Manufacturing method of steel structure box girder/column

A manufacturing method and box girder technology, applied in manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of increasing product manufacturing costs, low production efficiency, delaying construction period, etc., and achieve cost saving, high production efficiency and low cost Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

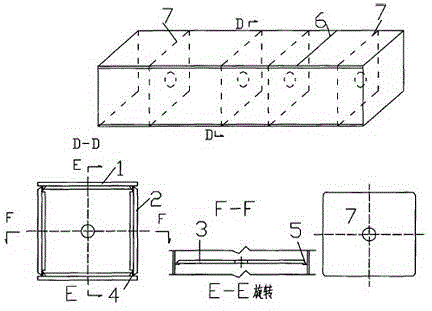

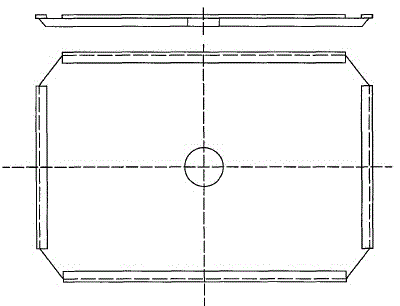

[0021] Among them, the clapboard assembly is to add the liner to the clapboard after cutting the groove. figure 2 parts shown.

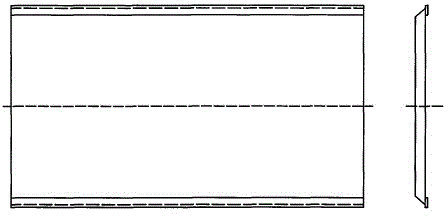

[0022] The web assembly is to add the liner to the web after cutting the groove. image 3 parts shown.

[0023] The segmental splicing of the cover plate is to disconnect the cover plate at 200mm from the first set of dividers when there is a certain distance between the divider group and the next set, so as to facilitate the welding of the divider. The joint processing such as Figure 4 shown.

[0024] The manufacturing method of steel structure box beam / column of the present invention is as Figure 5 As shown, its specific production process is as follows:

[0025] (1) Use the computer to control the size of the cover plate, web plate and its lining plate, partition plate and its lining plate for blanking, and at the same time make grooves on both sides of the web plate and four sides of the partition plate. center drilling;

[0026] (2) As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com