Glass tank furnace with high melting rate

A glass tank kiln and melting rate technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of low operation efficiency and operation yield, too large furnace area, high bottom temperature, and prolong life. , the effect of reducing the furnace area, reducing energy consumption and carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0038] In this specific embodiment, a horizontal pure oxygen burner is provided.

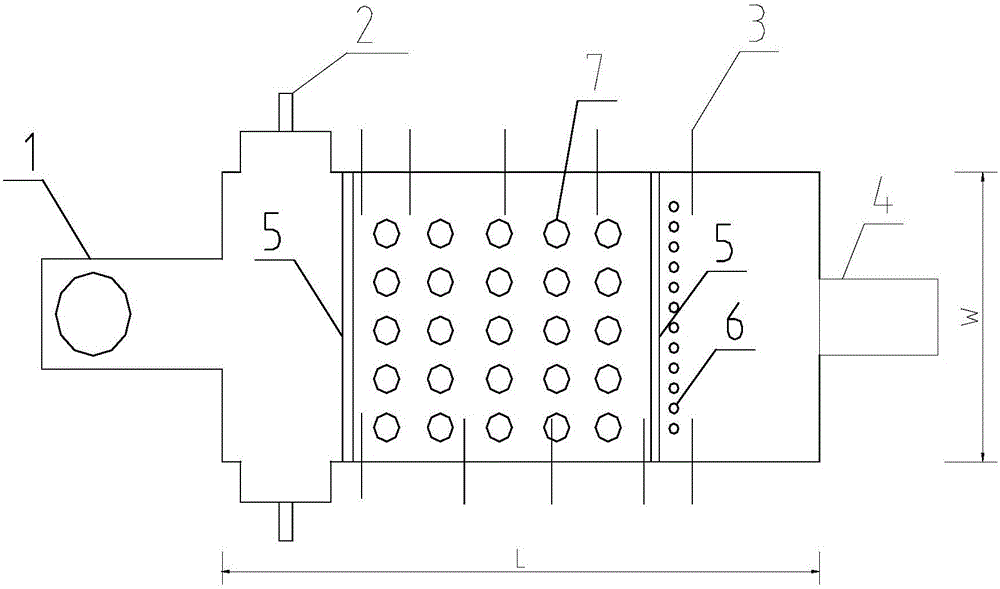

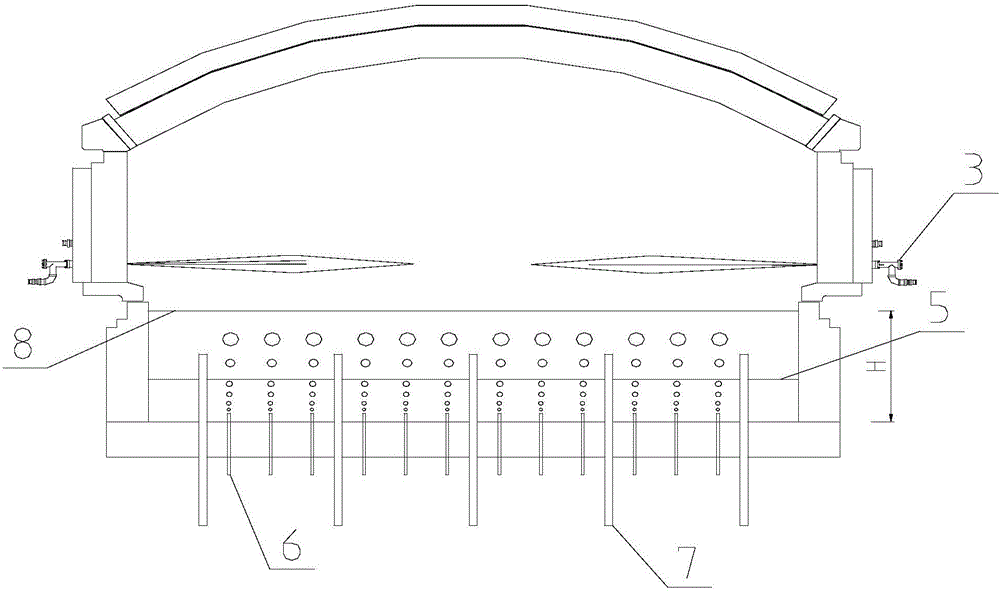

[0039] see figure 1 , figure 2 , the high melting rate kiln includes flue 1, feeder 2, melting part and main passage, wherein the flue is arranged on the back wall of the kiln, L in the figure indicates the length of the kiln, W indicates the width of the tank, high melting The length-to-width ratio of the kiln is 2.32, the melting rate is 2.97 tons / day*square meter, and the feeding port and ear pool are arranged on both sides of the kiln. This specific embodiment includes a horizontal pure oxygen burner 3, a liquid flow hole 4, a bottom kiln ridge 5, a bubble 6 and an electrode 7, wherein there are 5 pairs of pure oxygen burners 3 arranged horizontally on both sides of the parapet Above, five rows of electrodes 7 are arranged at the bottom of the pool kiln, and each row is provided with five electrodes; kiln ridges 5 are arranged before and after the electrodes 7, and bubbles 6 are arranged ...

specific Embodiment 2

[0040] An inclined pure oxygen burner is provided in this specific embodiment.

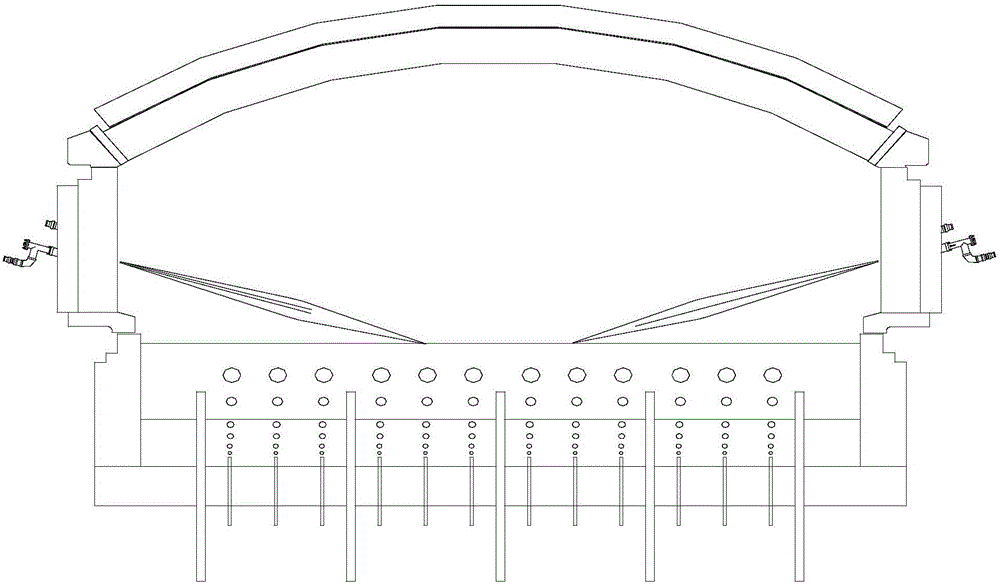

[0041] Such as image 3 As shown, the length-to-width ratio of the high melting rate tank kiln in this embodiment is 2.36, and the melting rate is 2.76 tons / day*square meter. Pure oxygen burners are installed obliquely on the parapets on both sides.

specific Embodiment 3

[0042] In this specific embodiment, the pure oxygen burner located on the top of the mountain is called the top pure oxygen burner 11 .

[0043] Such as Figure 4 As shown, the difference between the structure of the high melting rate tank kiln in this specific embodiment and the high melting rate tank kiln in specific embodiment 1 is that it does not include the pure oxygen burner arranged on the parapet, only includes the Oxygen burners on the roof. Specifically, there are three pure oxygen burners 11 on the top of the kiln, and they are arranged on the large wall of the kiln. There are four rows of electrodes 7 at the bottom of the kiln, four of which are arranged in the first row, and each row is arranged in the second to fourth rows. 6 pieces; kiln sills 5 are arranged on the front and back of the electrode 7, and the bubbles 6 are arranged on the kiln sill.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com