Method for welding box-shaped column

A welding method and box-column technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems affecting the machining accuracy of the box-shaped column, the quality of production efficiency components, etc., so as to improve the quality of components, improve the machining accuracy, The effect of reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

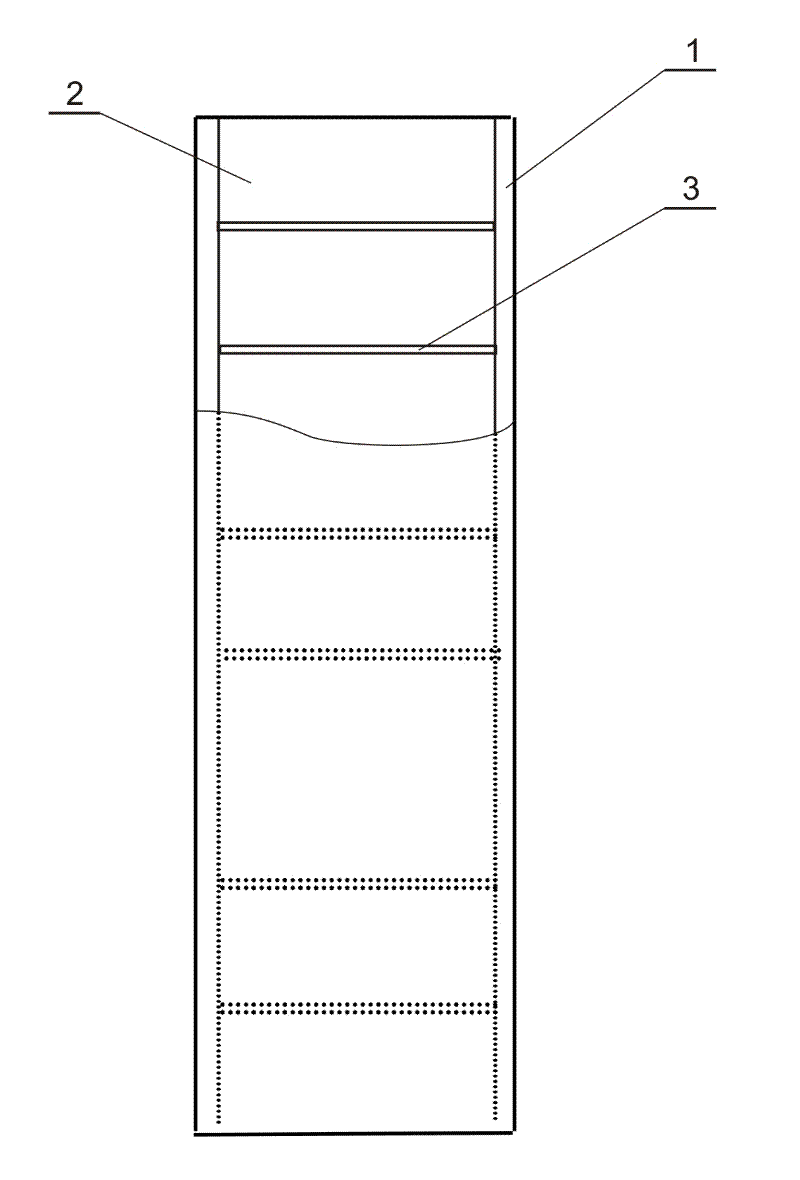

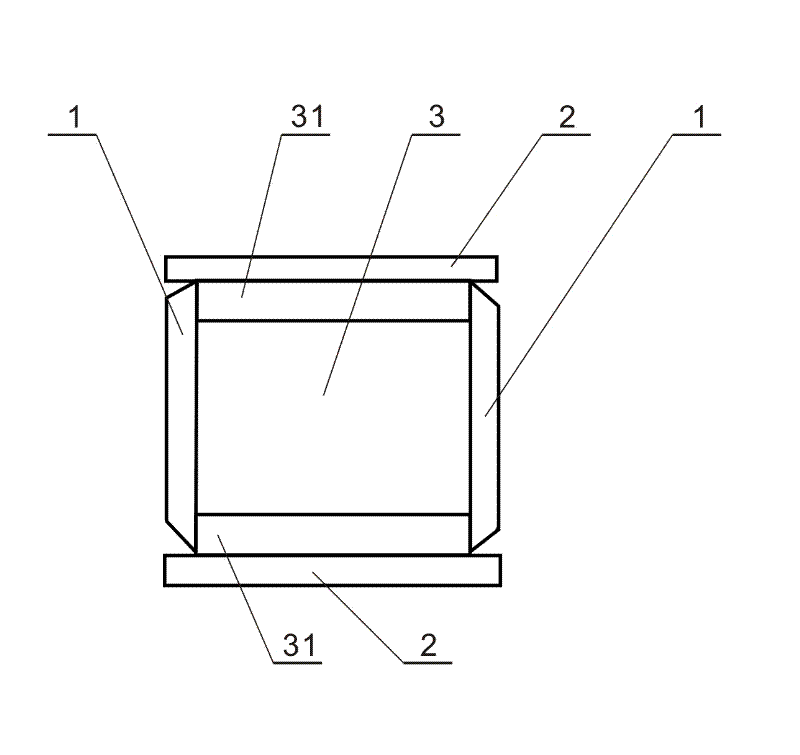

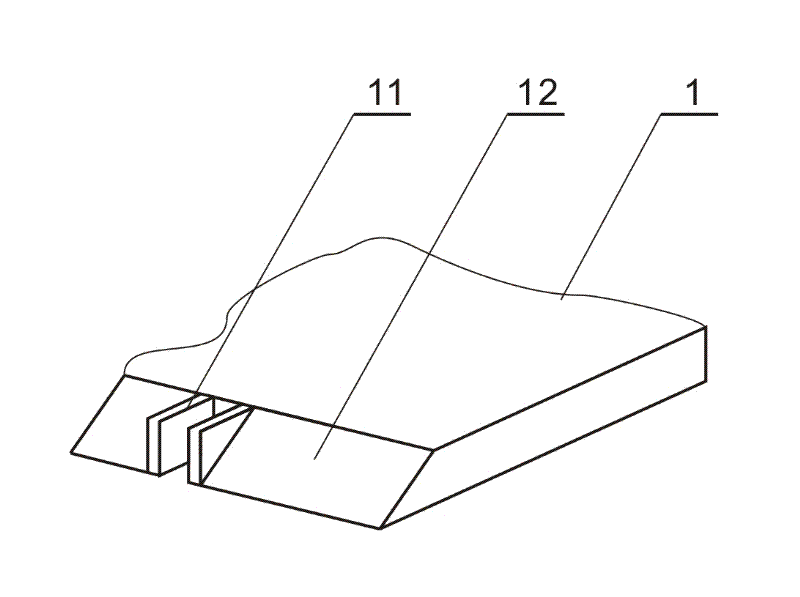

[0039] The steel structure steel column of Beijing Yintai Center adopts box-shaped column. The basic parameters of the box-shaped column: the cross-sectional size of the box-shaped column is 700*700, the thickness of the wing plate 2 and web plate 1 is 40mm, the thickness of the partition is 32mm, the length of the box-shaped column is 12m, There are three nodes in the full length of the column, and each node is equipped with two partitions 3. Since manual welding cannot enter the column to complete the welding of the partitions 3, electroslag welding is used to complete the welding of the partitions 3 and the flange 2. The electroslag welding seam is set between the partition plate 3 and the wing plate 2, and the welding process steps of the overall box-shaped column are as follows:

[0040] a) Blanking: According to the drawing size of the box-shaped column, use a CNC cutting machine to blank, among which, there are two pieces of web 2, two pieces of wing plate 2 and six piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com