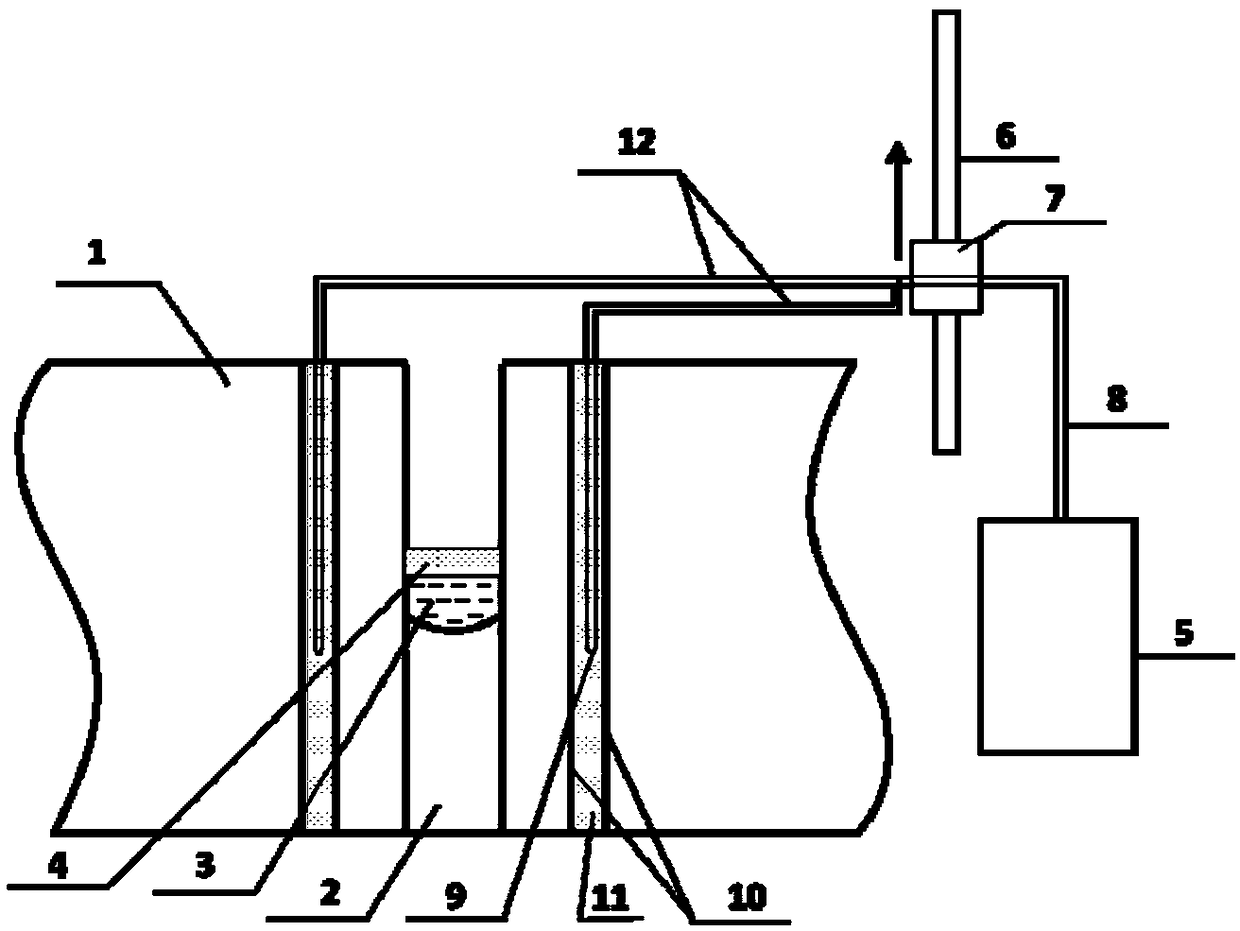

Method and device for resisting softening of electroslag welding joint

A welding head and electroslag technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing welding residual stress, increasing the temperature gradient in the weld zone, and increasing the sensitivity of weld cracks. Solve the effect of softening, improving production efficiency, increasing residual stress and crack susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Select 40mm thick Q345B as the test base material, the base material hardness is 152HV10. First assemble according to the conventional electroslag welding method, and then install four baffles on both sides of the weld. The positions of the baffles are 19.1 mm and 30.1 mm from the center of the weld; before welding, turn on the power of the air compressor to start working. The gas pressure in the air compressor is not lower than 0.8MPa; conduct electroslag welding on the base metal, the welding current is 380A, the voltage is 51V, after the welding process is stable, adjust the position of the nozzle in the baffle so that it is at the same level as the molten pool Then fix the air supply pipe on the lifting mechanism through the clamp, open the air compressor valve and start spraying gas to the softening zone of the weld seam, the gas flow rate is 45 L / min; during the welding process, adjust the lifting of the clamp fixed on the lifting mechanism The speed keeps the pos...

Embodiment 2

[0033] The test base metal and welding process are the same as in Example 1, only the gas flow rate of the air supply pipe is adjusted to 70 L / min, the measured high temperature residence time above 600 °C in the softening zone is 22s, and the minimum hardness value is 161 HV10, which is 9 HV10 higher than the hardness of the base metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com