Water-coal-slurry vibrating screen

A technology of vibrating screen and coal water slurry, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of low strength, incomplete vibration, poor rigidity, etc., and achieve long life, high screening efficiency and low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

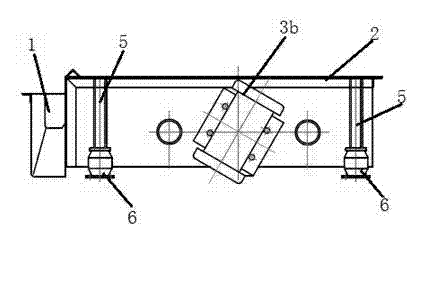

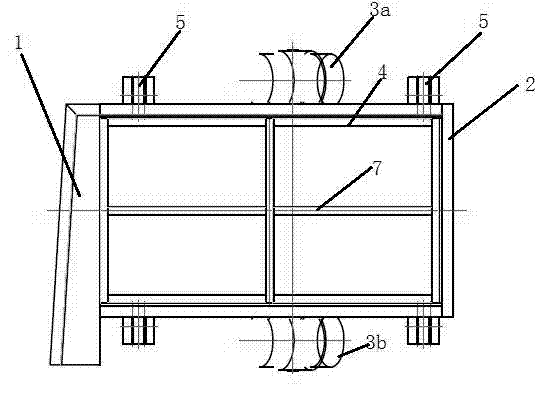

[0014] The coal water slurry vibrating screen includes a block discharge chute 1, a screen body 2 and an excitation source. The block discharge chute 1 is set at one end of the sieve body 2, and the sieve body 2 is provided with a vibrating tank body and a stainless steel trapezoidal bar screen (not shown in the figure), and the excitation source is two vibration motors 3a and 3b, respectively installed On both sides of the sieve body 2.

[0015] In the present invention, the two vibrating motors 3a and 3b start at the same time, but the rotation directions are opposite. The four corners of the screen body 1 are provided with support bases 5, and the bottom of the support base 5 is provided with rubber springs 6.

[0016] In the present invention, the four corners of the sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com