

Owner:CHINA CONSTR EIGHTH ENG DIV

Device and method for simulating influences of underground water on coalbed methane

The invention discloses a device and method for simulating influences of underground water on coalbed methane. The device comprises a sample bin and a high pressure gas bottle. The sample bin is mainly composed of a pressure tank. The whole pressure tank is in a cylindrical shape and formed by separably combining two semicylinders. The pressure tank is provided with a pressure meter and a gas-water separator. The pressure tank and the high pressure gas bottle are communicated. The device and method are simple, effective, applicable to large-size coal samples without breaking and capable of adapting to inspecting influences of different pressure, water qualities, coal qualities and coal-water ratios on coalbed methane storage.

Owner:CHINA UNIV OF MINING & TECH

Method for preparing stannous chloride crystals by utilizing PCB tin stripping waste liquid

InactiveCN112499670AReduce pollutionReduce manufacturing costPhotography auxillary processesStannous chlorideTetrachloridePhysical chemistry

The invention relates to the technical field of preparation methods of stannous chloride crystals, and provides a method for preparing stannous chloride crystals by utilizing PCB tin stripping waste liquid, which comprises the following steps: washing tin hydroxide solids recovered from the PCB tin stripping waste liquid, dissolving tin hydroxide into a tin tetrachloride solution by using hydrochloric acid, reducing the stannous chloride solution the stannous chloride solution through a diaphragm electrolysis method, further purifying and concentrating the stannous chloride solution under reduced pressure, performing cooling to obtain clean and white stannous chloride crystals, and stannous chloride prepared through the method is free of caking, good in liquidity and free of crushing and screening. According to the method, the stannic chloride solution is reduced into the stannous chloride solution through diaphragm electrolysis, a traditional process for reducing the stannous chloridesolution mainly through a metallic tin ingot is replaced, expensive metallic tin is saved, and the production efficiency is greatly improved.

Owner:HUIZHOU ZHENDING ENVIRONMENTAL PROTECTION TECH CO LTD

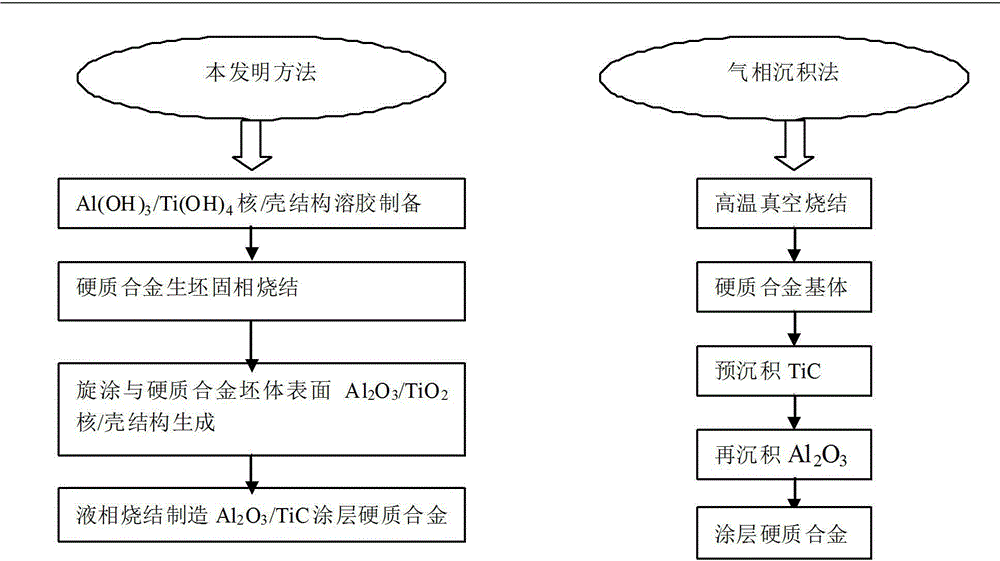

Preparation method of al2o3/tic coated cemented carbide based on liquid phase sintering process

InactiveCN103820695BHigh bonding strengthAvoid destructionPretreated surfacesCoatingsAlloyCemented carbide

The invention discloses a method for preparing an Al2O3 / TiC coated hard alloy based on a liquid phase sintering process, which is characterized in that the Al(OH)3 / Ti(OH)4 core / shell structure sol is firstly prepared by a liquid phase method , and then spin-coated on the surface of the solid-phase sintered cemented carbide blank with a density of 85% to 95% to form an Al2O3 / TiO2 layer, and then use the CO atmosphere in the liquid-phase sintering process to undergo a carbothermal reduction reaction with the surface layer to make TiO2 Converted to TiC, and finally produced Al2O3 / TiC coated cemented carbide. The process of the invention is simple, easy to control, and avoids the problem of step-by-step vapor deposition of two coatings in the manufacturing process of Al2O3 / TiC coated hard alloy, and the step-by-step problem of coating treatment and substrate preparation, based on liquid phase sintering The process prepares Al2O3 / TiC coated cemented carbide in one step.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

A kind of copper-containing sludge sintering method

Owner:BEIJING GEOENVIRON ENG & TECH +1

A method for removing green oil film in waste circuit boards

ActiveCN105483727BSolve the problem of removing green oil filmEasy to operateEngineeringPrinted circuit board

The invention discloses a method for removing green oil films in waste circuit boards. The method comprises the following steps: removing a green oil film on the surface of a waste circuit board by using a diluted alkali solution, and washing with water. A film removing agent 1 m(3) can be used for removing green oil films of circuit boards 300-700 m(2). The method solves the problem that green oil films are difficultly removed from single-layer waste circuit boards in a whole board recycling process, is simple, convenient and feasible in operation process and low in cost, and has important significance on environmental protection.

Owner:TSINGHUA UNIV

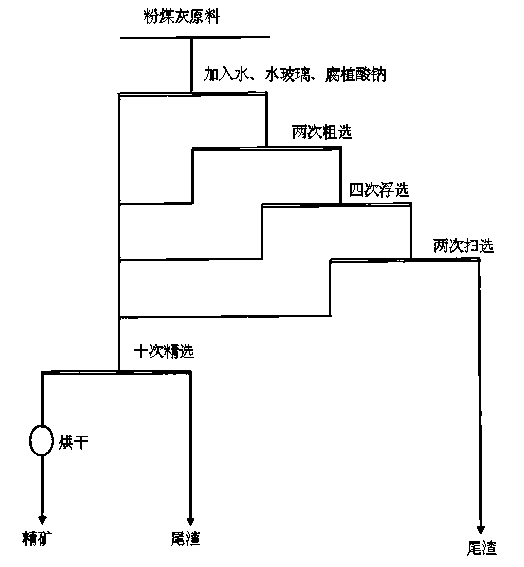

Method for flotation of cobalt in fly ash

The invention discloses a method for flotation of cobalt in fly ash. The method comprises the steps that the fly ash and water are mixed uniformly according to the ratio of one to three, water glass and sodium humate are added, stirred and steeped in the mixture, then a collecting agent is added into the mixture, roughing is carried out, the mixture is transferred into a flotation column, a foaming agent is added into the mixture, compressed air is guided into the mixture to carry out floating and scavenging, concentration of ten times is carried out after the fly ash rich in cobalt is processed through roughing of two times, floating of four times and scavenging of two times and then combined, and then the mixture is dried to obtain good fly ash products rich in cobalt. The method has the advantages that the process is simple, the energy consumption is low, the flotation cost is low, the recovery rate is high, the pollution to the environment from exhausted dust, sewage and the like is small, and the generated solid waste can be recycled.

Owner:HENAN TIANGANG IND

A kind of high-strength microporous mullite refractory aggregate and its preparation method

The invention relates to a high intensity microporous mullite refractory aggregate and a preparation method thereof. The technical solution thereof is: first using 50-70wt% of kaolin fine powder and 30-50wt% of active alpha-Al2O3 micropowder as raw materials, and additionally adding raw materials of 2-5wt% of dextrin, 1-5wt% of metal aluminum powder and 1-3wt% of carbon black for mixing evenly to obtain a mixture; evenly mixing the raw materials of 3-10wt% of alumina sol, 1-3wt% of silica sol, 0.5-1.0wt% of spodumene and 2-8wt% of water to prepare slurry; placing the mixture in a disk for pelleting, and spraying the slurry while pelleting to prepare particles with a particle size of 1-10mm; and naturally drying the particles, then drying same under the condition of 100-110 DEG C, then rising the temperature to 1200-1600 DEG C, maintaining the temperature for 2-4h, naturally cooling, and screening to prepare the high intensity microporous mullite refractory aggregate. The invention has characteristics of simple process and low preparation power consumption, and the prepared product has great compression strength, high using temperature, low volume density, and small heat conductivity coefficient.

Owner:ANHUI JINYAN GAOLING SCI & TECH CO LTD

A kind of coated magnetic abrasive grain and its preparation method

InactiveCN107256750BSmall particlesSimple processOther chemical processesInorganic material magnetismSilicic acidActive agent

Provided are a coated magnetic abrasive particle and a preparation method thereof. The iron ion based molar ratio of iron dichloride to ferric chloride of the coated magnetic abrasive particle is 1 to 1-3, the molar ratio of Fe ions to ammonia water ammonia ions is 1 to 2-7, the mass ratio of ferroferric oxide to a modifying agent is 1 to 5, an ethyl alcohol-water solution is prepared according to the ethyl alcohol-water proportion of 1 to 5, and the volume ratio of tetraethoxysilane to the solution is 1 to 20-30. Preparation is performed according to the volume ratio of ammonia water to the solution. The preparation method comprises the preparation steps that 1, the iron dichloride, the ferric chloride, the ammonia water, the modifying agent, ethyl alcohol, the tetraethoxysilane and distilled water are weighed; 2, the distilled water and the ferric chloride and the iron dichloride are mixed and prepared into a solution; 3, the ammonia water is added for stirring; 4, drying is performed; 5, a drying product, an activator and distilled water are prepared into a solution, and dispersion is performed; 6, the alcohol-water solution is added for stirring; 7, the tetraethoxysilane is dropwise added; 8, the ammonia water is dropwise added and is stirred; 9, drying is performed after product suction filtration. The coated magnetic abrasive particle is low in cost and easy to recover.

Owner:TAIYUAN UNIV OF TECH

A device and method for simulating the impact of groundwater on coalbed methane

Owner:CHINA UNIV OF MINING & TECH

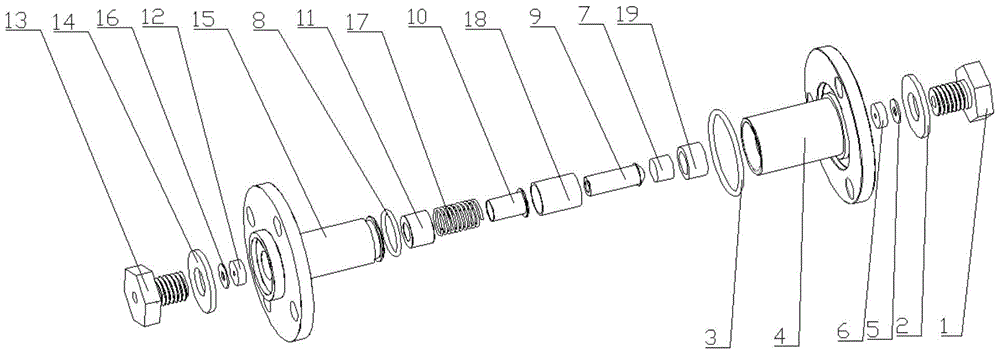

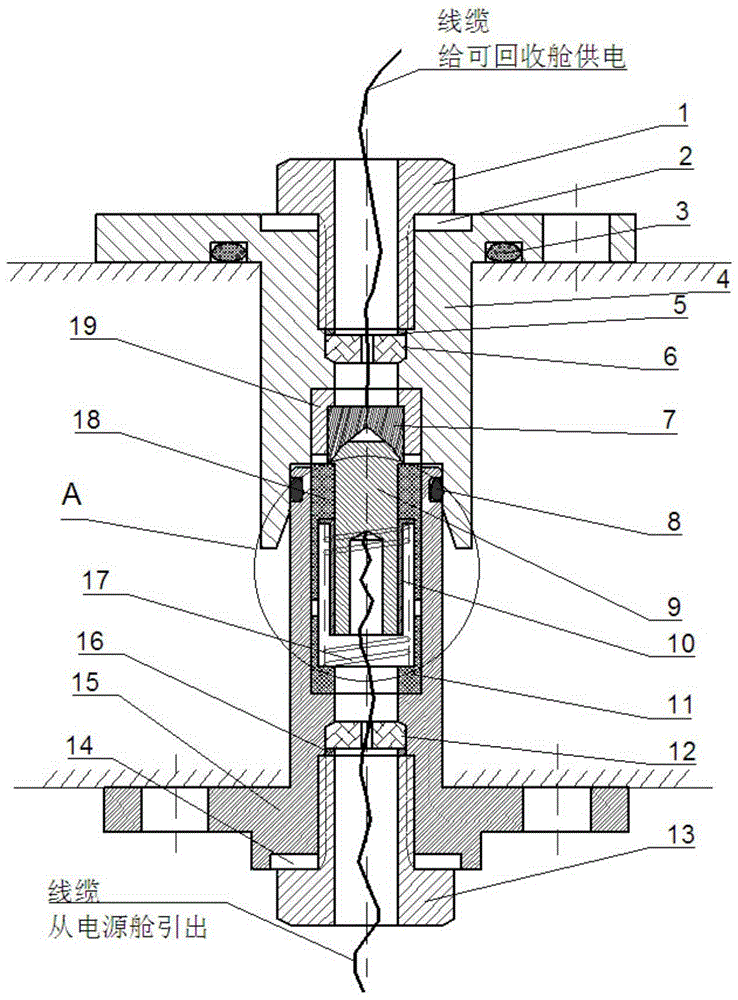

Low Separation Force Watertight Connectors

ActiveCN104934727BReliable electrical connectionNo need to breakCouplings bases/casesTwo-part coupling devicesInterference fitElectricity

The invention discloses a watertight connector of a low separating force, and the connector can be used for cable connection between a power cabin and a recoverable cabin of recoverable acoustic UWSN nodes. The watertight connector comprises an upper installation body and a lower installation body, the upper installation body is installed in the recoverable cabin, and the lower installation body is mounted in a structural body of the power cabin. A traditional pin-and-jack type watertight connector realizes sealing via interference fit between pins and jacks, the axial resistance is high during separation, and separation cannot be realized without labor force or other auxiliary devices. When the watertight connector of the low separating force is in a connected state, a preload spring ensures reliable electrical connection between a copper cone and a copper cap of a conductor, and non-rigid connection is characterized by that cables are not broken during separation, the separating force is low, separation is rapid, and the sealing performance is high after separation.

Owner:ZHEJIANG UNIV

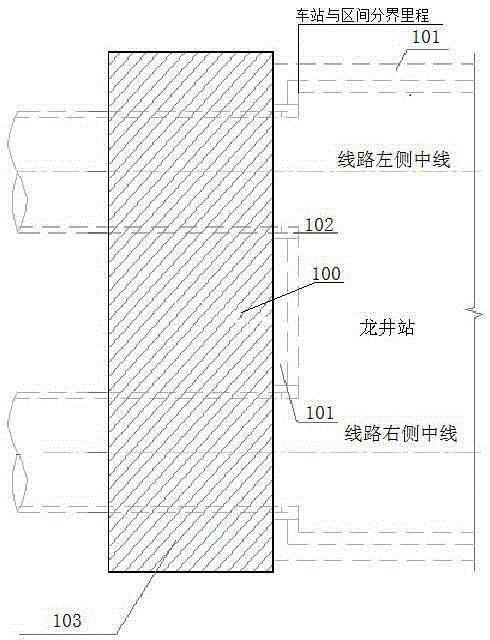

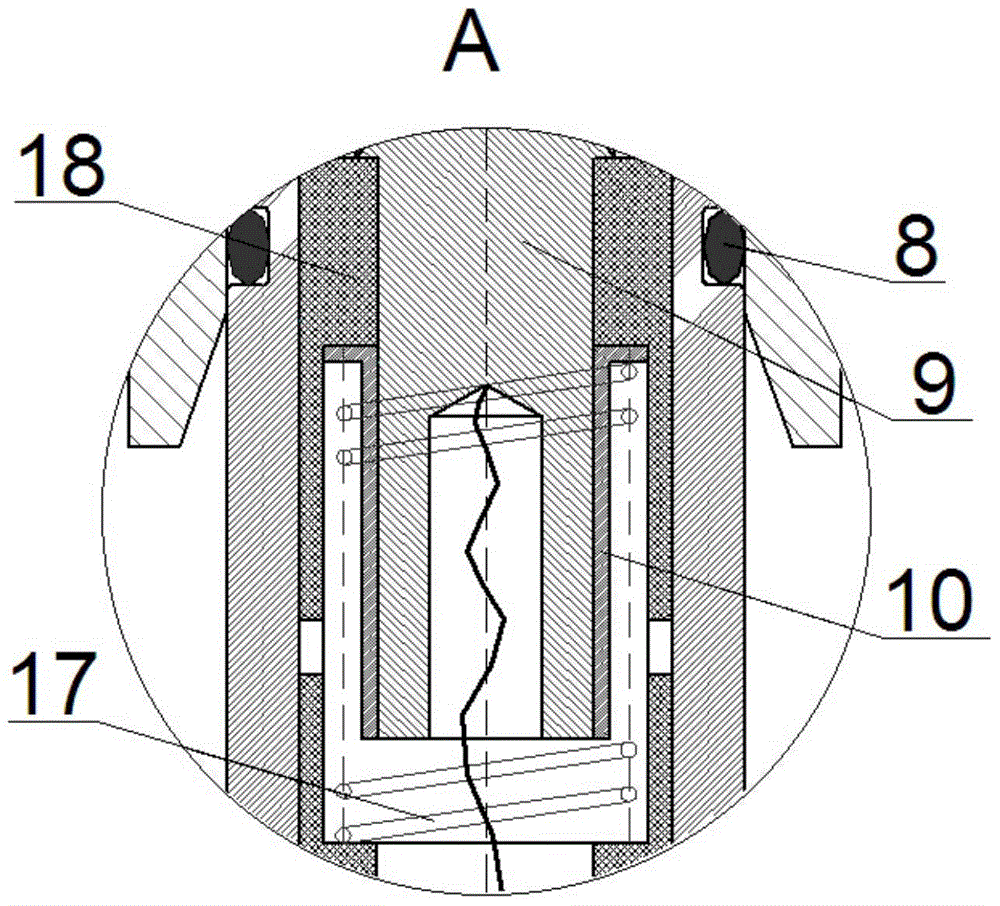

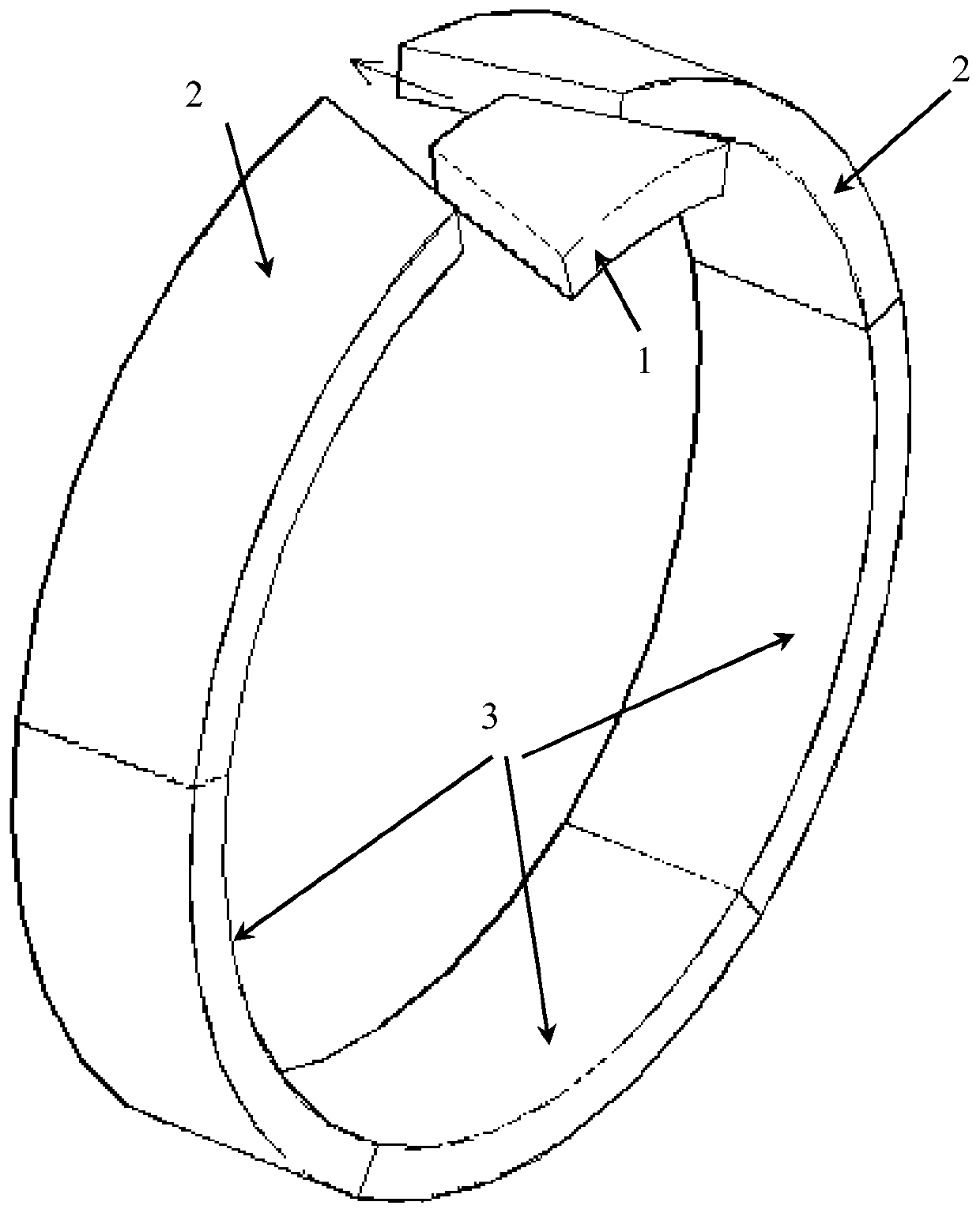

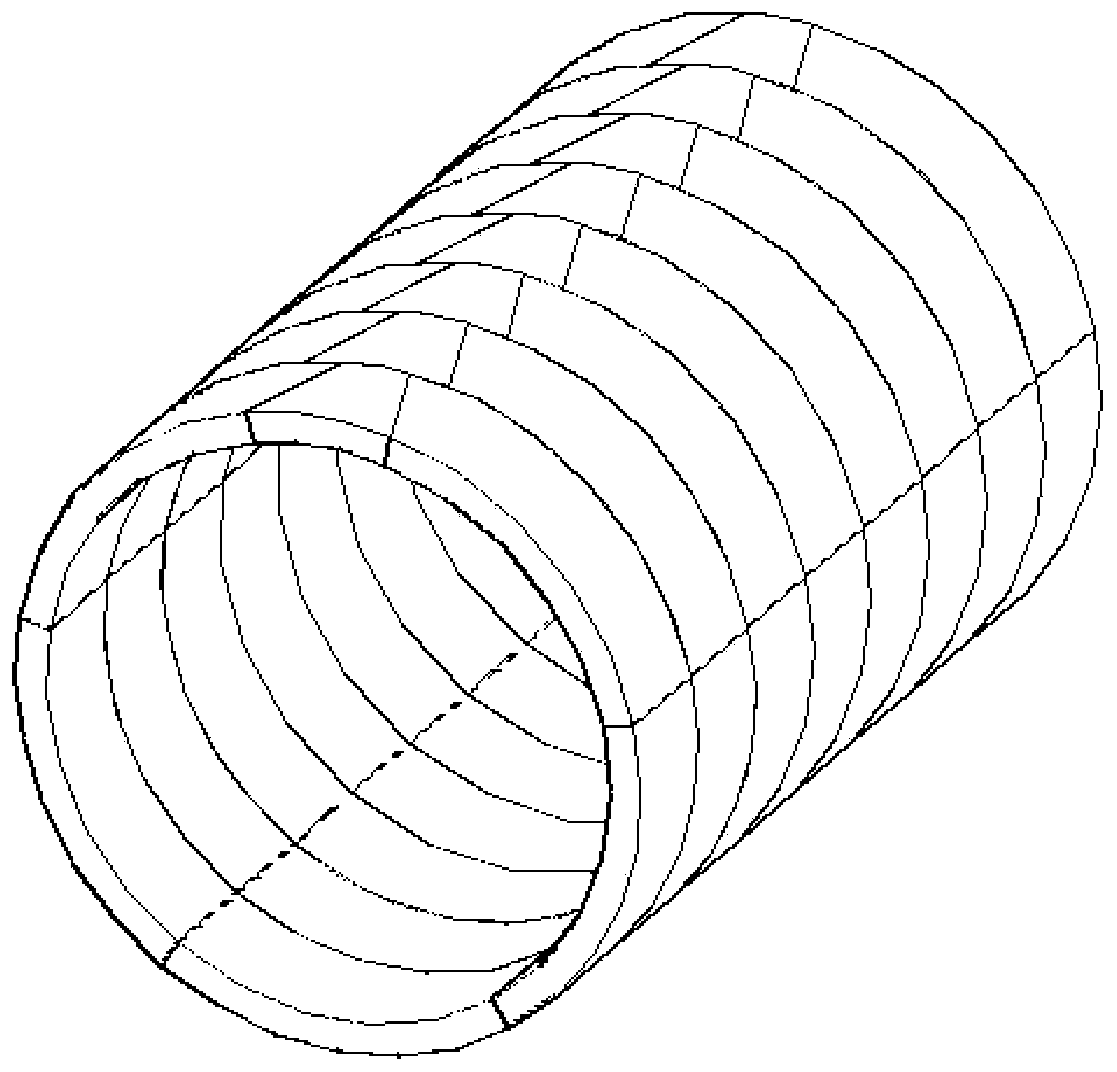

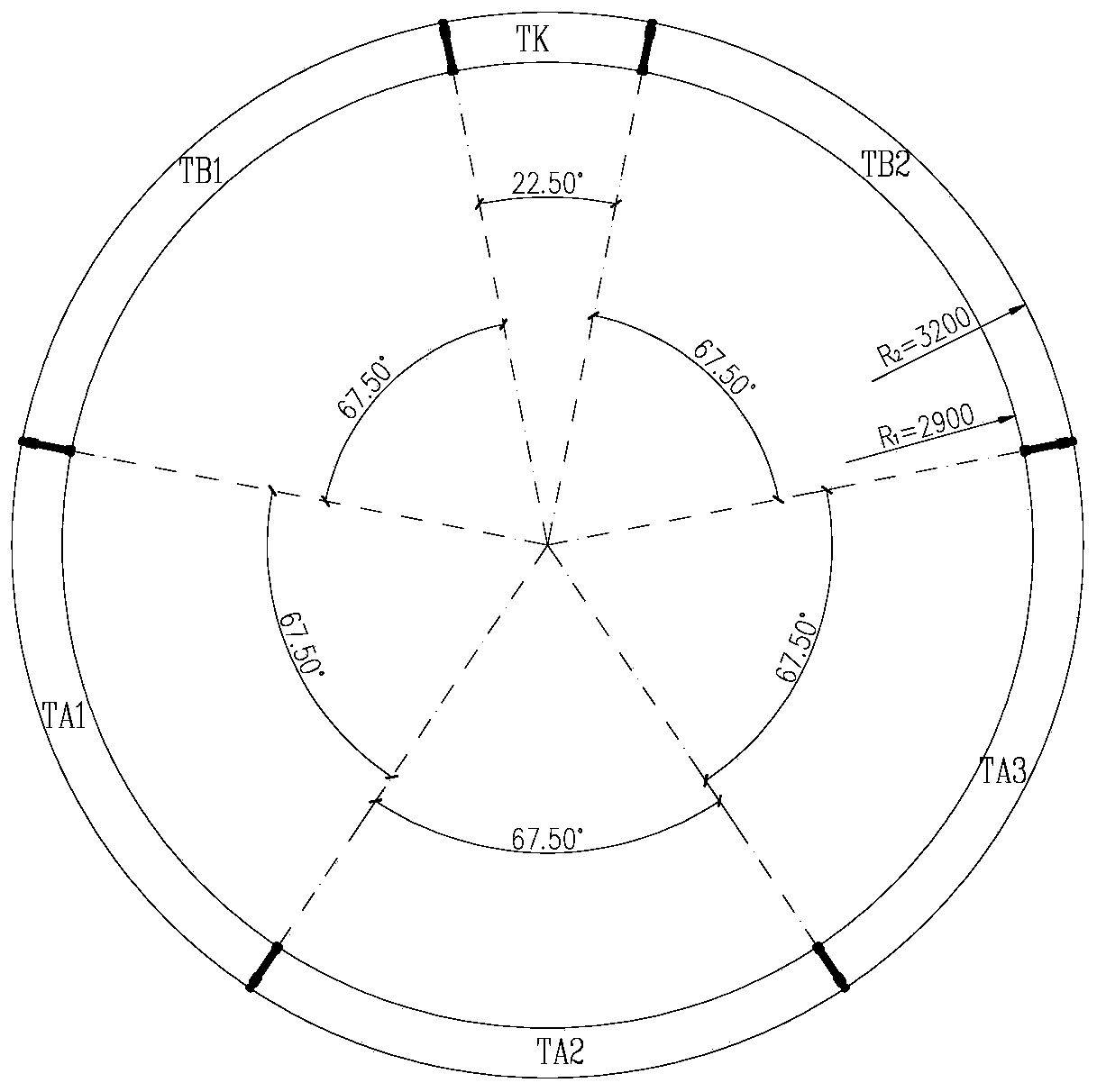

A shrinkable segment for demolition inside a tunnel and its construction method

ActiveCN108547634BLight in massEasy to installUnderground chambersTunnel liningStructural engineering

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

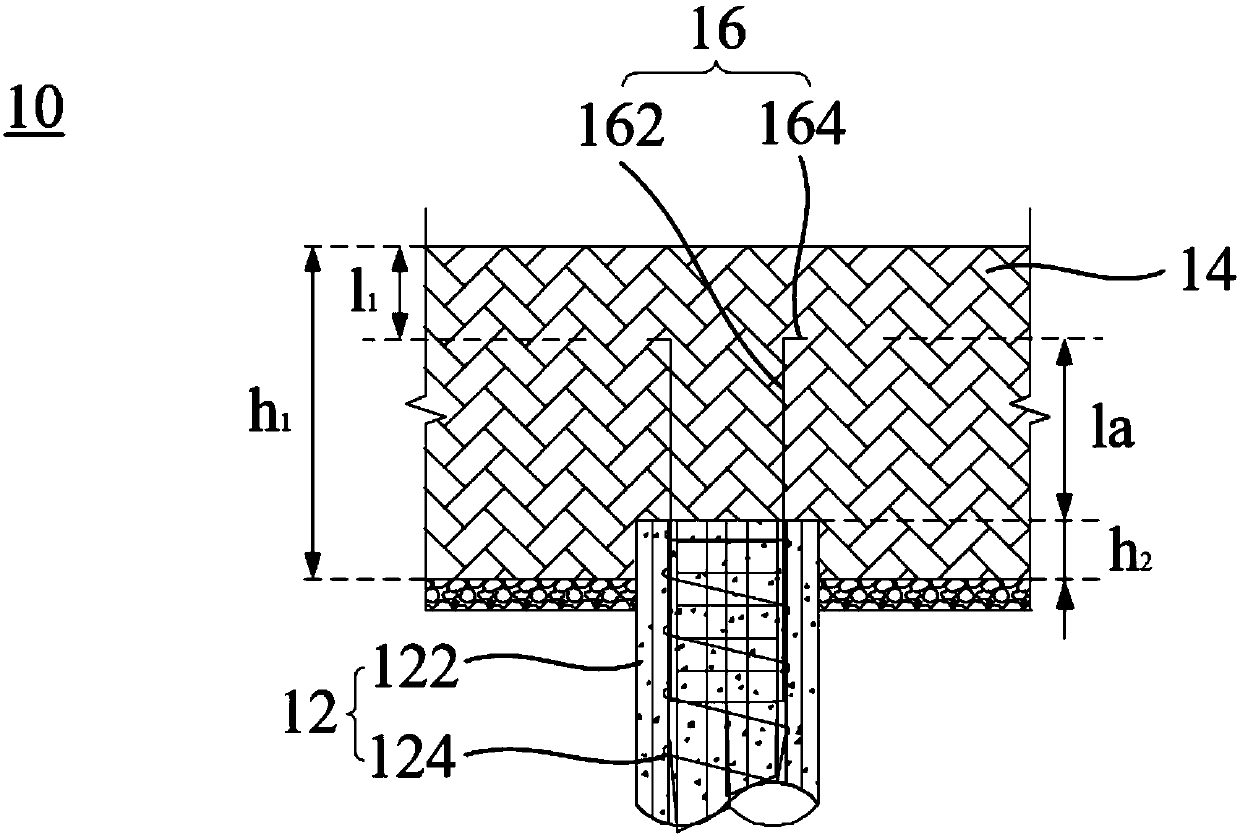

Cast-in-place pile and formation method thereof

PendingCN109537614AImprove connection strengthNo need to breakBulkheads/pilesEngineeringUltimate tensile strength

The invention relates to a cast-in-place pile. The cast-in-place pile comprises a base pile body, a bearing table and multiple connectors or multiple connectors and multiple fixing parts; the bearingtable is connected with the base pile body, the bearing table is also connected with the base pile body through the connectors or the connectors and the fixing plates, so that the connection strengthof the base pile body and the bearing table is guaranteed, in this way, detachment of a pile head is not needed, the step of detaching the pile head is omitted, the method is simple and easy to implement, the whole construction speed is effectively increased, and the construction efficiency is improved. The invention further relates to a formation method of the cast-in-place pile.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

An Embedded Vehicle Vehicle Identification System Based on Virtual Coil

ActiveCN103473933BNo need to breakPromote smart applicationsRoad vehicles traffic controlVideo monitoringDual core

The invention discloses an embedded type vehicle type recognition system based on a virtual coil. The embedded type vehicle type recognition system comprises an external program and data memorizer, an external high-speed dynamic memorizer SDRAM, an image collecting device, an image AD sampling module, a power source control module, a dual-core DSP digital signal processor chip, a virtual coil distinguishing unit and a vehicle type recognition unit. The image AD sampling module is used for acquiring the video image date provided by the image collecting device. The dual-core DSP digital signal processor chip is used for calling the virtual coil distinguishing unit to carry out virtual coil distinguishing on the collected video image to select the keyframe image emerging when a vehicle appears. The dual-core DSP digital signal processor chip is used for calling the vehicle type recognition unit to carry out vehicle type recognition calculation on the keyframe image. The embedded type vehicle type recognition system can extract characteristic values about the vehicle from the video image information and carry out structuring description with the cooperation with the virtual coil, the type of the vehicle in the video image can be recognized, and a video monitoring system can be applied and managed intelligently and conveniently.

Owner:THE THIRD RES INST OF MIN OF PUBLIC SECURITY

Method for fabricating sanitary ceramics by using waste sand of quartz

The present invention relates to a method for producing sanitary ceramics by using waste quartz sand. Its main raw materials including waste quartz sand, violet wook knot, clay, raw material, feldspar, waste ceramics, talcum and electrolyte, and its production process includes the procedures of breaking, ball-grinding, injection-forming, glazing and baking to obtain finished product.

Owner:宜昌长江陶瓷有限责任公司

Sodium-demanding Vibrio producing agarase and its application

The invention discloses vibrio natriegens HJPH YXJ-1 for producing agarase and application of the vibrio natriegens; the strain is preserved in China Center for Type Culture Collection with preservation number of CCTCC M 2015244 on April 23, 2015, wherein the China Center for Type Culture Collection is located in Wuhan University, and post code is 430072. The agarase generated from the strain is an extracellular enzyme, which is simple in separation and purification and is free from cell breakage; enzyme-producing activity is relatively high, and under optimized conditions, the activity of unpurified crude enzyme reaches 103U / mL; to degrade agar, the agarase produced from the strain is mild in reaction condition, good in specificity and free from environmental pollution, and the is suitable for the large-scale preparation of neoagaro-oligosaccharides.

Owner:HUAQIAO UNIVERSITY

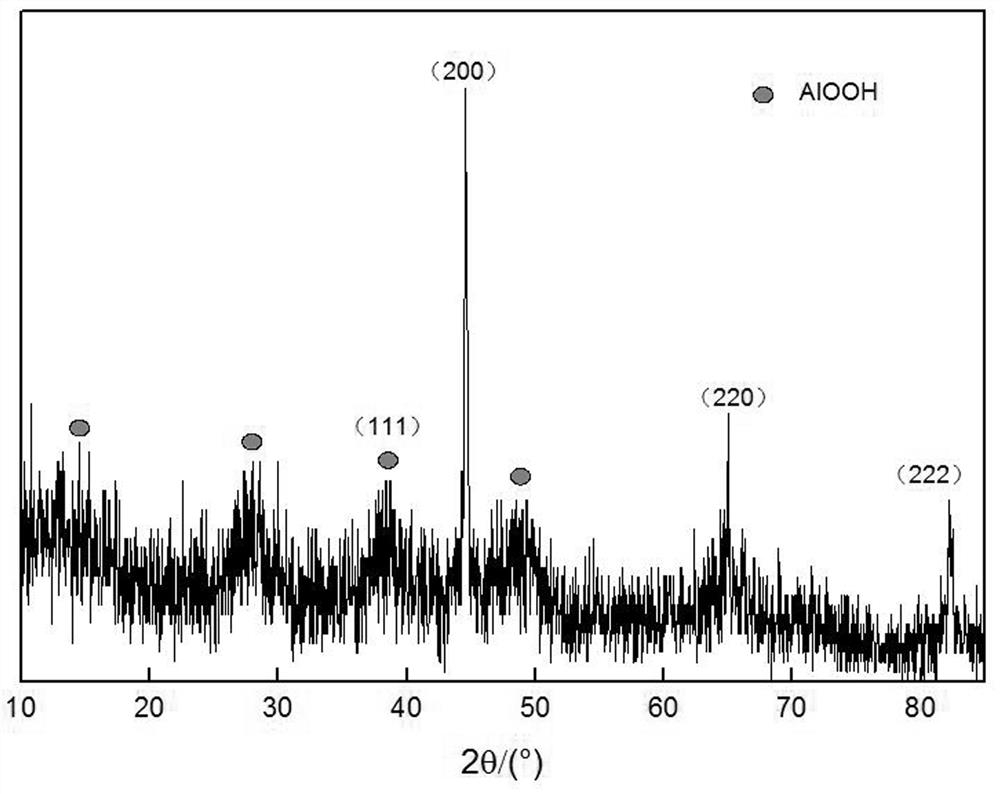

A method for preparing magnetic abrasive particles by sol-gel method

ActiveCN109054744BGood magnetic responseSmall particle sizeOther chemical processesDistilled waterAluminium isopropoxide

The invention belongs to the technical field of surface finishing processing of mechanical parts. In order to solve the problems that during traditional magnetic abrasive particle preparation, an abrasive grain phase and a magnetic medium phase are mixed unevenly, and crushing is very hard, the invention provides a method for preparing magnetic abrasive particles through a sol-gel method. Carbonyliron powder, citric acid and distilled water are mixed to prepare a solution, the solution is dried, and dried powder is ground into iron-based particles; aluminium isopropoxide is dissolved in deionized water, HNO3 is dropwise added into an aluminium isopropoxide aqueous solution, after dropping is completed, water-bath heating and stirring are conducted to form alumina sol; the dried ground iron-based particles are added into the alumina sol, stirring is conducted to form iron-based alumina sol, and after ageing is conducted at a room temperature, drying is conducted in a drying box to formthe Fe-AlOOH magnetic abrasive particles. A process is simple, easy, fast and convenient, and the magnetic abrasive particles are smaller in particle size; crushing and screening are not needed; theperformance of the abrasive particles is improved, and the service life of the abrasive particles is prolonged; the particles are small, the process is simple, crushing is not needed, the magnetic response performance is good, the cost is low, and recovery is easy.

Owner:TAIYUAN UNIV OF TECH

Method for removing green oil films in waste circuit boards

ActiveCN105483727ASolve the problem of removing green oil filmEasy to operatePrinted circuit boardMono layer

The invention discloses a method for removing green oil films in waste circuit boards. The method comprises the following steps: removing a green oil film on the surface of a waste circuit board by using a diluted alkali solution, and washing with water. A film removing agent 1 m(3) can be used for removing green oil films of circuit boards 300-700 m(2). The method solves the problem that green oil films are difficultly removed from single-layer waste circuit boards in a whole board recycling process, is simple, convenient and feasible in operation process and low in cost, and has important significance on environmental protection.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com