Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Improve melting ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

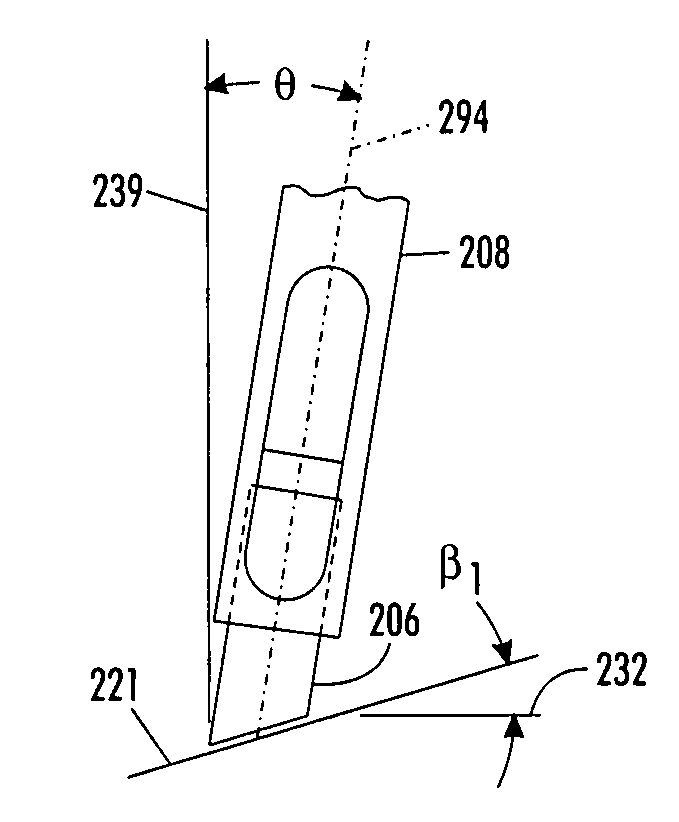

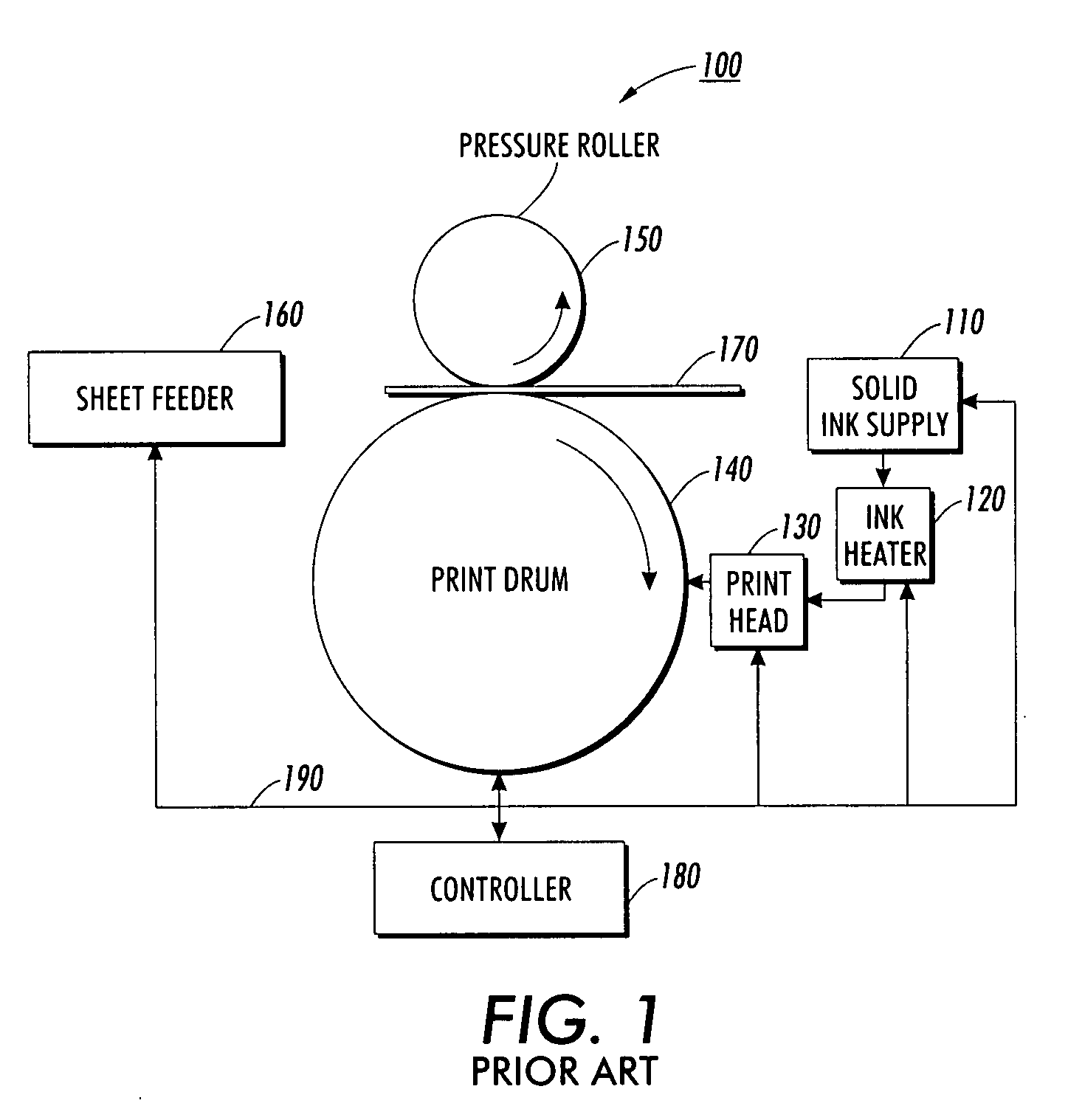

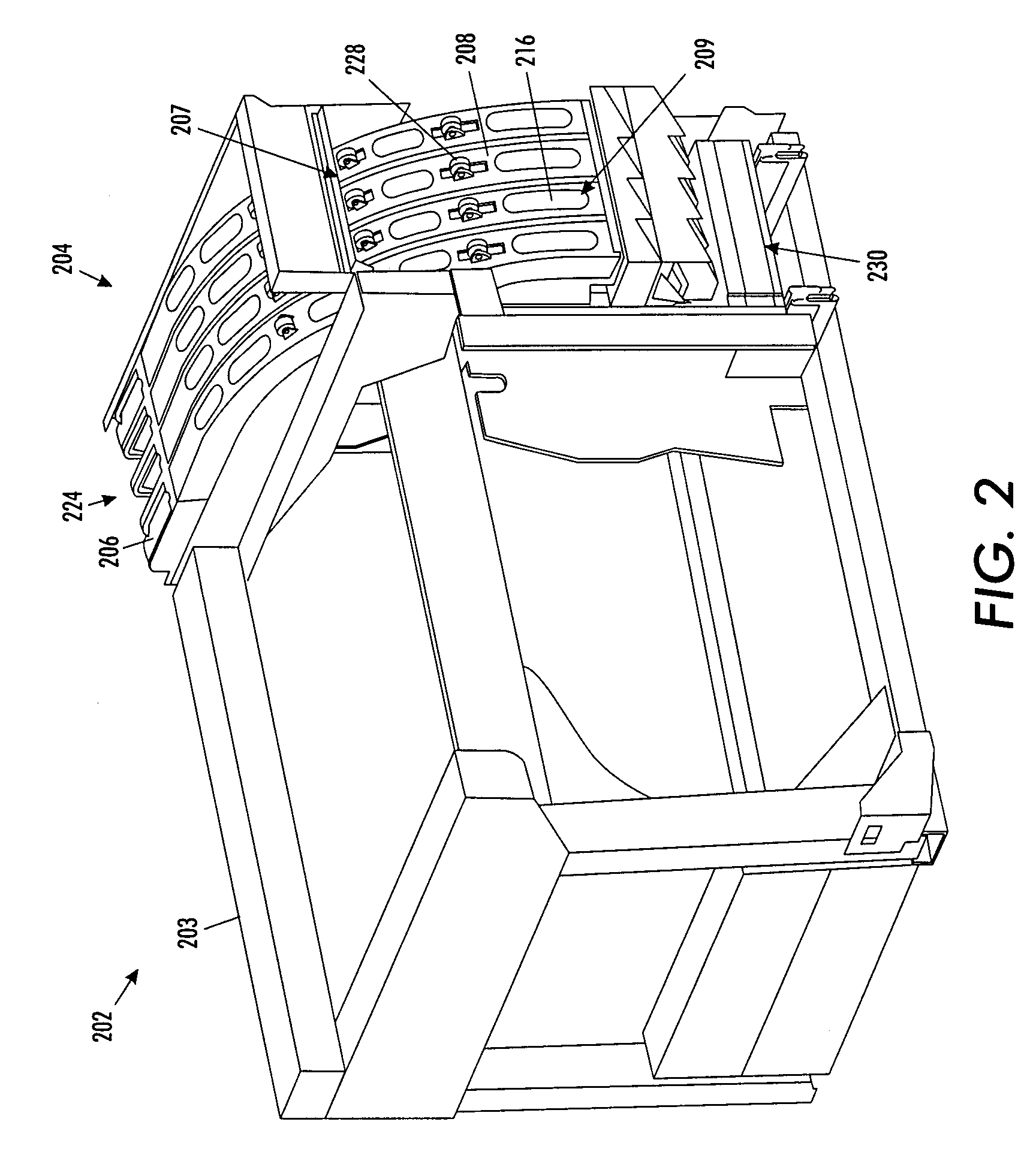

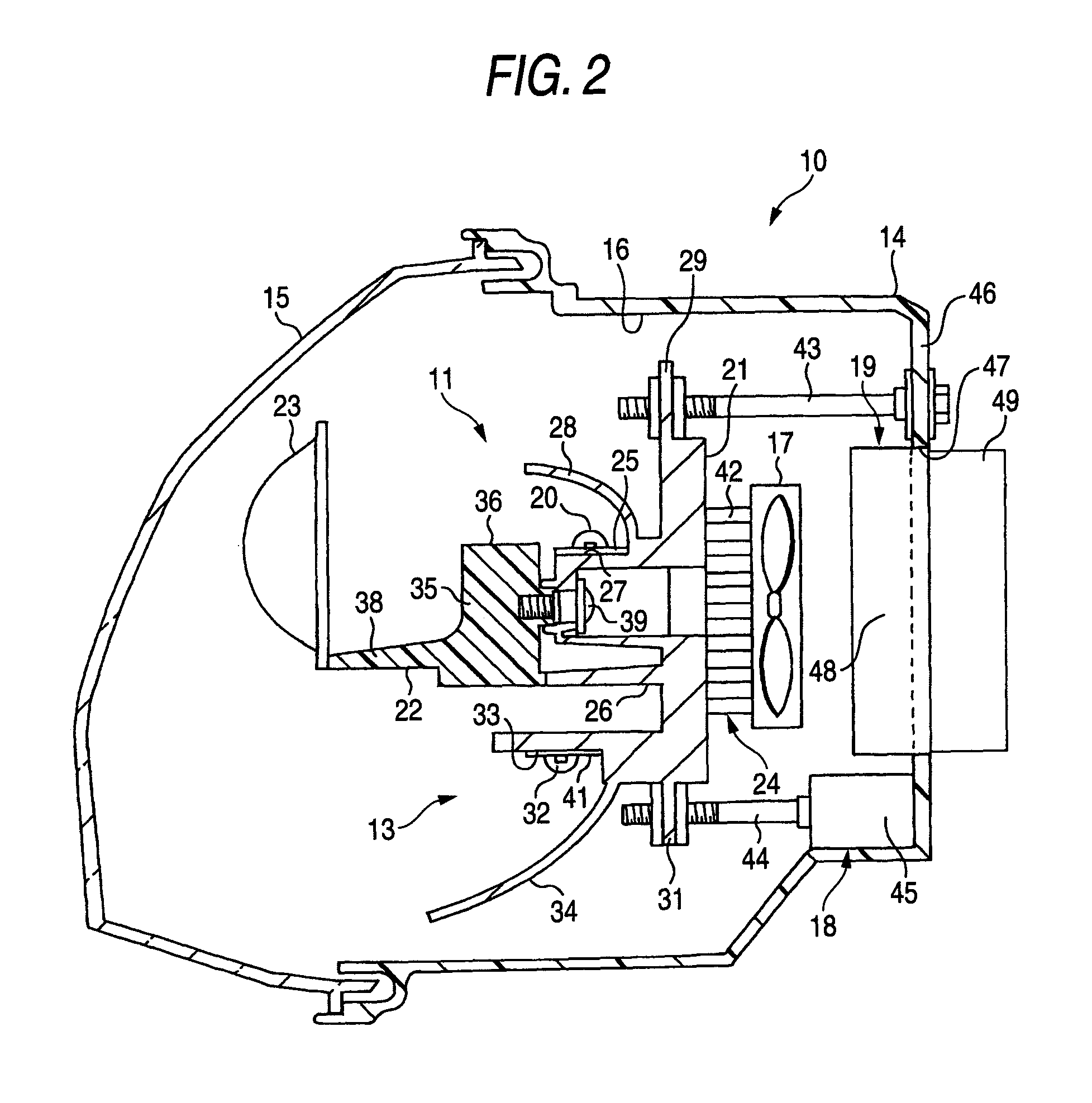

Transport system for solid ink for cooperation with melt head in a printer

InactiveUS20080117266A1Improve melting abilityLow costOther printing apparatusTransport systemAcute angle

An ink delivery system for use with a solid ink stick for use in printers is provided. The ink delivery system is used for receiving the stick and converting it to molten ink that may be transferred to media to form an image on the media. The delivery system includes a guide for receiving the stick and guiding the stick in a prescribed path and a melting unit. The melting unit is operably associated with the guide. The melting unit converts the stick to molten ink. The melting unit defines a receiving surface for receiving a first end of the stick. The receiving surface defines a plane. The guide defines a longitudinal axis of the guide adjacent the melting unit. The longitudinal axis defines an acute angle with respect to the plane.

Owner:XEROX CORP

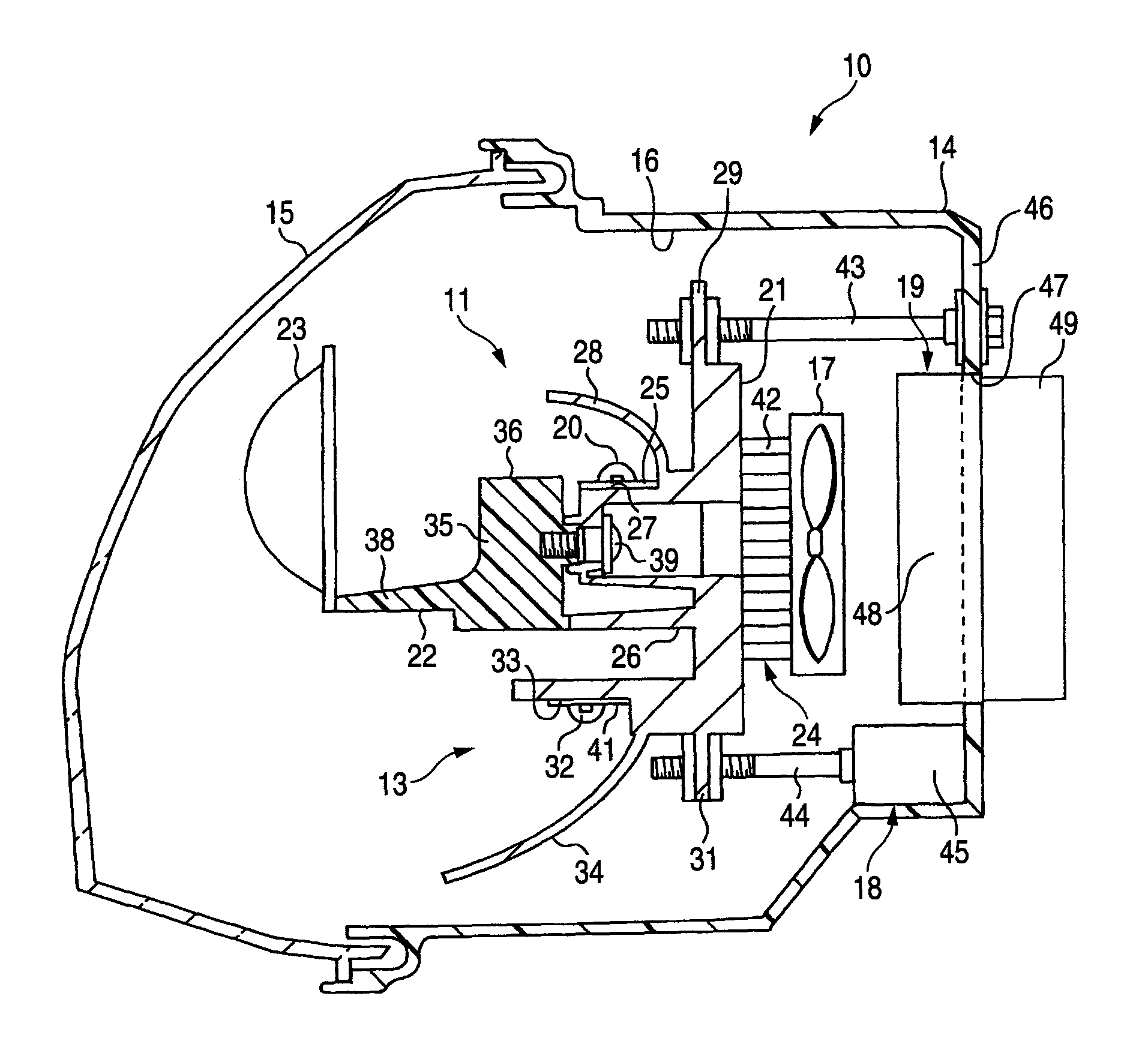

Vehicle lighting device

InactiveUS7985013B2Improve melting abilityVehicle headlampsPoint-like light sourceEngineeringSemiconductor

A vehicle lighting device is provided with: a lamp chamber defined by a lamp body and a cover; a light source unit including a semiconductor light emitting element as a light source and provided within the lamp chamber; a metallic heat transfer member attached to the lamp body and penetrating between an outside and an inside of the lamp chamber; and an air blower disposed between the light source unit and the heat transfer member so that an air blowing direction of the air blower directs toward the heat transfer member.

Owner:KOITO MFG CO LTD

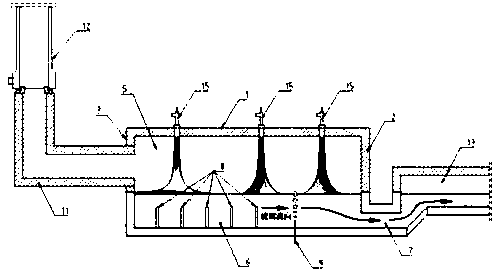

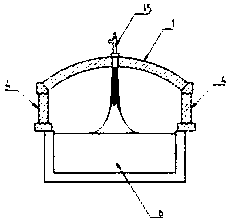

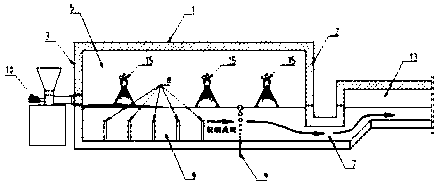

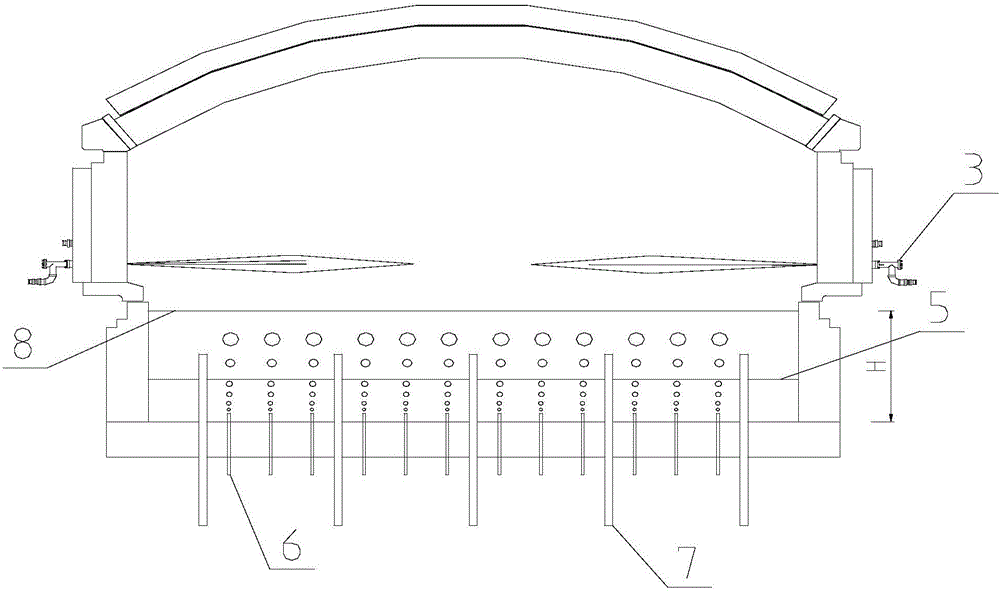

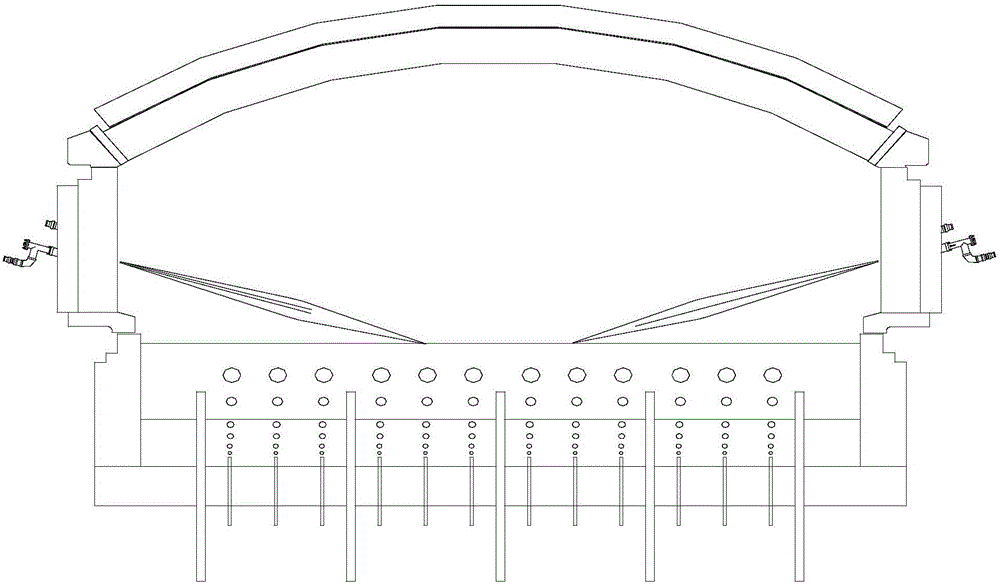

Glass fiber tank furnace structure and glass smelting method

ActiveCN103508652AHigh heat transfer efficiencyReduce erosionCharging furnaceTank furnacesCorrosionSmoke

The invention discloses a glass fiber tank furnace structure and a glass smelting method. The glass fiber tank furnace structure comprises a smelting part and a passage. The smelting part comprises a feeding tank for feeding a glass raw material, and a smelting pool for receiving the supplied materials and forming a glass liquid. A glass liquid separation device of the smelting pool and the passage is a throat or a baffle brick structure. The upper part of the smelting pool is provided with a crown, two side breast walls, a front wall, a back wall and a smoke flue. The smelting pool is divided into a zone A as a raw material zone, a zone B as a foam zone and a zone C as a clarification zone C along a glass melt flowing direction. The smelting pool is provided with at least one combustor, the combustor is installed on the crown or the breast walls, the combustor sprays flame to glass batch and the sprayed flame forms an included angle of 0-80 degrees with the two side breast walls and forms an included angle of 0 degree with the front wall or the back wall. The glass smelting method adopting the glass fiber tank furnace structure comprises that above the smelting pool of the glass fiber tank furnace structure, the at least one combustor is arranged on the crown or the breast walls; a gaseous oxidant and a gaseous, liquid or solid fuel fluid are supplied to the combustor; and the combustor sprays flame to the glass batch. The glass fiber tank furnace structure has the advantage of high heat transfer efficiency, small corrosion on a refractory material, long tank furnace service life, and energy saving.

Owner:JUSHI GRP CO

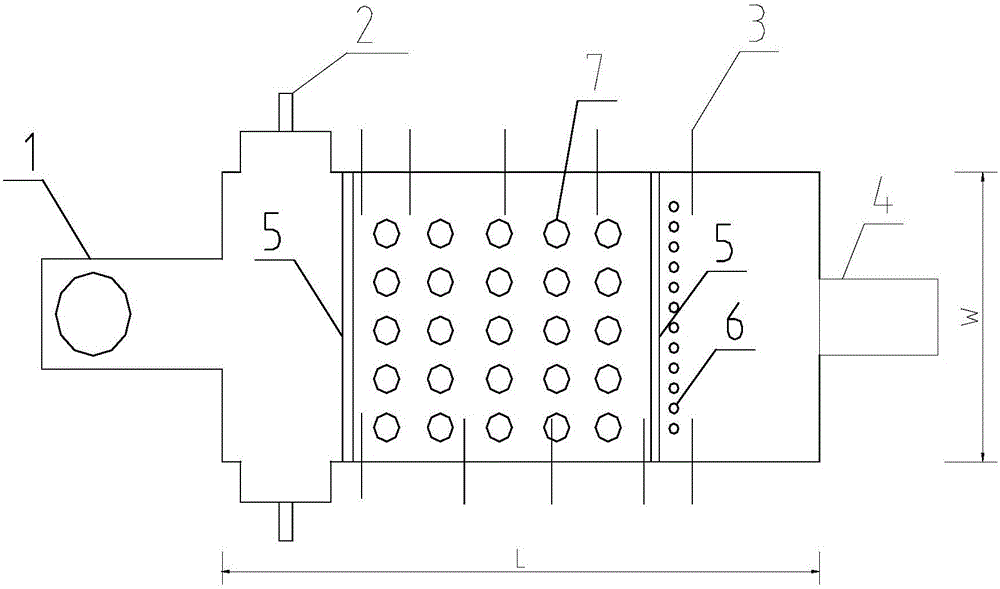

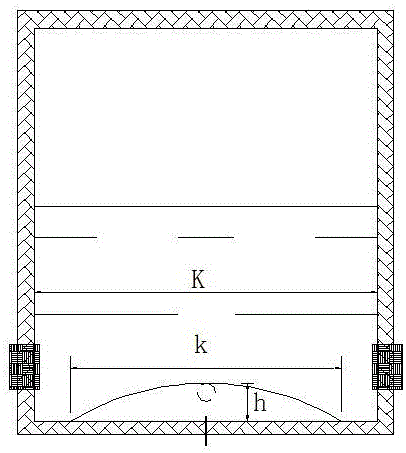

Glass tank furnace with high melting rate

ActiveCN105776819AHigh aspect ratioReduce lossTank furnacesGlass furnace apparatusHeat lossesEngineering

The invention discloses a glass tank furnace with high melting rate. The ratio of the length of the glass tank furnace to the width of the glass tank furnace is 2.3-2.8. The glass tank furnace has the advantages that the area of the tank furnace is reduced and the length-width ratio of the tank furnace is optimized so as to reduce heat loss; reasonable liquid glass tank depth is designed to improve the bottom temperature of the tank furnace and guarantee the quality of liquid glass; a pure-oxygen burner and an auxiliary capacitor provides sufficient energy to increase the melting ability and heating efficiency of the tank furnace, and the energy consumption and the discharge amount of carbon dioxide are lowered greatly; furnace ridges at the bottom of the tank furnace increase the outlet temperature of the liquid glass, lower energy consumption, lower the furnace bottom temperature of an electrode area, prolong the service life of the furnace bottom and guarantee the increasing of auxiliary electric energy proportion; bubbling at the bottom of the tank furnace increases the return strength of the liquid glass and increases the melting ability and the quality of the liquid glass; to sum up, the melting rate of the tank furnace can be increased effectively, and the energy consumption can be lowered.

Owner:JUSHI GRP CO

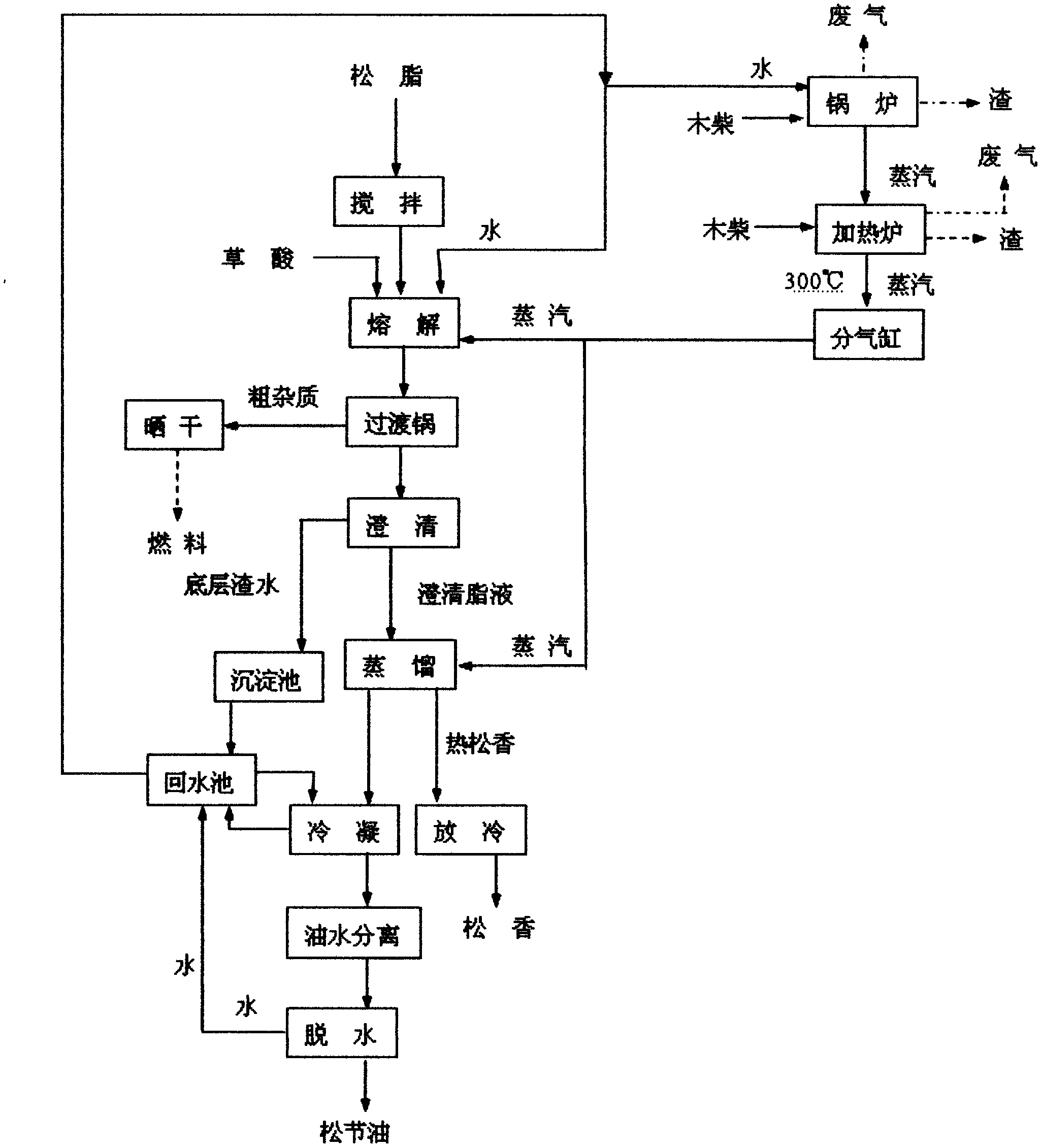

Rosin production technology process

InactiveCN104342034AImprove melting abilityThere will be no meltingChemical industryTurpentine spiritsSteam pressureTurpentine

The invention discloses a rosin production technology process. The process comprises the following steps: conveying turpentine to a melting boiler, adding water, turpentine oil, and oxalic acid, wherein the weight ratio of turpentine to water to turpentine oil is 2-4:1-2:1, and the oxalic acid accounts for 0.1 to 0.3% of the turpentine weight; heating the boiler to melt the mixture in the boiler; transferring the melt mixture to a transition boiler; introducing the melt mixture into a clarifying boiler after precipitation in the transition boiler, then transferring the liquid to a steaming boiler to carry out steaming, wherein during the steaming process, water and turpentine oil are continuously steamed out from the liquid. The provided rosin production technology process has the following advantages: the turpentine is fully stirred before melting so as to grind the turpentine, thus the turpentine melting effect is improved, at the same time the phenomenon that some turpentine is not melted during the melting process is avoided, and thus the yield is increased; moreover, the metling is reduced, the energy consumption is reduced, and the rosin color will not turn darker; the condensed hot water can be directly applied to the boiler so as to reduce the temperature difference between the inlet water and outlet water, the boiler efficiency is improved, the steam pressure is more stable, and more energy is saved.

Owner:琼中森富松香加工厂有限公司

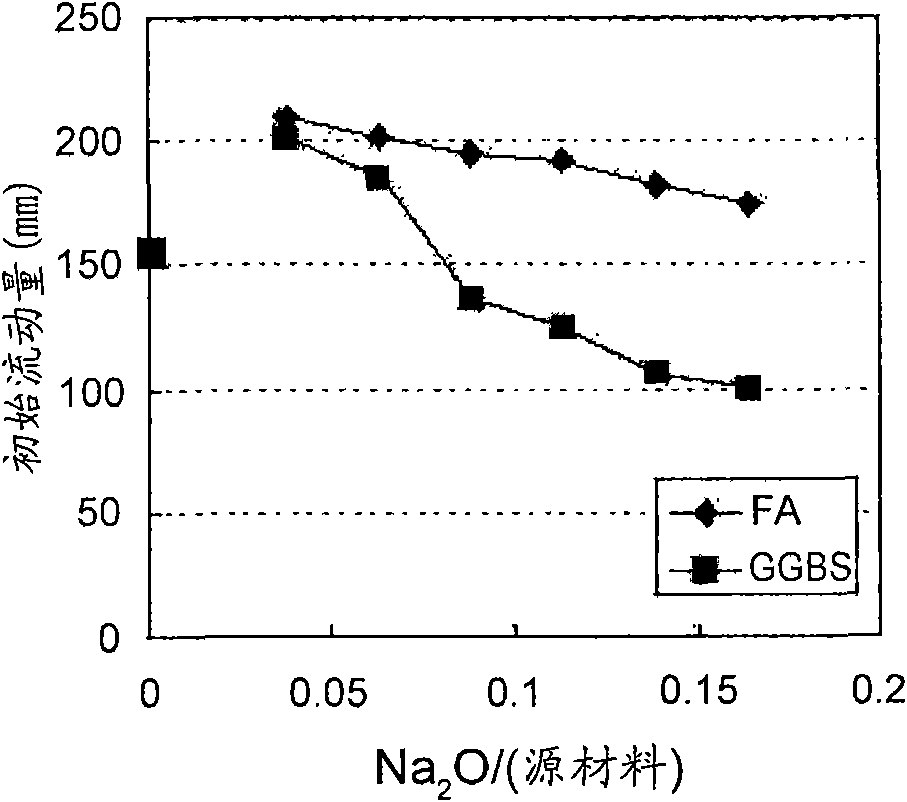

Alkali-activated binder with no cement, method for fabricating mortar using it, and method for fabricating alkali-activated reinforcement mortar with no cement

InactiveCN101687704AImprove initial strengthLow heat of hydrationSolid waste managementCement productionPortland cementKaolin clay

The present invention relates to a cement-free alkali activated binder in which alkaline inorganic materials are appropriately added to an industrial waste such as blast furnace slag, fly ash, meta kaolin and the like, a method for producing mortar using the same and a method for producing cement-free alkali activated reinforcement mortar. Specifically, the present invention relates to a cement-free alkali activated binder that is not only environmentally friendly as being capable of dramatically reducing the carbon dioxide emission, which has been remained as a problem for producing Portlandcement, but also has an excellent property, a method for producing mortar using the same and a method for producing cement-free alkali activated reinforcement mortar.

Owner:IND FOUND OF CHONNAM NAT UNIV

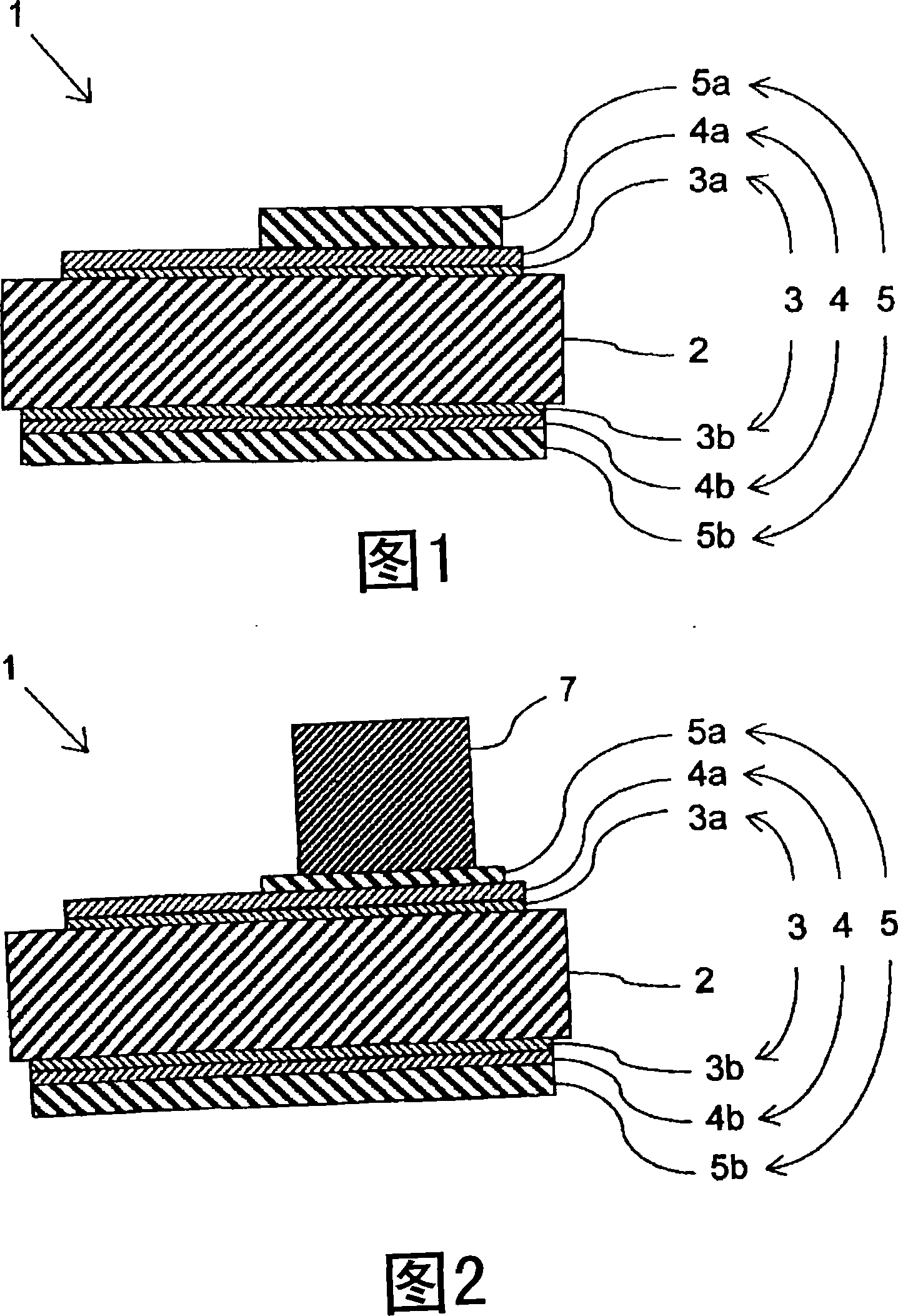

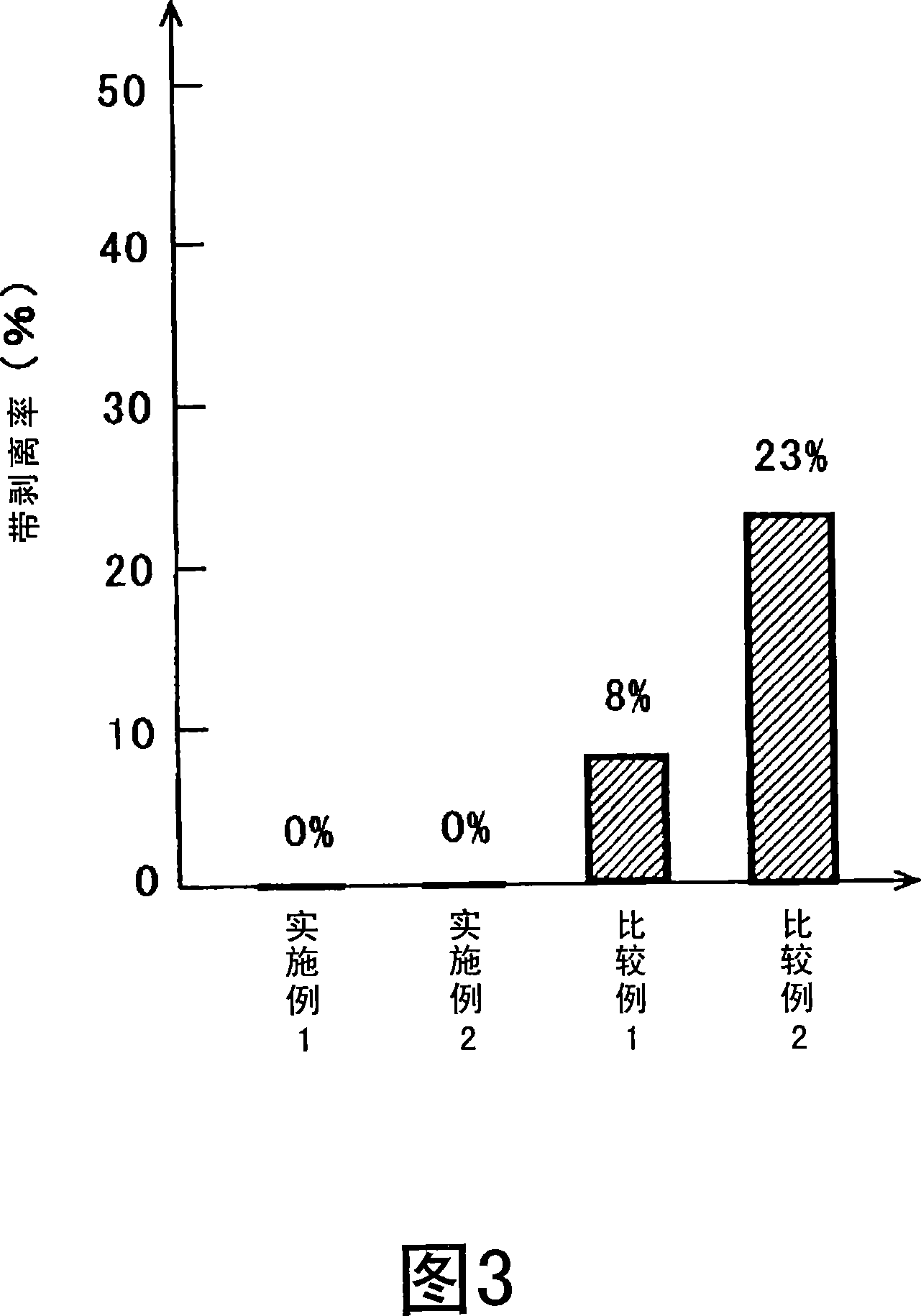

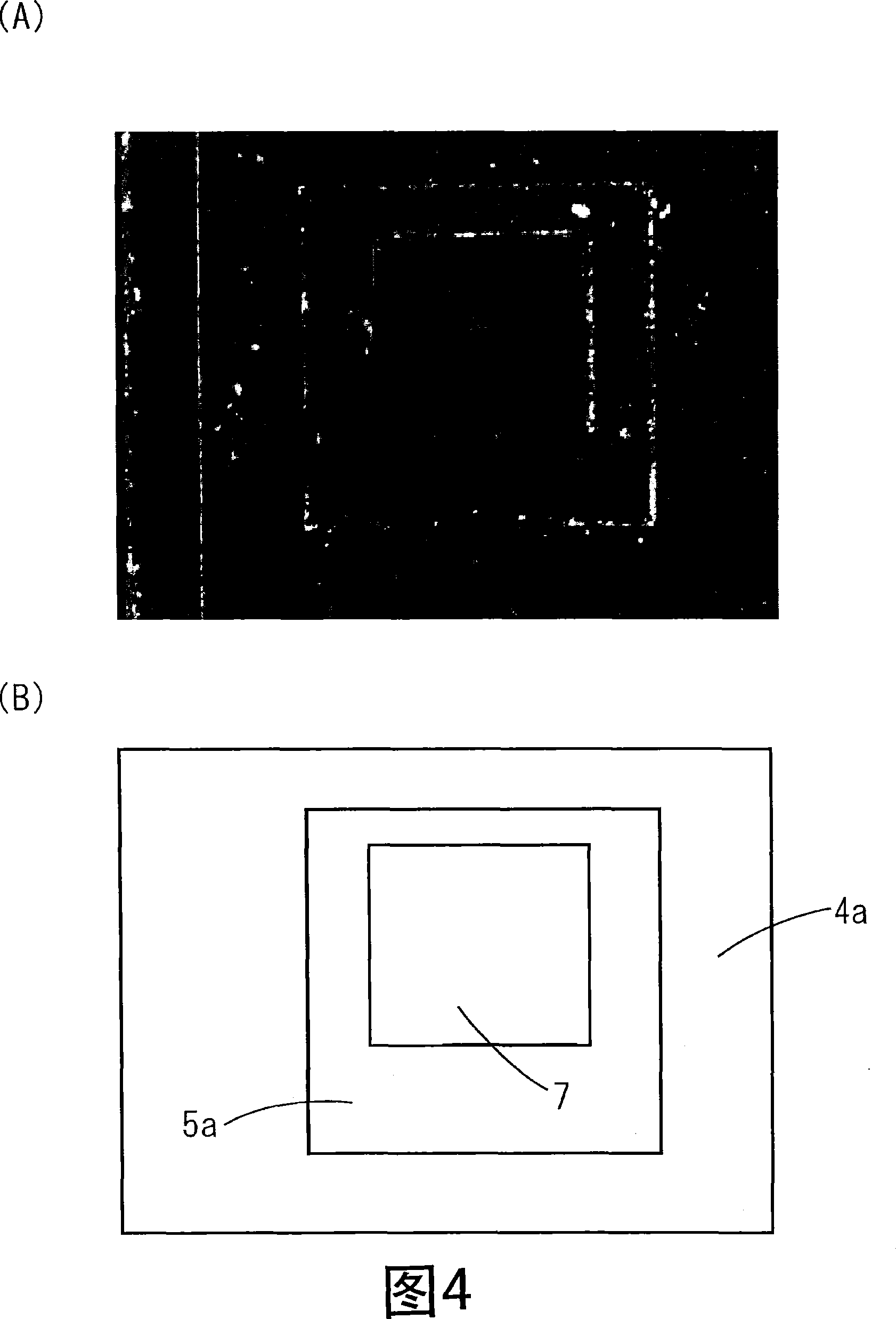

Sub-mount and its manufacturing method

InactiveCN101194359AImprove wettabilityImprove performanceSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceSurface roughness

A submount with an electrode layer having excellent wettability in soldering and method of manufacturing the same are disclosed. A submount (1) for having a semiconductor device mounted thereon comprises a submount substrate (2), a substrate protective layer (3) formed on a surface of the submount substrate (2), an electrode layer (4) formed on the substrate protective layer (3) and a solder layer (5) formed on the electrode layer (3) wherein the electrode layer (4) is made having an average surface roughness of less than 1 [mu]m. The reduced average surface roughness of the electrode layer (4) improves wettability of the solder layer (5), allowing the solder layer (5) and a semiconductor device to be firmly bonded together without any flux therebetween. A submount (1) is thus obtained which with the semiconductor device mounted thereon is reduced in heat resistance, reducing its temperature rise and improving its performance and service life.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Borosilicate glass and preparation method

The application belongs to the technical field of glass preparation, and particularly relates to a borosilicate glass and a preparation method of the borosilicate glass. The borosilicate glass is prepared from, by weight percent, 50-60% of SiO2, 15-27% of Al2O3, 3-8% of B2O3, 13-28% of CaO, 0.2-0.45% of Fe2O3, 0.1-0.5% of TiO2, 0.1-1.2% of MgO, and 0.1-1.2% of alkali metal R2O. The borosilicate glass provided by the application is excellent in physical performance, corrosive resistance and outstanding heat resistance; moreover, the environmental pollution during the preparation process is small, and energy consumption is low.

Owner:清远忠信世纪电子材料有限公司

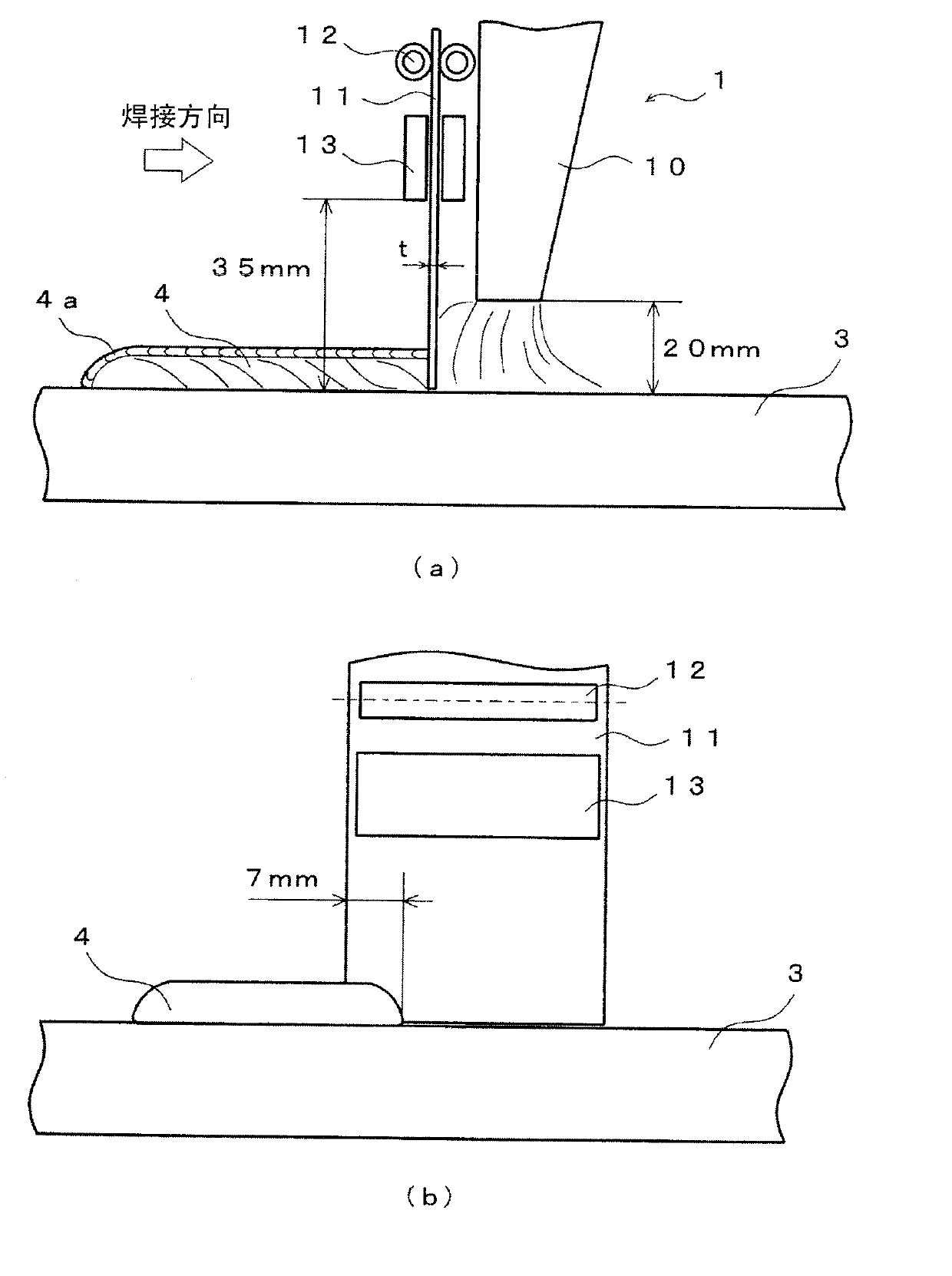

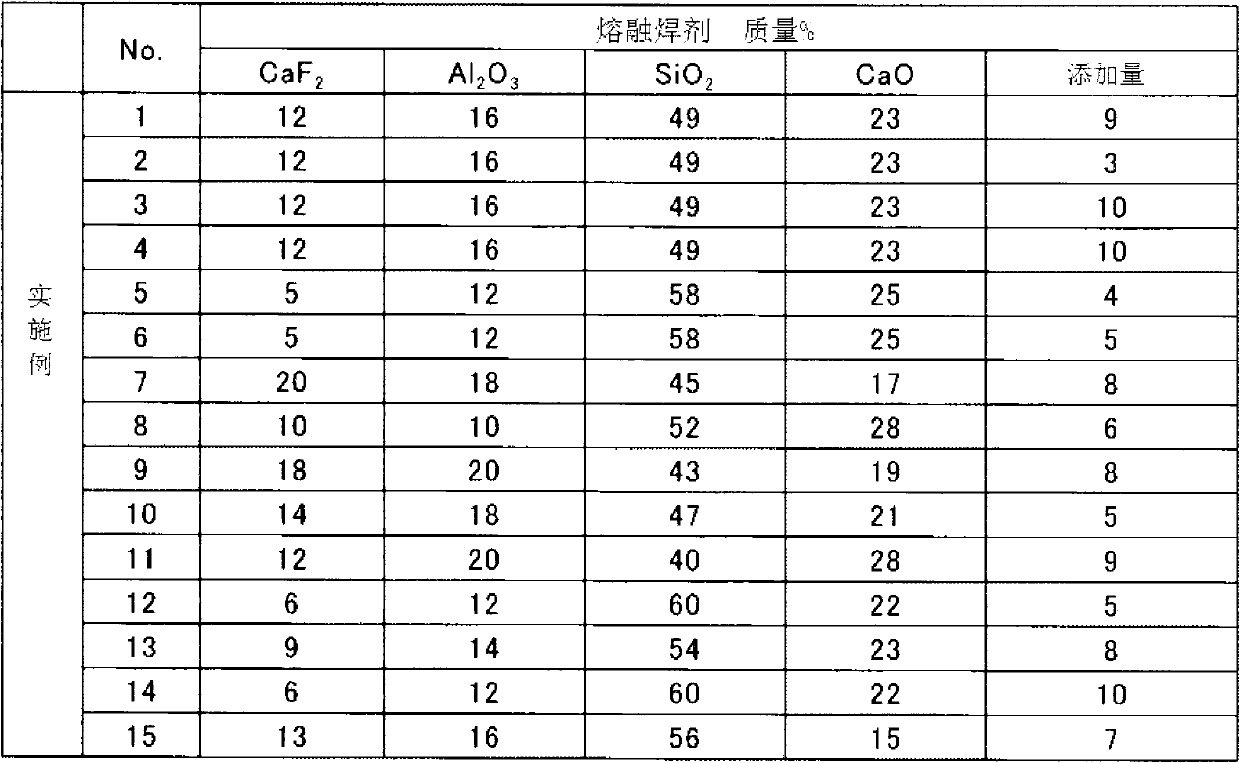

Flux for electroslag overlay welding

ActiveCN102990251AExcellent peelabilityImprove melting abilityArc welding apparatusWelding/cutting media/materialsElectroslag weldingBead shape

The invention provides a flux for electroslag overlay welding. The flux is advantageous in that, in electroslag overlay welding for which band steel formed by a Ni-based alloy is used, even under the condition of small heat input amount in welding, stability of welding is excellent, and good welding bead shape and welding bead appearance can be obtained. The flux (1) is used for the electroslag overlay welding for which the band steel formed by the Ni-based alloy is used. The flux (1) is a sintered flux obtained by mixing and sintering, in total mass percent of the flux, 3-10 mass% of a molten flux as a part of raw materials for the sintered flux, wherein the molten flux comprises CaF2: 5-20 mass%, Al2O3: 10-20 mass%, SiO2: 40-60 mass%, and CaO: 15-30 mass%. In addition, whole composition of the flux is optimized.

Owner:KOBE STEEL LTD

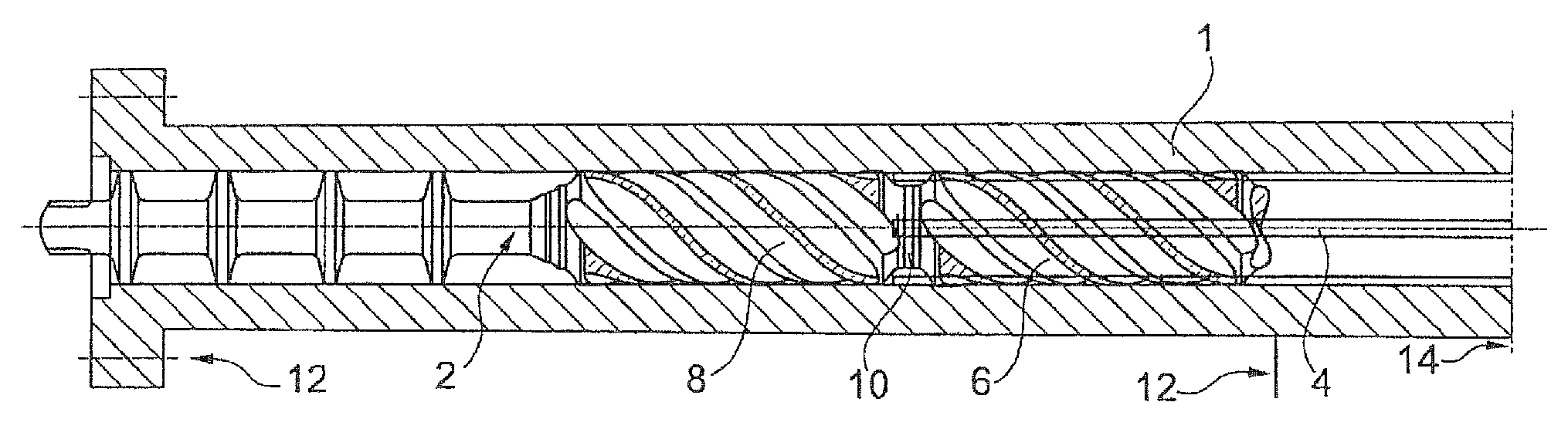

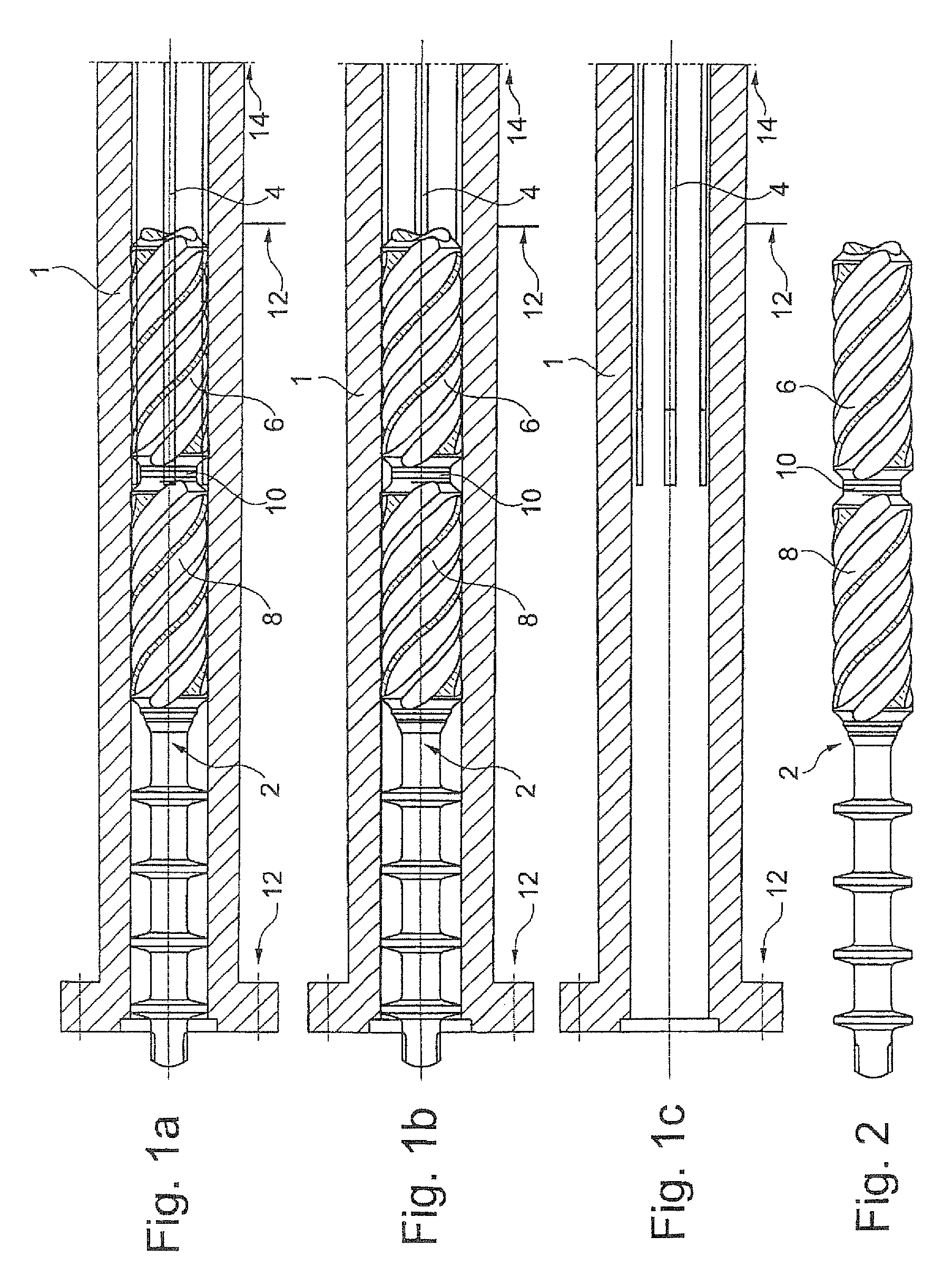

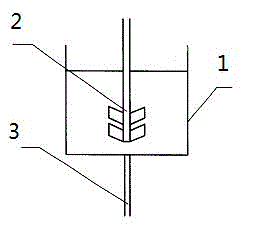

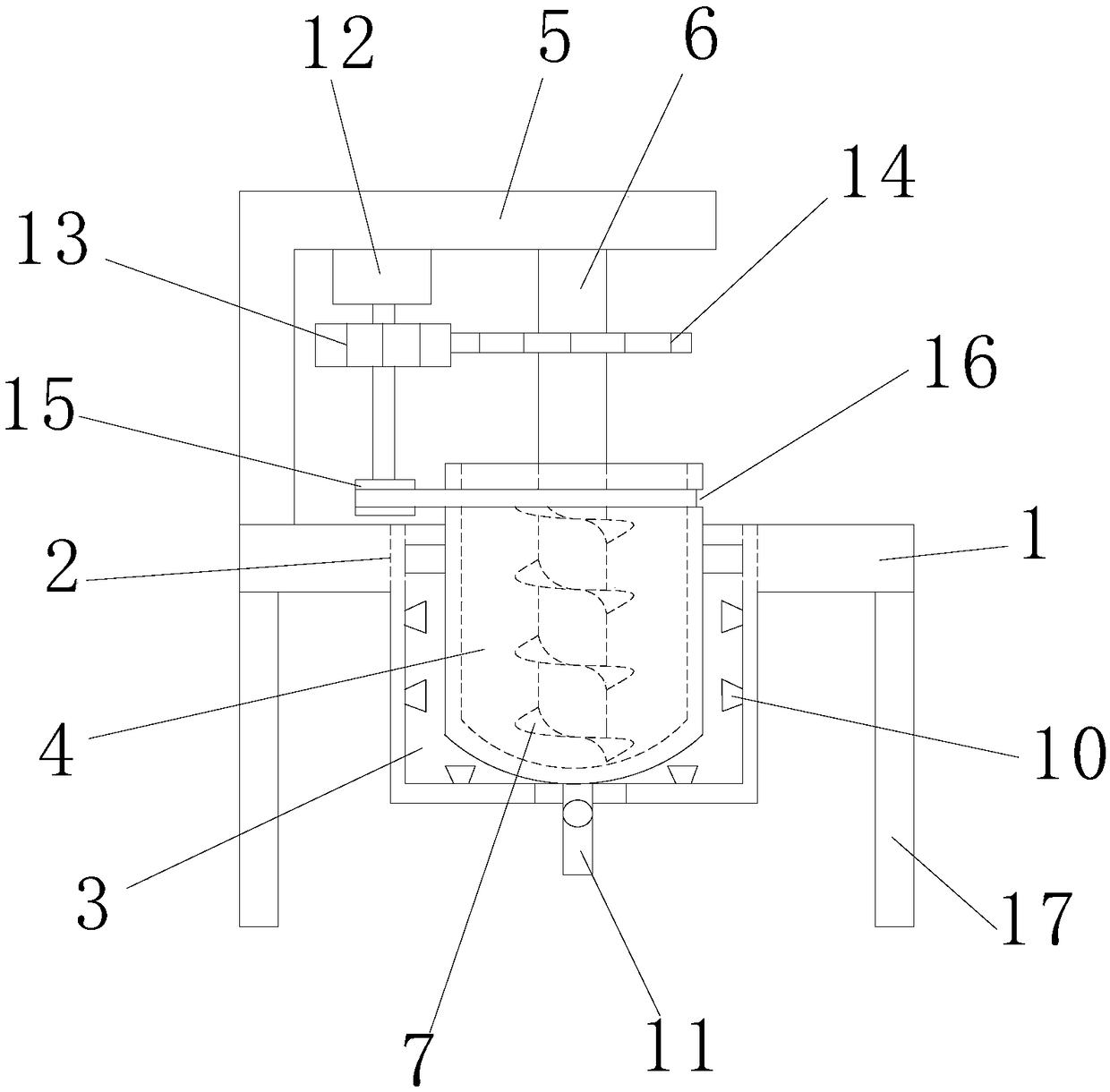

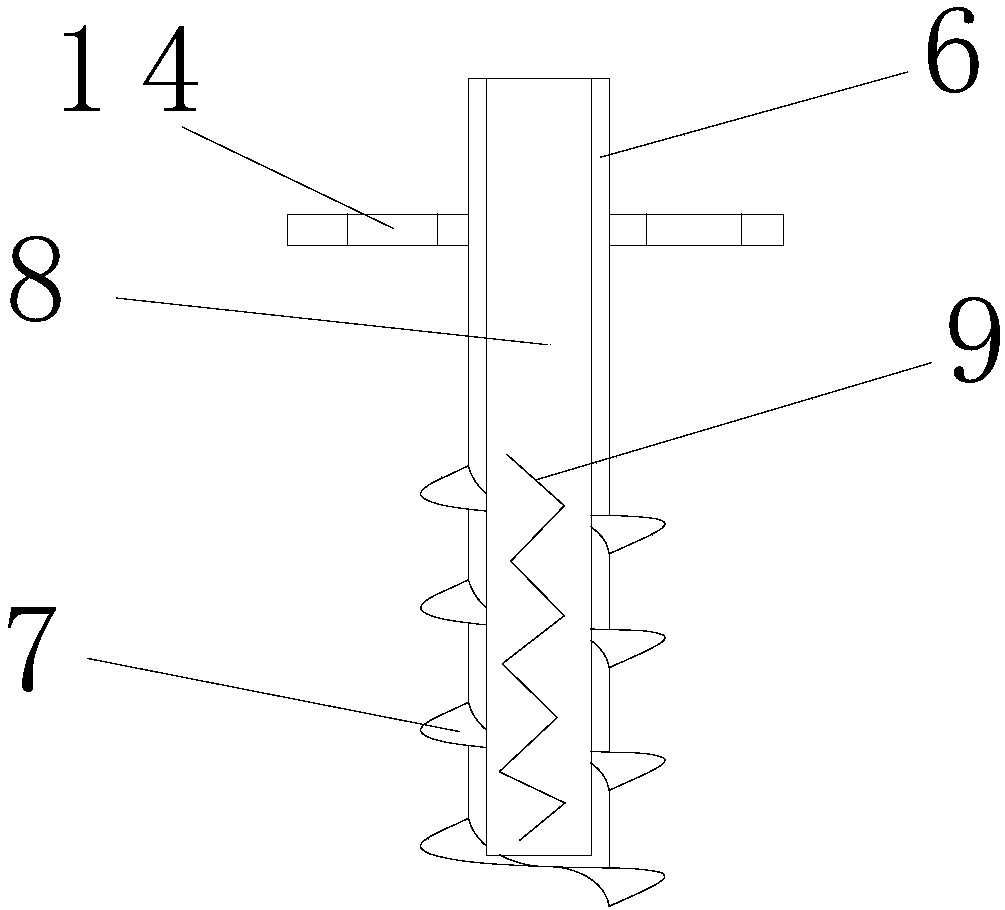

Single screw extruder

ActiveUS9156201B2Improve product qualityExtend your lifeRotary stirring mixersMixing/kneading with horizontally-mounted toolsEngineeringMechanical engineering

The invention relates to a single-screw extruder comprising a cylinder (1), which comprises a transition zone (14), and a homogenizing zone (12) that is connected to the transition zone (14), and a screw (2) which is rotatably supported in the cylinder (1) and which has at least two consecutive displacement parts (6, 8) in the homogenizing zone (12), the second displacement part of which in the conveying direction is designed as a shearing part. The aim of the invention is to provide a single-screw extruder which enables an improved melting effect along with an increased throughput, a lowered melt temperature, and an improved pressurization capability. According to the invention, it was recognized that this aim can be achieved in that at least one groove (4) running in the longitudinal direction in the inner cylinder wall is provided in the homogenization zone (12) of the single-screw extruder, and said groove ends in the area between a first displacement part and the subsequent shearing part (8) as viewed in the conveying direction.

Owner:KRAUSSMAFFEI EXTRUSION GMBH

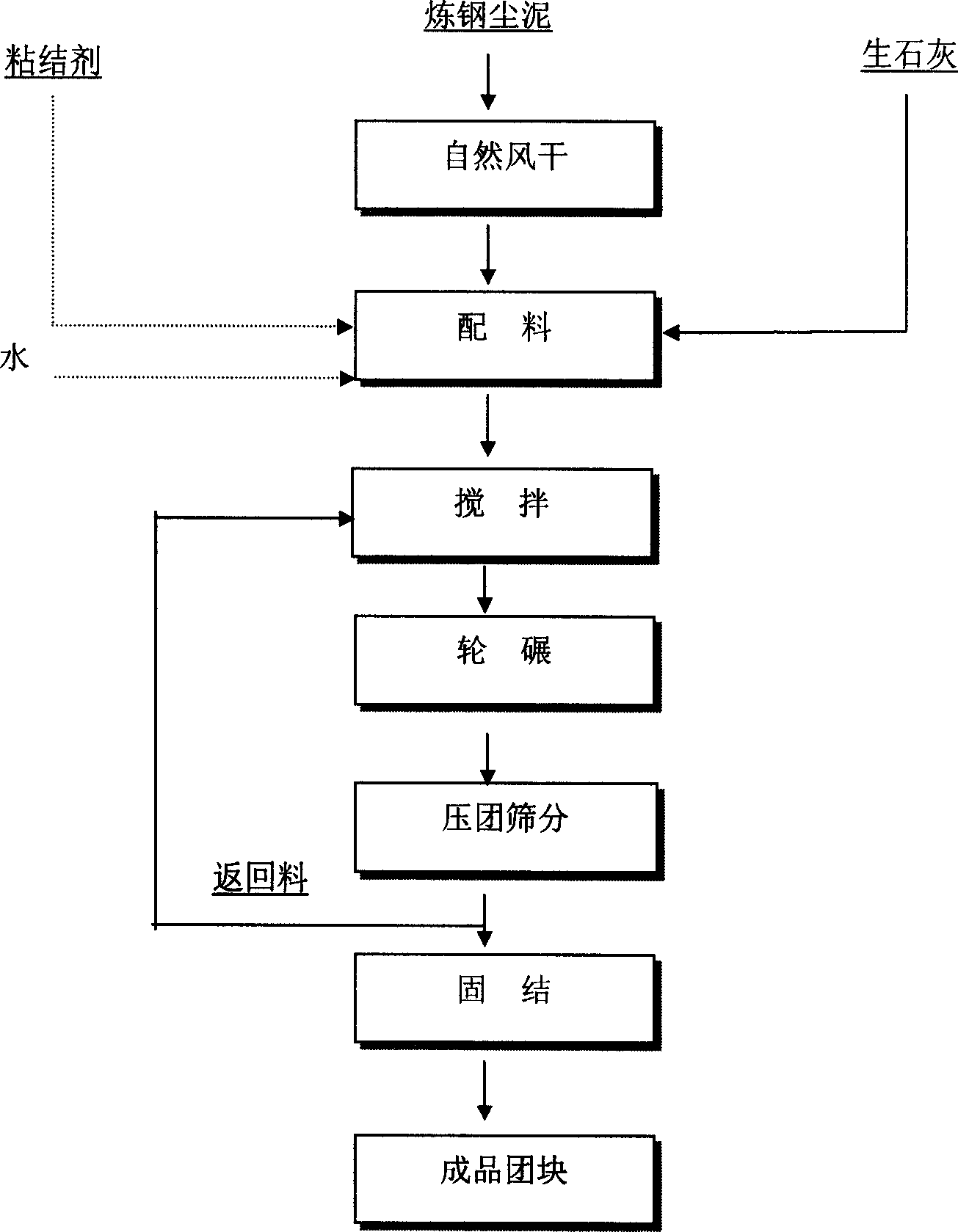

Process for preparing slag by pelletization of steel-making dust slime

InactiveCN1664120AHigh strengthIncreased degree of plastic deformationManufacturing convertersProcess efficiency improvementSteelmaking

The invention relates to a comprehensive utilization method of dust and mud in steelmaking process, which is specifically a spheroiditic slagging agent production process. The invention comprises the following steps: drying dust and mud in the open, adding 2-6% burnt lime and 0.5-1% adhensive to the mud to produce mixture, sending the mixture to agitator to intimate mixing, sending the mixture to roller to be pulverized fully, sending it to pelletizer to produce green-ball of phi20-phi30mm size by roll-type briquetting process in presure of 40-60KN, processing green-ball in jigging screen to get green-ball end product on sifter and sliver as return material under sifter and sending green-ball to tower furnace via charging system to be adglutinate and get end product.

Owner:张清学

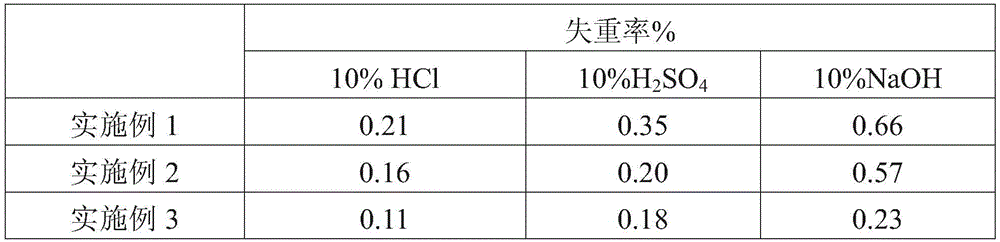

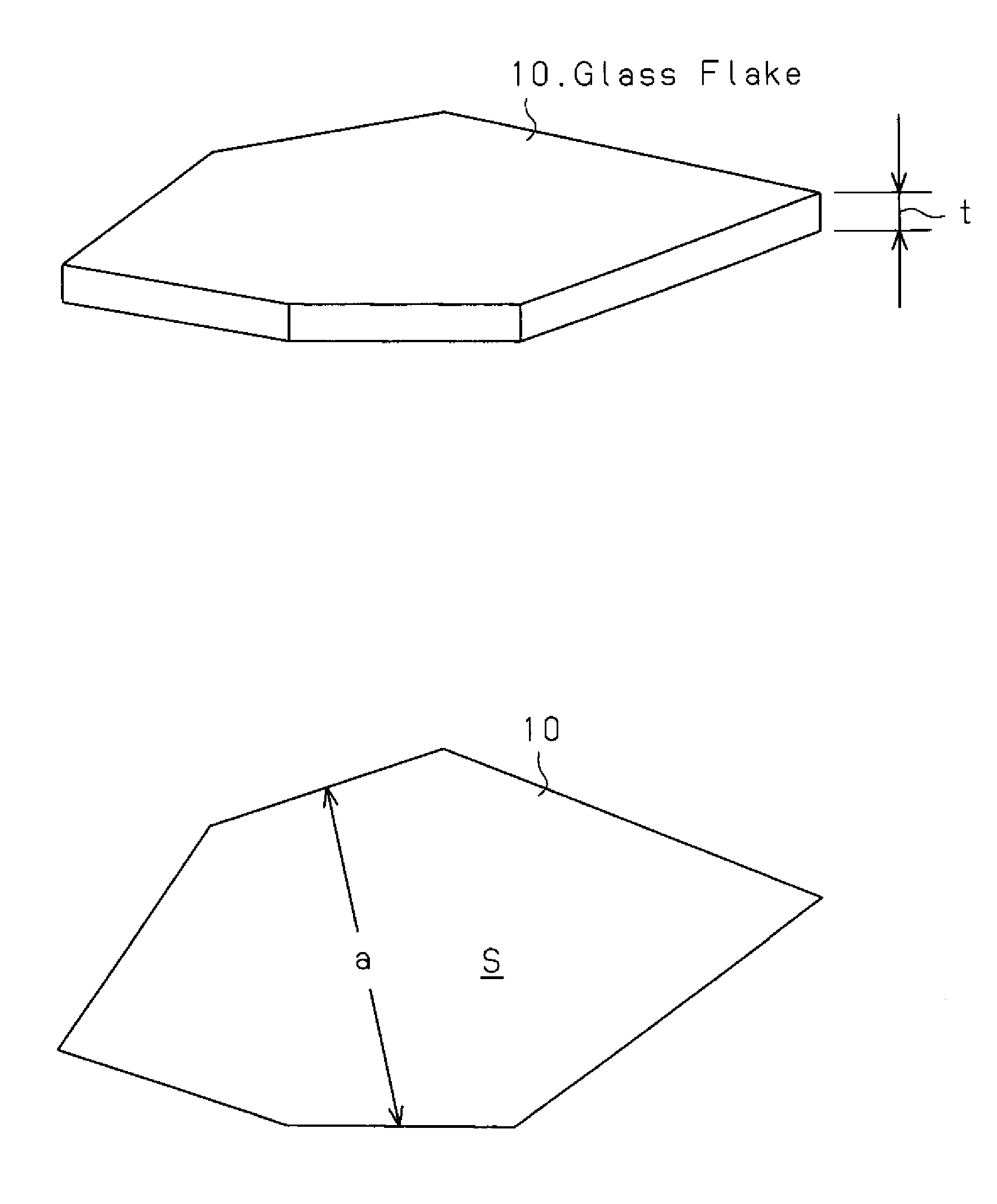

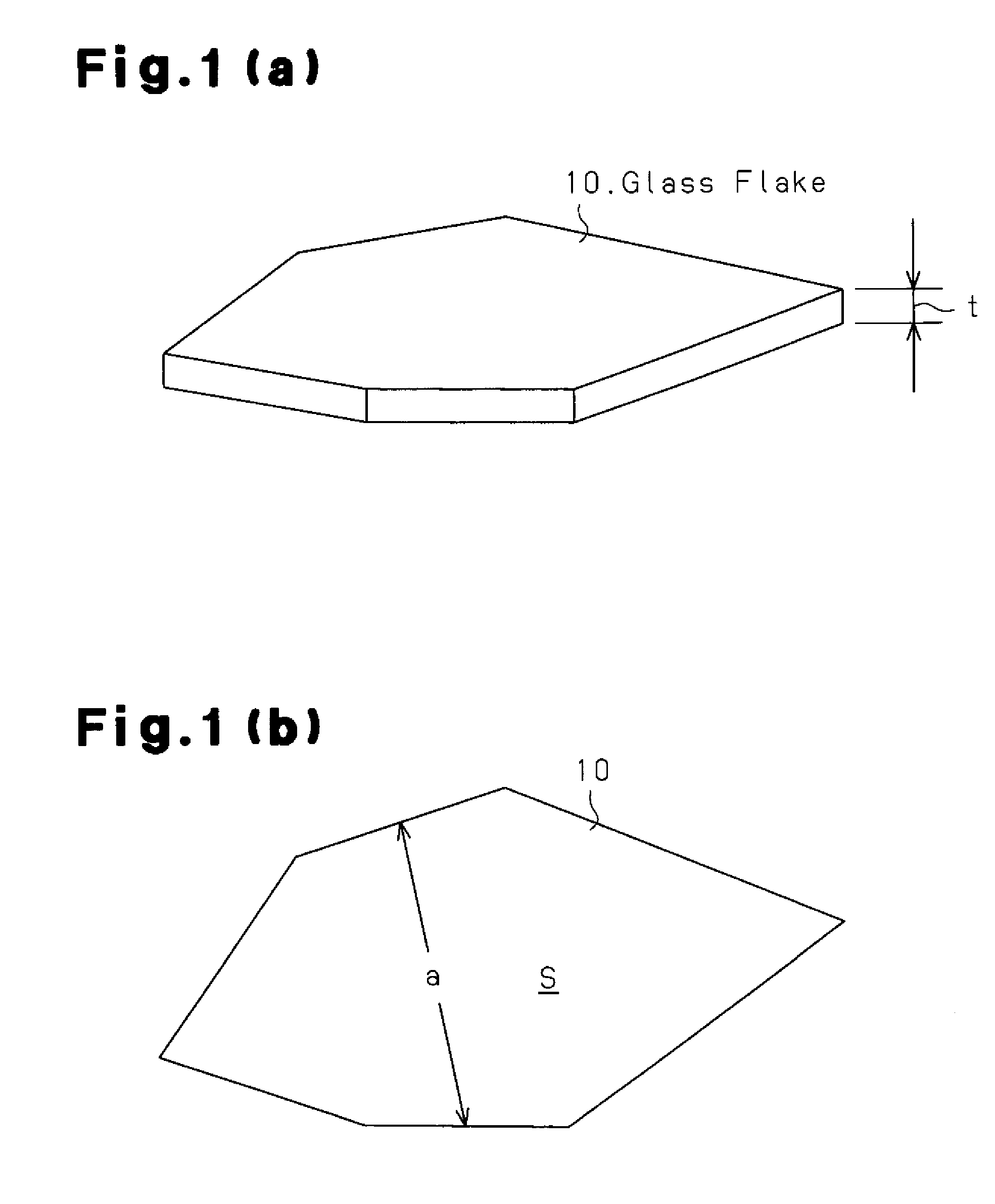

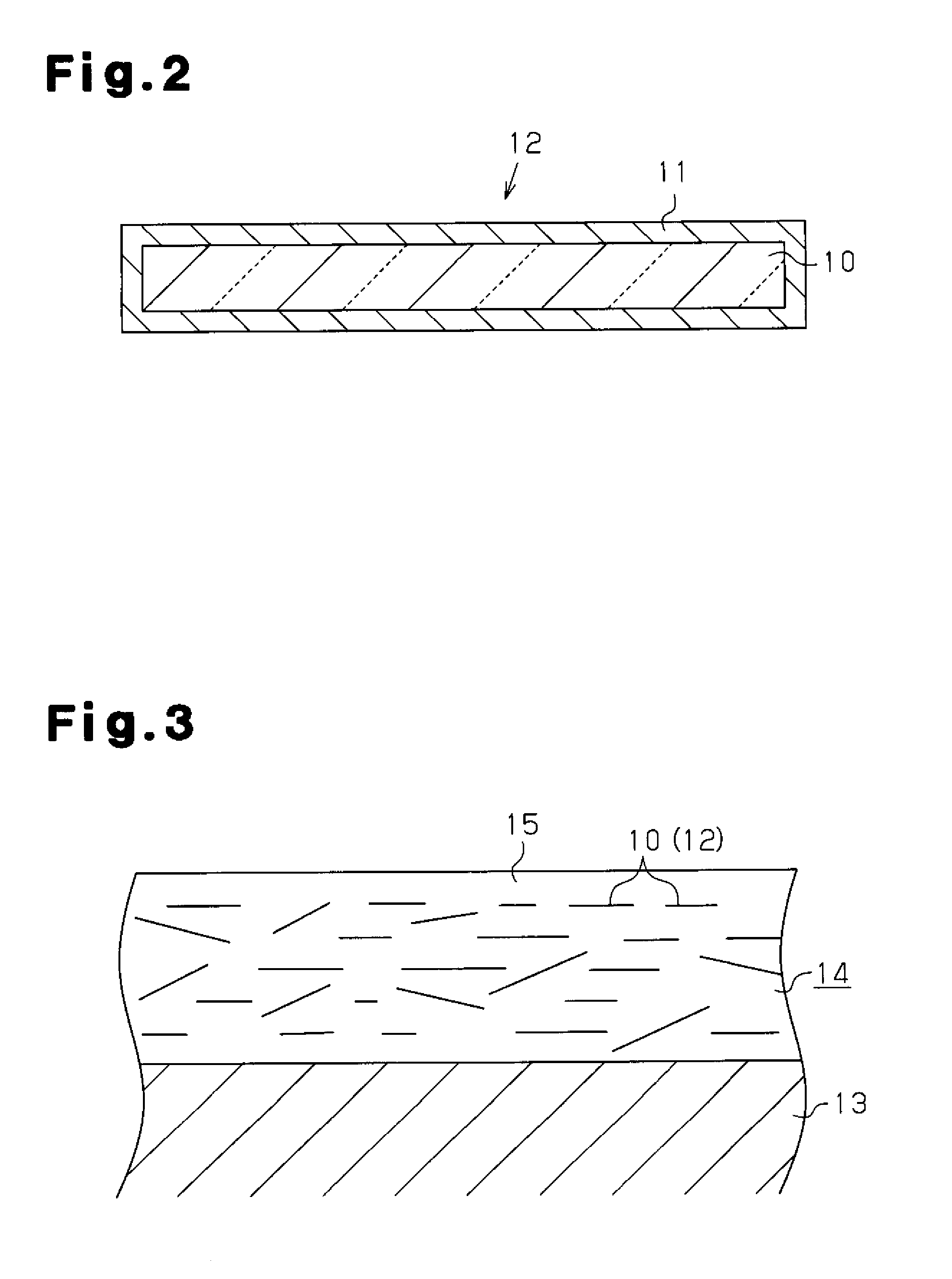

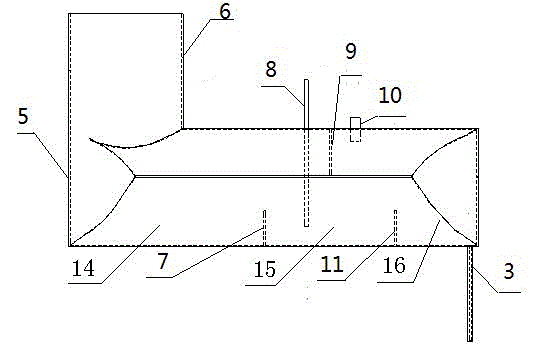

Glass flake and coated glass flake

ActiveUS20110151261A1Improve heat resistanceAcid resistance be increasePigmenting treatmentCosmetic preparationsWorking temperatureAcid resistance

A glass flake (10) having improved heat resistance and chemical resistance is formed from a glass base material satisfying, in mass %, 60≦SiO2≦75, 5<Al2O3≦15, 3≦CaO≦20, 6≦Na2O≦20 and 9≦(Li2O+Na2O+K2O)≦13. When 9≦(Li2O+Na2O+K2O)≦13 is satisfied in mass %, the CaO content and the Na2O content are preferably set within the ranges of 5≦CaO≦20 and 6≦Na2O≦13, respectively. When 13≦(Li2O+Na2P+K2O)≦20 is satisfied in mass %, the CaO content and the Na2O content are preferably set within the ranges of 3≦CaO≦15 and 9≦Na2O≦20, respectively. The working temperature of the glass base material is preferably 1180° C.-1300° C. The temperature difference ΔT obtained by taking the devitrification temperature of the glass base material from the working temperature of the glass base material is preferably 0° C.-200° C. The glass transition temperature of the glass base material is preferably 550° C.-700° C. The acid resistance index ΔW of the glass base material is preferably 0.05-1.5 mass %.

Owner:NIPPON SHEET GLASS CO LTD

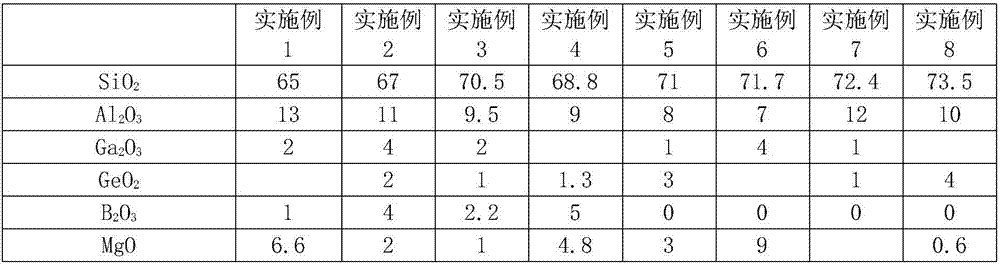

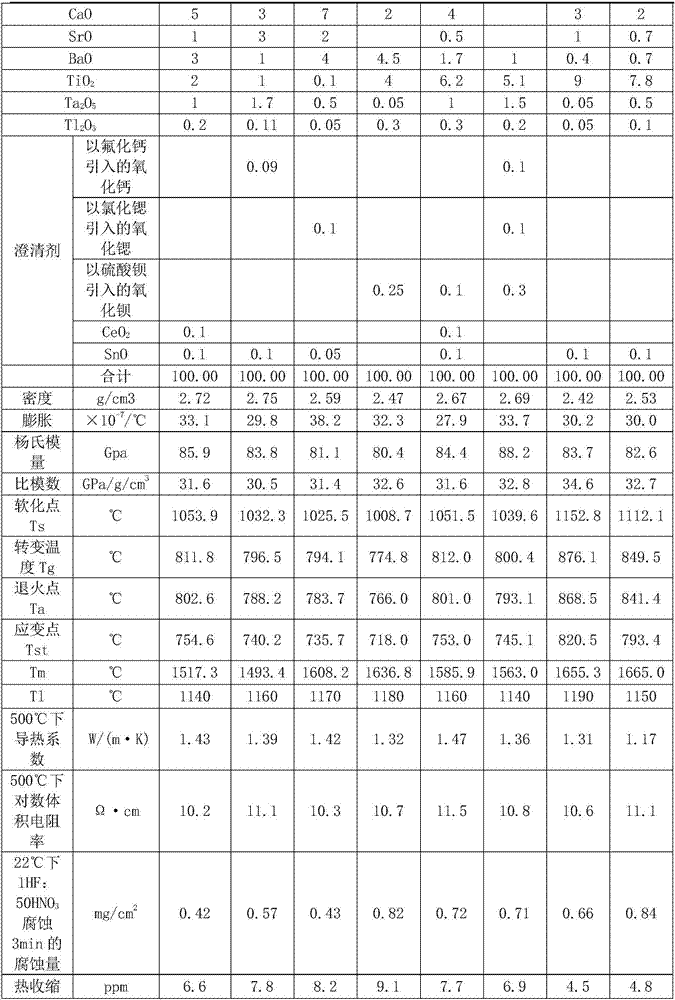

Alkali-free silicate glass and preparation method and application thereof

ActiveCN107382052AHelps to reduce weightHigh expansion coefficientGlass shaping apparatusGlass productionAlkali freeSilicate glass

The invention relates to the field of glass and particularly relates to alkali-free silicate glass and a preparation method and application thereof. The alkali-free silicate glass comprises, by mole, 65-75 mol% of SiO2, 11-17 mol% of Al2O3, Ga2O3 and GeO2, 0-8 mol% of B2O3, 0-15 mol% of MgO, 2-10 mol% of CaO, 0.5-14 mol% of SrO and BaO, 0-10 mol% of TiO2, 0.01-2 mol% of Ta2O5 and 0.01-0.5 mol% of Tl2O3. The alkali-free silicate glass has high thermal stability and dimensional stability, a high strain point, a high specific modulus, a low melting temperature, a low liquidus temperature and low density and is suitable for large-scale industrial production.

Owner:ZHENGZHOU UNIV

Glass tank for melting high-boron low-alkali or alkali-free glass

InactiveCN101880120AEasy to manageTimely managementTank furnacesGlass productionMelting tankAlkali free

The invention relates to a glass tank for melting high-boron low-alkali or alkali-free glass and manufacturing a TFT-LED glass substrate. The glass tank comprises a heating system matched with the glass tank and is characterized in that: the internal structure of the glass tank comprises a pre-melting tank with a feed inlet, a cross flame melting tank connected with the pre-melting tank, a cross flame clarification tank communicated with the cross flame melting tank through a lower passage of a flow-limiting diaphragm wall, and a cross flame work pool communicated with the cross flame clarification tank through a pipeline; and a forming passage for delivering molten glass is formed on the cross flame work pool. The glass tank reasonably utilizes energy; and the generated molten glass has the advantages of quick temperature rise, uniformity and high defoaming efficiency.

Owner:TUNGHSU GRP

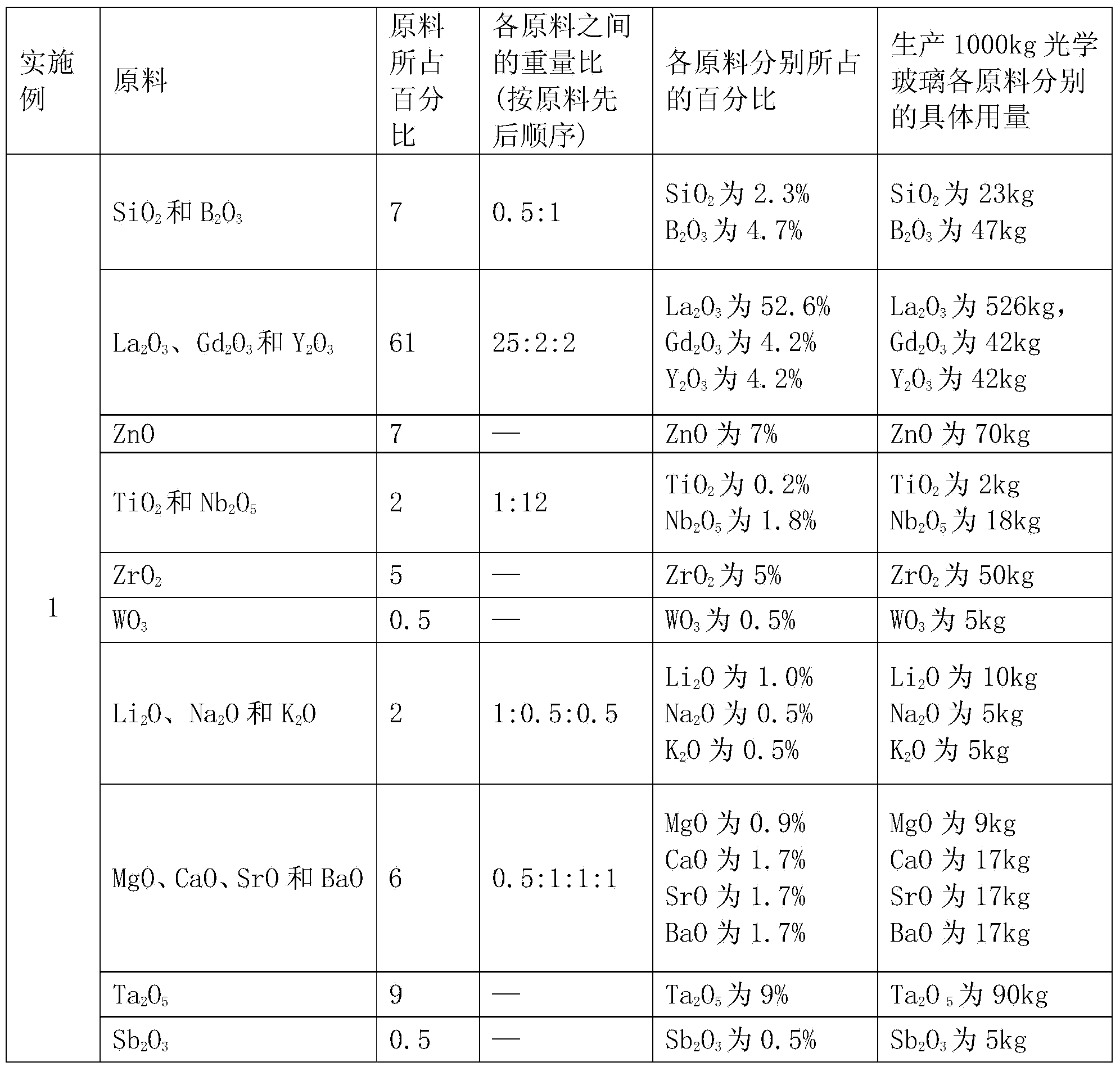

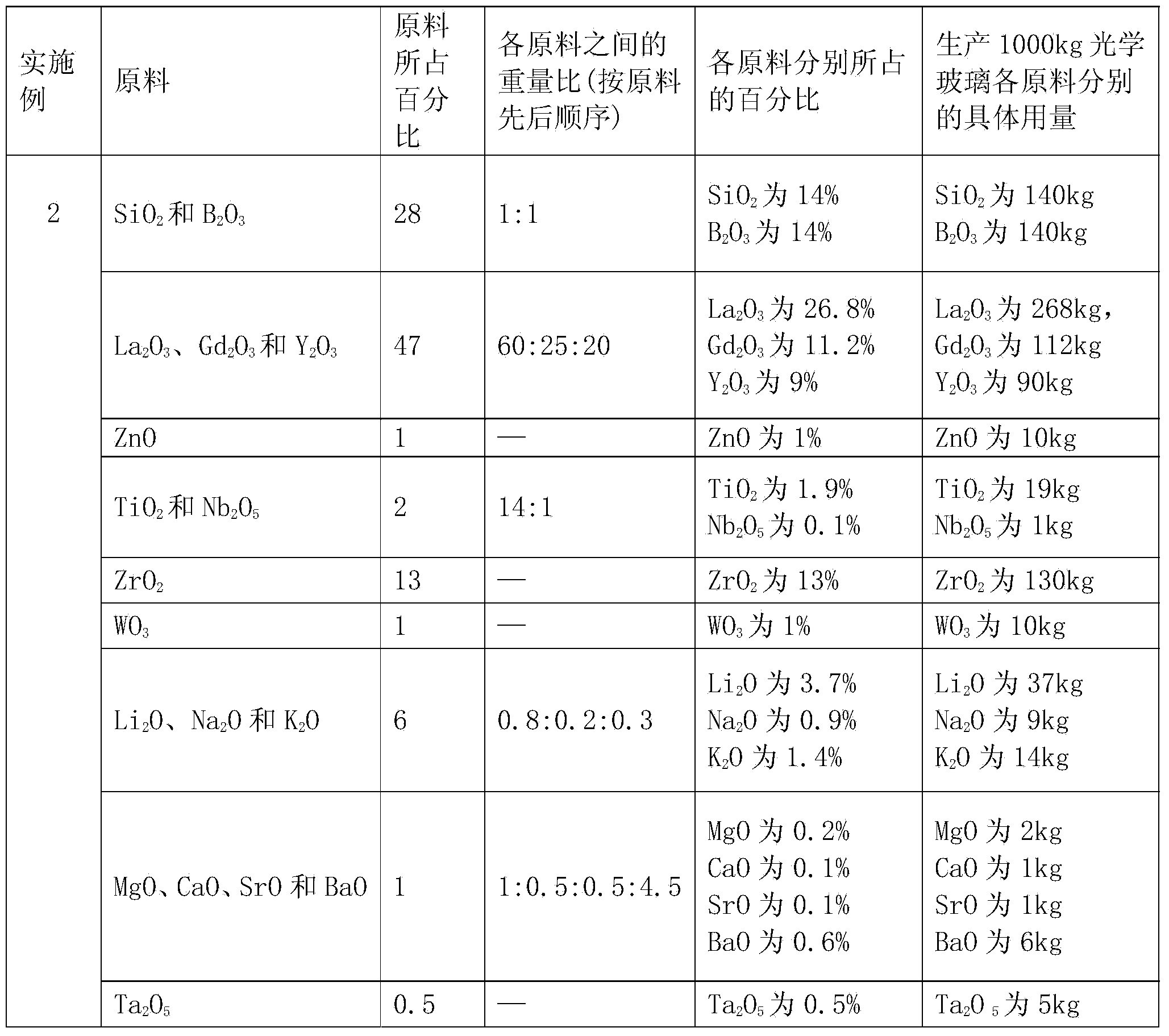

High-refractive-index and low-dispersion optical glass and preparation method thereof

The invention provides high-refractive-index and low-dispersion optical glass. The optical glass consists of the following raw materials in percentage by weight: 5-32 percent of SiO2 and B2O3, 45-65 percent of La2O3, Gd2O3 and Y2O3, 0.5-10 percent of ZnO, 1-20 percent of TiO2 and Nb2O5, 0-15 percent of ZrO2, 0-2 percent of WO3, 0-10 percent of Li2O, Na2O and K2O, 0-10 percent of MgO, CaO, SrO and BaO, 0-12 percent of Ta2O5 and 0-1 percent of Sb2O3. Compared with the prior art, the high-refractive-index and low-dispersion optical glass has the beneficial effects of higher internal color penetration degree, small specific weight, low smelting process temperature, smaller adding amounts of Ta2O5 and Gd2O3 and lowered cost.

Owner:SICHUAN RUITIAN OPTICAL

Anti-blue-light high-strength lithium-aluminum-silicon cover plate glass and preparation method and application thereof

PendingCN113121109AIncrease intrinsic strengthFacilitate ion exchangeGlass shaping apparatusGlass tempering apparatusPhysical chemistrySilicon

The invention relates to the technical field of cover plate glass, in particular to anti-blue-light high-strength lithium-aluminum-silicon cover plate glass which is prepared from the following raw materials in percentage by mass: 56%-70% of SiO2, 18%-23% of Al2O3, 2%-4% of Li2O, 6%-15% of Na2O, 1%-10% of MgO, 0.5%-6% of ZnO, 1%-5% of ZrO2, 0.05%-3% of CdS, 0.05%-2% of CdSe, 0.6%-1.5% of SnO2, 0-8% of K2O, 0-5% of B2O3 and 0.01%-1% of a reducing agent. The invention further discloses a preparation method of the anti-blue-light high-strength lithium-aluminum-silicon glass, the anti-blue-light high-strength lithium-aluminum-silicon glass is prepared through mixing, founding, annealing, secondary developing treatment and then composite chemical strengthening, and the anti-blue-light high-strength lithium-aluminum-silicon glass has an anti-blue-light effect, is suitable for being used as a screen protection material of electronic equipment such as a mobile phone and can effectively prevent the surface of a panel display product from being impacted or scratched and damaged.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

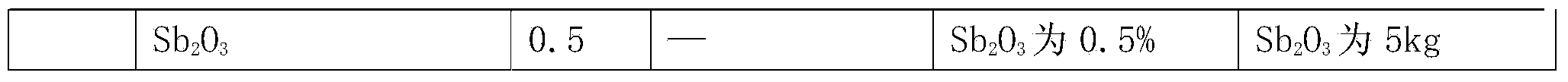

Non-ferrous metal isothermal smelting furnace

InactiveCN112304090ATake advantage ofReduce wasteFurnace safety devicesStirring devicesActivated carbonCircular disc

The invention discloses a non-ferrous metal isothermal smelting furnace. The isothermal smelting furnace comprises a base, wherein a furnace body is arranged on the upper surface of one side of the base, a purification mechanism is fixedly connected to the upper surface of one side of the furnace body, a waste heat utilization mechanism is arranged on the upper surface of the other side of the base, a stirring mechanism is embedded in the middle of the upper surface of the furnace body, and a door handle is fixedly connected to a door of the furnace body. The invention relates to the technicalfield of smelting furnaces. According to the non-ferrous metal isothermal smelting furnace, by arranging the purification mechanism, when non-ferrous metal is machined, a filter screen and an activated carbon adsorption net in a purification box can play a role in purifying smoke, in the purification process, a rotating motor is powered on to drive discs on a second rotating shaft to rotate, circular racks on the discs can drive gear discs to rotate, then under the elasticity of springs, adjusting rods on the gear discs can enable the filter screen and the activated carbon adsorption net to shake off continuously so as to shake off the dust adhering to the surface of the filter screen and the surface of the activated carbon adsorption net.

Owner:叶宗欢

Submount and method for manufacturing same

InactiveCN101656236AImprove wettabilityImprove performanceSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceSurface roughness

A submount with an electrode layer having excellent wettability in soldering and method of manufacturing the same are disclosed. A submount (1) for having a semiconductor device mounted thereon comprises a submount substrate (2), a substrate protective layer (3) formed on a surface of the submount substrate (2), an electrode layer (4) formed on the substrate protective layer (3) and a solder layer(5) formed on the electrode layer (3) wherein the electrode layer (4) is made having an average surface roughness of less than 1 [mu]m. The reduced average surface roughness of the electrode layer (4) improves wettability of the solder layer (5), allowing the solder layer (5) and a semiconductor device to be firmly bonded together without any flux therebetween. A submount (1) is thus obtained which with the semiconductor device mounted thereon is reduced in heat resistance, reducing its temperature rise and improving its performance and service life.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

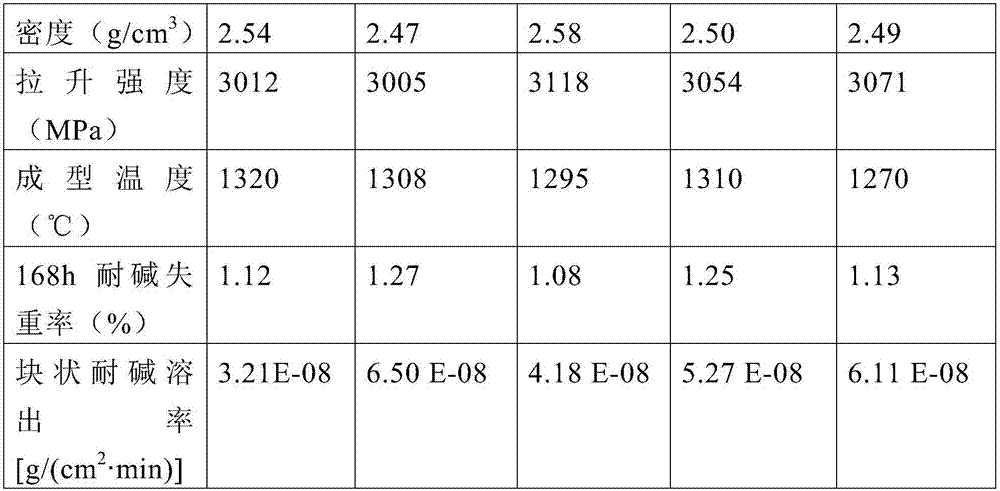

An alkali-resistant heat-resistant glass fiber and a preparing method thereof

An alkali-resistant heat-resistant glass fiber is provided. The glass fiber is characterized by comprising, by mass, 48-65 parts of SiO2, 22-30 parts of Al2O3, 23-35 parts of CaO, 3.5-6 parts of CaF2, 2.5-6.8 parts of CaWO4, 0.5-3.5 parts of TiO2, 0.2-1.7 parts of MgO, and 1-5.5 parts of FeCr2O4. The glass fiber has a flat and smooth appearance, even color and high mechanical strength. A preparing process is simple. The glass fiber prepared by a corporation has good alkali resistance, and can be widely applied in the fields of precision meter thermal protection member manufacturing, ablative material manufacturing, heat insulation material manufacturing, and the like.

Owner:太仓市格雷得五金有限公司

Sodium calcium silicon series fire-proofing glass

ActiveCN1792919AImprove melting abilitySmall coefficient of thermal expansionChemical stabilitySilicon

A fire-proof Na-Si-Ca glass based on float glass contains SiO2 (67-75 Wt%), Al2O3 (1.5-4), CaO (5-10), MgO (0.5-3), R2O (3-13), ZrO2 (0.2-2.5), BaO (2-6) and SrO (1-6). Its advantages are low thermal expansibility and high softening point, fire-proofing performance and chemical stability.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

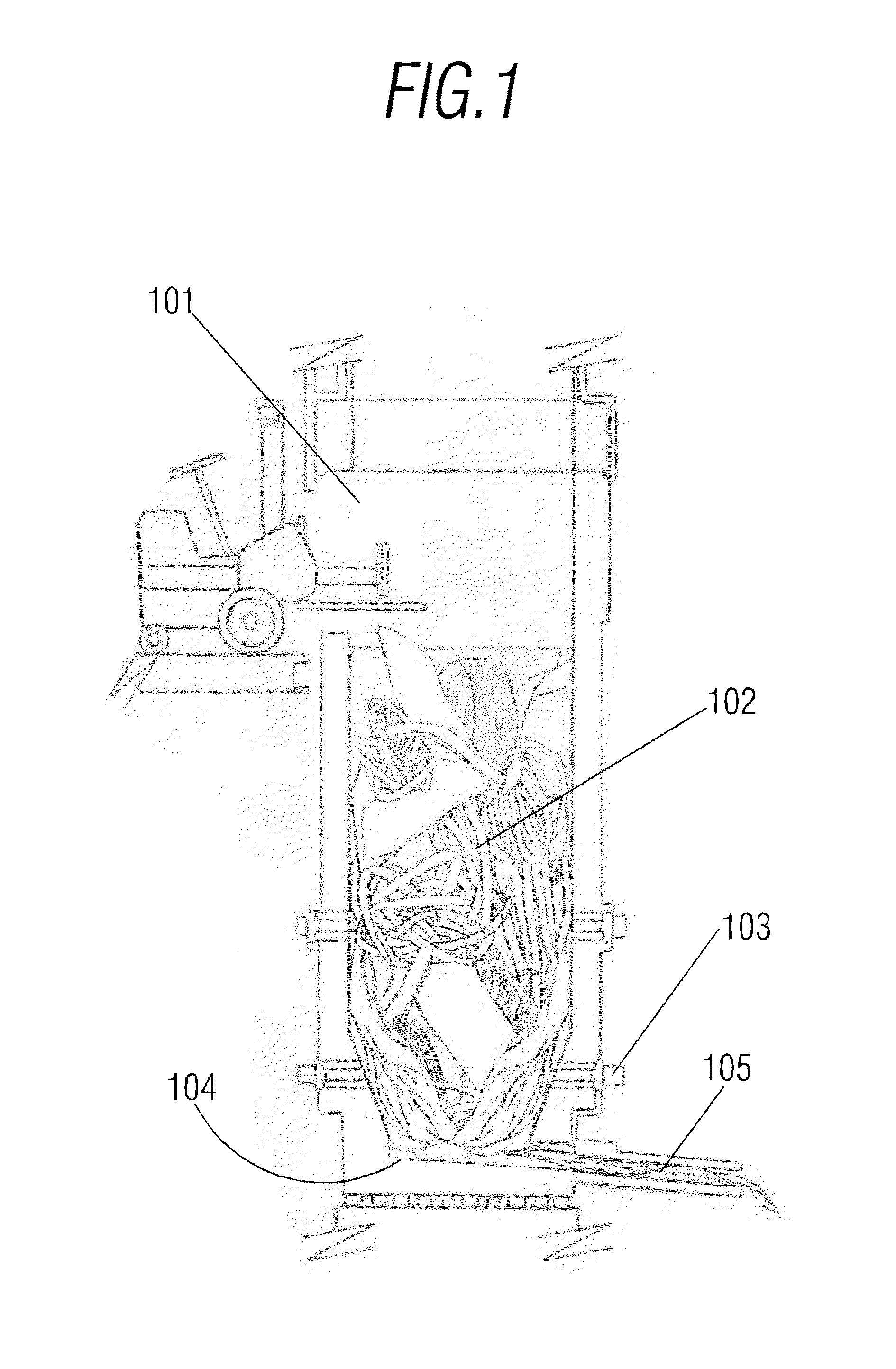

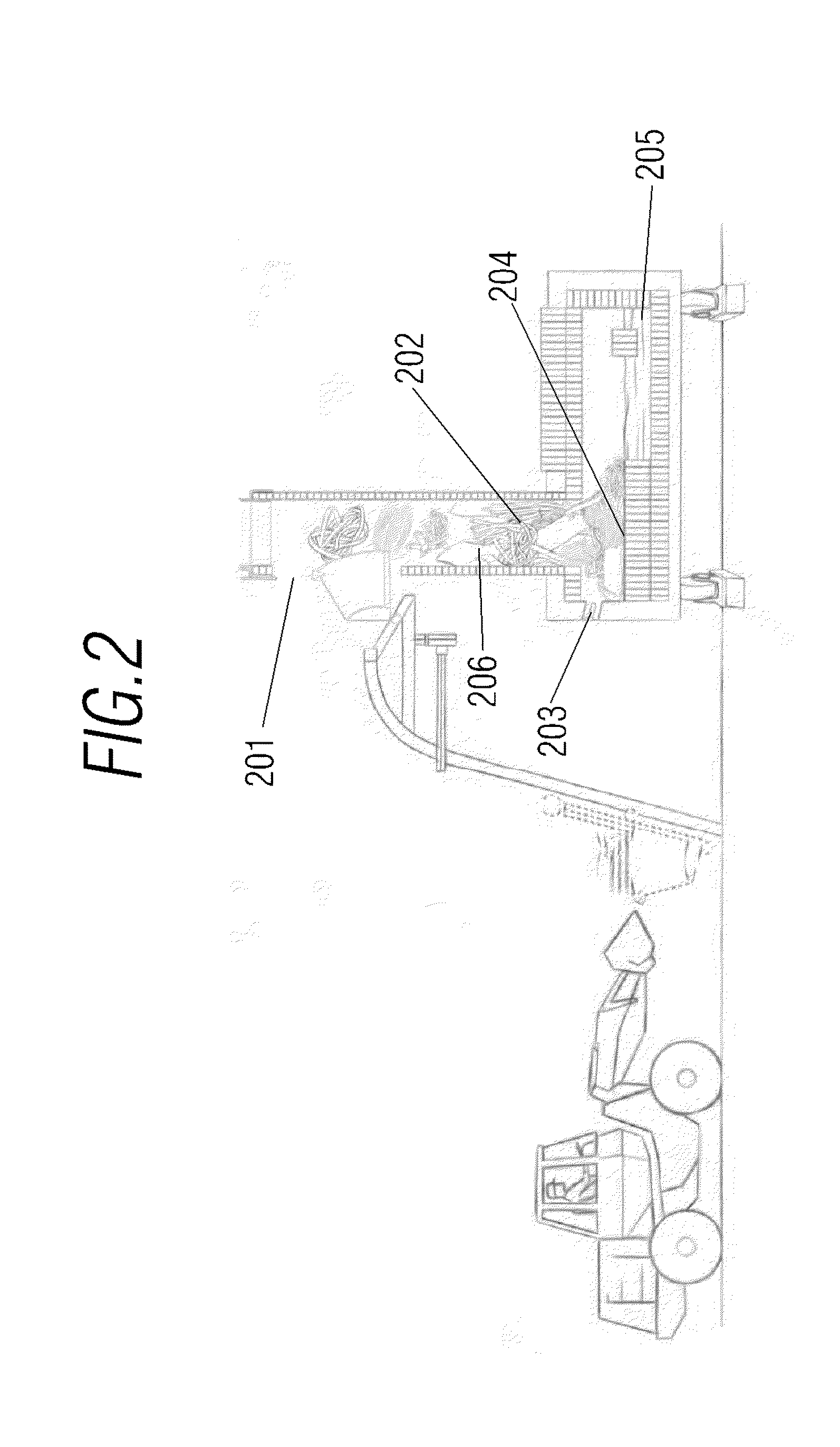

System and Method for Charging a Furnace for Melting and Refining Copper Scrap, and Furnace Thereof

InactiveUS20150159954A1Improve energy efficiencyReduce presenceCharge manipulationCrucible furnacesCopperMaterials science

System and method for charging a furnace for melting and refining copper scrap, comprising at least one shredder intended to receive copper scrap to be refined, associated with screening means linked to at least one vibrating feeder table through continuous conveyance means, such that said vibrating feeder table allows shredded copper scrap to be put into the furnace. A furnace is also described which is suitable for receiving a volume of copper scrap from the above charging system and method, characterized by a flat vault with a horizontal charging door, whose opening width for receiving the charge of shredded scrap is less than 0.6 m. The system, method and furnace described make it possible to optimize the process of melting and refining copper scrap, as well as reduce the consumption of energy and the emission of polluting gases.

Owner:LA FARGA LACAMBRA

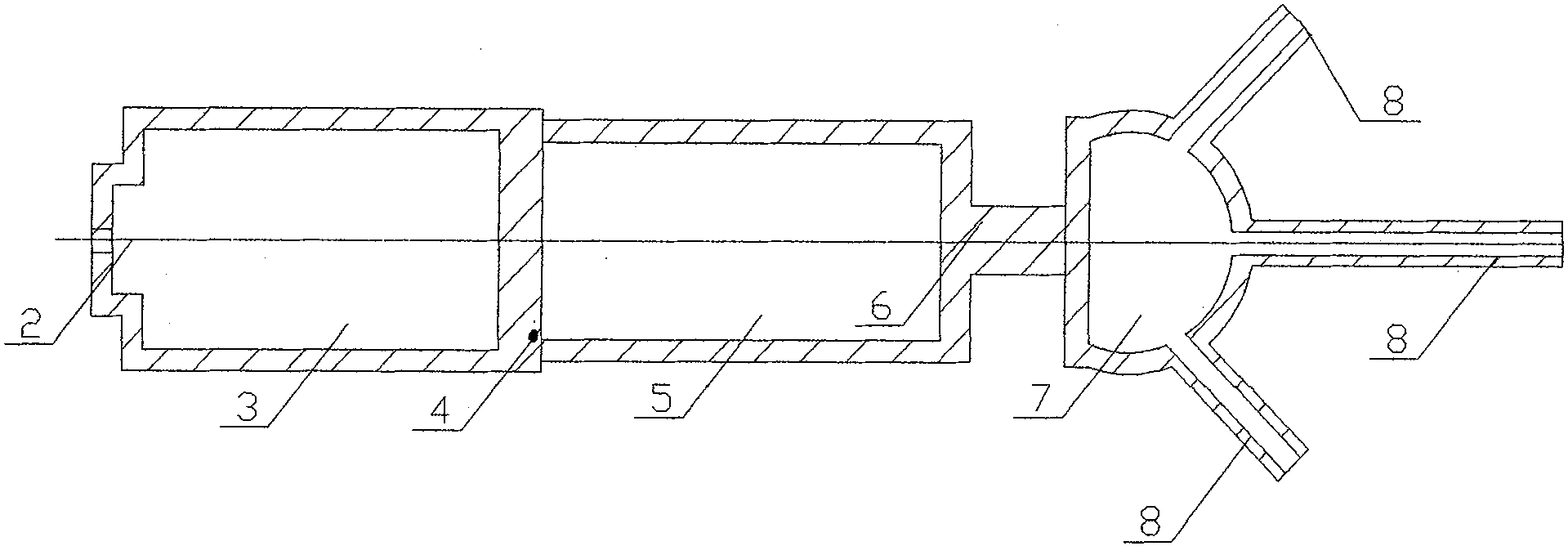

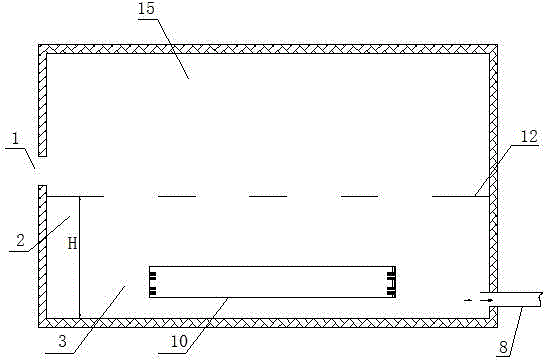

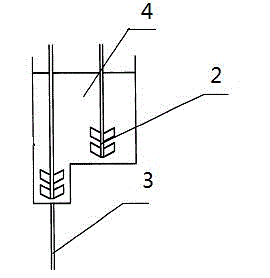

Efficient optical glass melting tank

ActiveCN105152520AImprove efficiencyRefined management and control of production capacityGlass furnace apparatusGlass productionMelting tankOptical glass

The invention relates to an efficient optical glass melting tank, belongs to the technical field of optical glass melting, and mainly solves the problem of low work efficiency of a conventional melting tank. The efficient optical glass melting tank is mainly characterized by comprising a melting tank; a batch feeding opening and a melting tank communicating pipe respectively arranged at the two ends of the melting tank; a melting electrode arranged in the melting tank; a fuel gas burning gun heating system arranged above the melting tank; a partition of which the lower end is passage port-shaped is arranged in the melting tank, and used for diving the melting tank into a melting area and a feeding area; the melting electrode is a melting area melting acceleration electrode, and positioned in the melting area; a furnace ridge, a feeding area melting acceleration electrode and a feeding area bubbler are sequentially between the partition and the melting tank communicating pipe to form a passage to allow glass metal below the partition to flow above the furnace ridge and then flow to the melting tank communicating pipe. The discharging amount of the optical glass melting tank can be improved by 0.4-0.8 time on the premise that a melting area and the energy consumption are the same as those in the prior art, and the optical glass melting tank is mainly used for a furnace for continuous smelting production of high-quality optical glass.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

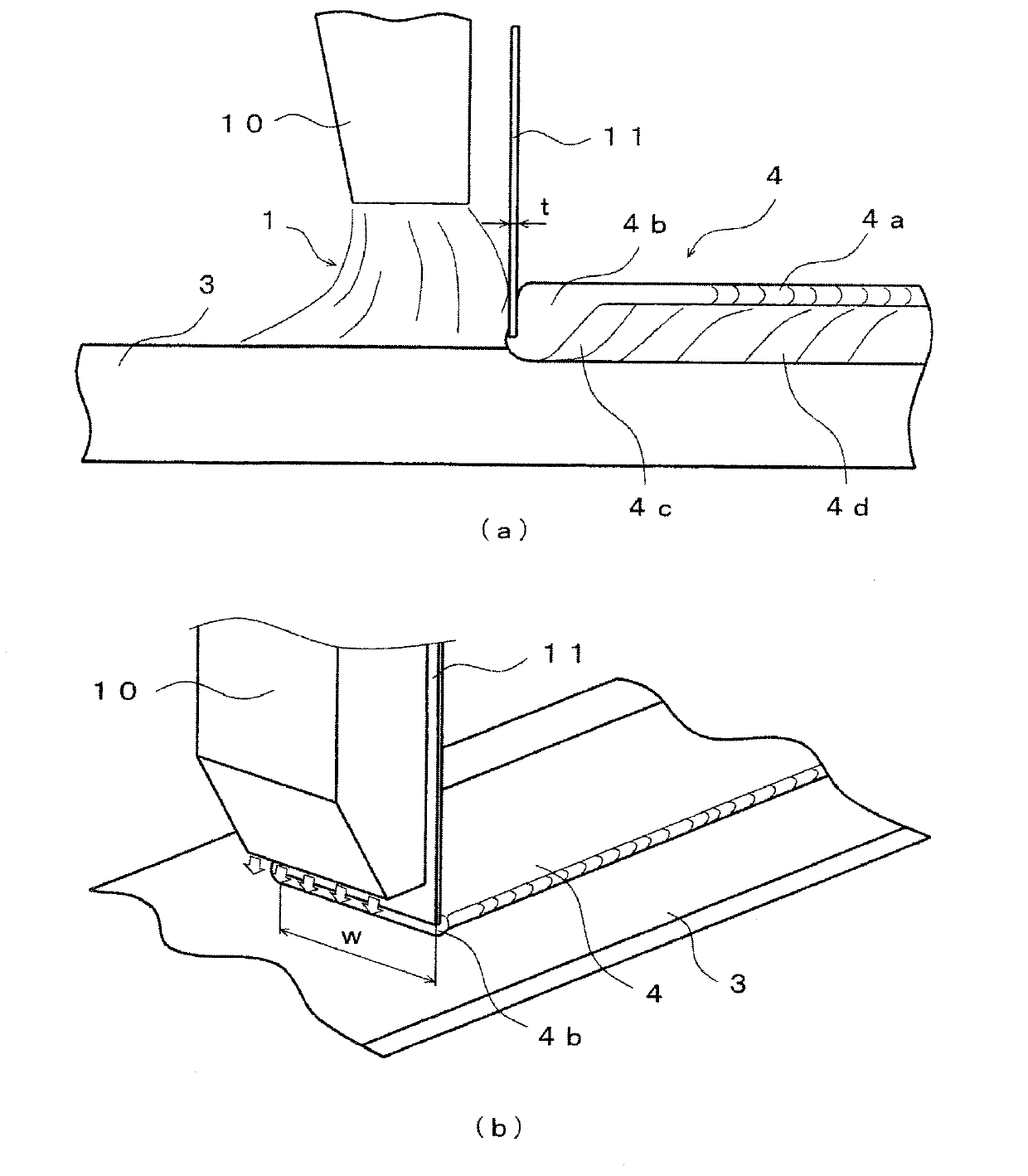

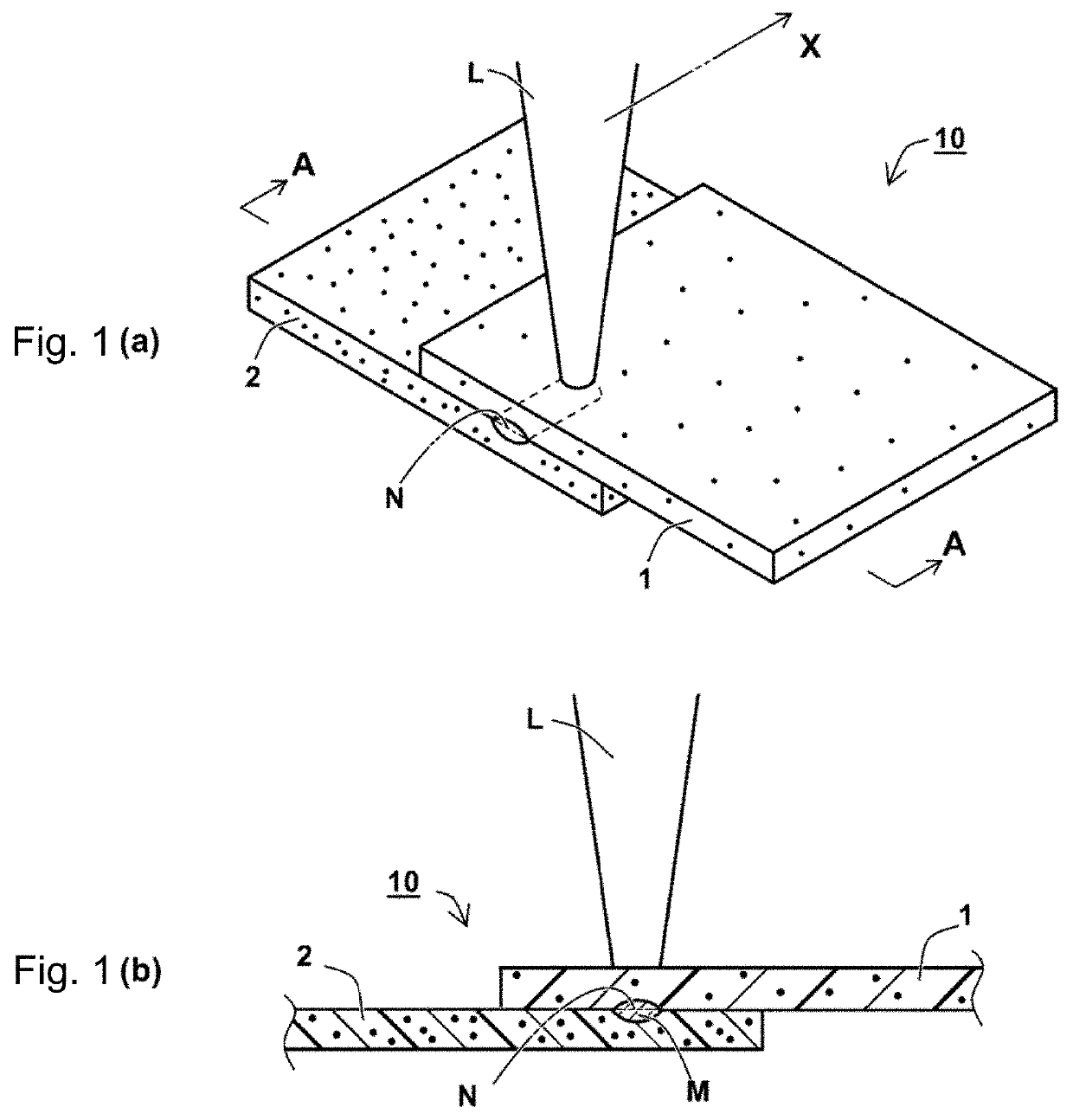

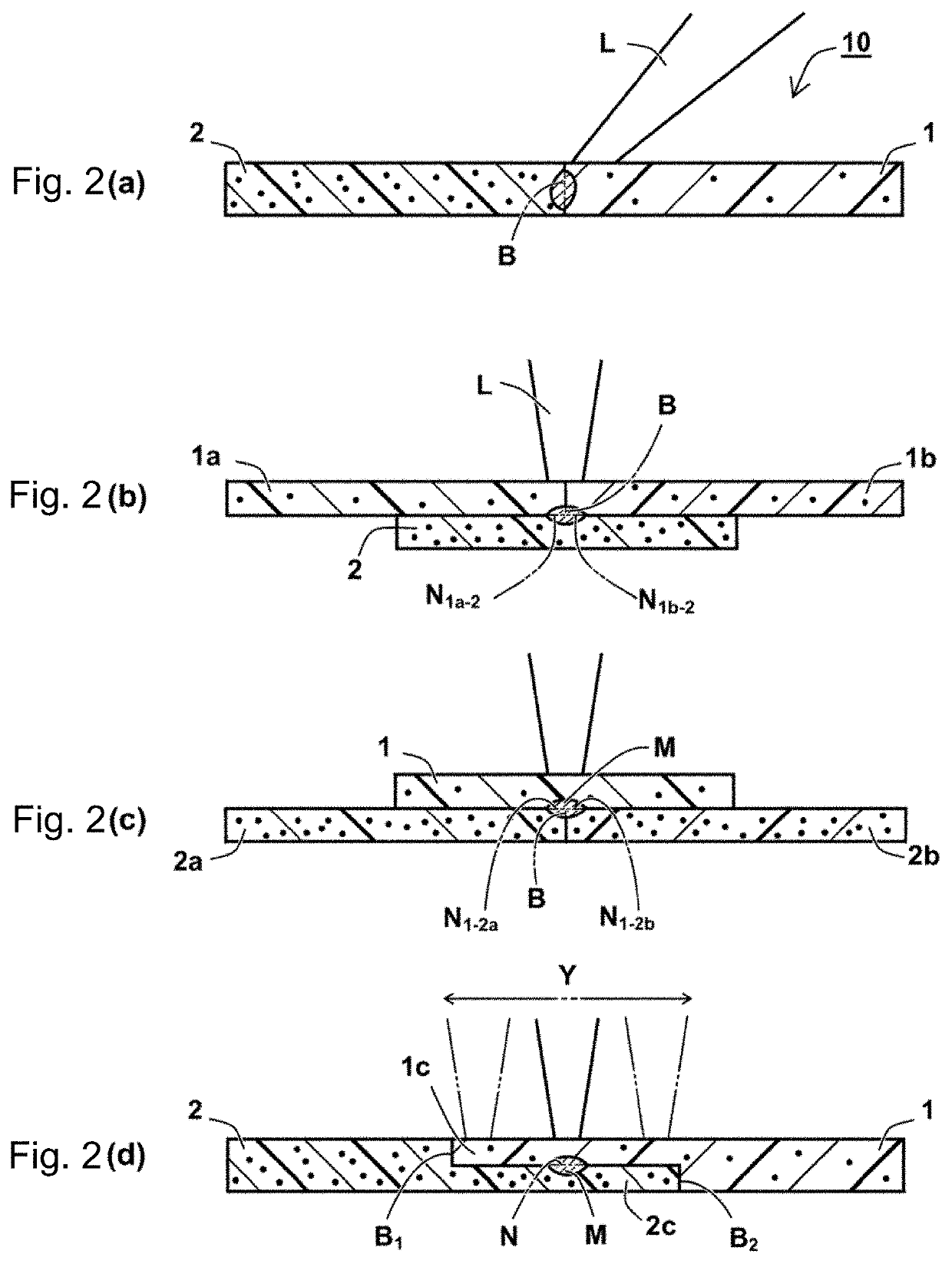

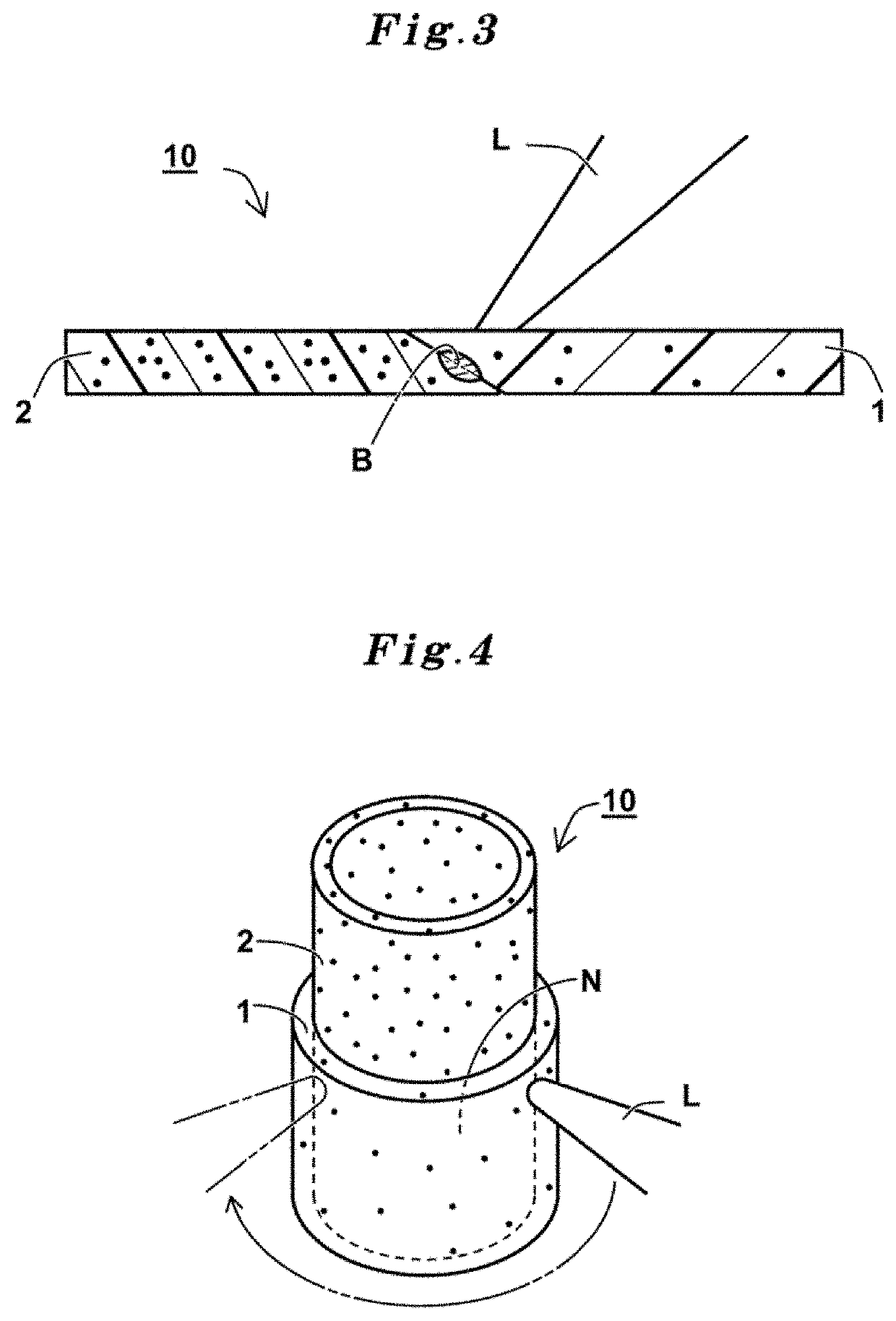

Laser welded body and method for manufacturing same

ActiveUS20190351623A1High strengthDecrease in crystallization temperatureSynthetic resin layered productsMedical devicesSulfateLaser scanning

Provided is a laser welded body which can be manufactured without undergoing complicated steps and maintain the characteristics of a resin contained in a resin member, which exhibits high welding strength even when scanned with a laser beam at a high speed, and which can be manufactured at high production efficiency.The laser welded body 10 comprises a first resin member 1 which is a laser-irradiated subject which contains a thermoplastic resin and nigrosine sulfate and has an absorbance a1 of 0.09 to 0.9; and a second resin member 2 which contains a thermoplastic resin as the same kind as or different kind from the thermoplastic resin and a laser beam absorbent, and has an absorbance a2 of 3.0 to 15, wherein the first resin member 1 and the second resin member 2 are laser-welded at a part at which the both resin members are overlapped and / or butted.

Owner:ORIENT CHEM INDS

Platinum device for optical glass feed preparation

ActiveCN103145317AIncrease or decrease diameterImprove melting efficiencyGlass furnace apparatusGlass productionPlatinumOptical property

The invention relates to a platinum device for optical glass feed preparation and belongs to the technical field of a feed preparation furnace for continuous smelting in a tank furnace. The platinum device mainly solves the problems that a conventional single crucible generates optical property fluctuation, influences uniformity and has limited smelting capacity. The platinum device is mainly characterized in that the crucible is a boot-shaped crucible; a left division plate and a right division plate are arranged at the inner bottom of the crucible at intervals and are used for dividing the inner bottom of the crucible into a material melting chamber, a homogenization chamber and a discharging chamber which are communicated; a discharging pipe is arranged at the bottom of the discharging chamber; a feeding pipe is arranged on the upper port of the material melting chamber of the crucible, and the port of the feeding pipe is higher than the upper flat surface of the crucible; and a breather pipe, a middle division plate and an air-bleed hole are arranged on the crucible above the homogenization chamber. The platinum device has the characteristics that the continuous smelting process can be realized, the glass smelting capacity and efficiency under the same volume can be effectively improved, the product is uniform, and the yield is high; and the platinum device is used for a continuous platinum smelting device for optical glass feed preparation.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Glass flake and coated glass flake

ActiveUS9237994B2Insufficient heat resistanceReduced durabilityPigmenting treatmentCosmetic preparationsVitrificationDevitrification

A glass flake (10) having improved heat resistance and chemical resistance is formed from a glass base material satisfying, in mass %, 60≦SiO2≦75, 5<Al2O3≦15, 3≦CaO≦20, 6≦Na2O≦20 and 9≦(Li2O+Na2O+K2O)≦13. When 9≦(Li2O+Na2O+K2O)≦13 is satisfied in mass %, the CaO content and the Na2O content are preferably set within the ranges of 5≦CaO≦20 and 6≦Na2O≦13, respectively. When 13≦(Li2O+Na2O+K2O)≦20 is satisfied in mass %, the CaO content and the Na2O content are preferably set within the ranges of 3≦CaO≦15 and 9≦Na2O≦20, respectively. The working temperature of the glass base material is preferably 1180° C.-1300° C. The temperature difference AT obtained by taking the devitrification temperature of the glass base material from the working temperature of the glass base material is preferably 0° C.-200° C. The glass transition temperature of the glass base material is preferably 550° C.-700° C. The acid resistance index ΔW of the glass base material is preferably 0.05-1.5 mass %.

Owner:NIPPON SHEET GLASS CO LTD

Plastic material melting equipment

The invention discloses plastic material melting equipment. The plastic material melting equipment comprises a worktable, a mounting port, a heating box, a material box, a frame, a stirring shaft, stirring blades, a mounting groove, an electric heating wire, a fire spraying gun, a discharge pipe, a motor, a driving gear, a driven gear, a belt wheel, a belt groove and support legs; the mounting port is formed in the worktable; the heating box is fixedly arranged in the mounting port; the material box is rotationally arranged in the heating box through a bearing; the frame is fixedly arranged atthe upper art of the worktable; the stirring shaft is vertically arranged in the material box; the upper end of the stirring shaft is rotationally connected with the frame through a bearing; the stirring blades are integrally arranged at the external of the part, positioned in the material box, of the stirring shaft; the mounting groove is axially formed in the top of the stirring shaft; and theelectric heating wire is arranged in the mounting groove. Compared with the prior art, the plastic material melting equipment can efficiently and quickly melt plastic materials, improves the melting efficiency and effect, and achieves more convenience for plastic processing.

Owner:浙江省新昌县华佳国财塑胶有限公司

High-strength thick glass substrate and preparation method thereof

InactiveCN107721155AImprove flexural strengthReduce melting effectGlass shaping apparatusOptical propertyHigh intensity

The invention discloses a high-strength thick glass substrate which comprises the following raw materials in percentage by weight: 56-63 percent of SiO2, 6-8 percent of Al2O3, 2-6 percent of B2O3, 8-9percent of CaO, 3-5 percent of MgO, 13-15 percent of Na2O, 1-3 percent of K2O, 0-1 percent of Sb2O3 and 0.1-1 percent of a clarifying agent. The invention further discloses a preparation method of the high-strength thick glass substrate. The high-strength thick glass substrate prepared by the preparation method disclosed by the invention is high in mechanical and optical properties, good in melting effect and low in processing difficulty.

Owner:株洲醴陵旗滨玻璃有限公司 +1

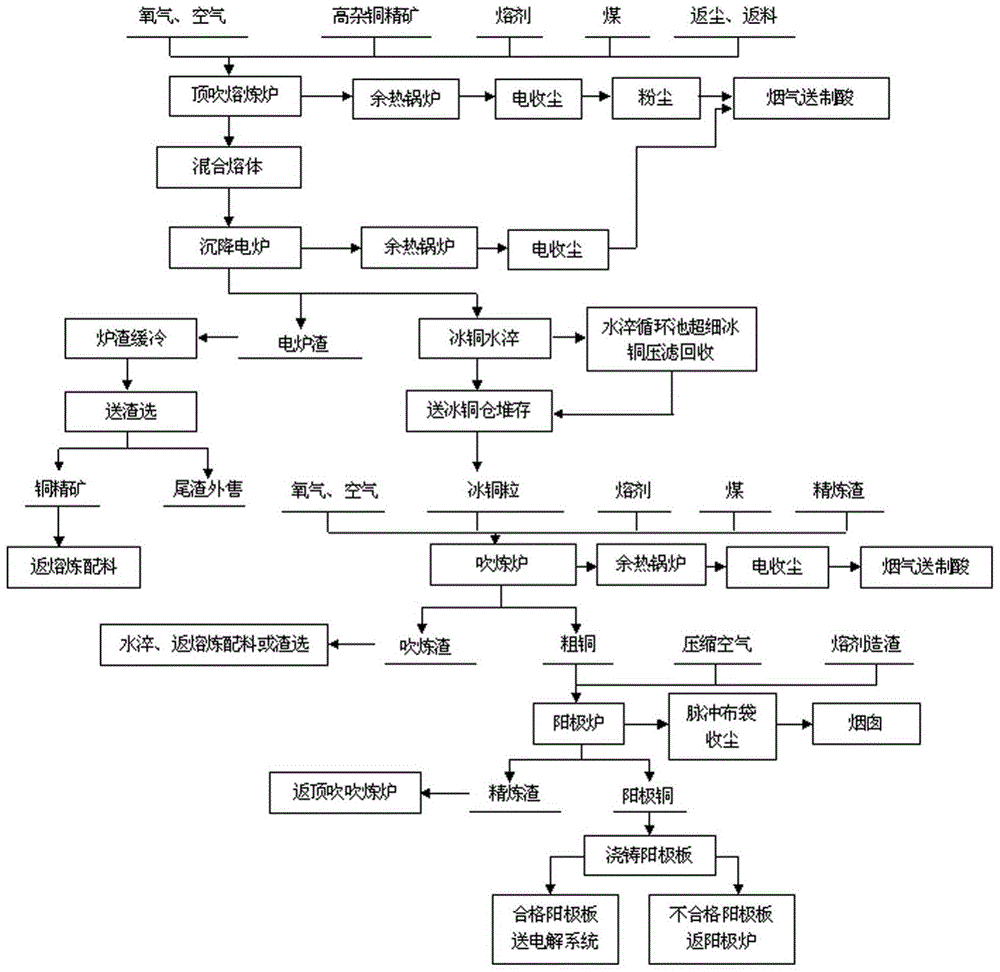

Method for recovering valuable metals by double top-blowing smelting of high-impurity copper-containing materials

The invention discloses a method for recovering valuable metal from high-impurity-content copper-contained materials through double-top-blowing smelting. The method comprises the steps of mixing high-impurity-content copper concentrate with quartz sand flux, coal, returned charge and / or returned dust in a matched mode, directly adding the mixture to a top-blowing smelting furnace, blowing oxygen into the smelting furnace for smelting, and feeding obtained mixed melt into a sedimentation electric furnace to obtain electric furnace slag and high-impurity-content copper matte through sedimentation and separation; conducting water quenching on the high-impurity-content copper matte to obtain copper matte particles; mixing the high-impurity-content copper matte, the quartz sand flux, the coal and refining slag in a matched mode, adding the mixture into a top-blowing converting furnace, and blowing oxygen into the converting furnace for converting to obtain blister copper and converting slag; mixing the electric furnace slag with the converting slag according to the weight ratio of 3:1-5:1, feeding the mixture into a slag mineral separation system to recover copper concentrate; placing the blister copper into an oxygen-rich combustion type anode furnace to be refined, and conducting casting to obtain a copper anode plate. By the adoption of the method, the adaptability of smelting equipment to the copper-contained materials such as the high-impurity-content copper concentrate can be improved, valuable metal in the high-impurity-content copper concentrate or / and the high-impurity-content copper matte can be effectively recovered, valuable metal dust contained in smoke generated during smelting can be effectively recovered, the technology is simple, and environment pollution is light.

Owner:YUNNAN TIN

Sodium calcium silicon series fire-proofing glass

ActiveCN100366560CImprove melting abilitySmall coefficient of thermal expansionChemical stabilitySilicon

A fire-proof Na-Si-Ca glass based on float glass contains SiO2 (67-75 Wt%), Al2O3 (1.5-4), CaO (5-10), MgO (0.5-3), R2O (3-13), ZrO2 (0.2-2.5), BaO (2-6) and SrO (1-6). Its advantages are low thermal expansibility and high softening point, fire-proofing performance and chemical stability.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

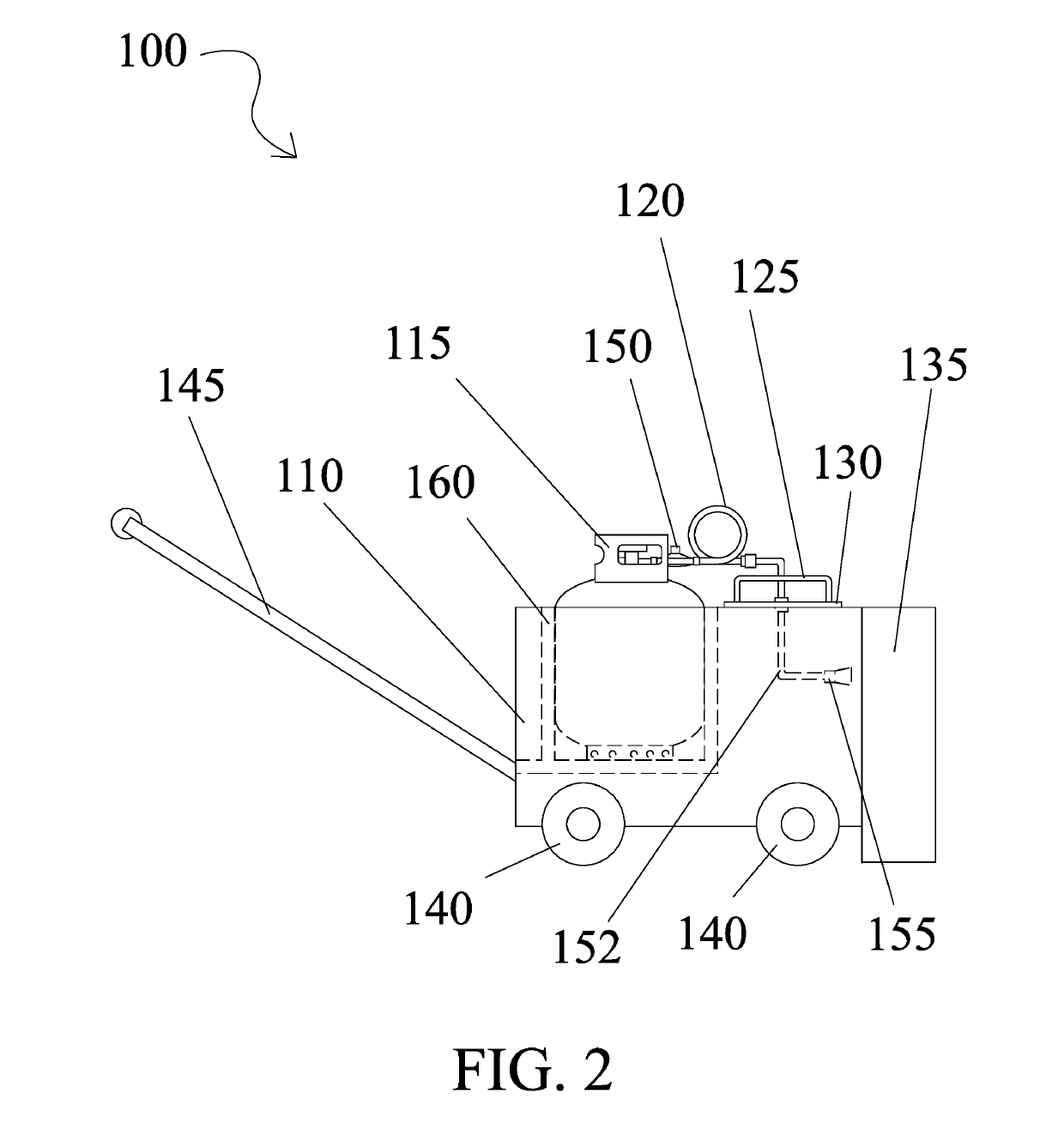

Snow and ice melting device

A snow and ice melting device has a frame that uses a trailer hitch to connect to a propane truck. The frame also holds a plurality of flame nozzles that directs heat down towards a snow and / or ice covered surface. In one embodiment, at least one propane tank is provided that allows the device to be hooked up to any vehicle rather than a propane truck such as a pickup truck, or small tractor. In one embodiment, a front mounted snow and ice melting device is also attached to the front of the vehicle to further enhance the snow and melting effect. In another embodiment, the snow and ice melting device has a frame that holds a propane tank. The frame has a handle and wheels to allow the user to maneuver the device to melt ice and snow. A riding embodiment is also shown.

Owner:LEGNAIOLI RICHARD W

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com