Method for producing silicate cement by using silico-calcium dregs and carbide dregs

A technology of Portland cement and calcium silicate slag, which is applied in the field of building materials, can solve the problems that the performance of cement clinker is not optimal, cannot be directly produced with cement, and the alkali content of calcium silicate slag is high, so as to achieve resource utilization , Improve the utilization rate of heat and realize the effect of waste heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

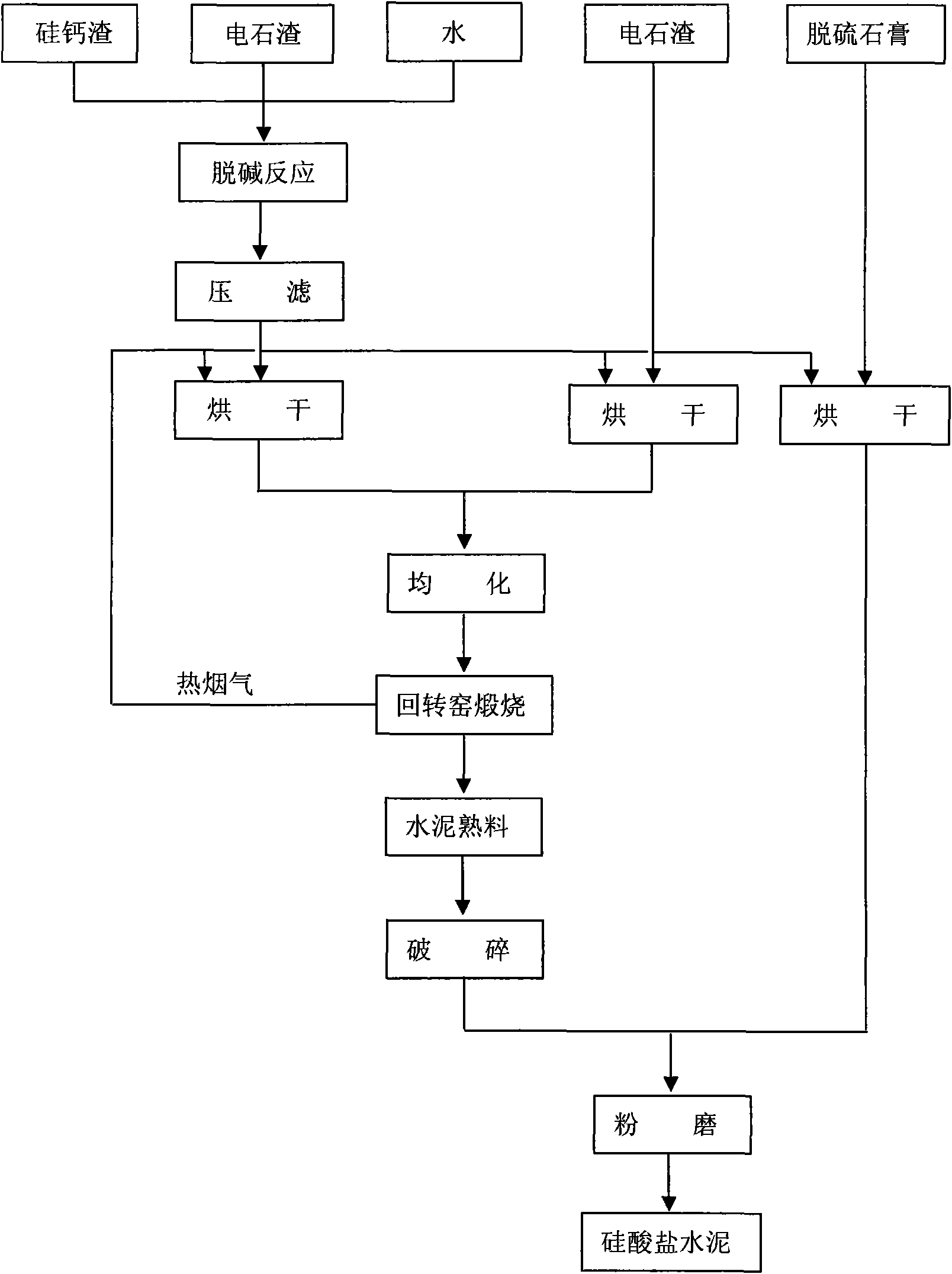

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] Referring to accompanying drawing, production step of the present invention is:

[0028] 1) Using the soda lime sintering method to extract alumina from fly ash, the silica-calcium slag filter cake with 35% water attached, Na 2 O3.81% (calculated on a dry basis), 41% of water attached to calcium carbide slag in a chemical plant, CaO60.85% (calculated on a dry basis), and the proportioning of silicon-calcium slag: calcium carbide slag = 100:8 by weight on a dry basis, plus appropriate amount Water undergoes a dealkalization reaction. Keep the reaction temperature at 90°C, keep stirring, press filter and wash after reacting for 1 hour, and dry the filter cake of dealkalized calcium calcium slag with a dryer. Na 2 The O content was reduced to 0.44%. Carbide slag is dried with a dryer.

[0029] 2) The dried dealkalized calcium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com