Droplet-free flame-retardant polyester fiber/fabric and preparation method thereof

A flame-retardant polyester and fabric technology, applied in the direction of flame-retardant fibers, etc., can solve problems such as poor hand feeling, polyester fiber anti-melt drop problem has not been fundamentally solved, fabric hand feel and poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

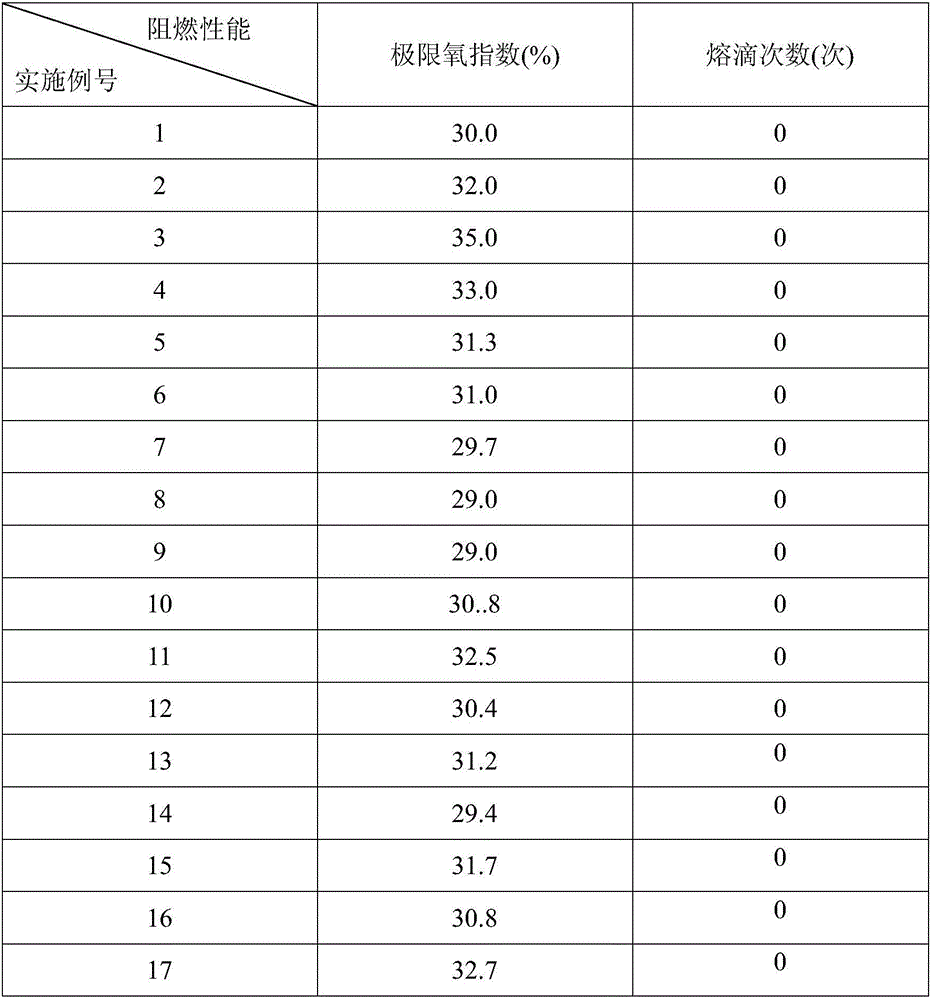

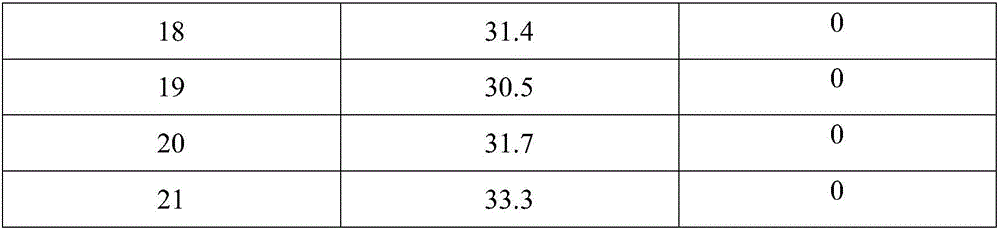

Examples

preparation example Construction

[0053] 1. Preparation of flame-retardant polyester fiber / fabric for raw materials

[0054] Taking the phosphorus-containing flame-retardant copolyester chips with a phosphorus content of 10000ppm as an example, the method for preparing flame-retardant polyester fibers / fabrics as raw materials is:

[0055] Put the phosphorus-containing flame-retardant copolyester chips into vacuum drying at 120° C. for 12 to 14 hours, so that the water content in the flame-retardant copolyester chips is lower than 0.02 wt %, and the melting of conventional polyester fibers Spinning method, melt spinning is carried out to obtain flame-retardant polyester fibers, and then the flame-retardant polyester fibers are passed through conventional weaving methods to obtain flame-retardant polyester fabrics. The flame-retardant polyester fibers / fabrics are hereinafter referred to as flame-retardant polyester fibers / fabrics1 ;

[0056] Can be prepared by the above method:

[0057] Flame-retardant copolye...

Embodiment 1

[0060] At room temperature, 750 grams of vinyl phosphoric acid and 250 grams of N-methylolacrylamide were formulated into a water-based glue solution with a concentration of 30% by mass, mixed evenly, placed in the glue tank of a padding machine, and the flame-retardant polyester fiber / The fabric 1 passes through the glue in the glue tank, under the roll pressure of 0.25Mpa, goes through the second dipping and second rolling of the padding machine, and then dries in a blast oven at 120°C to obtain the dipped polyester fiber / fabric 1;

[0061] Under the protection of normal temperature and nitrogen, the above-mentioned dipped polyester fiber / fabric 1 is irradiated by 10MeV high-energy electron beam equipment, and the irradiation dose is 120KGy. After the fabric is steamed for 3 minutes, it is washed with soap and water, and then dried. After weighing, its mass percentage increased by 18%, and no droplet flame-retardant polyester fiber / fabric 1 was obtained. After 50 times of wa...

Embodiment 2

[0063] 650 grams of phosphorus-containing cyanuric acid epoxy acrylate (structural formula A) and 350 grams of N-methylol acrylamide are formulated into a water-based glue solution with a mass percentage concentration of 35%, mix well, and place the padding machine glue tank In the process, the flame-retardant polyester fiber / fabric 2 is passed through the glue in the glue tank, under the roll pressure of 0.3Mpa, through the second dipping and second rolling of the padding machine, and then dried in a blast oven at 100°C to obtain the dipped polyester fiber / fabric2;

[0064] The above-mentioned dipped polyester fiber / fabric 2 is irradiated with an electron beam with a radiation dose of 100KGy, steamed the fabric for 5 minutes, rinsed with soap and water, then weighed after drying, and its mass percentage increased by 15 %, to obtain no droplet flame-retardant polyester fiber / fabric 2; others are the same as in Example 1, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com