High-elastic wearproof athletic floor material and preparation method thereof

A surface material and floor technology, applied in the direction of elastic floor, floor, building, etc., can solve the problems of low service life, environmental pollution of production conditions, insufficient surface wear resistance, etc., and achieve small shrinkage of product size and surface wear resistance Good sex and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

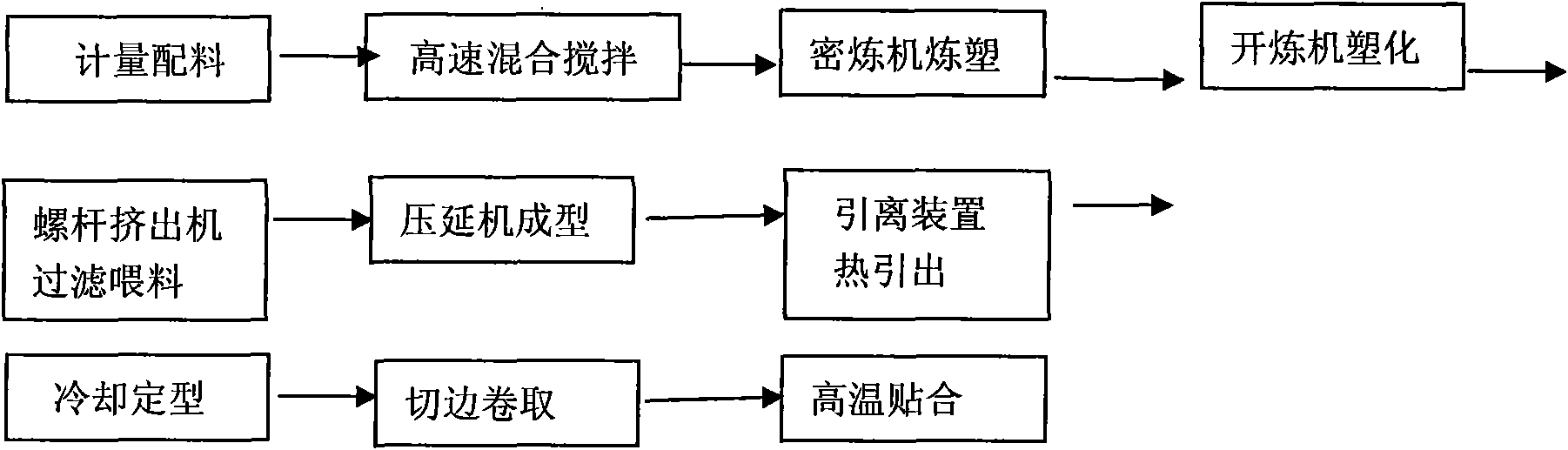

Method used

Image

Examples

Embodiment 1

[0039] A high-elastic and wear-resistant sports floor surface material is made of the following raw materials with the following weight ratio:

[0040] PVC high polymer resin 100

[0041] Phthalate Dicaprylate 50

[0042] TPU polyurethane elastomer 8

[0043] Composite heat stabilizer 3

[0044] Antifungal agent 0.05

[0046] Described composite heat stabilizer is made up of the following materials by weight:

[0047] Liquid barium zinc low toxicity stabilizer 2

[0048] Powder barium zinc low toxicity stabilizer 1.3.

Embodiment 2

[0050] A high-elastic and wear-resistant sports floor surface material, which is made of two layers of raw materials described in Example 1, and a layer of glass fiber mesh cloth is compounded between two layers of embryonic membranes on the surface and bottom.

Embodiment 3

[0052] A high-elastic and wear-resistant sports floor surface material is made of the following raw materials with the following weight ratio:

[0053] PVC high polymer resin 100

[0054] Phthalate Dicaprylate 60

[0055] TPU polyurethane elastomer 5

[0056] Composite heat stabilizer 2.5

[0057] Antifungal agent 0.07

[0059] Described composite heat stabilizer is made up of the following materials by weight:

[0060] Liquid barium zinc low toxicity stabilizer 1.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com