A kind of preparation method of water-soluble benzoxazine compound containing dopo

A technology for benzoxazine and compound, which is applied in the field of preparation of water-soluble benzoxazine compounds, can solve the problems of complicated synthesis steps, harm the environment, inconvenient for large-scale industrial production, etc., achieves good chemical stability and improves water solubility. properties, excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

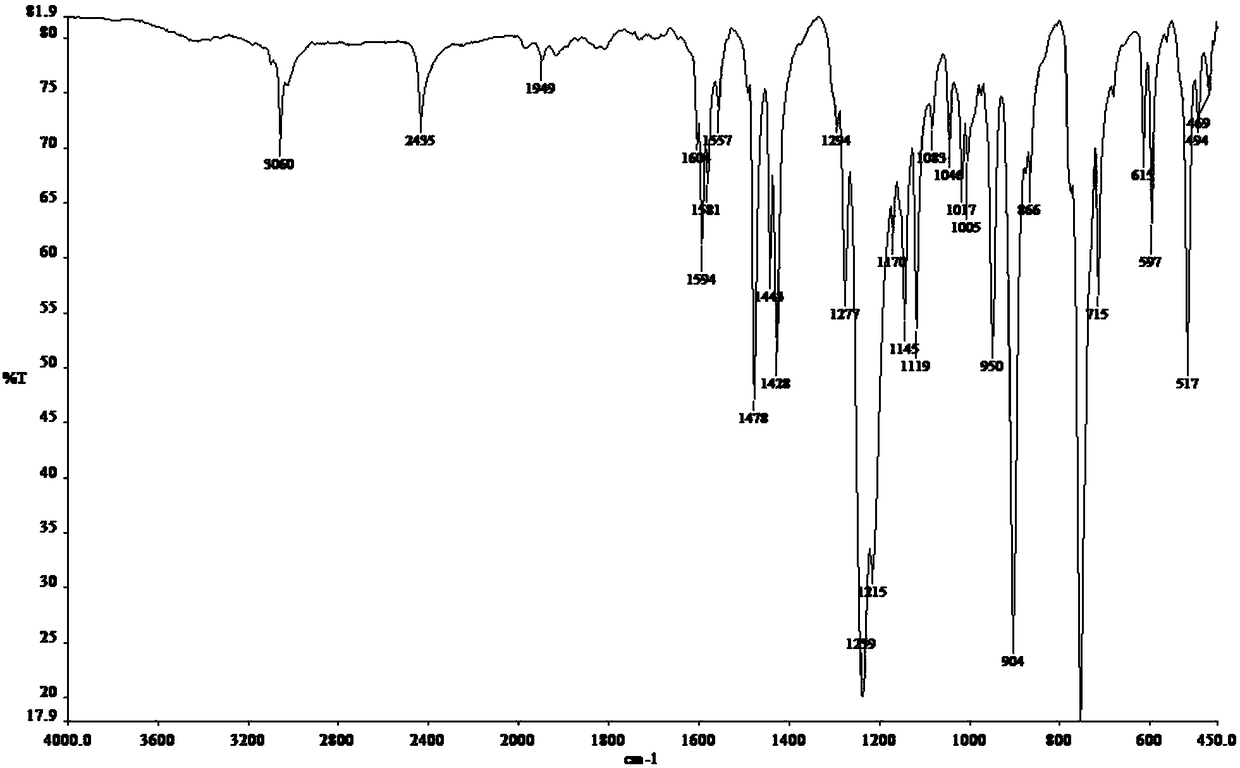

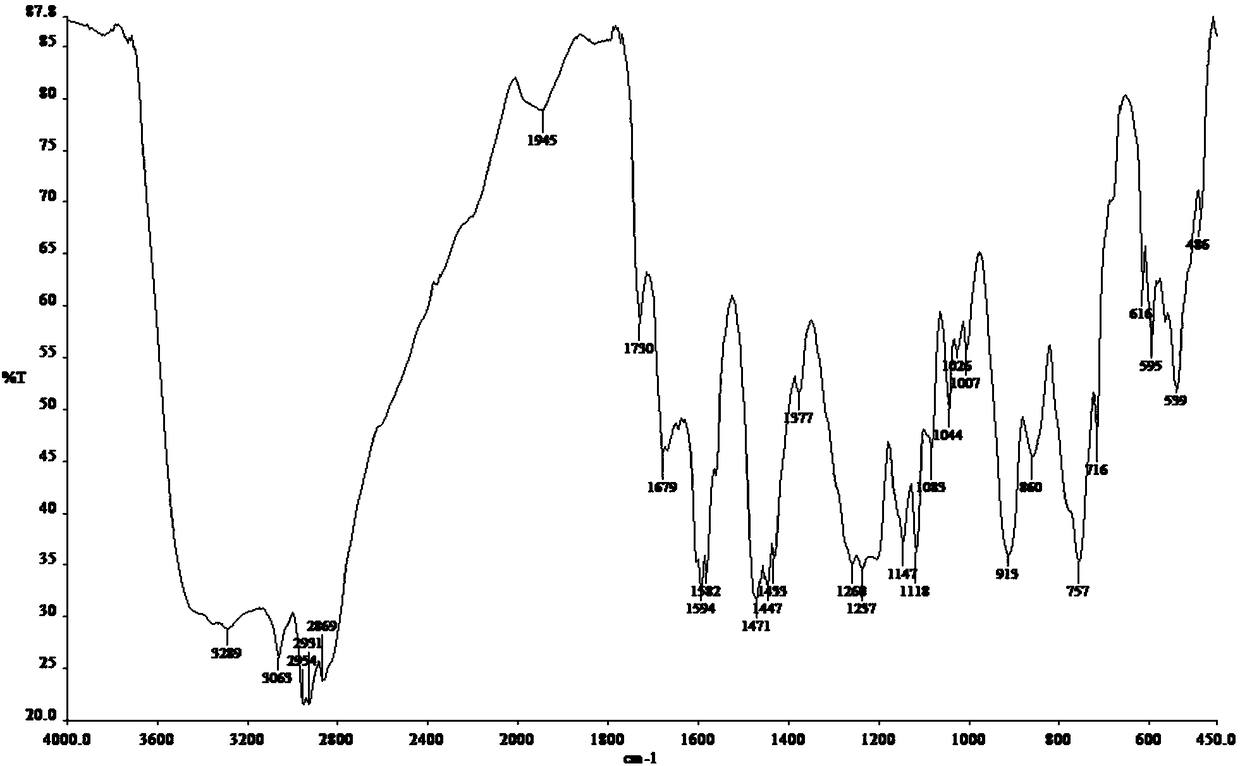

Embodiment 1

[0039] Take 24.32g (0.30mol formaldehyde) and 50ml dioxane in a reactor with a mass fraction of 37% formaldehyde solution, adjust the pH of the solution to 8 with triethylamine, add 9.01g (0.15mol) ethylenediamine dropwise, and Stir the reaction for 1 h, then add 12.21 g (0.10 mol) of p-hydroxybenzaldehyde, raise the temperature to 80 ° C, stir the reaction for 5 h, cool to room temperature, and distill off the dioxane under reduced pressure to obtain the crude product; dissolve the crude product in 50 ml of acetic acid ethyl ester, the resulting solution was washed 3 times with 1mol / L sodium hydroxide solution, and then washed with distilled water until the pH was neutral, and the resulting neutral solution was distilled off under reduced pressure to remove ethyl acetate under a vacuum of 0.09Mpa, and dried to obtain Refined benzoxazine product; get refined benzoxazine product in the reactor, add anhydrous dioxane and stir evenly, then add 21.6g (0.10mol) DOPO (9,10-dihydro-9-...

Embodiment 2

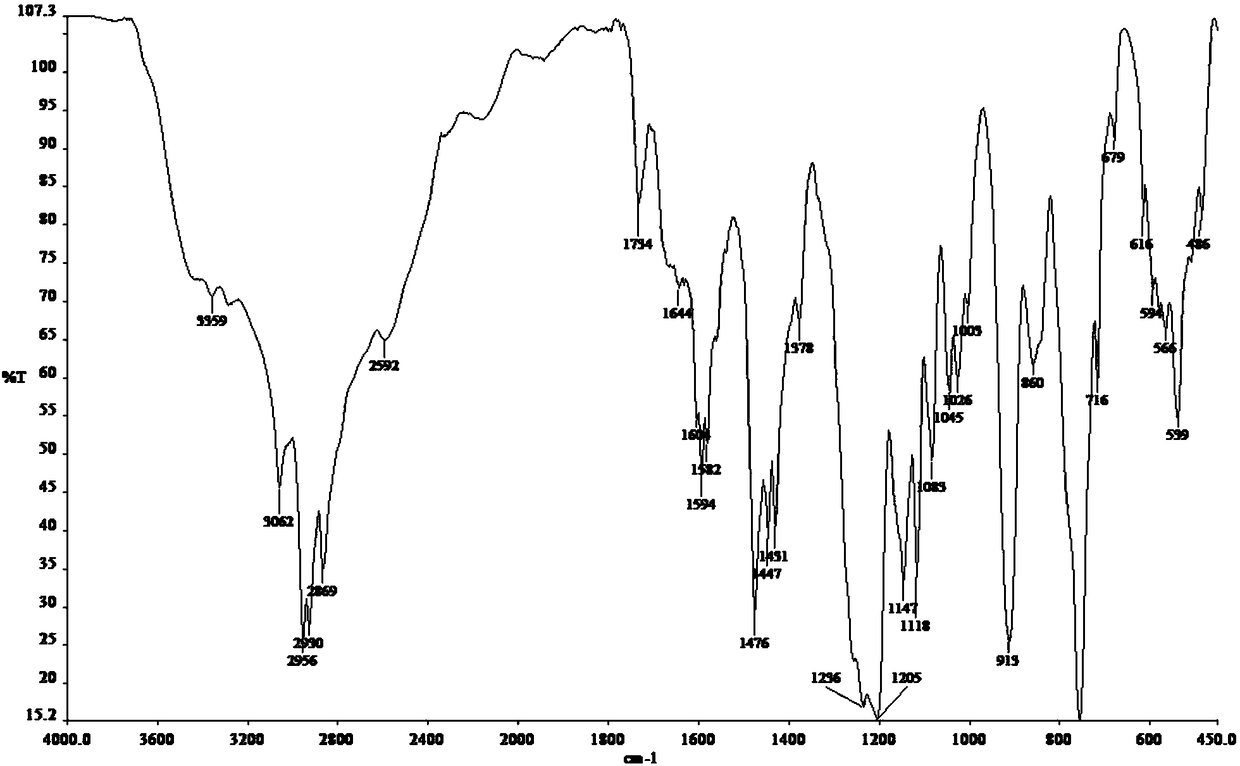

[0045] Take 16.62g (0.20mol formaldehyde) of 37% mass fraction of formaldehyde solution and 50ml ethanol in a reactor, adjust the pH of the solution to 9 with triethylamine, add dropwise 0.10mol (14.62g) triethylenetetramine, stir and react at low temperature for 2h, Then add 0.10mol (mass is 12.26g) p-Hydroxybenzaldehyde, heat up to 90°C, stir and react for 10h, cool to room temperature, and remove dioxane by distillation under reduced pressure to obtain the crude product, which is dissolved in 50ml ethyl acetate, The resulting solution was washed 3 times with 1mol / L sodium hydroxide solution, and then washed with distilled water until the pH was neutral. The resulting neutral solution was distilled off under reduced pressure to remove ethyl acetate and dried to obtain the refined benzo Oxazine product; take the refined benzoxazine product in the reactor, add anhydrous dioxane and stir evenly, then add 0.1mol (mass is 21.6g) DOPO (9,10-dihydro-9-oxa- 10-phosphaphenanthrene-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com