Copper alloy laser-cold metal transition compound heat source material increase manufacturing method

A technology of cold metal transition and composite heat source, applied in manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve problems such as large thermal expansion coefficient and shrinkage rate, small surface tension of copper alloy, laser damage, etc., and achieve low equipment cost , improve the absorption rate, reduce the effect of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

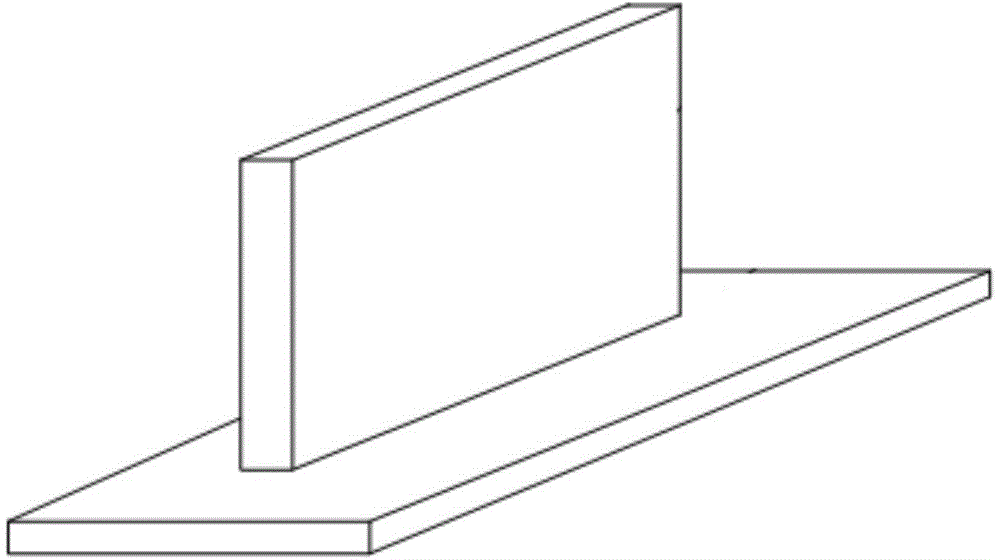

[0030]Such as figure 2 The size of the copper alloy component shown is 100mm×10mm×40mm, and it is composed of 40 layers of surfacing welding layers, each layer height is 1mm, and each layer of welding seam is composed of 7 welding seams.

[0031] Welding process parameters: welding wire 2 uses ERCuSi-A with a diameter of 1.2mm, welding current is 80A, welding voltage is 9.9V, laser power is 500W, wire feeding speed is 3.7m / min, welding speed is 1.2m / min, CMT shielding gas The flow rate is 16L / min, and the flow rate of the protective gas ejected from the protective gas nozzle 4 is 18L / min.

[0032] The specific plan is as follows:

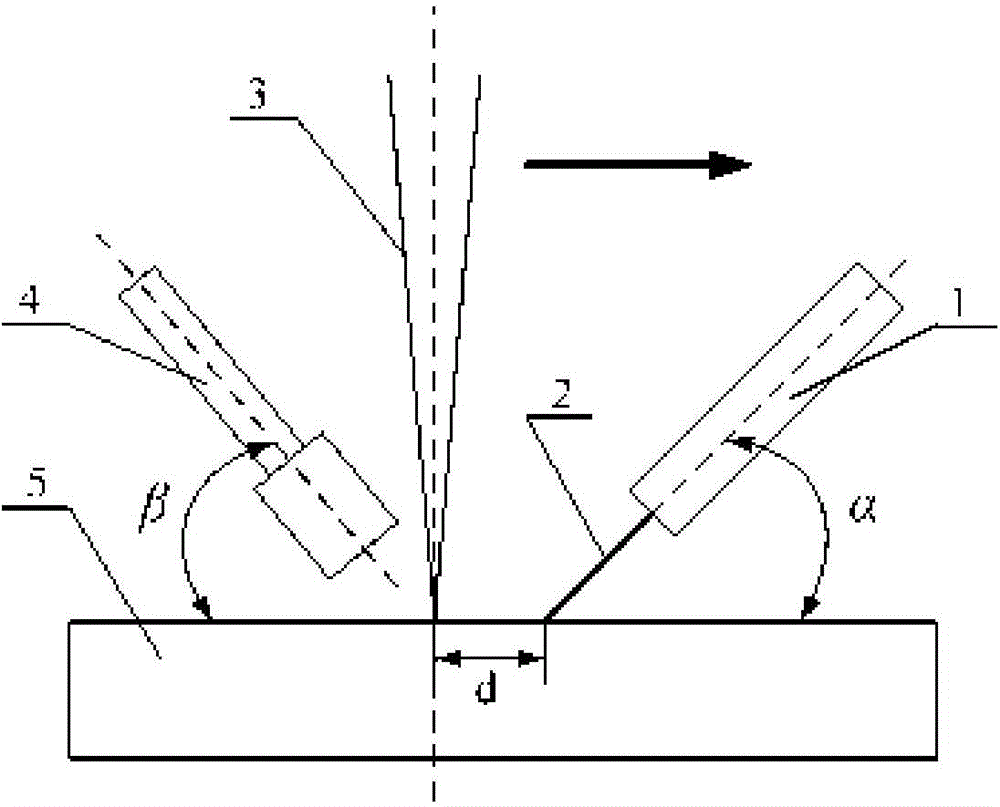

[0033] (1) Fix the laser welding torch 3, CMT welding torch 1, and shielding gas nozzle 4, the cold metal transition arc is in front, the laser is behind, the distance between the light filaments is 1mm, the defocus is 3mm, and the angle between CMT welding torch 1 and the horizontal plane is 70° , the angle between the laser input and the normal...

example 2

[0041] Such as figure 2 As shown, the copper alloy component is 100mm×15mm×60mm, and the height of each layer of surfacing welding is 1.2mm. It is composed of 50 layers of welding, and each layer of welding seam is composed of 10 welding seams.

[0042] Welding process parameters: welding wire 2 uses ERCuSi-A with a diameter of 1mm, welding current is 50A, welding voltage is 10V, laser power is 400W, wire feeding speed is 2.5m / min, welding speed is 1m / min, CMT shielding gas flow rate is 15L / min, the auxiliary protective gas flow rate is 15L / min.

[0043] The specific implementation plan is as follows:

[0044] (1) Fix the laser welding torch 3, CMT welding torch 1, and shielding gas nozzle 4, the cold metal transition arc is in front, the laser is behind, the distance between the light filaments is 1mm, the defocus is 2mm, and the angle between CMT welding torch 1 and the horizontal plane is 60° , the angle between the laser input and the normal direction of the substrate 5...

example 3

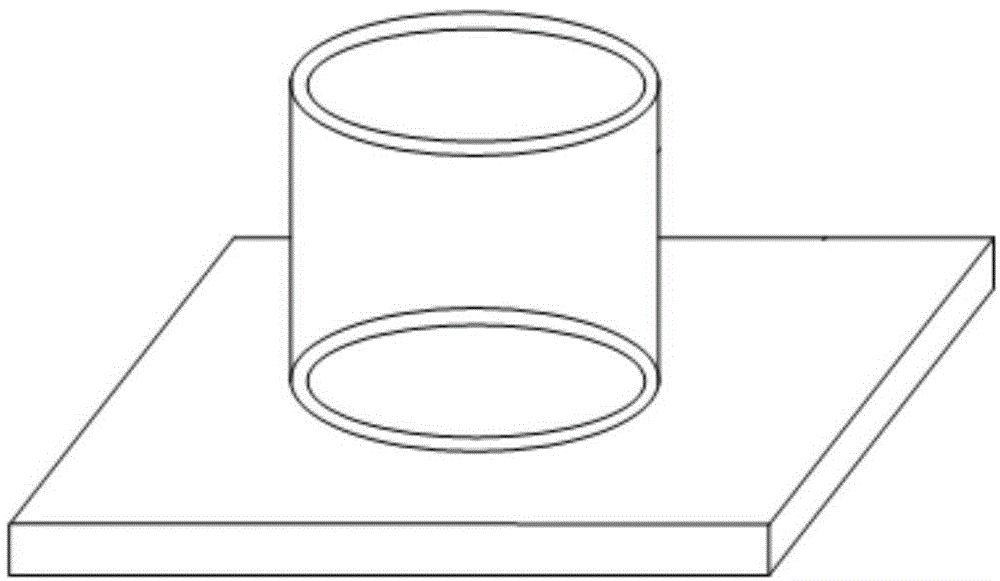

[0052] Such as image 3 As shown, the copper alloy component is 90 mm high, 20 mm thick, and 180 mm in inner diameter. It is composed of 60 layers of surfacing welding layers, each layer is 1.5 mm in height, and each layer is composed of 10 layers.

[0053] Welding process parameters: welding wire 2 uses ERCuSi-A with a diameter of 2mm, welding current is 150A, welding voltage is 17V, laser power is 800W, wire feeding speed is 6m / min, welding speed is 2m / min, CMT shielding gas flow rate is 25L / min, the auxiliary protective gas flow rate is 25L / min.

[0054] The specific implementation plan is as follows:

[0055] (1) Fix the laser welding torch 3, the CMT welding torch 1, and the shielding gas nozzle 4. The cold metal transition arc is in the front, the laser is behind, the distance between the light filaments is 3mm, the defocus is 0mm, the angle between the laser and the substrate 5 is 15°, the angle between the CMT welding torch 1 and the substrate 5 is 70°, and the angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com