Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Remove less" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

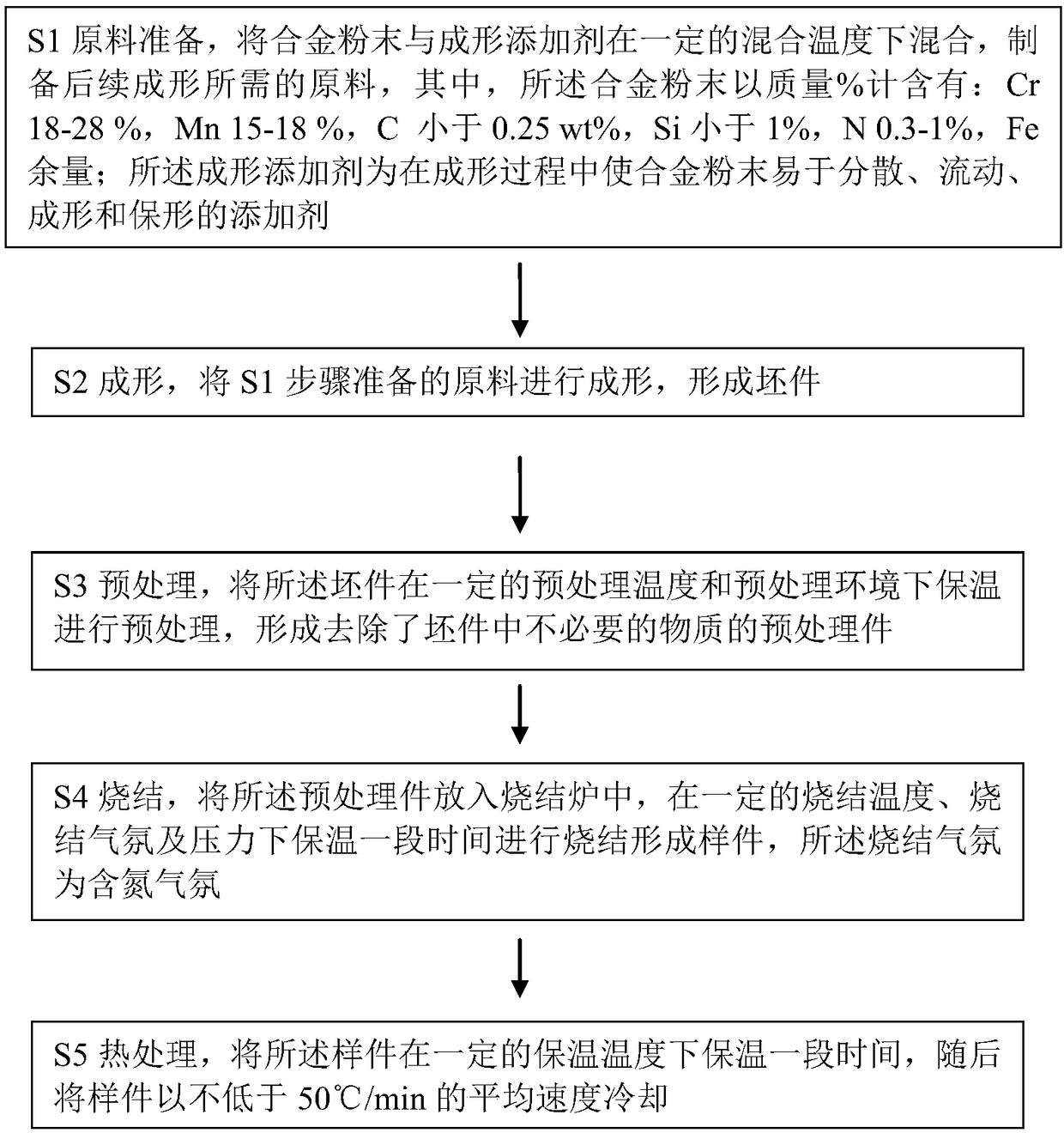

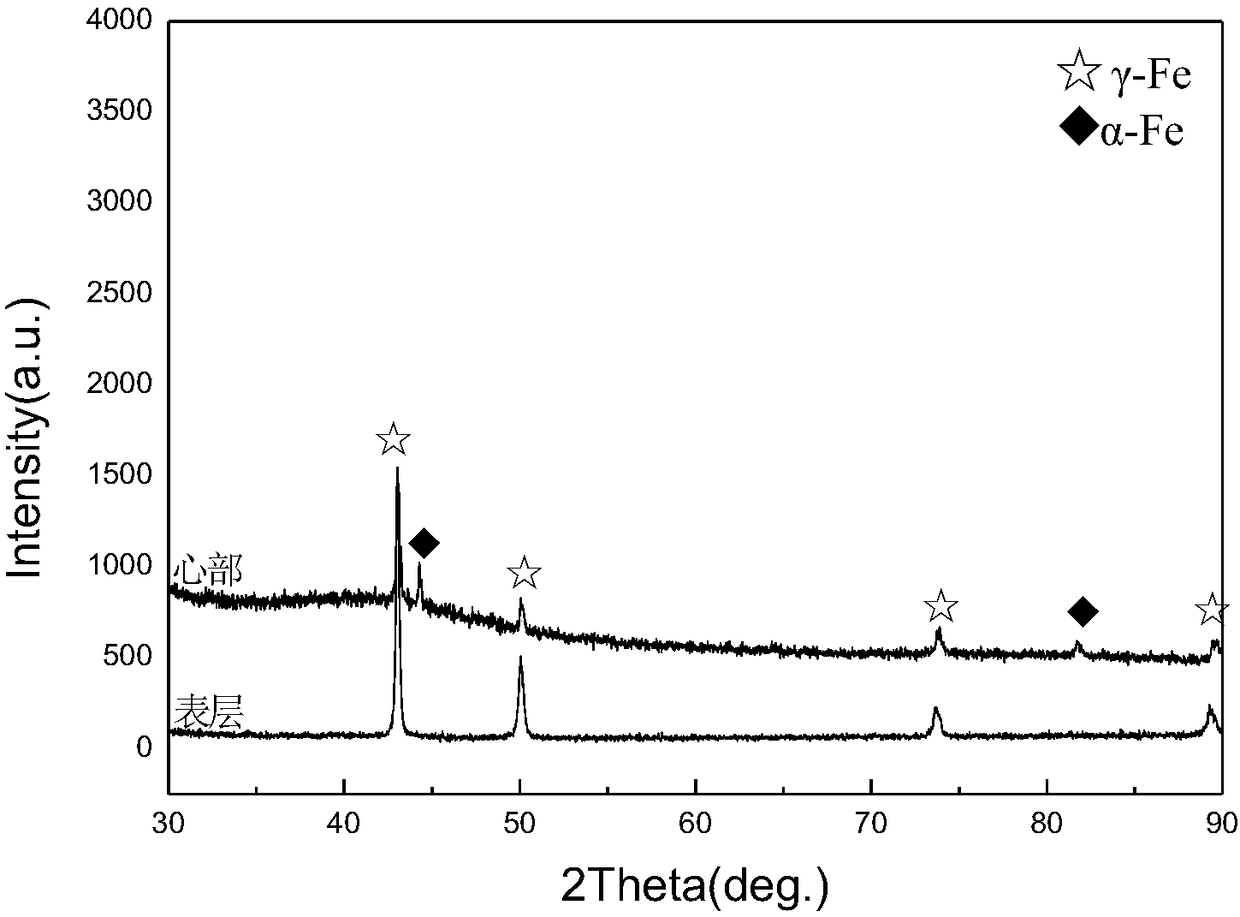

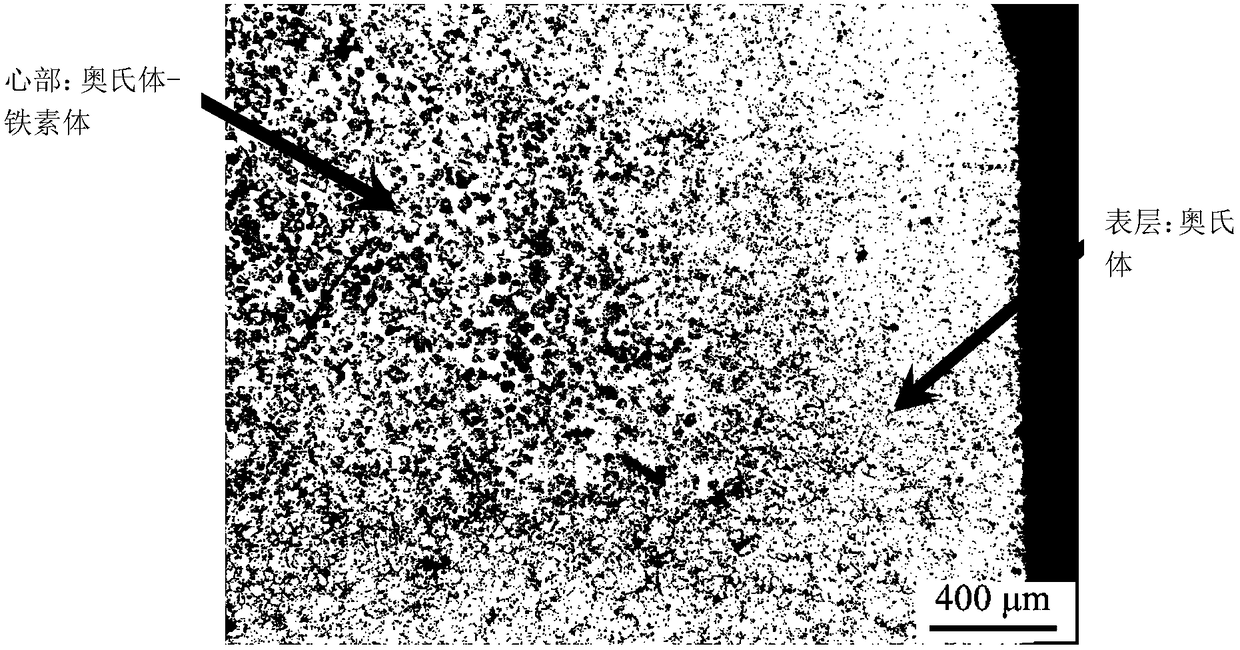

Stainless steel material and preparation method thereof

ActiveCN108546889AExcellent magnetic propertiesIncreased strength and corrosion resistanceMachining processSurface layer

The invention relates to a stainless steel material and a preparation method thereof. The stainless steel material comprises the following components of, by mass percentage, 16-25% of Cr, 12-17% of Mn, less than 0.25% of C, less than 1% of Si, 0.3-0.9% of N, and the balance Fe and unavoidable impurities; the stainless steel material is nickel-free, multilayer and biphase stainless steel; the surface layer of the stainless steel is an austenite structure; and the core of the stainless steel is an austenite-ferrite biphase structure. The provided stainless steel material can be subjected to 24 hsalt mist and 24 h artificial sweat instead of being corroded, does not contain nickel and molybdenum, does not have the nickel allergy risk, is lower in raw material cost, and has the obvious advantages in aspects such as the magnetic property, simplification of a machining technology, and less material removal in the part machining process.

Owner:FIYTA HOLDINGS LTD +1

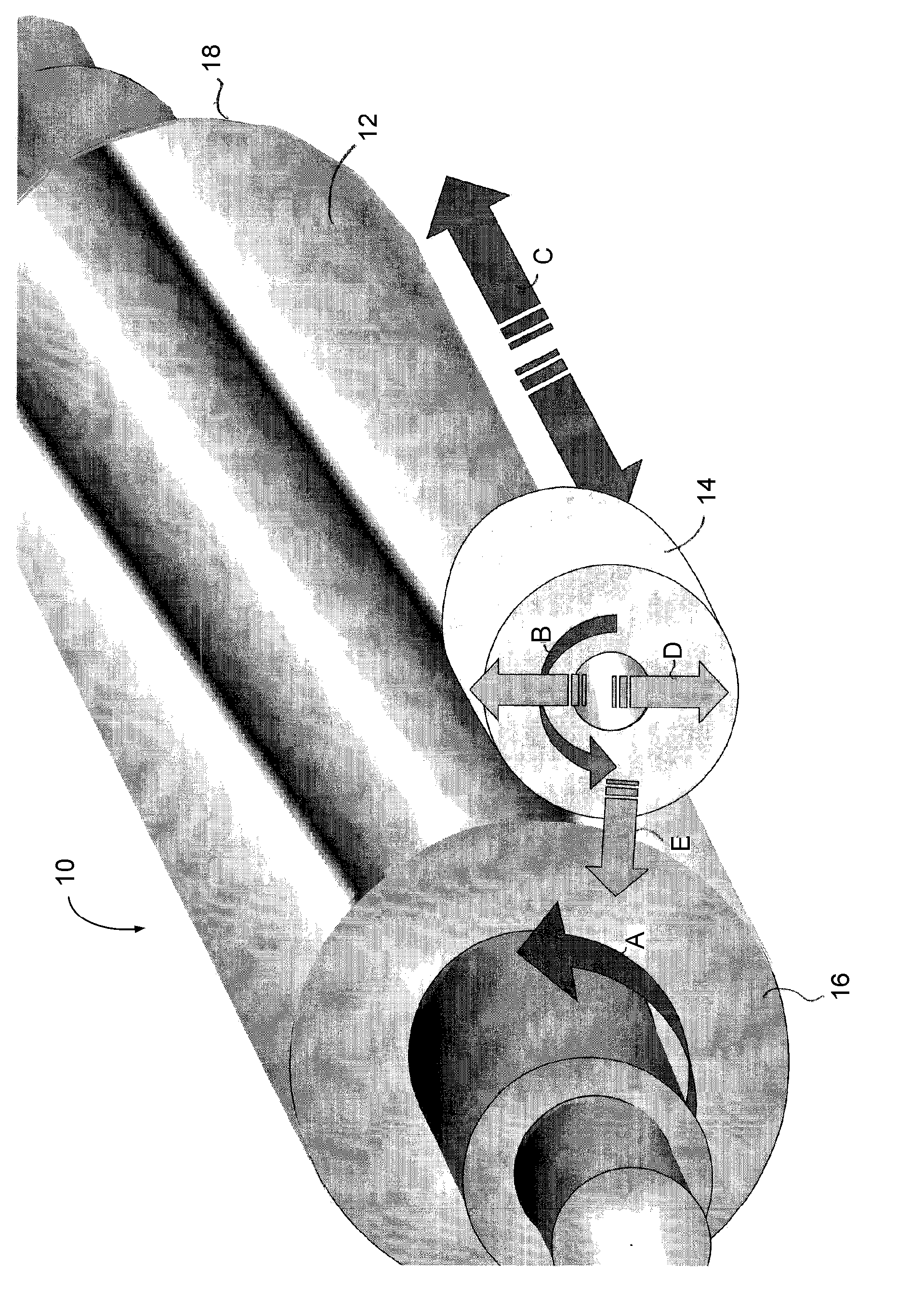

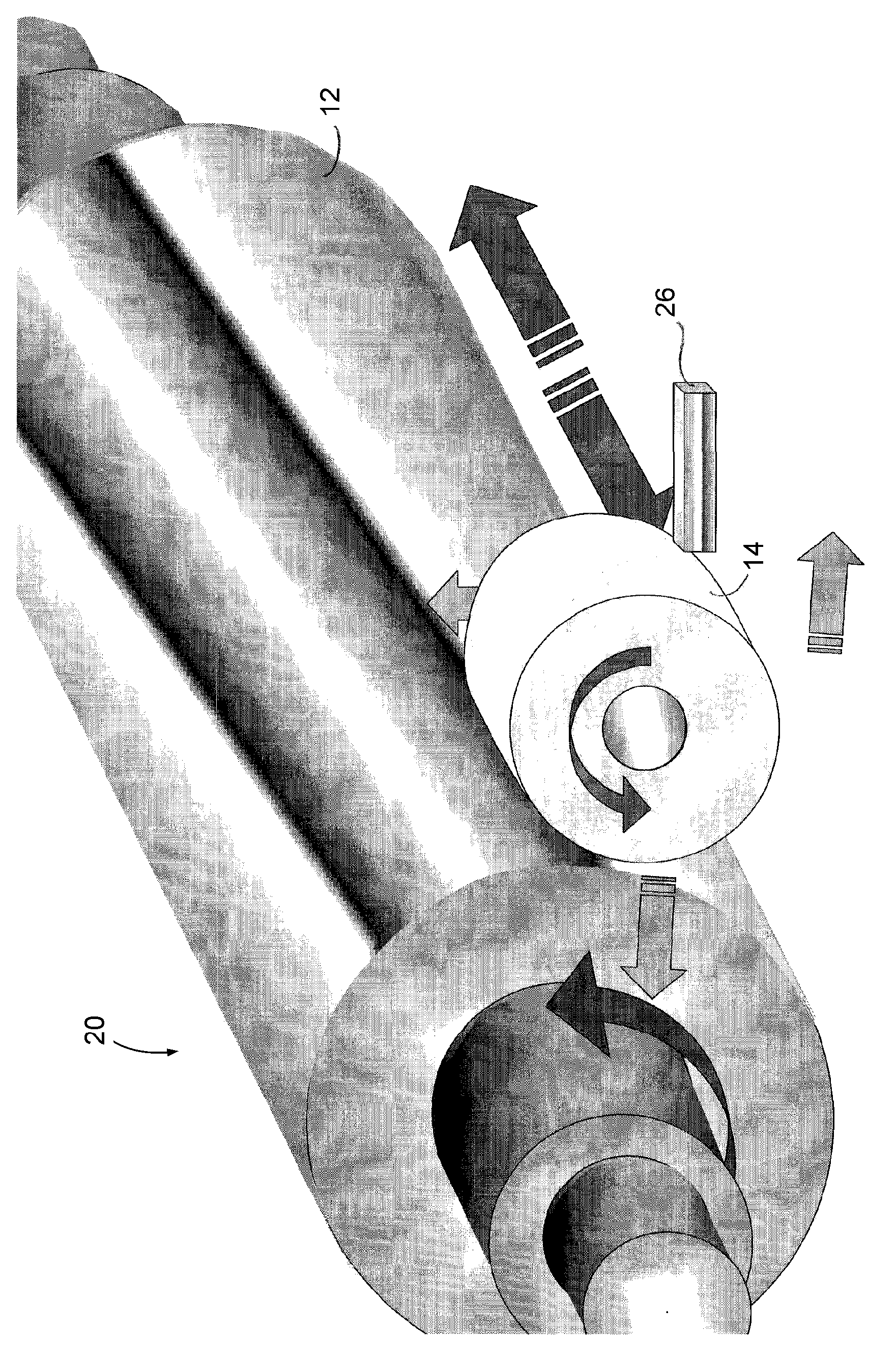

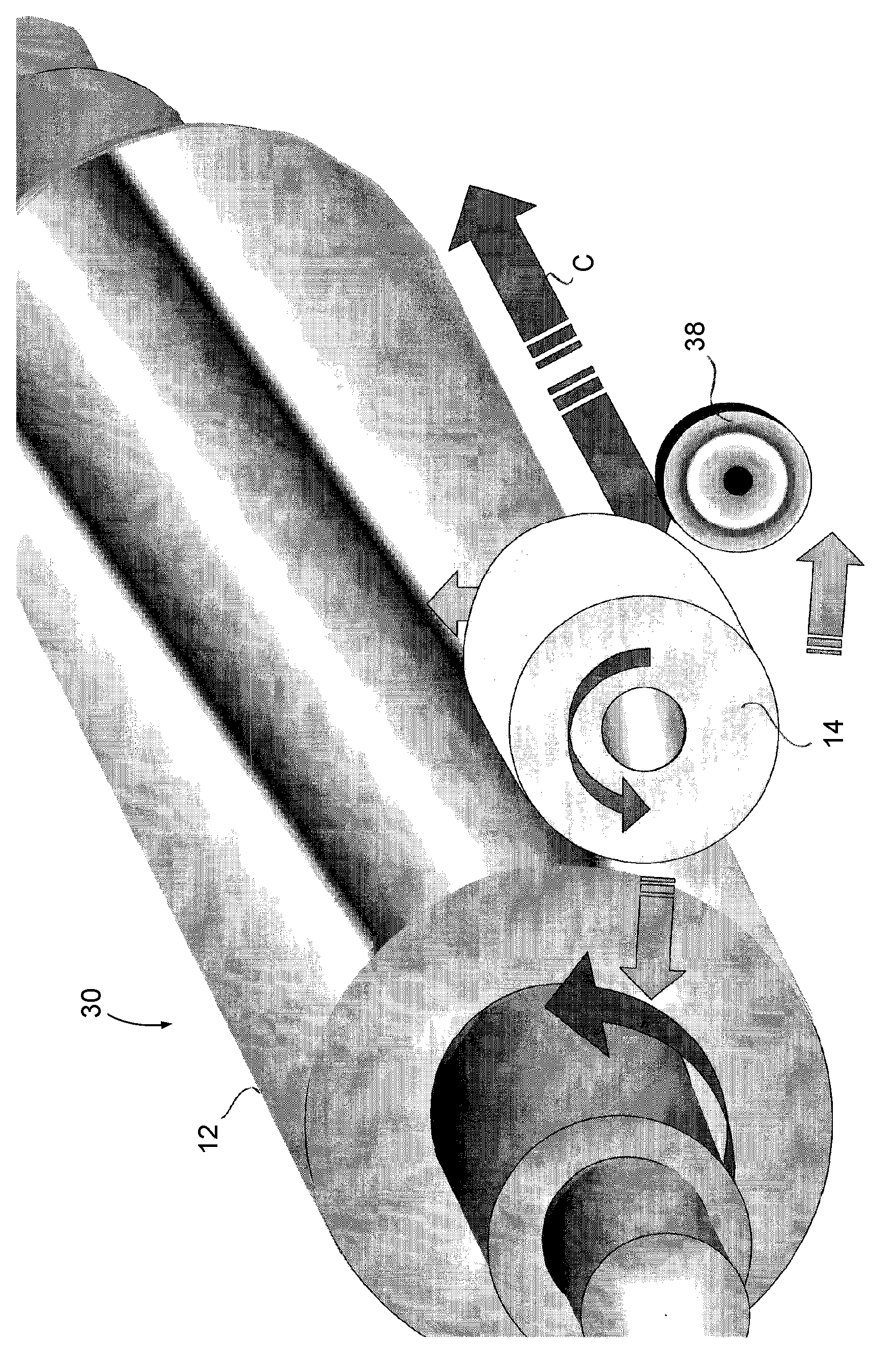

Method and apparatus for roll grinding

InactiveCN102725102ASolution to short lifeReduce the numberRevolution surface grinding machinesRolling equipment maintainenceEngineeringGrinding wheel

In one aspect, a process for roll grinding employs a grinding wheel that is porous and permeable. In another aspect, a process for grinding mill rolls includes dressing the grinding wheel as the wheel traverses the surface of a mill roll. Other aspects relate to a system, e.g., a mill roll grinding machine, or parts thereof, in which a dressing tool contacts the wheel as the wheel grinds the surface of the mill roll. In specific examples, the wheel and a rotary dressing tool are maintained in contact as the wheel traverses the surface of the mill roll.

Owner:SAINT GOBAIN ABRASIVES INC +1

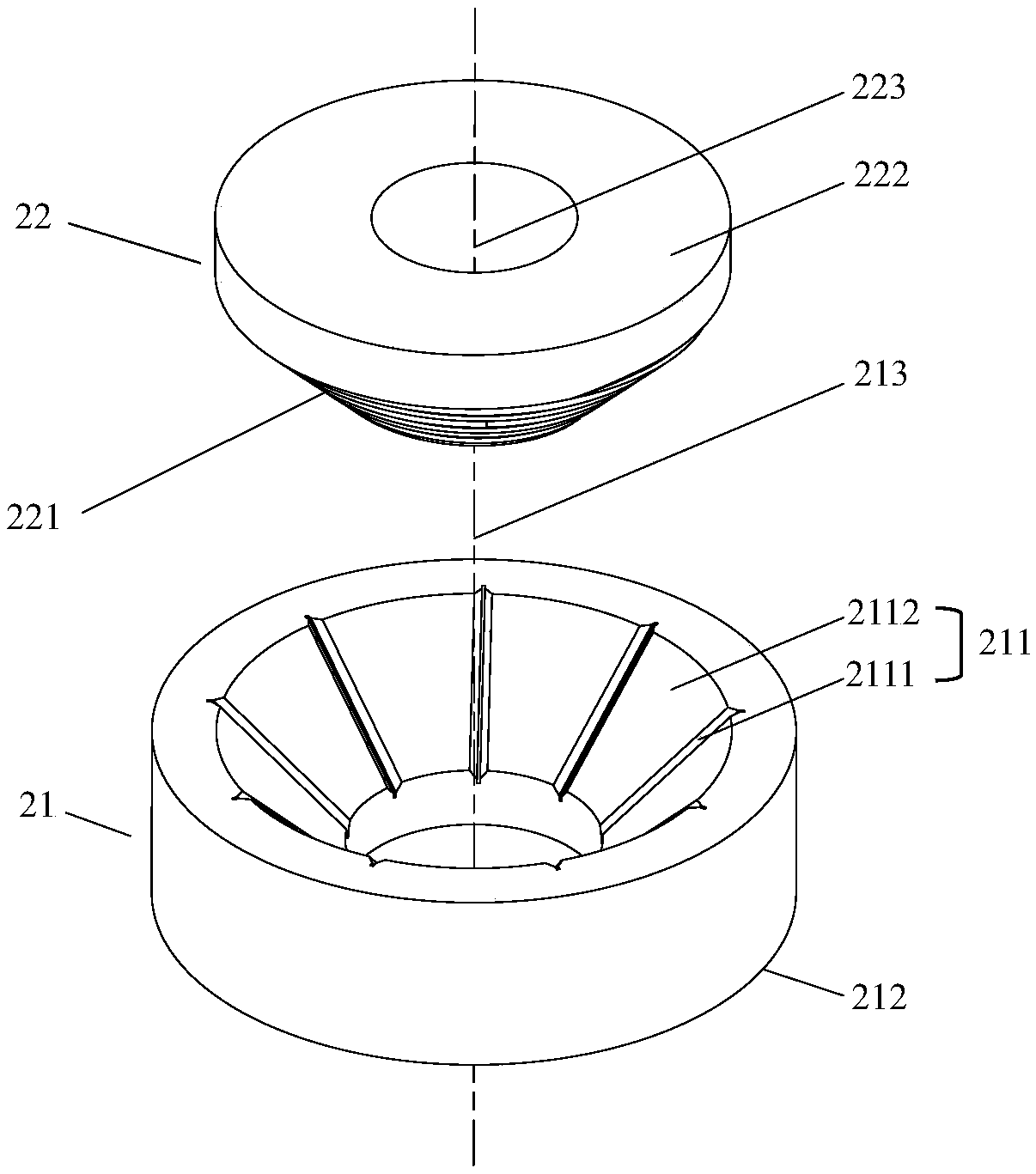

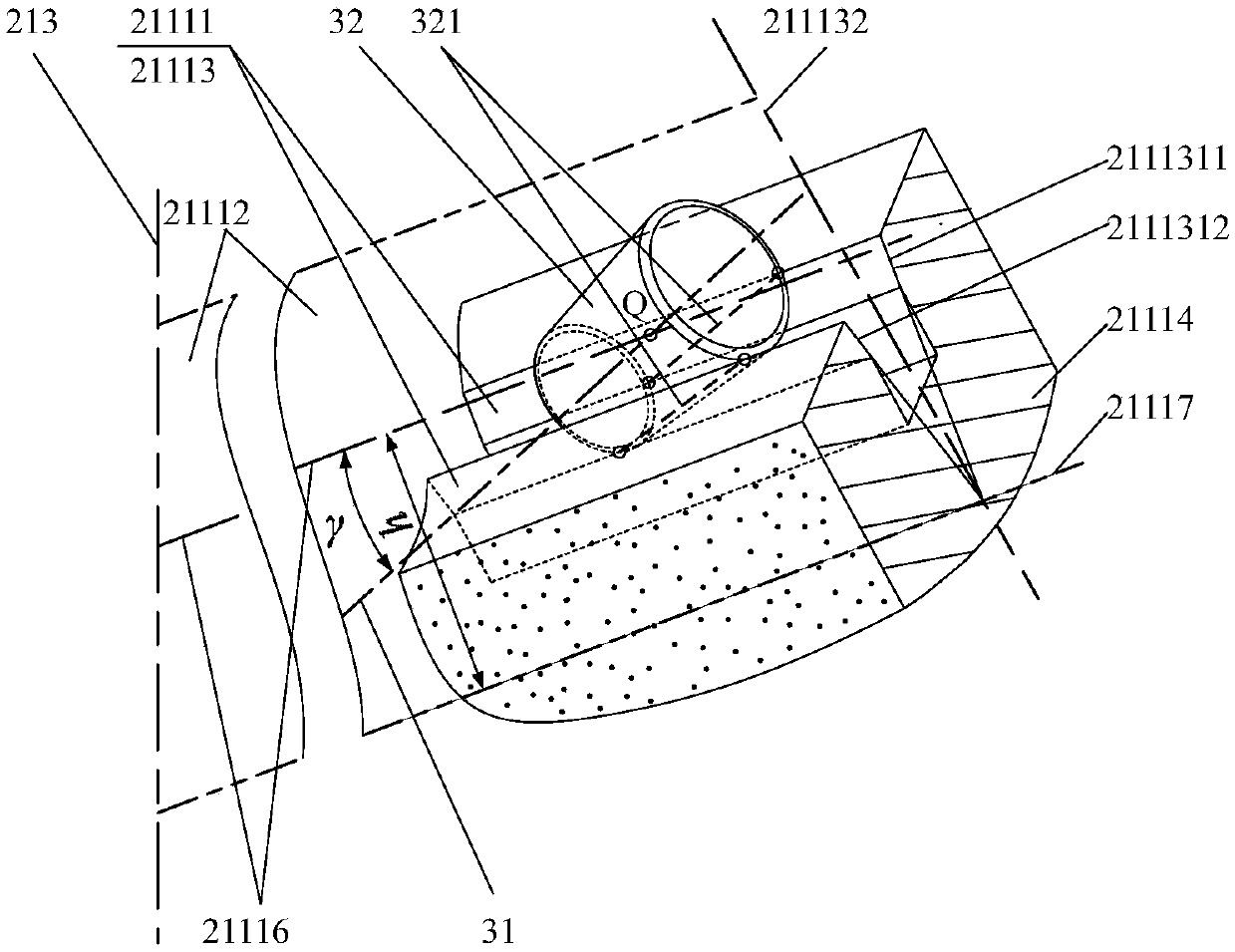

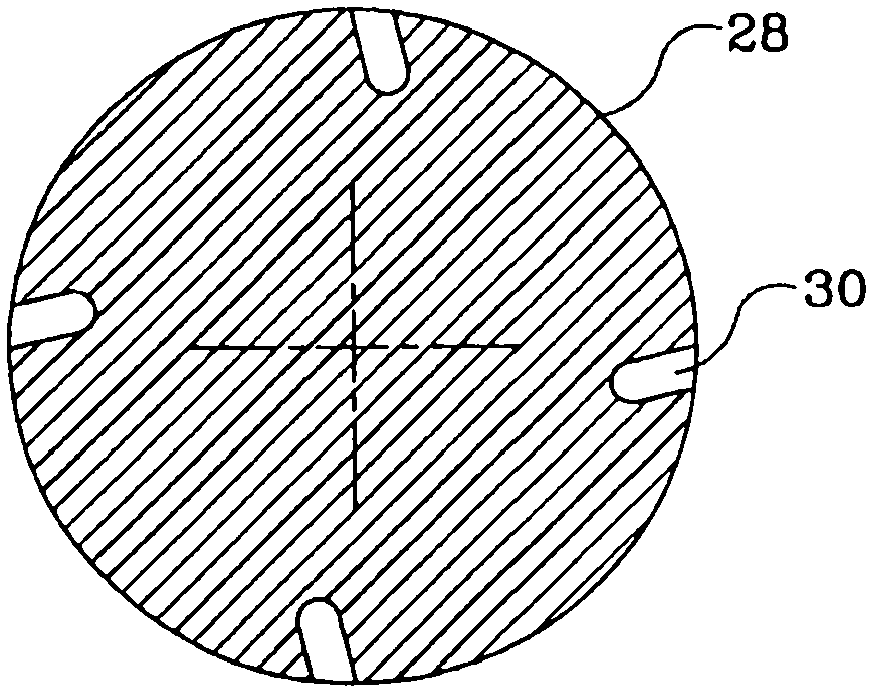

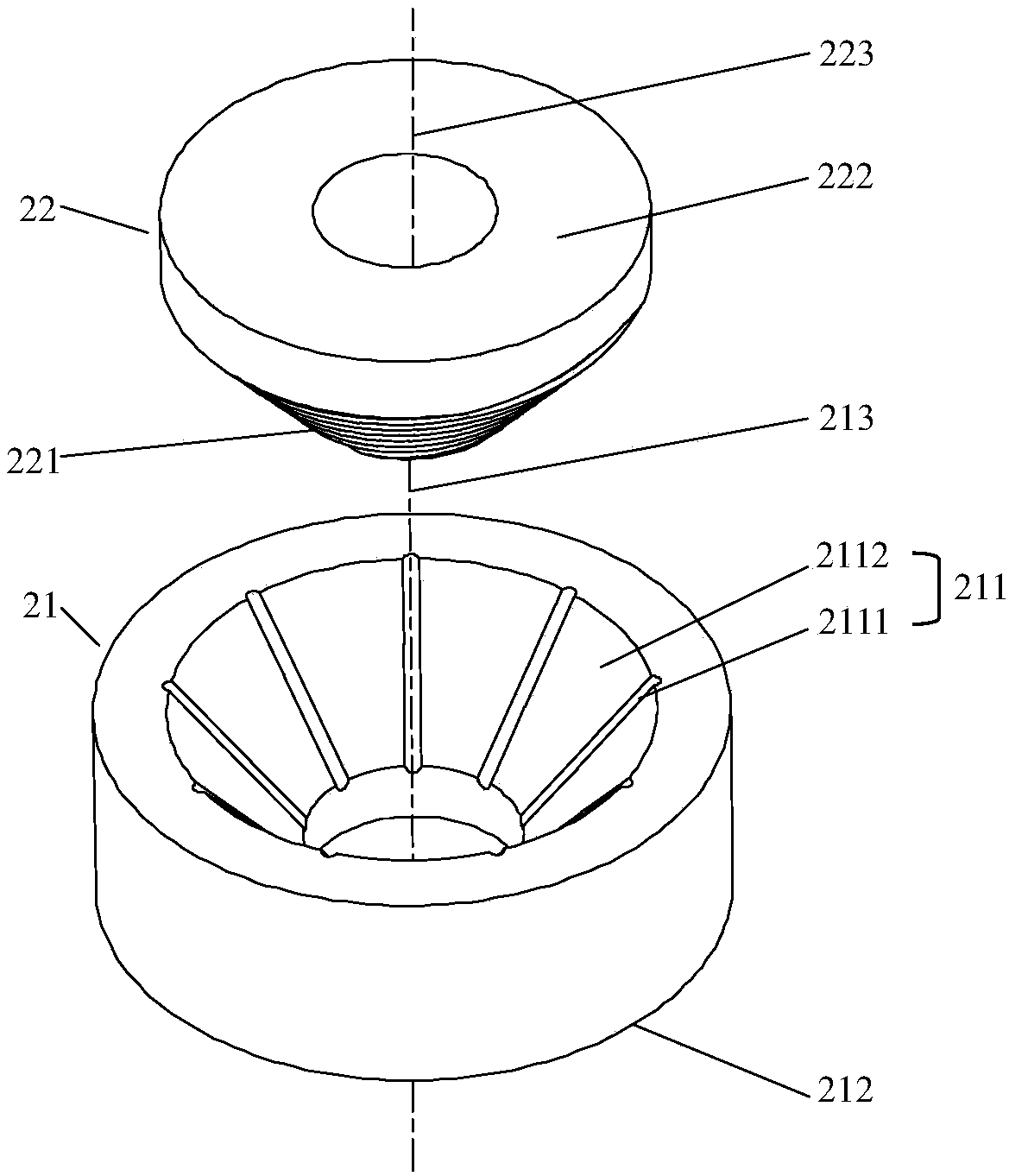

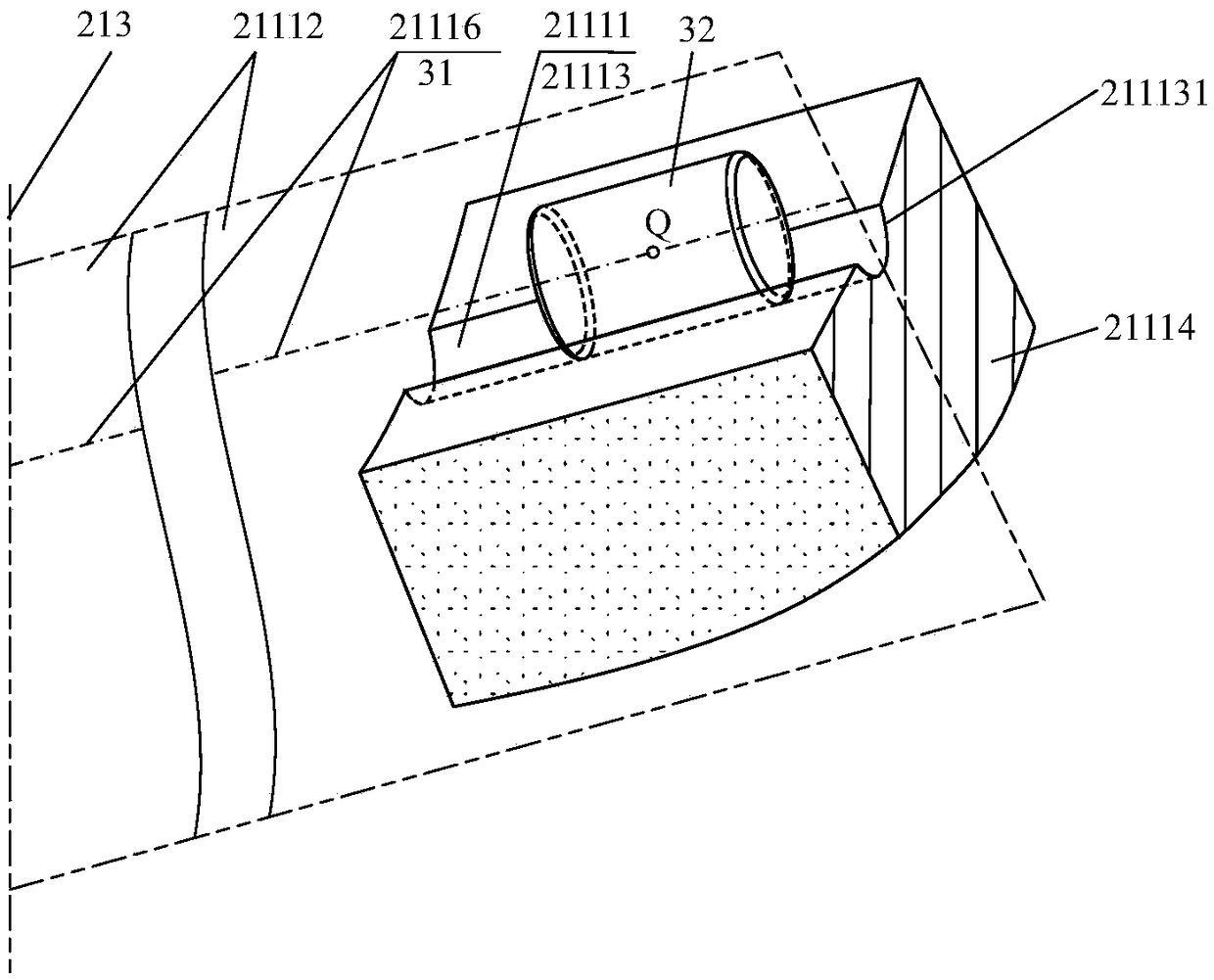

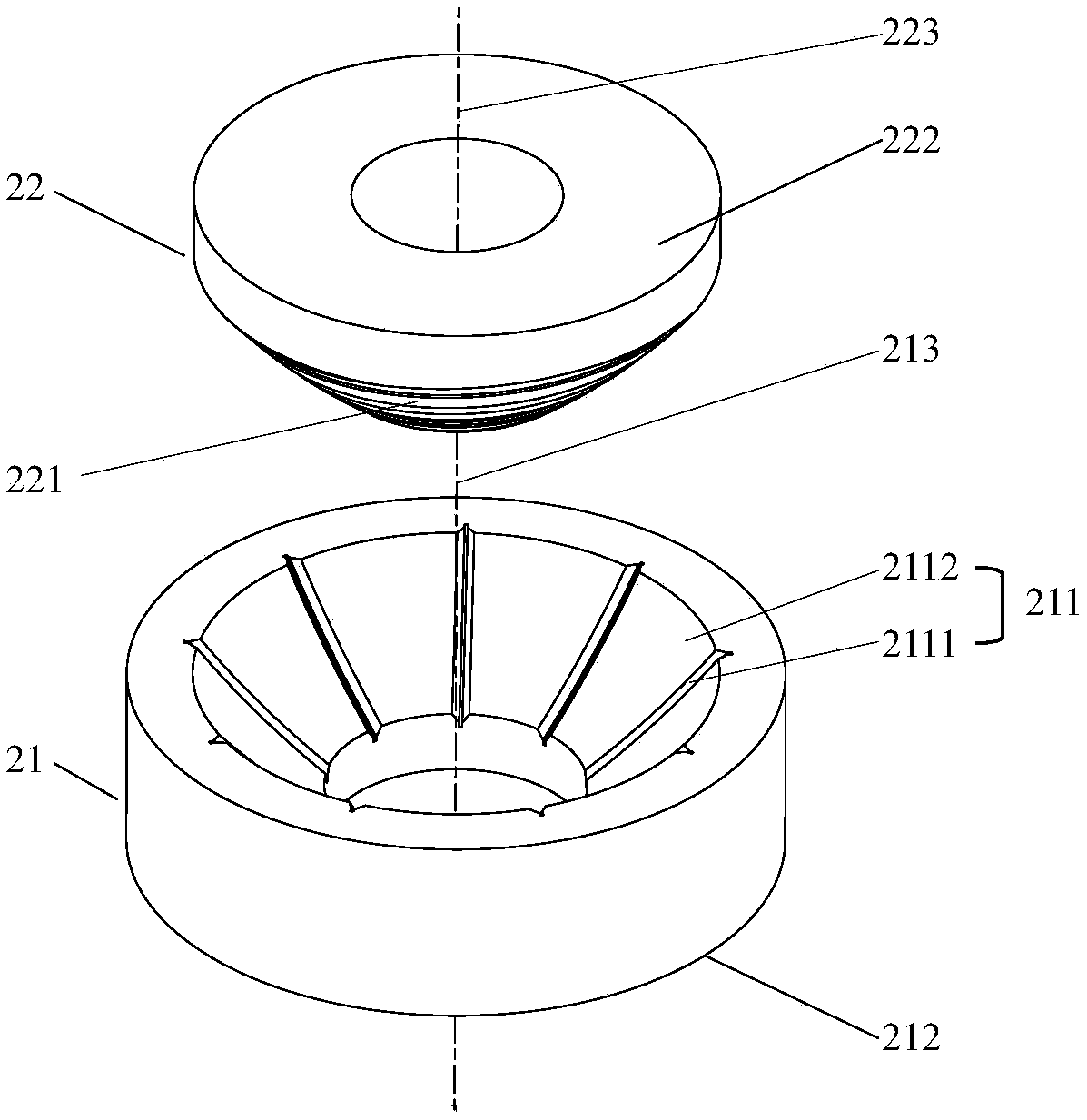

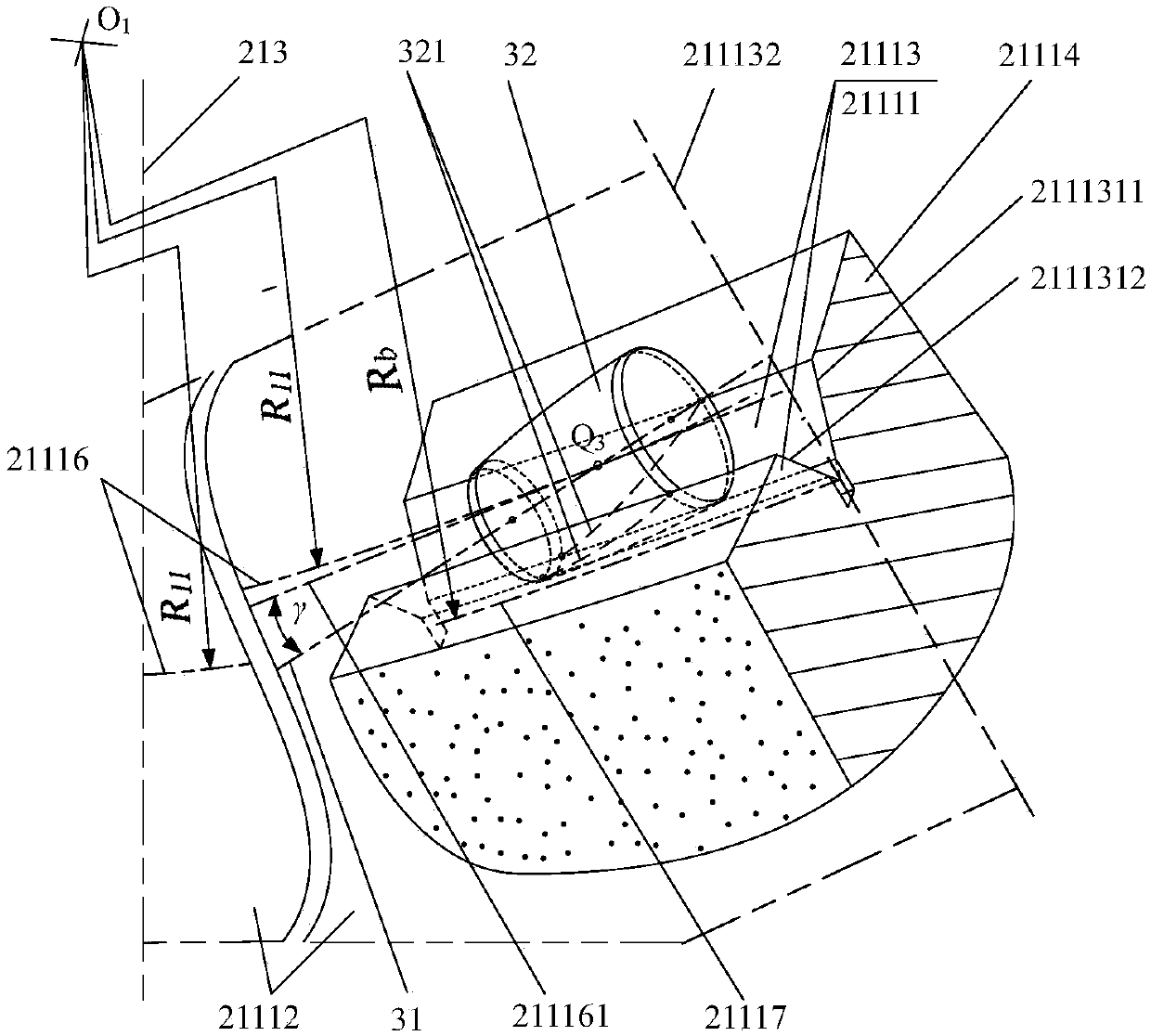

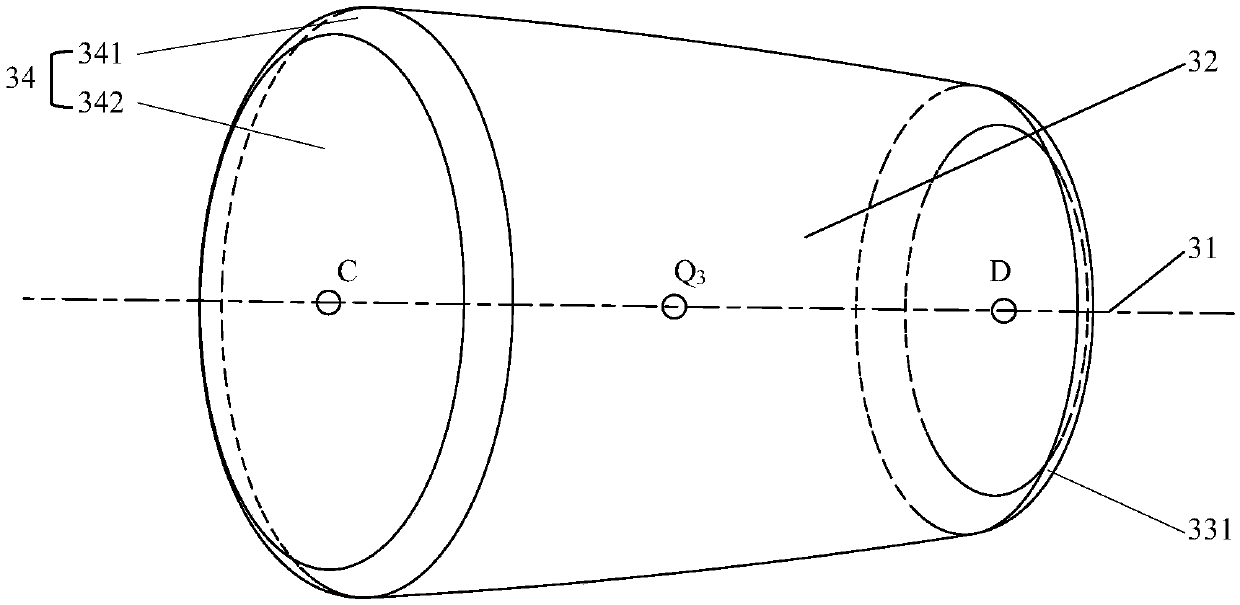

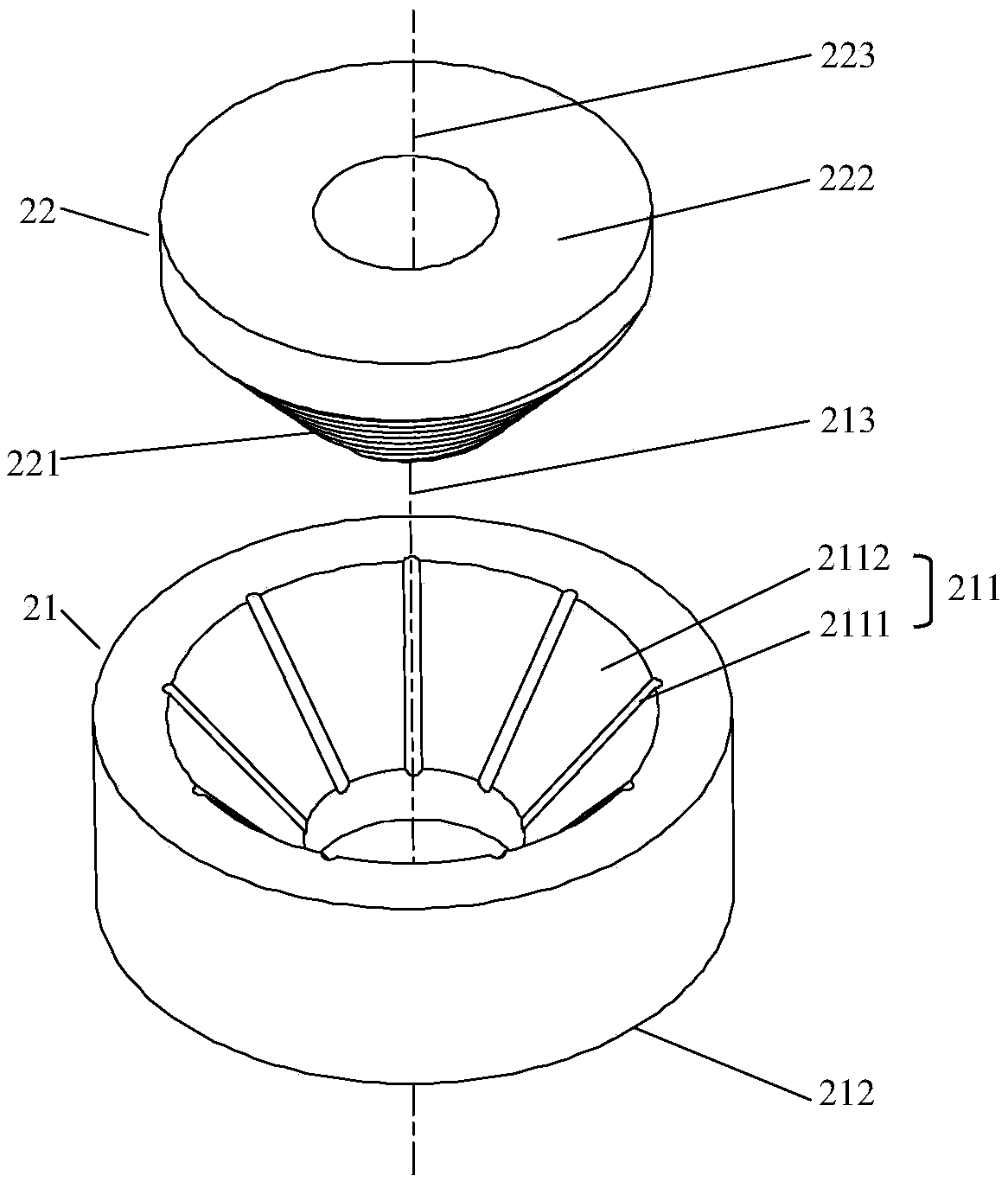

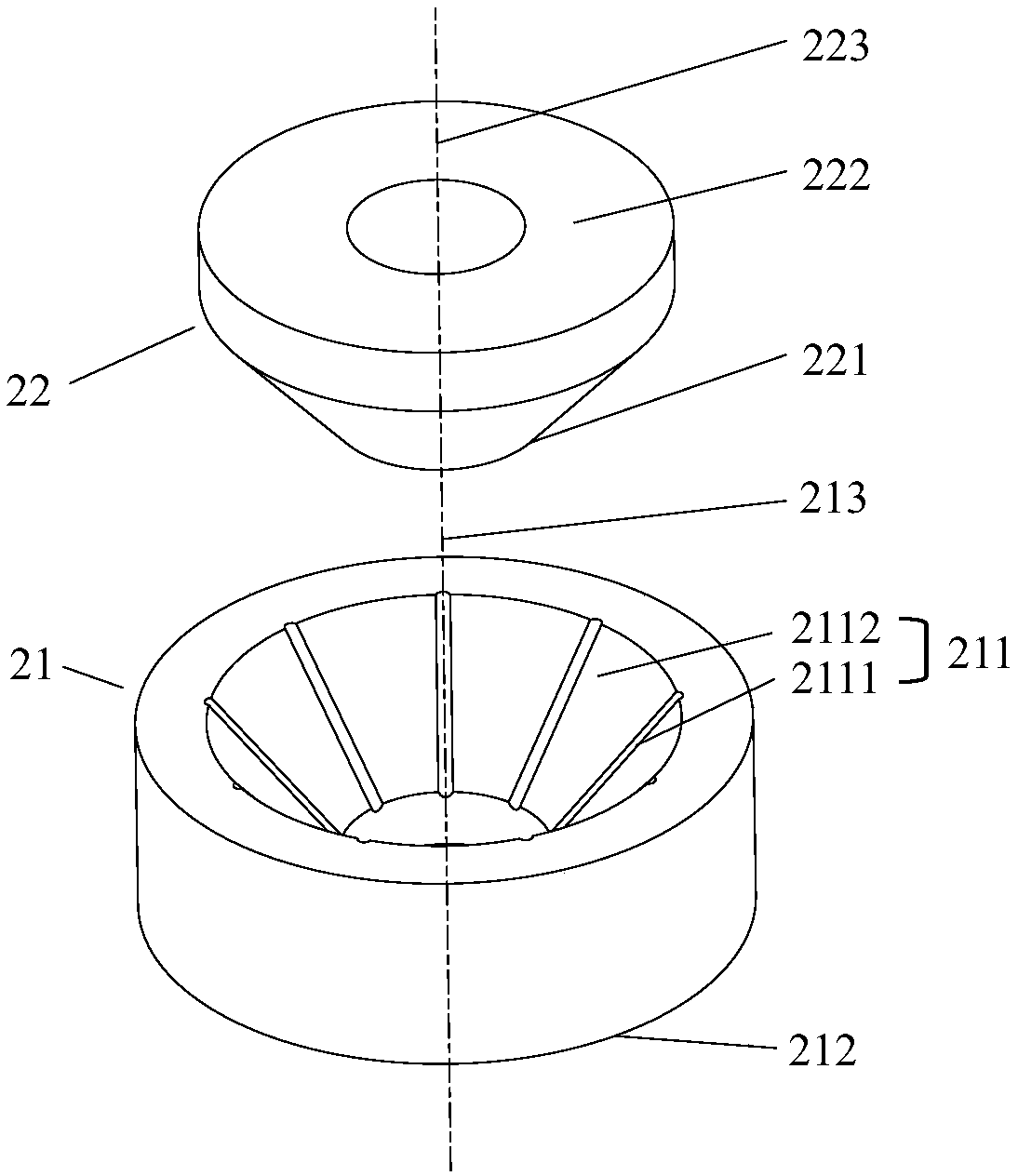

Grinding disc used for precise processing of rolling surface of tapered roller and equipment method

PendingCN108723979AReduce removalRemove comprehensivelyLapping machinesLapping toolsCircular discEngineering

The invention discloses grinding equipment used for precise processing of the rolling surface of a tapered roller and a grinding disc sleeving piece. The grinding equipment comprises main equipment, the grinding disc sleeving piece and a roller circular disc external system, the main equipment comprises a base, an upright column, a beam, a sliding table, an upper tray, a lower tray, an axial loading device and a main shaft device, and the roller circular disc external system comprises a roller collecting device, a roller transporting system, a roller arrangement system and a roller feed-in mechanism; the grinding disc sleeving piece comprises a pair of coaxially arranged first and second grinding discs of which the front surfaces are opposite to each other, the front surface of the first grinding disc comprises a set of linear grooves distributed on the base surface (right circular conical surface) of the first grinding disc in a radial form, the front surface of the second grinding disc comprises one or more spiral grooves distributed on the base surface (right circular conical surface) of the second grinding disc, and the sum of the cone apex angles of the base surfaces of the first and second grinding discs is 360 degrees. The grinding equipment has the precise processing capacity to process the rolling surfaces of mass tapered rollers.

Owner:TIANJIN UNIV

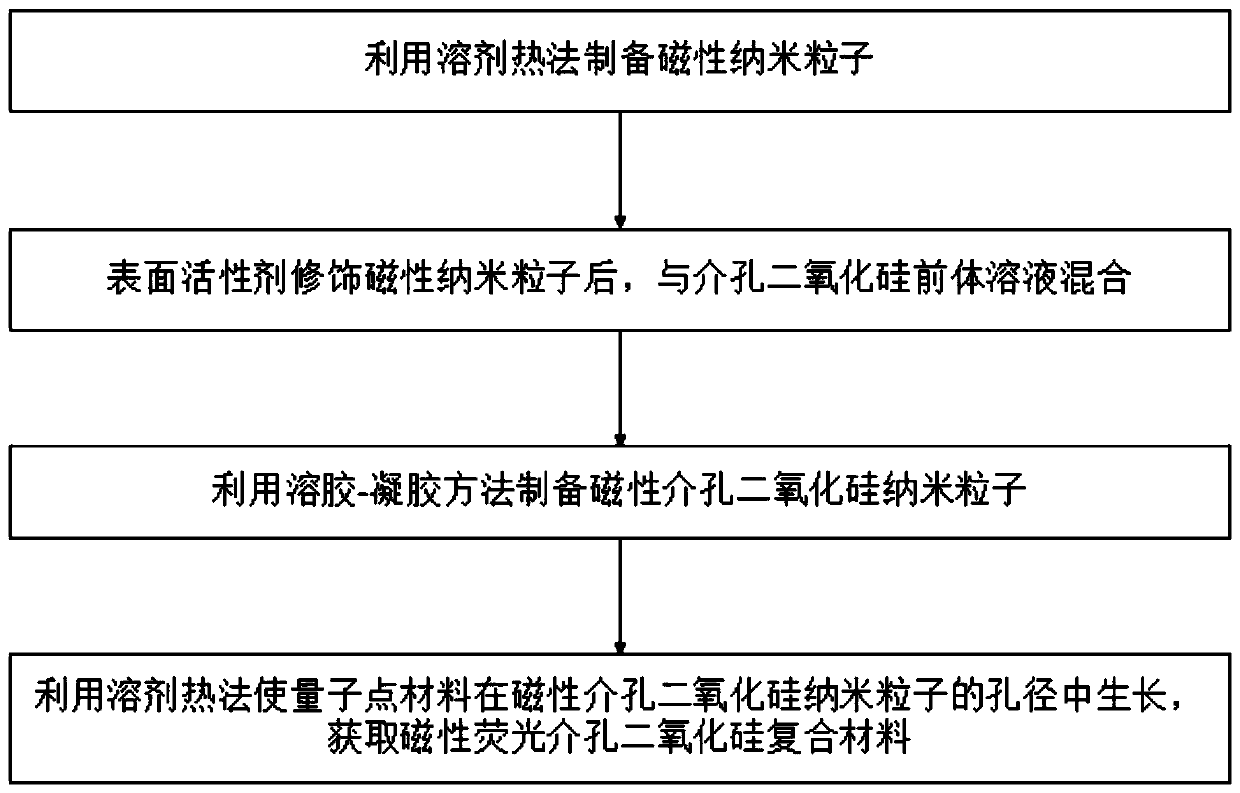

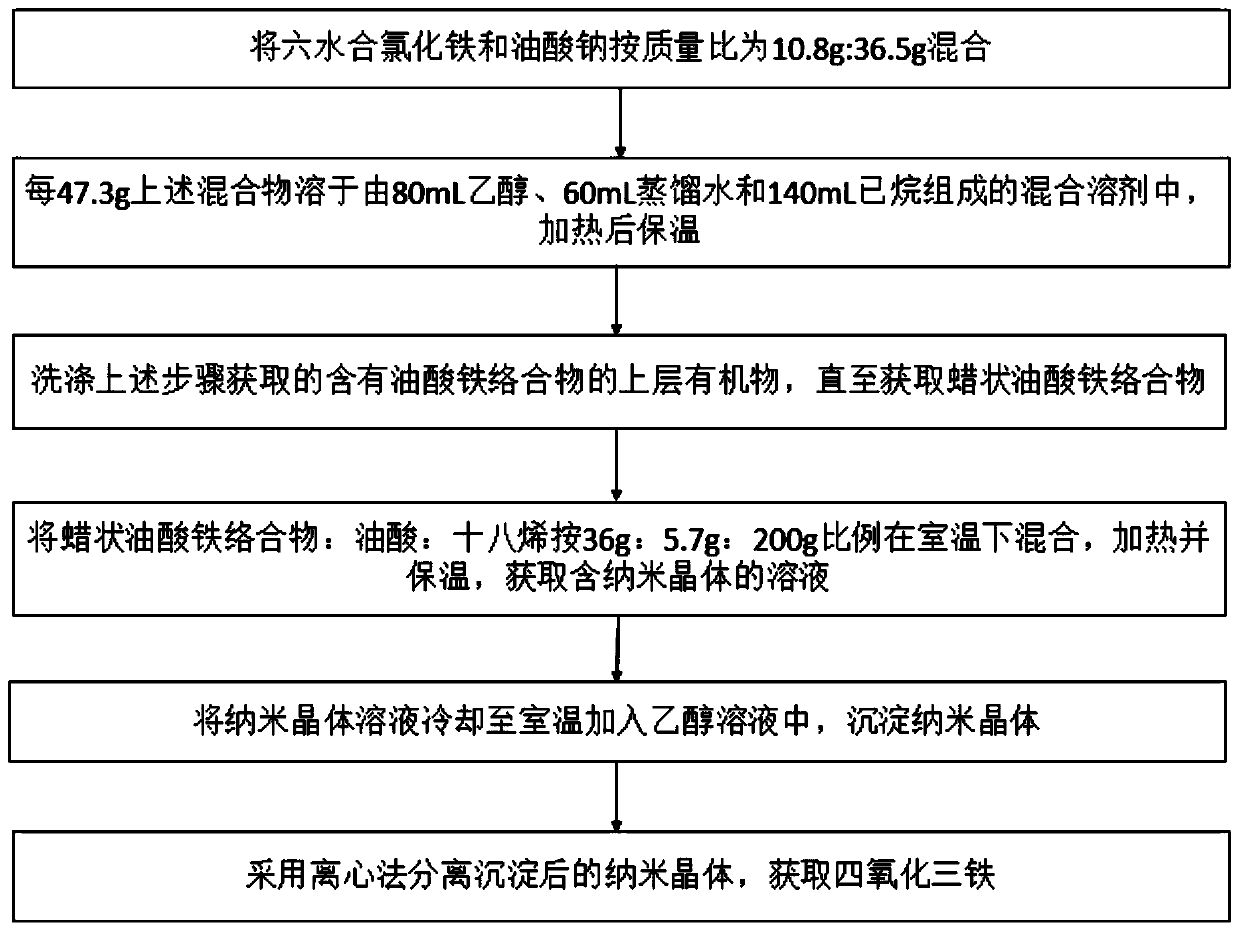

Magnetic fluorescent mesoporous silica composite nano material and preparation method thereof

InactiveCN111423880AAchieve integrationInhibit sheddingMaterial nanotechnologyPowder deliveryFluoProbesActive agent

The invention discloses a magnetic fluorescent mesoporous silica composite nano material and a preparation method thereof, and belongs to the field of nano composite materials. The composite materialis of a core-shell structure, a core is a magnetic nanoparticle and is used as a contrast agent for nuclear magnetic resonance imaging, a thermal release agent in magnetic thermal therapy and a driverfor targeted drug therapy, the shell is mesoporous silica and is used as a drug or gene carrier, and the quantum dot material is located in the pore diameter of the mesoporous silica and is used as afluorescent probe. The method comprises the following steps: preparing magnetic nanoparticles by using a solvothermal method, modifying the magnetic nanoparticles with a surfactant, mixing the magnetic nanoparticles with a mesoporous silica precursor solution, after mixing, preparing magnetic mesoporous silica nanoparticles with a core-shell structure by adopting a sol-gel method, and enabling the quantum dot material to grow in situ in the aperture of the magnetic mesoporous silica nanoparticle by adopting a thermal injection method. The composite material provided by the invention integrates diagnosis and treatment functions, and can improve the diagnosis accuracy and the treatment efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

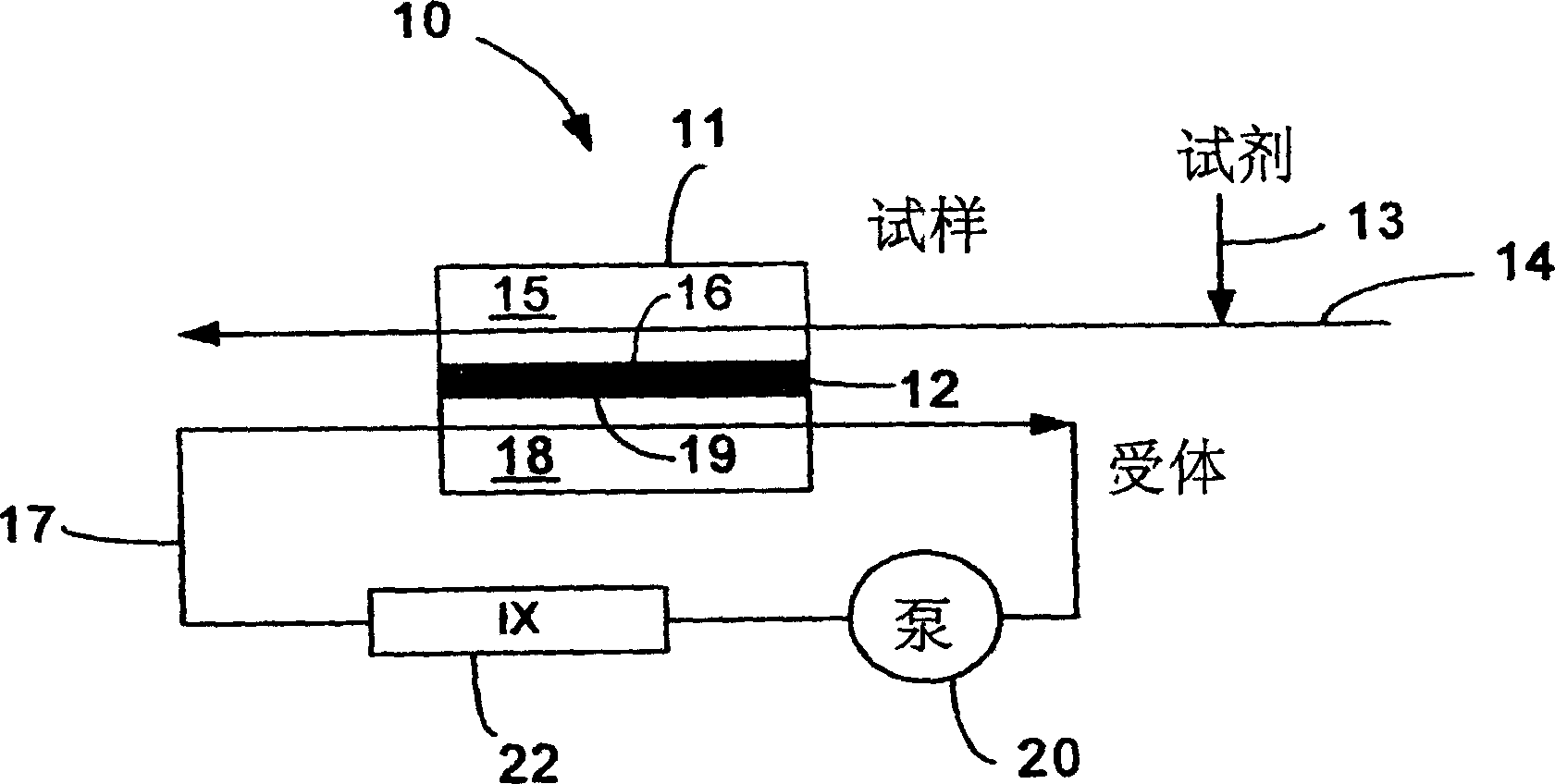

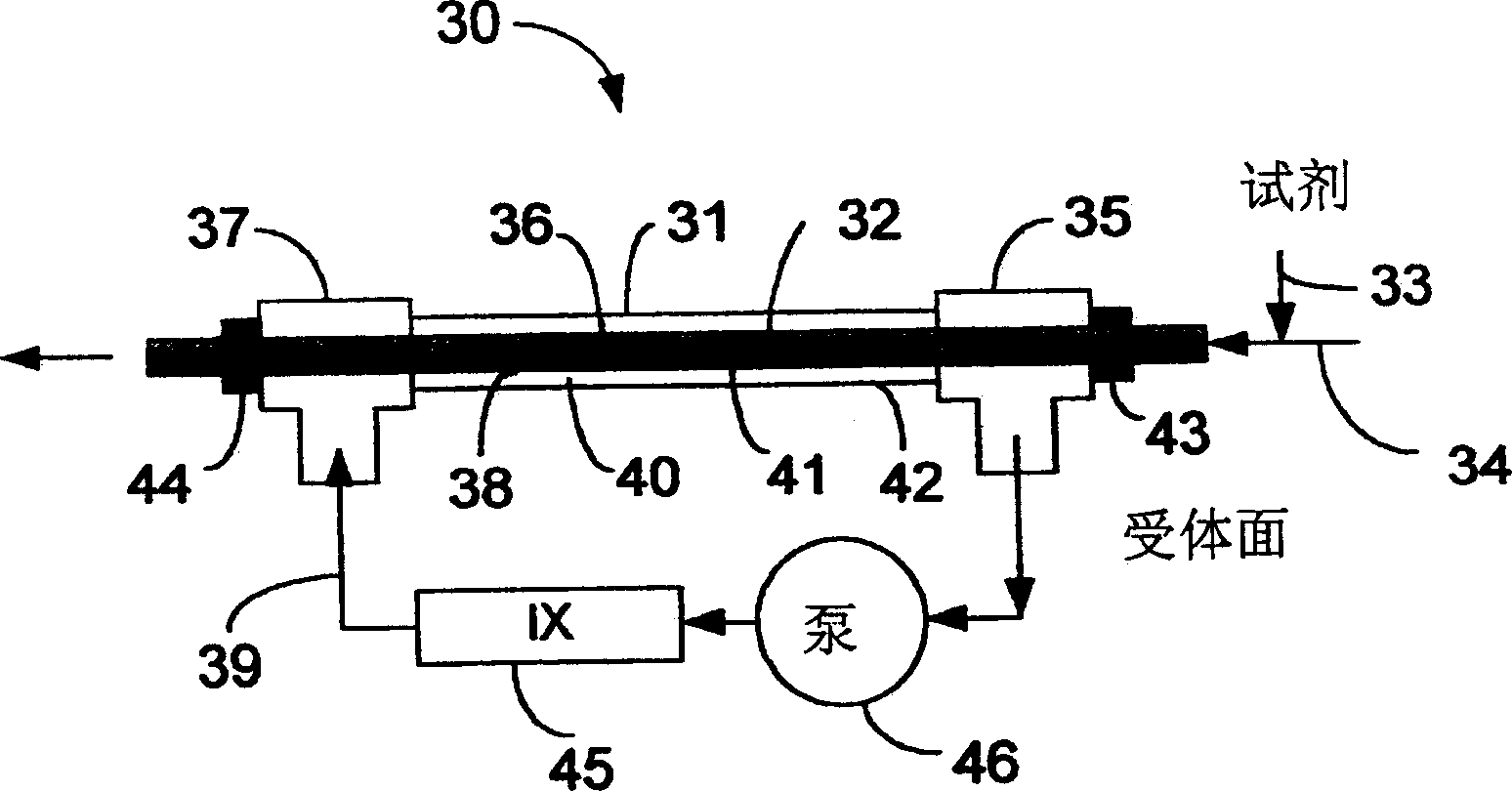

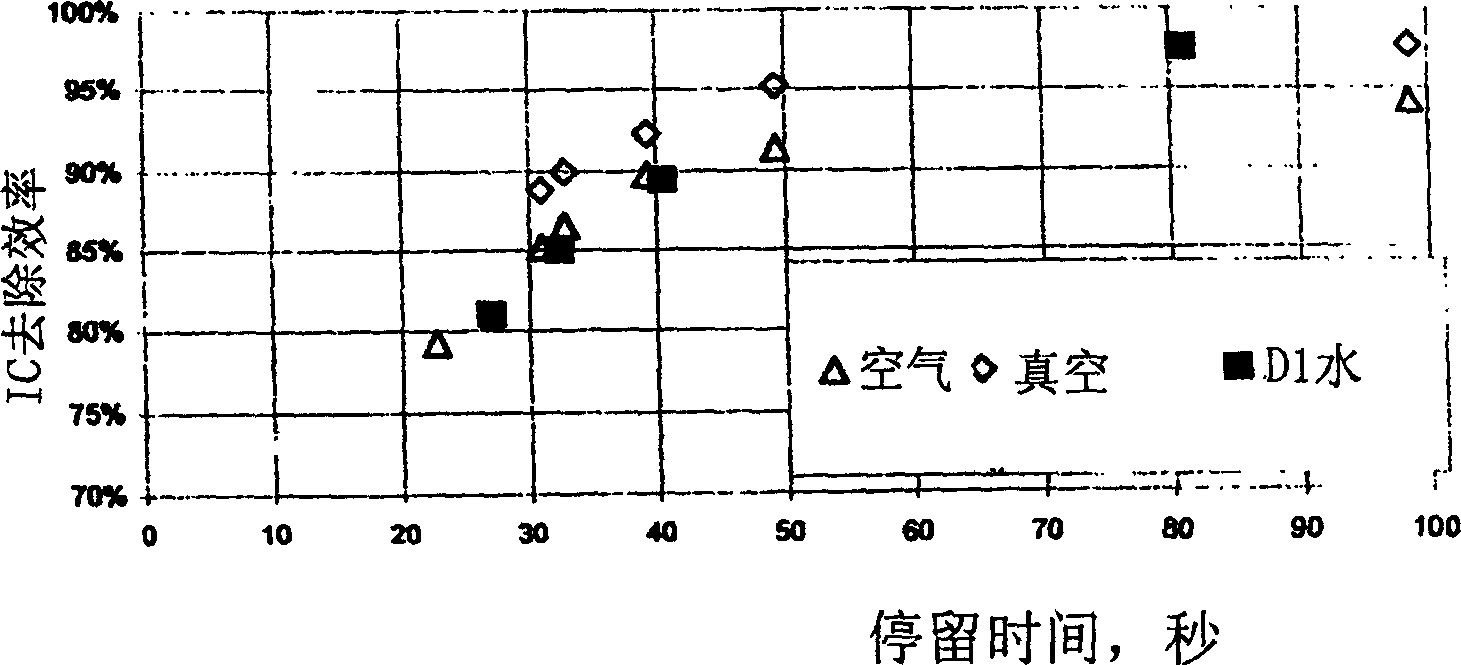

Inorganic carbon removal

InactiveCN1688879ARemove lessWater/sludge/sewage treatmentOrganic anion exchangersTotal organic carbonVolatile organic compound

Owner:SIEVERS INSTR

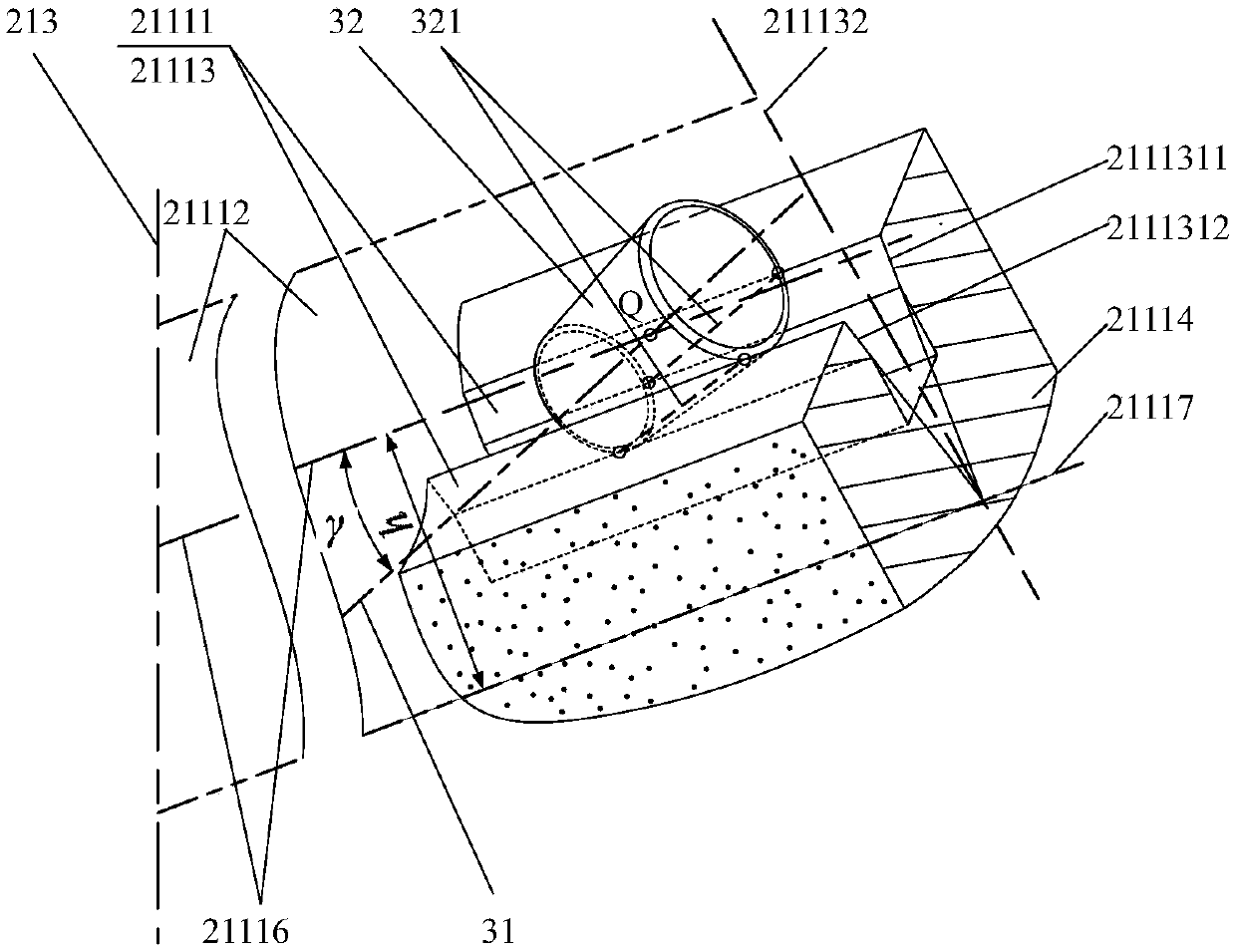

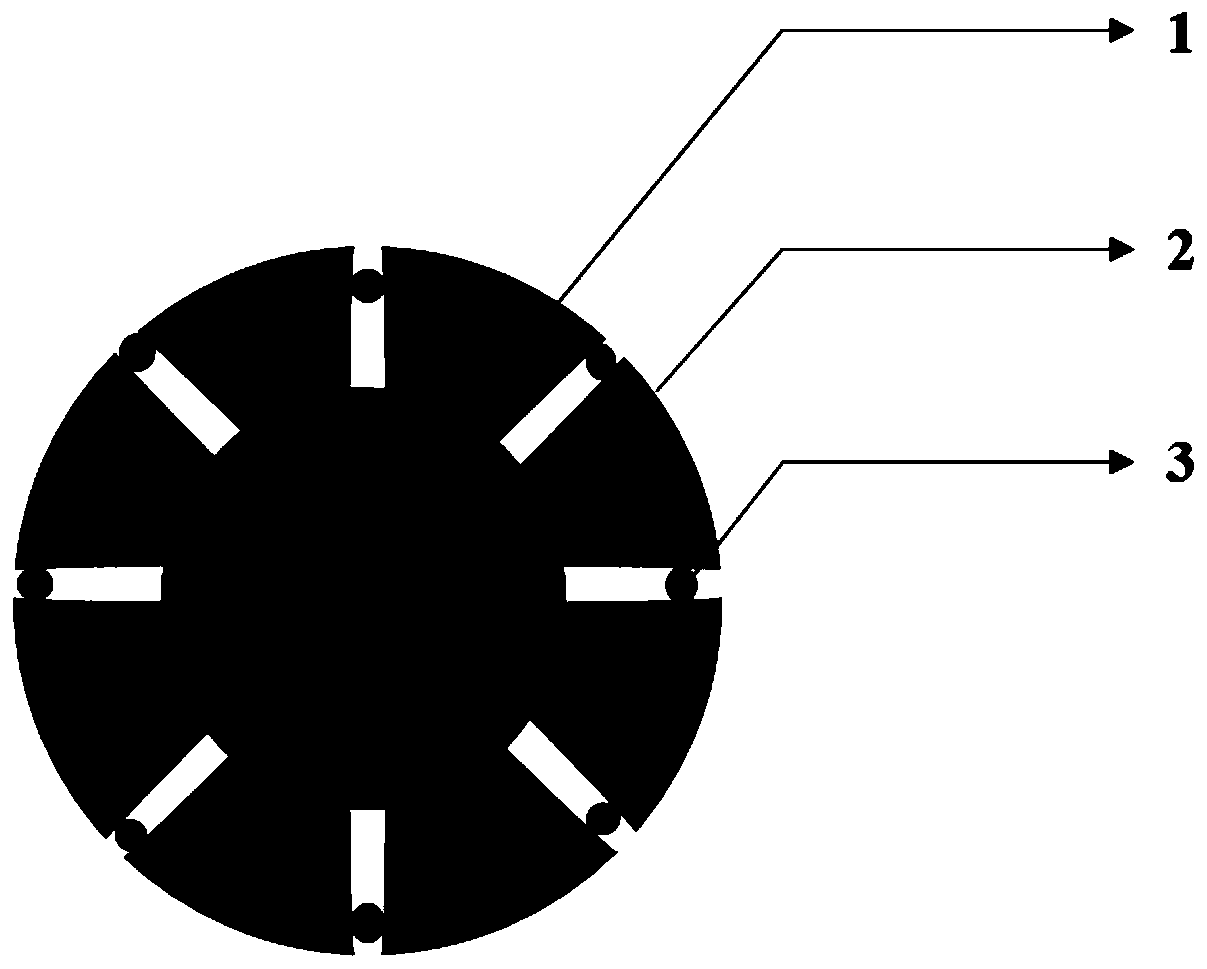

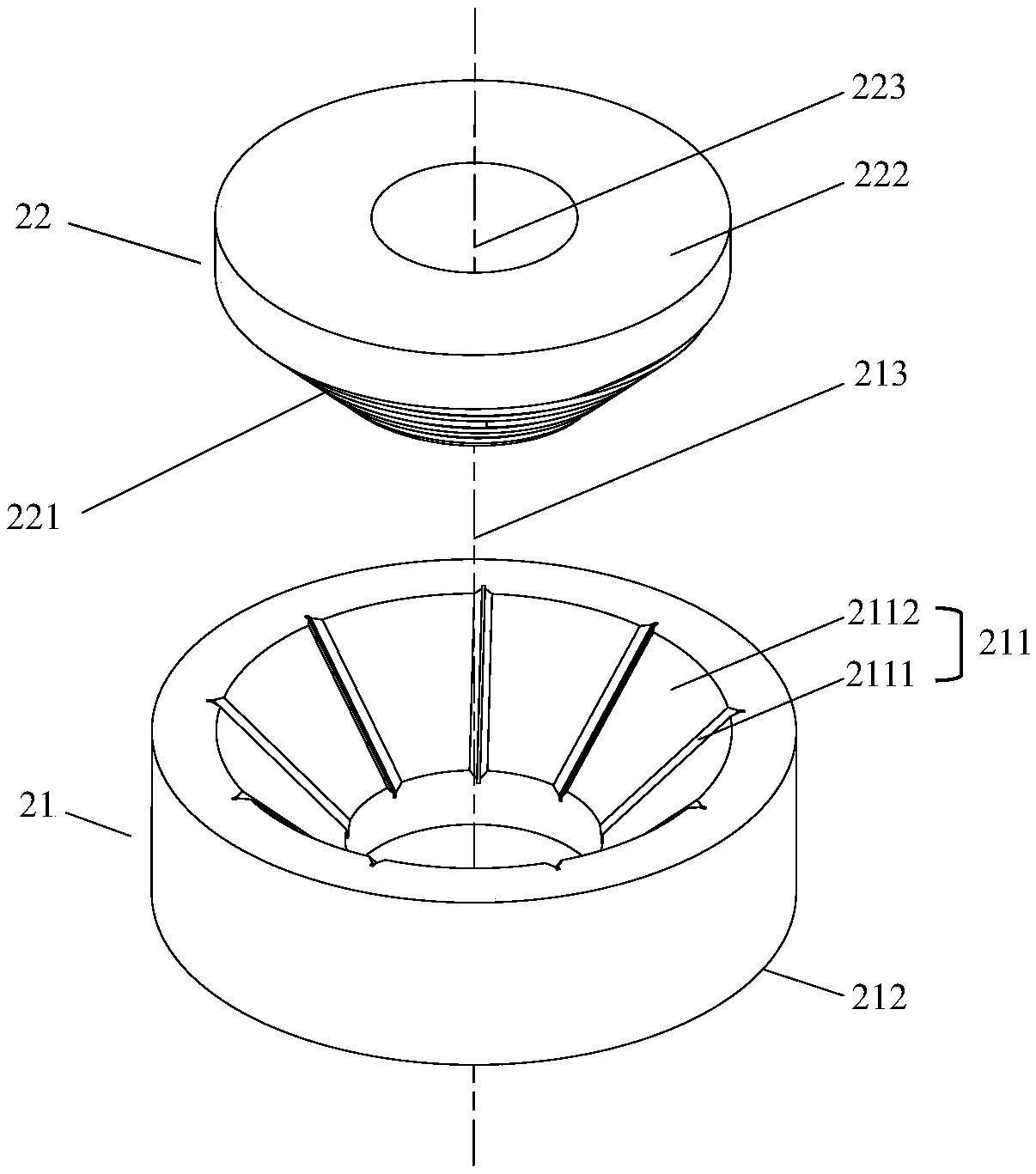

Magnetic grinding disc, equipment and method for tapered roller rolling surface finishing

PendingCN108723982AReduce removalRemove comprehensivelyLapping machinesLapping toolsDemagnetizing deviceSurface finish

The invention discloses grinding equipment and a magnetic grinding disc kit for tapered roller rolling surface finishing of ferromagnetic materials. The grinding equipment comprises a main body, the magnetic grinding disc kit and a roller circulation disc outer system. The main body includes a base, a column, a beam, a slide table, an upper tray, a lower tray, an axial loading device and a spindledevice. The roller circulation disc outer system includes a roller collecting device, a roller demagnetizing device, a roller conveying system, a roller finishing mechanism and a roller feeding mechanism. The magnetic grinding disc kit includes a pair of coaxial first and second grinding discs of which the front surfaces are disposed opposite to each other. The front surface of the first grindingdisc includes a set of linear grooves radially distributed on a base surface (positive conical surface) of the first grinding disc, the front surface of the second grinding disc includes one or morespiral grooves distributed in the base surface (positive conical surface) of the second grinding disc, and a ring-shaped magnetic structure is embedded inside a base body. The grinding equipment has the finishing ability of multitudinous ferromagnetic material tapered roller rolling surfaces.

Owner:TIANJIN UNIV

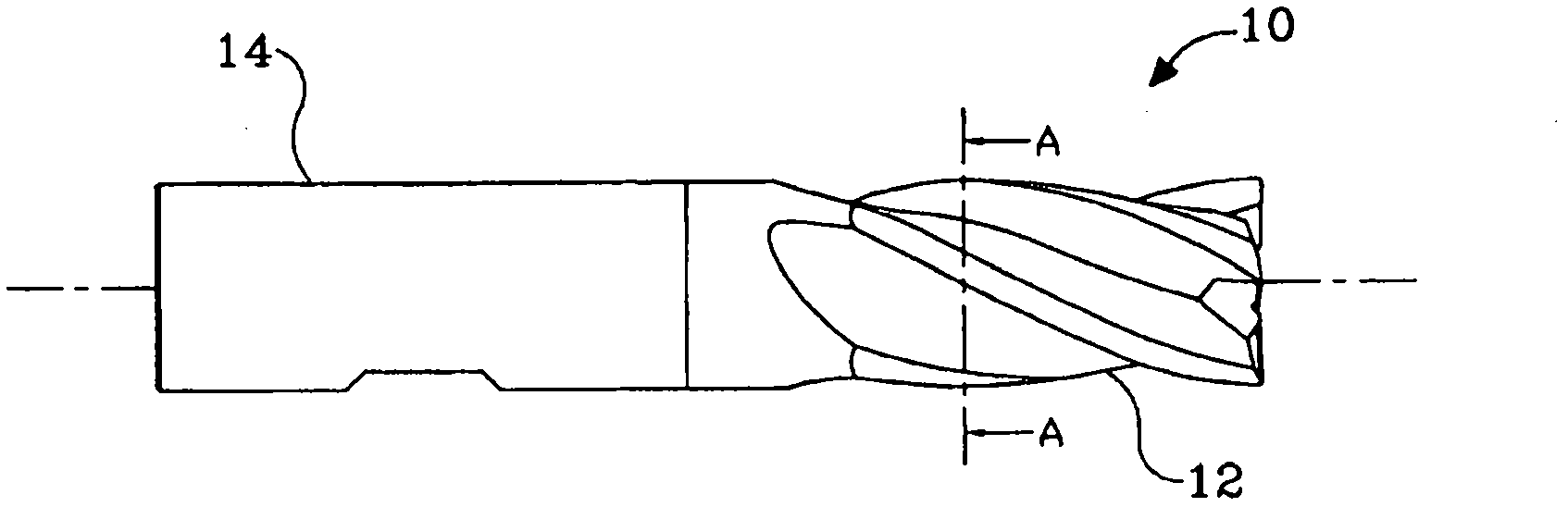

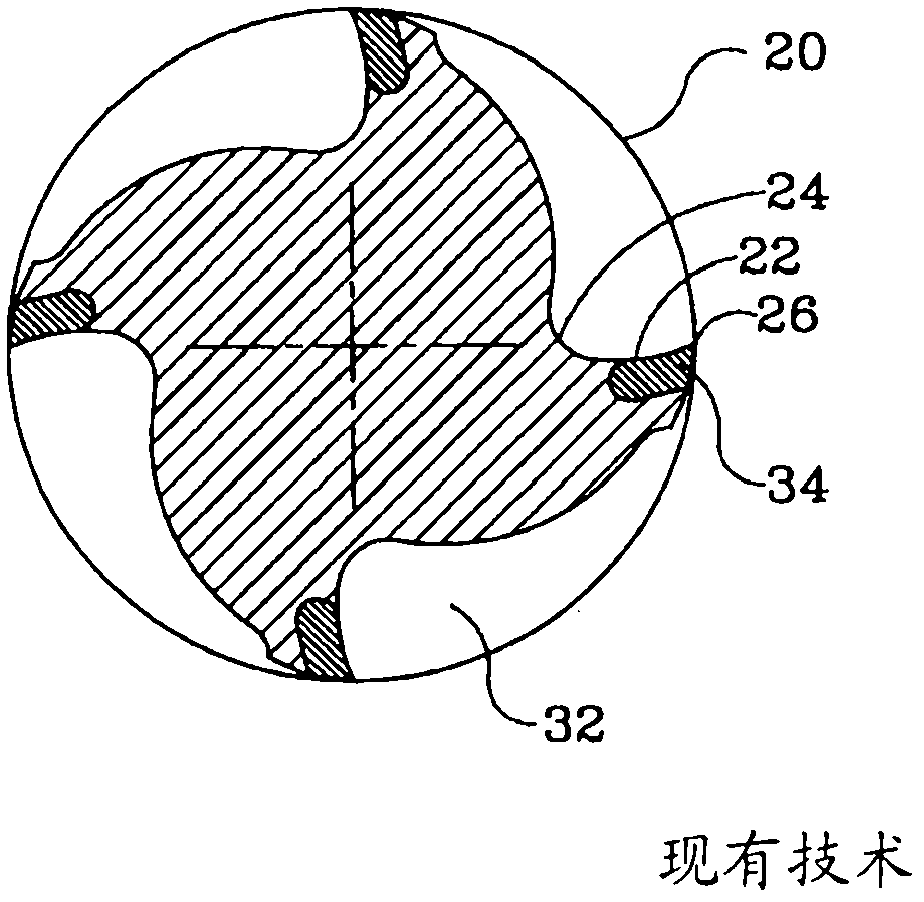

Rotary cutting tool having a cutting edge formed of veined PCD

A rotary cutting tool (40) formed from a blank (42) having at least one tooth (58) including a root (50) and a cutting edge (46) formed of veined PCD, wherein the tooth face as viewed in a cross-section perpendicular to an axis of the cutting tool includes a first curved surface (44, 64) proximate the cutting edge, and a second curved surface (48, 68) proximate the root (50) and the first curved surface. For each cutting edge, the blank is provided with a respective groove (52) having a leading surface (54) that corresponds in shape to the first curved surface of the respective tooth.

Owner:KENNAMETAL INC

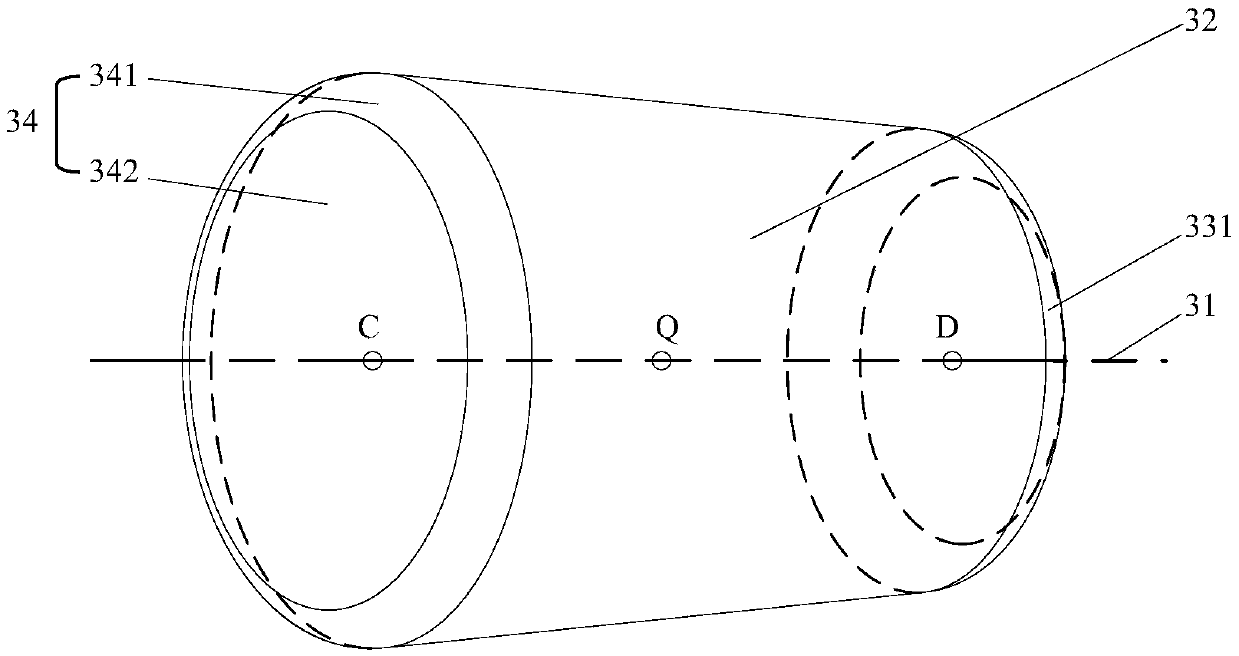

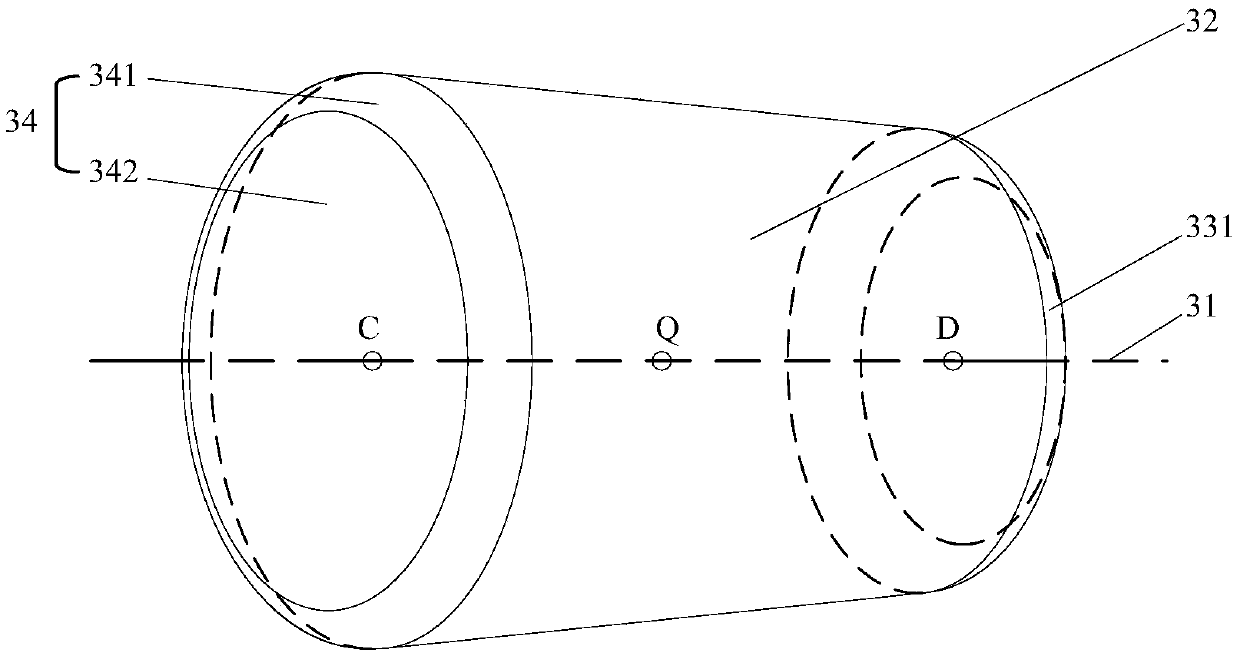

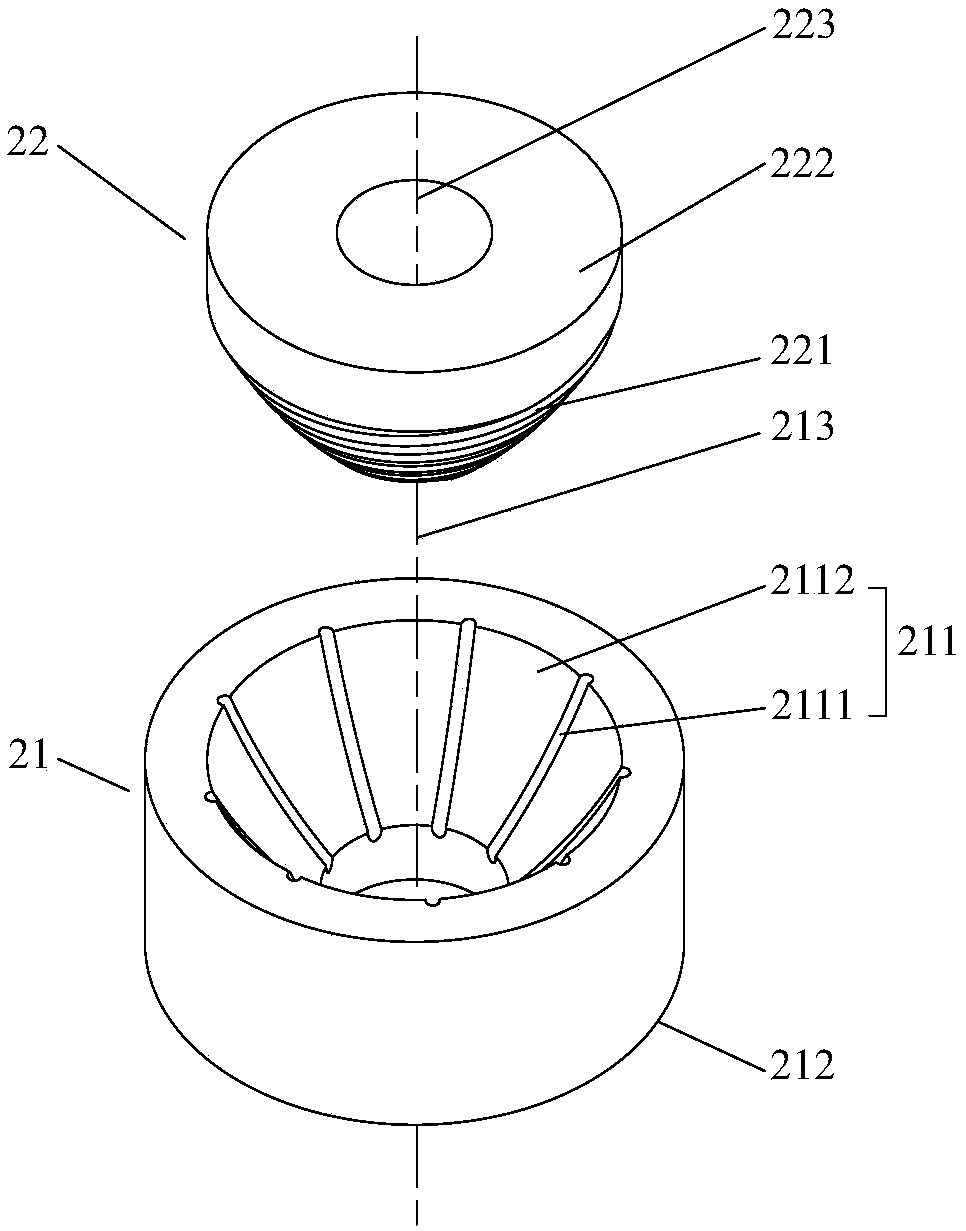

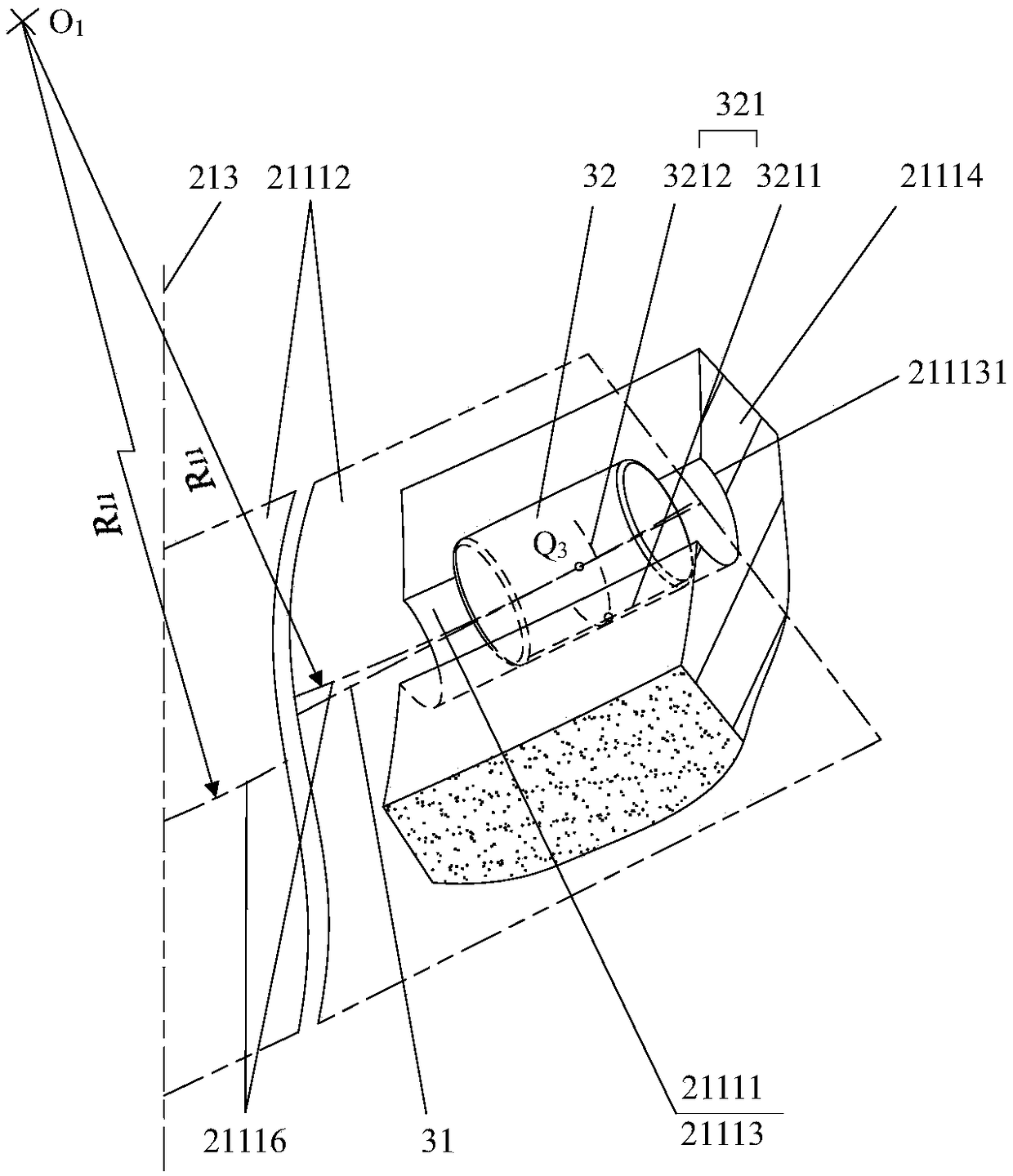

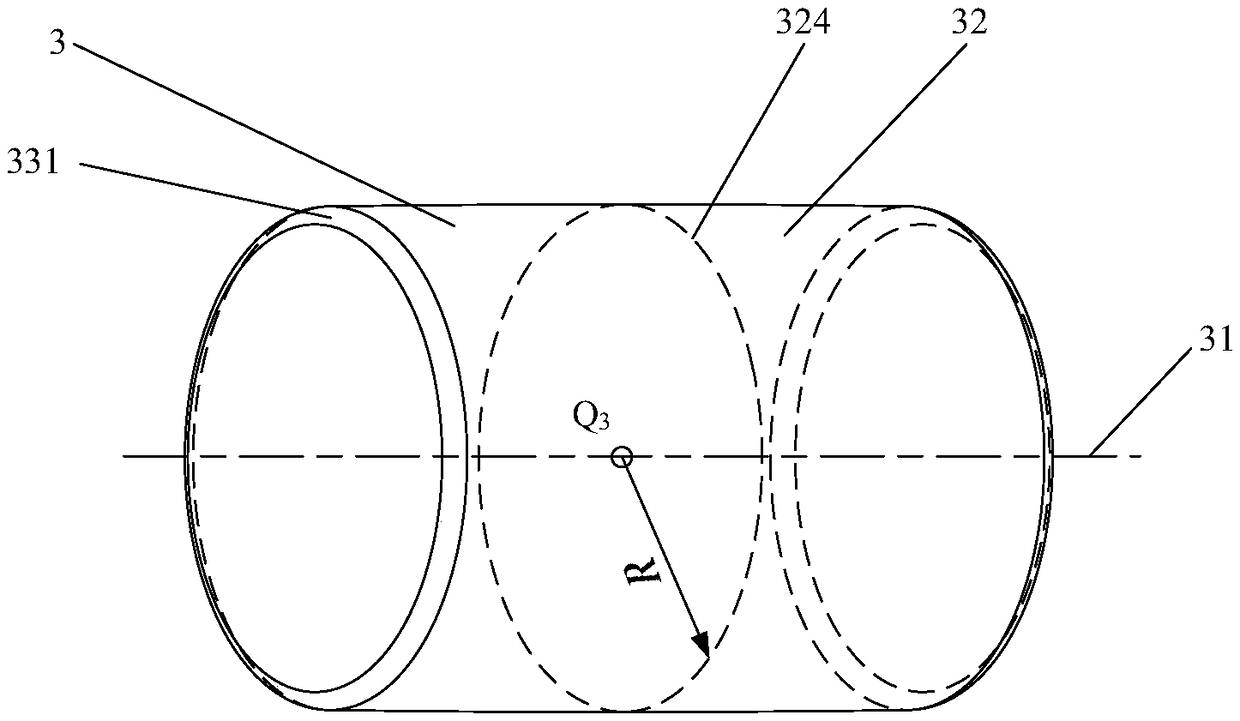

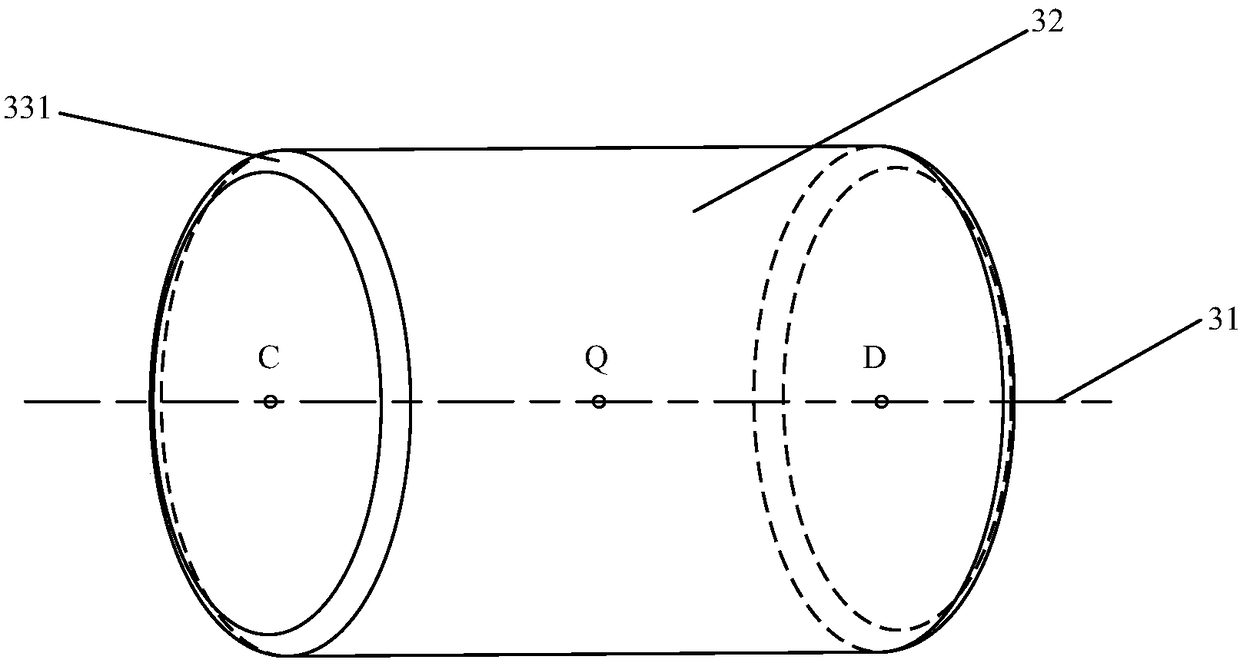

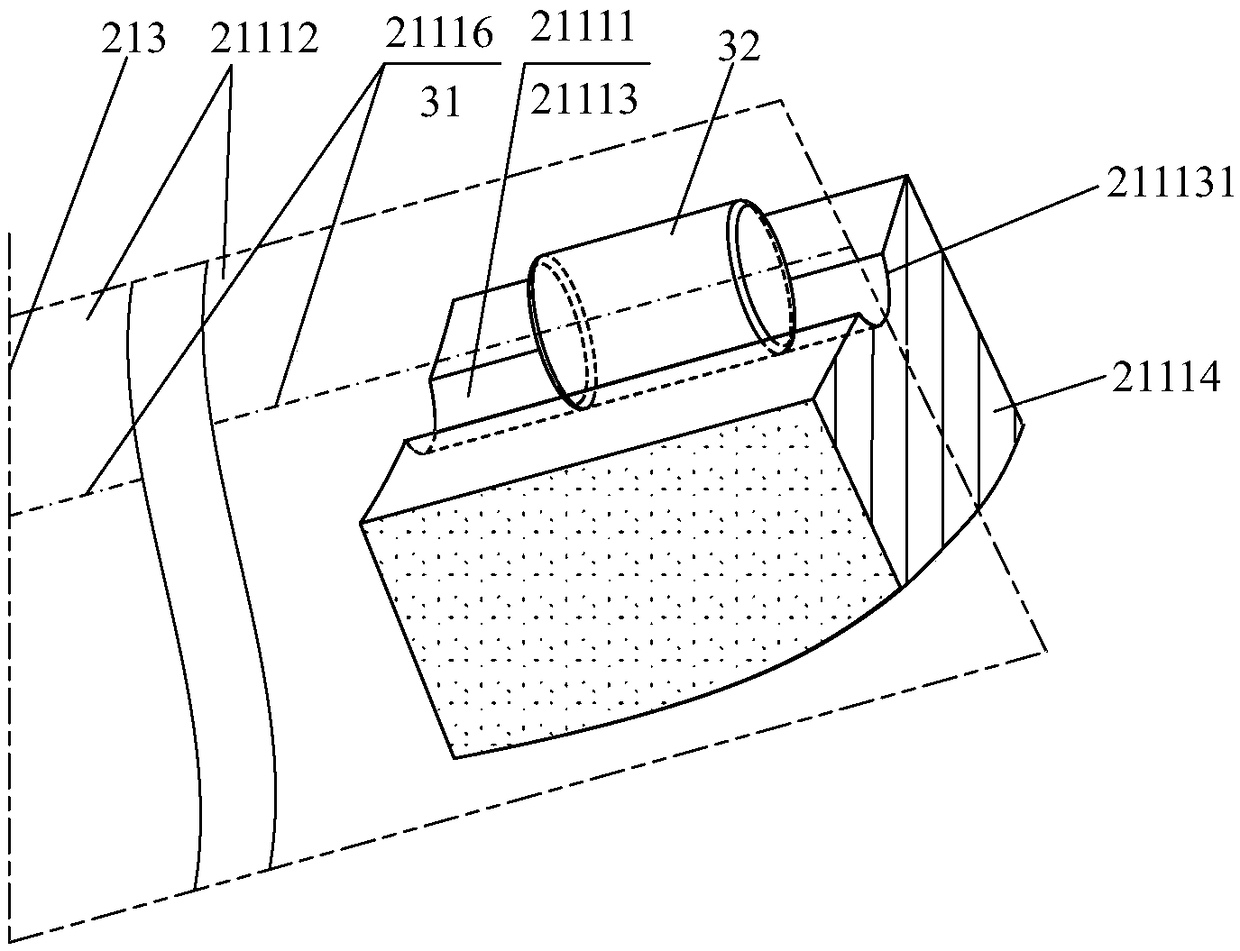

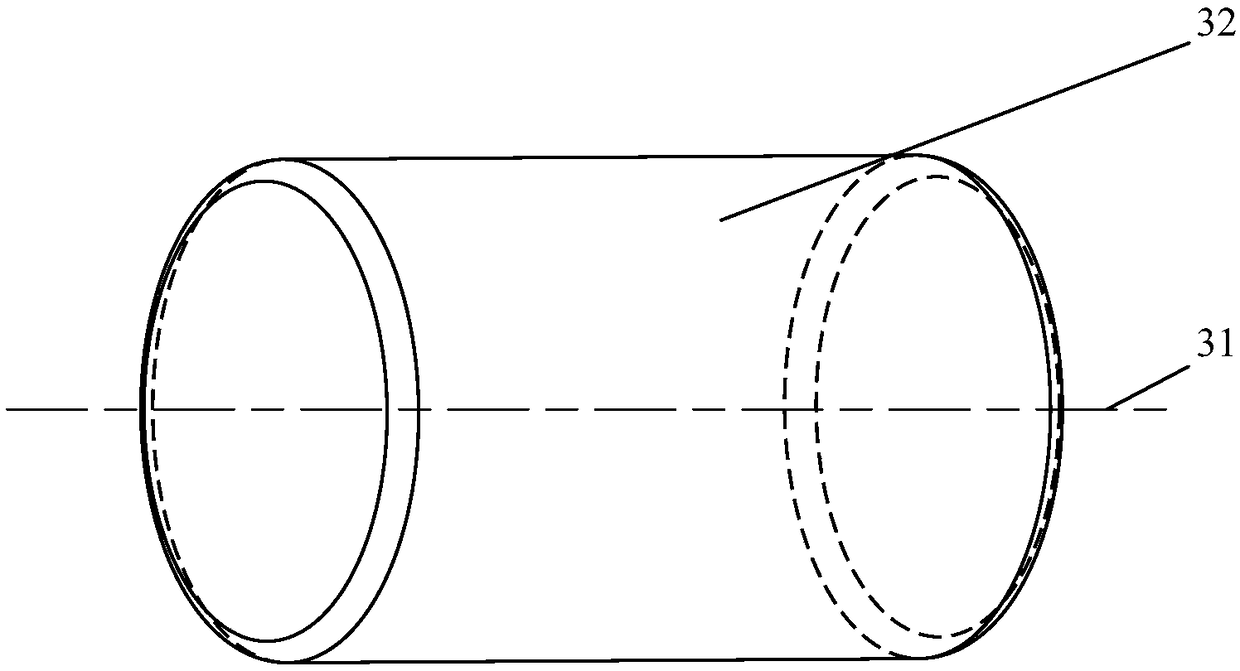

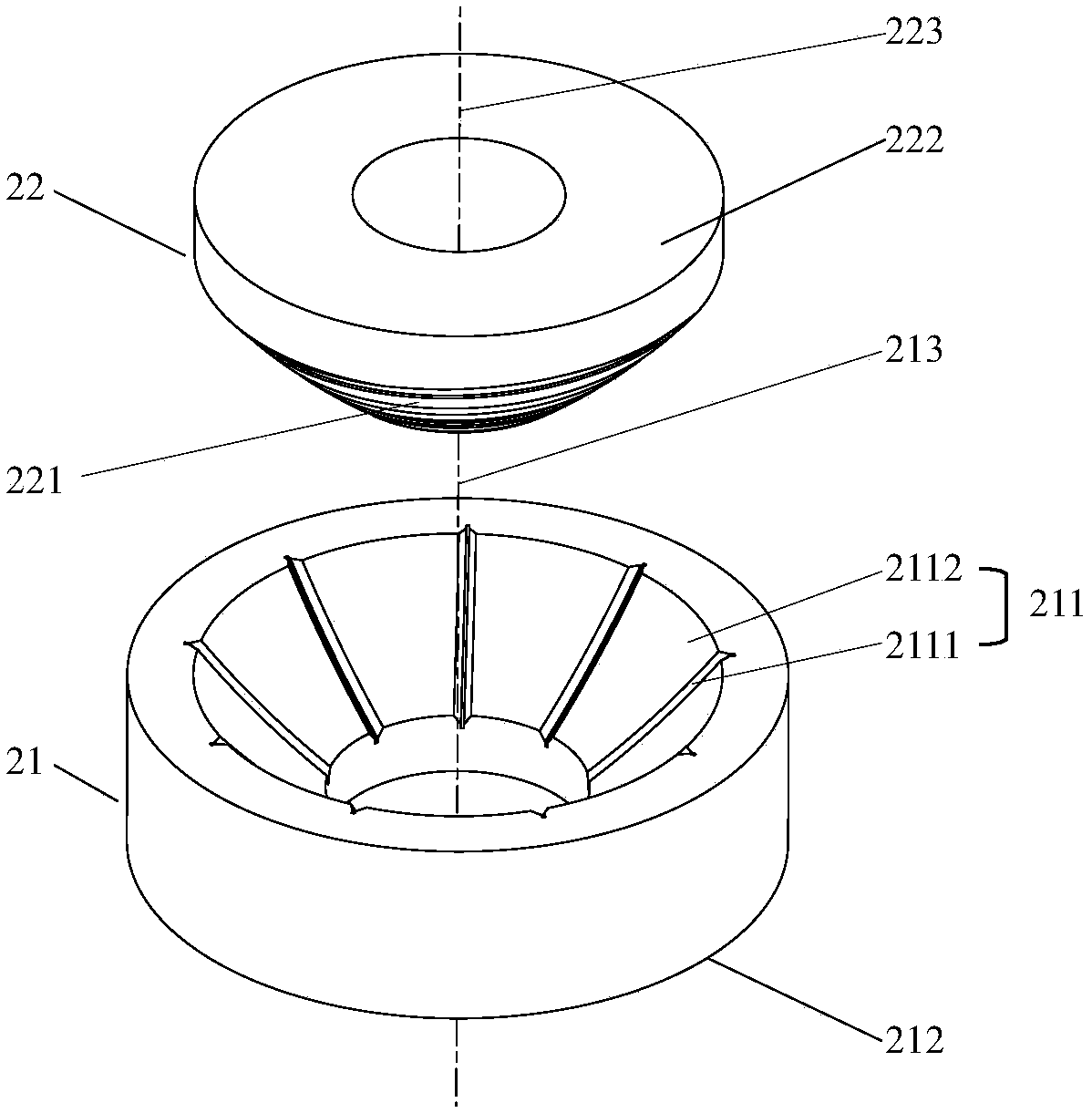

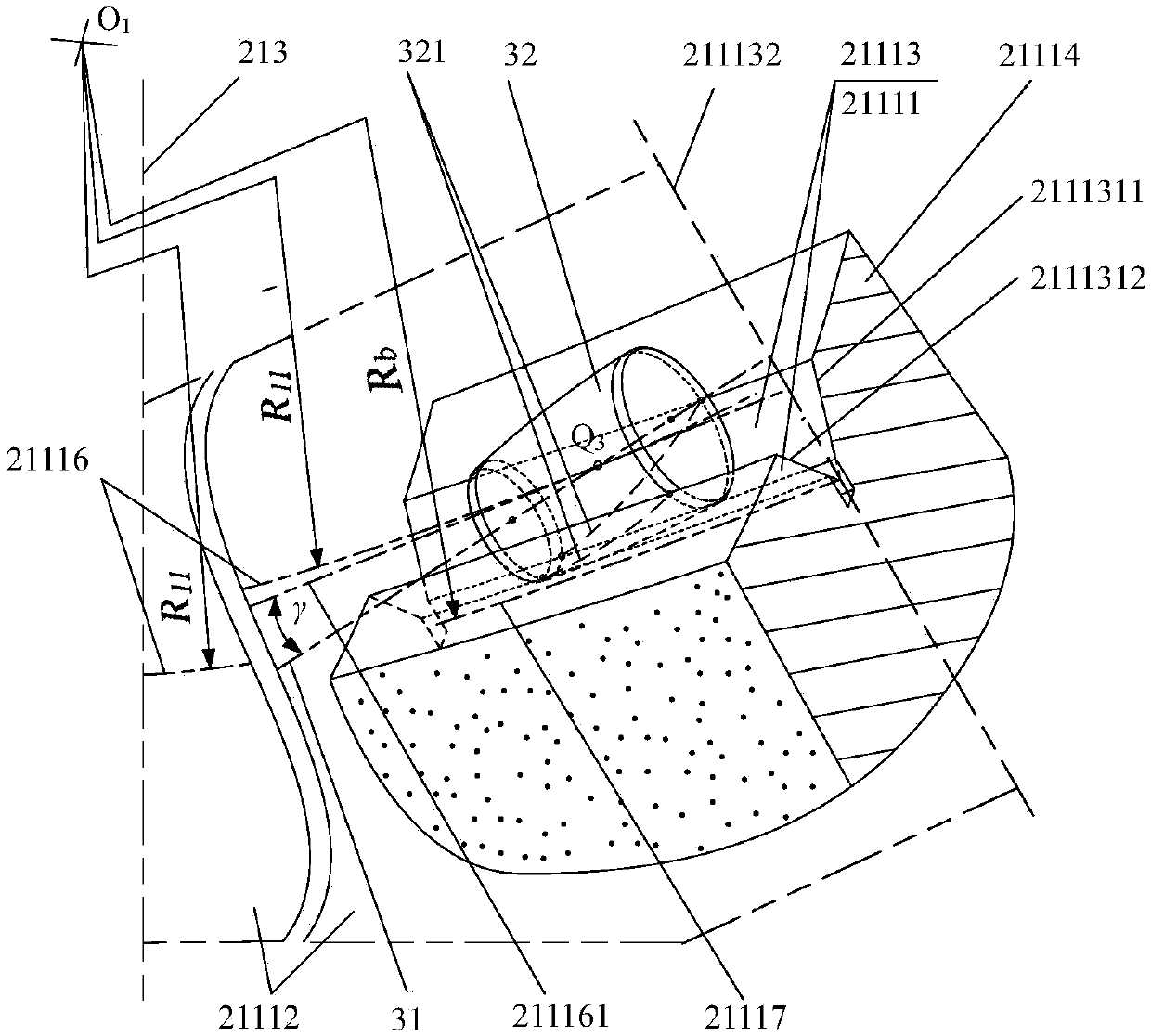

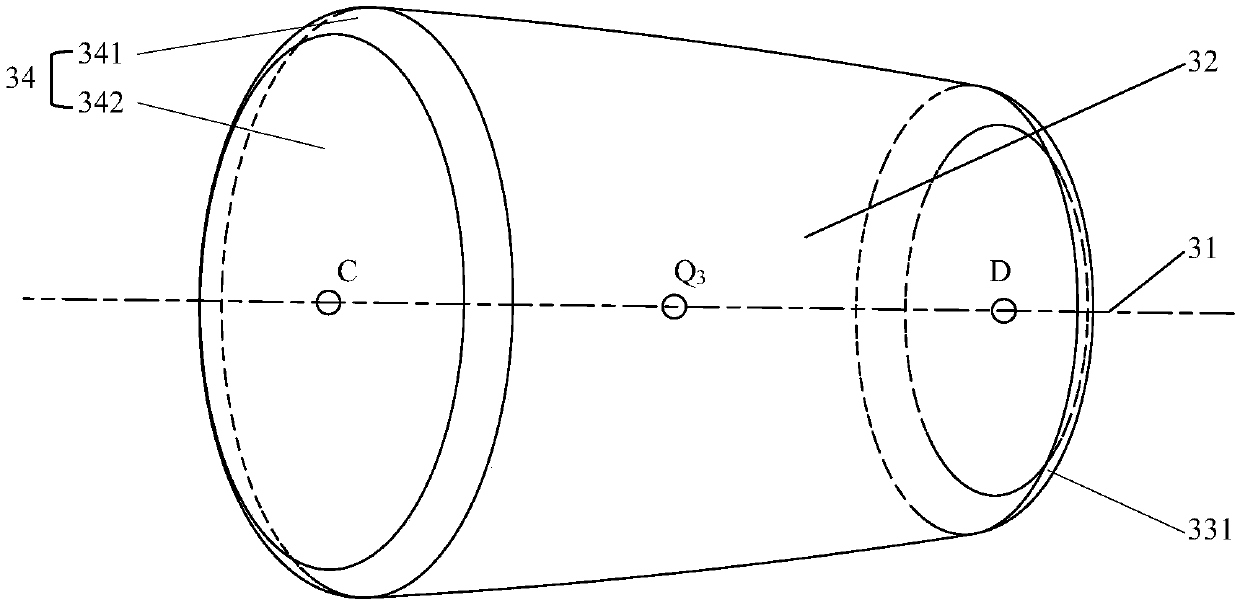

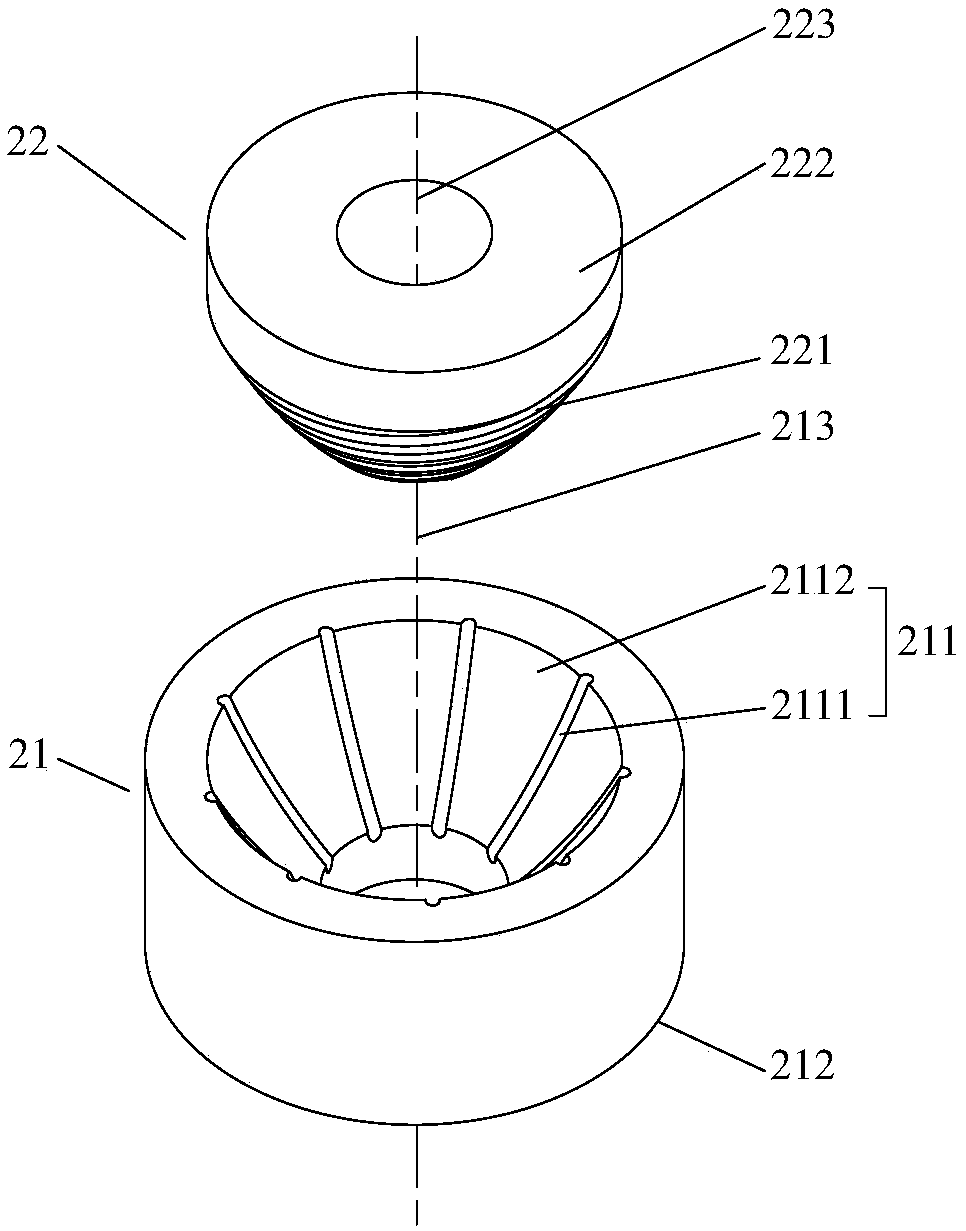

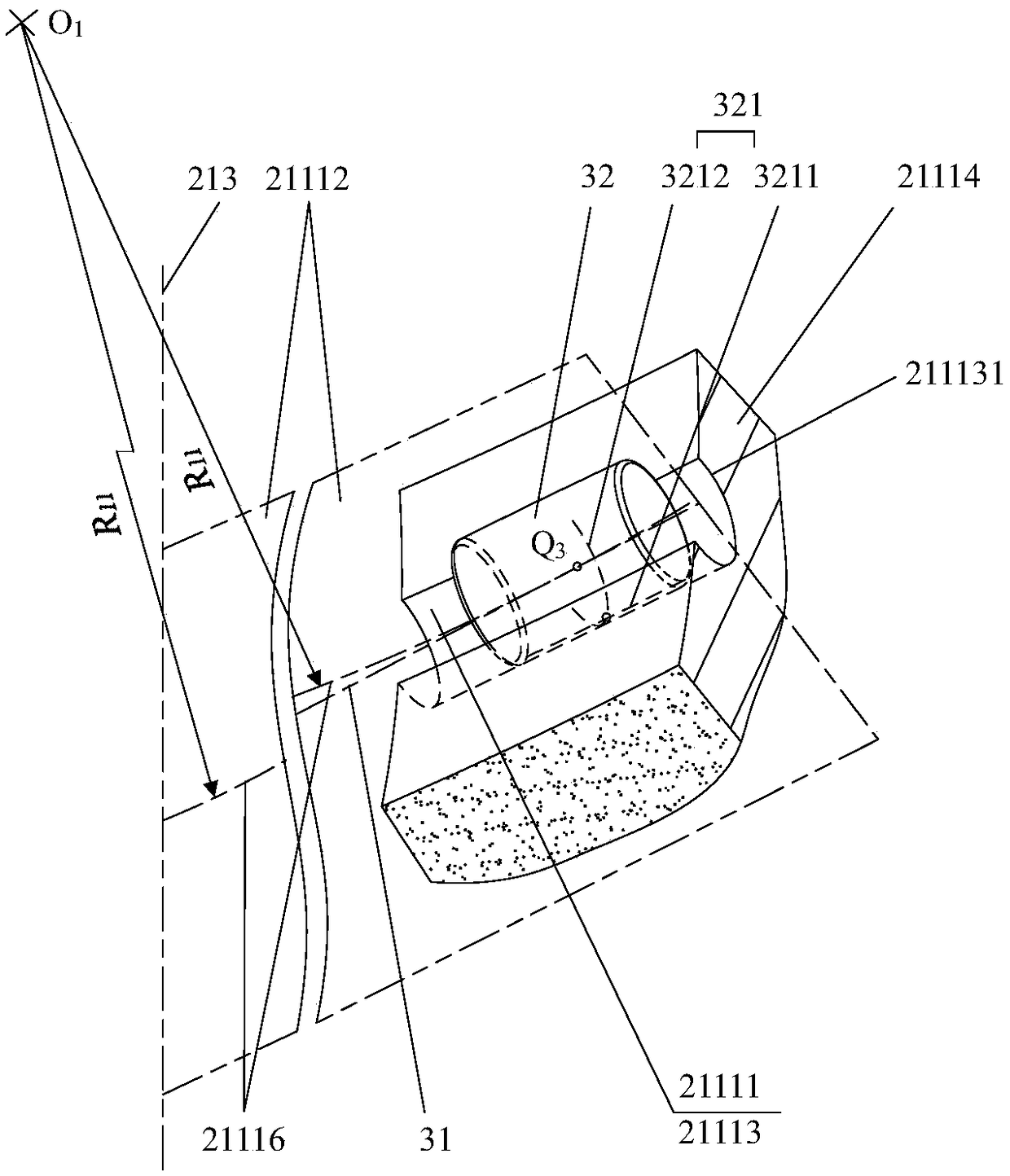

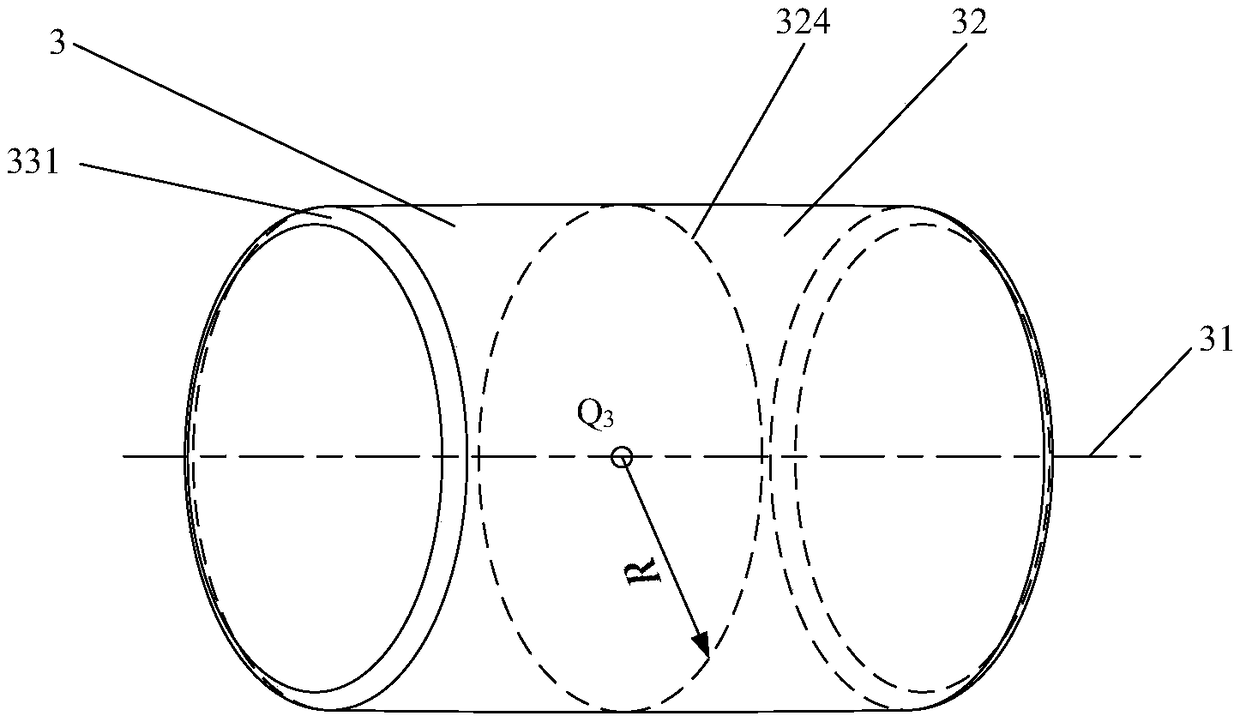

Grinding disk, apparatus and method for finishing rolling surface of convex cylindrical roller

ActiveCN108890516AAchieve removalRemove comprehensivelyLapping machinesLapping toolsMechanical engineeringEngineering

A lapping apparatus and a lapping disk kit for finis a rolling surface of a convex cylindrical roller are disclose. That lapping apparatus includes a main body, a lapping disk kit and a roller circulation disk out system. The main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device, wherein the main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device. The outer system of the roller circulating disk comprises a roller collecting device, a roller conveying system, a roller finishing mechanism and a roller feeding mechanism. The abrasive disk kit includes a pair of first and second abrasive disks coaxially and oppositely disposed facing each other. A front surface of the first abrasive disk includes a set of concave arc grooves radially distributed on a base surface of the first abrasive disk (concave circular arc rotating surface), The front surface of the second abrasive disk includes one or more spiral grooves distributed on the base surface of the second abrasive disk (convex circular arc rotating surface),and the radii of curvature of the base circle and the radii of curvature of the cross-section of the base surface of the first and second abrasive disks are equal to each other. A lapping apparatus ofthat present invention has the finis machining capability of a rolling surface of a large numb of convexity cylindrical rollers.

Owner:TIANJIN UNIV

Magnetic grinding plates, equipment and method for finish machining of rolling surface of cylindrical roller

The invention discloses grinding equipment and a magnetic grinding plate suite for finish machining of the rolling surface of a cylindrical roller made of a ferromagnetic material. The grinding equipment comprises a main unit, the magnetic grinding plate suite and a roller circulating plate external system, wherein the main unit comprises a base, a stand column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device; the roller circulating plate external system comprises a roller collecting device, a roller demagnetizer, a roller conveyor, a roller finishing mechanism and a roller feed-in mechanism. The magnetic grinding plate suite comprises a first grinding plate and a second grinding plate which are coaxial, and the front sides of the pair of grinding plates are opposite; a group of linear grooves radially distributed on the base surface (right circular conical surface) of the first grinding plate are arranged on the front side of the first grinding plate, one or more spiral grooves distributed on the base surface (right circular conical surface) of the second grinding plate are formed on the front side of the second grinding plate, and an annular magnetic structure is inlaid in a substrate of the second grinding plate. The grinding equipment has the finish machining capacity for the rolling surfaces of a large scale of cylindrical rollers made of the ferromagnetic material.

Owner:TIANJIN UNIV

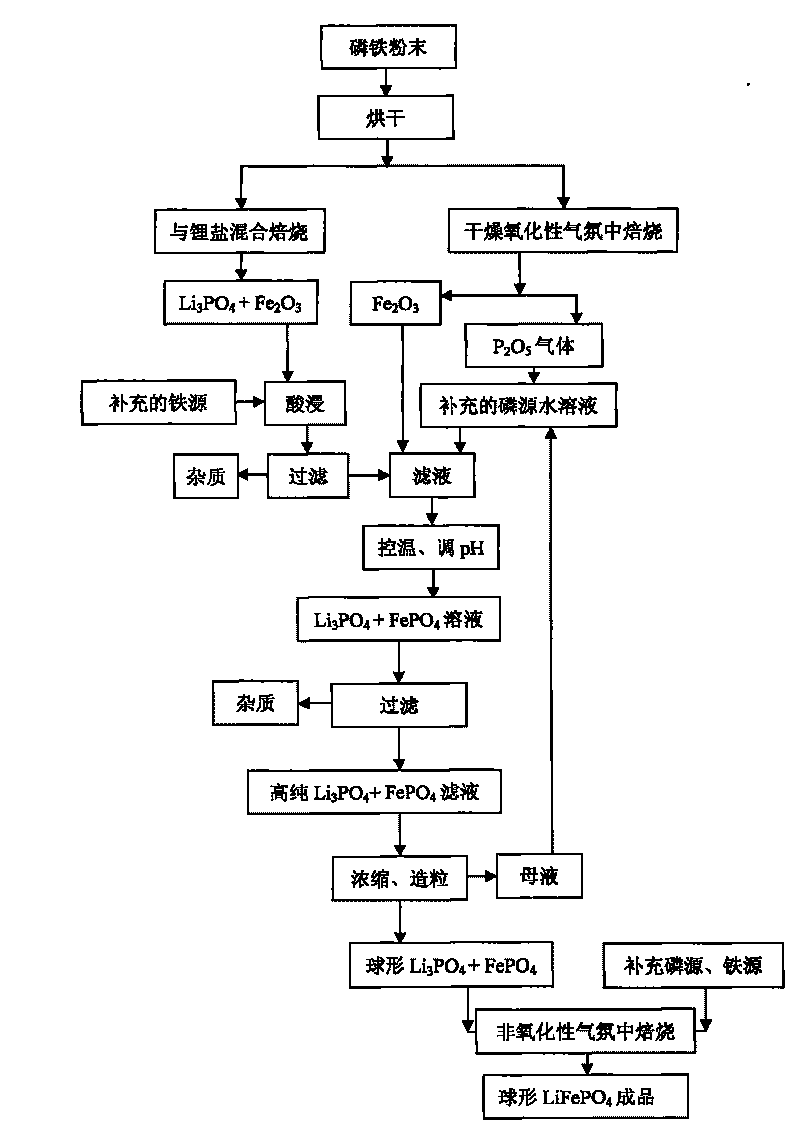

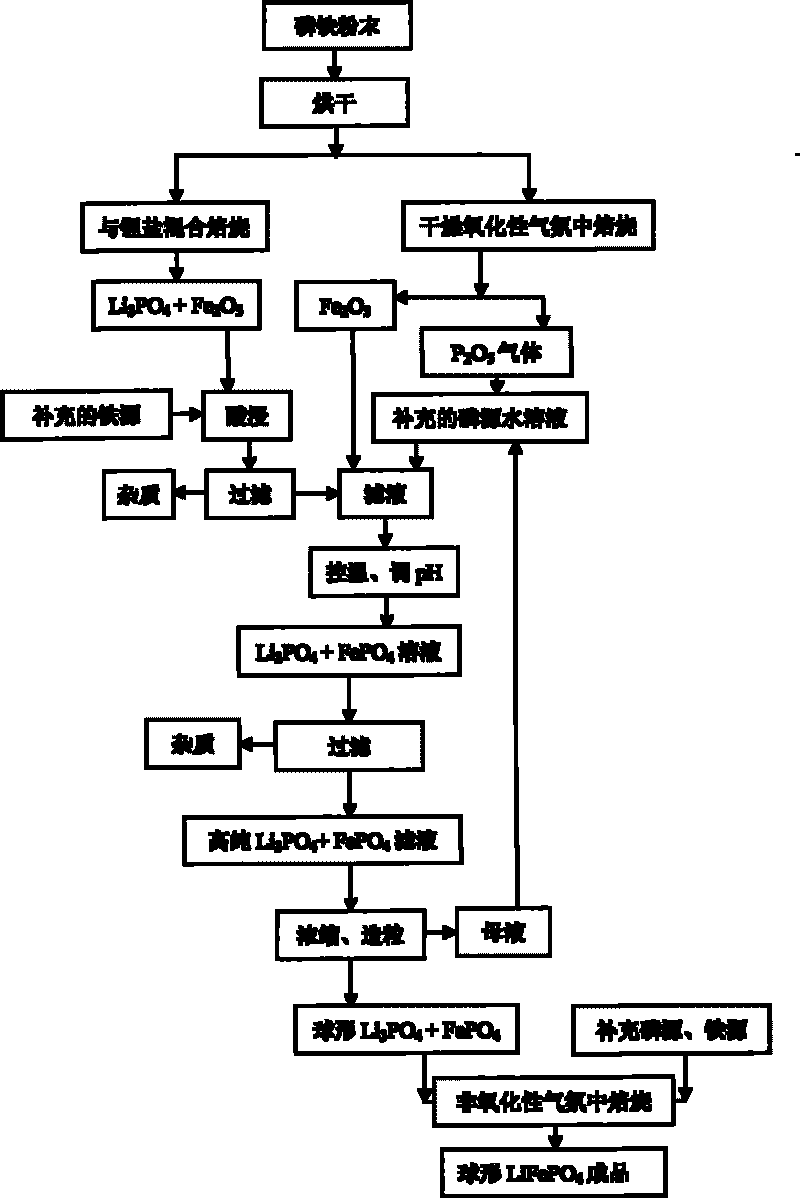

Method for reducing influences of impurity elements in ferrophosphorus on LixFeyPzO4

The invention relates to a simple method for reducing the influences of impurity elements in ferrophosphorus on LixFeyPzO4 (particularly LiFePO4, LiFe2 / 3PO4 and Li4 / 7Fe4 / 7P8 / 7O4), which comprises: reacting ferrophosphorus with a lithium salt react in an oxidizing atmosphere to obtain a product, leaching the product with acid and filtering the leachate; reacting the filtrate with phosphoric acid or a phosphate, and filtering the reaction solution to obtain high-purity Li3PO4 and FePO4 filtrate; concentrating the high-purity Li3PO4 and FePO4 filtrate, and graduating the concentrate to obtain Li3PO4 and FePO4 intermediates in special shapes; and adding supplementary phosphorus source, iron source or lithium source, mixing the supplementary phosphorus source, iron source or lithium source with the intermediates to perform a reaction in a non-oxidizing atmosphere to obtain the LixFeyPzO4. In the method, clean production is realized by the reaction design, raw material combination and by product utilization. In the method, a reaction process is used to remove the impurity elements in the ferrophosphorus and graduate the Li3PO4 and FePO4, the grain diameter and shape are easy to control, the oxygen amount is easy to control, the ferrophosphorus can replace reducing carbon as a reducer, the influences of the impurity elements in the ferrophosphorus on the LixFeyPzO4, the tap density of the LixFeyPzO4 product is improved, the production process is simple, the process steps are reduced, the reaction is easy to control, the steps are combined organically, no waste liquid is discharged, requirements on equipment are low, the cost is low, the investment is small, and the benefits are good. The method is suitable to be used for producing high-performance LixFeyPO4 from the ferrophosphorus at low cost.

Owner:SICHUAN UNIV

Grinding disc, equipment and method for finish machining of rolling surface of convex circular cone roller

PendingCN108673331AReduce removalIncrease contact stressLapping machinesLapping toolsEngineeringCircular cone

The invention discloses grinding equipment and grinding disc external member for finish machining of the rolling surface of a convexity circular cone roller. The grinding equipment comprises a main machine, the grinding disc external member and a roller circulating disc external system. The main machine comprises a base, a stand column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a main shaft device. The roller circulating disc external system comprises a roller collecting device, a roller conveying system, a roller cleaning mechanism and a roller feeding mechanism. The grinding disc external member comprises a pair of first and second grinding discs, wherein the front surfaces of the first and second grinding discs are coaxially arranged are arranged in an opposite mode. The front surface of the first grinding disc comprises a group of concave arc grooves radially distributed on the first grinding disc base surface (concave arc rotating surface), the front surface of the second grinding disc comprises one or more spiral grooves distributed on the second grinding disc base surface ( convex arc rotating surface ), and the radius of curvature of the base circle and the radius of curvature of the base surface cutting line of the first and second grinding discs are equal. The grinding equipment and grinding disc external member for finishmachining of the rolling surface of the convexity circular cone roller has the finish machining capability of rolling surfaces of large-scale convexity circular cone rollers.

Owner:TIANJIN UNIV

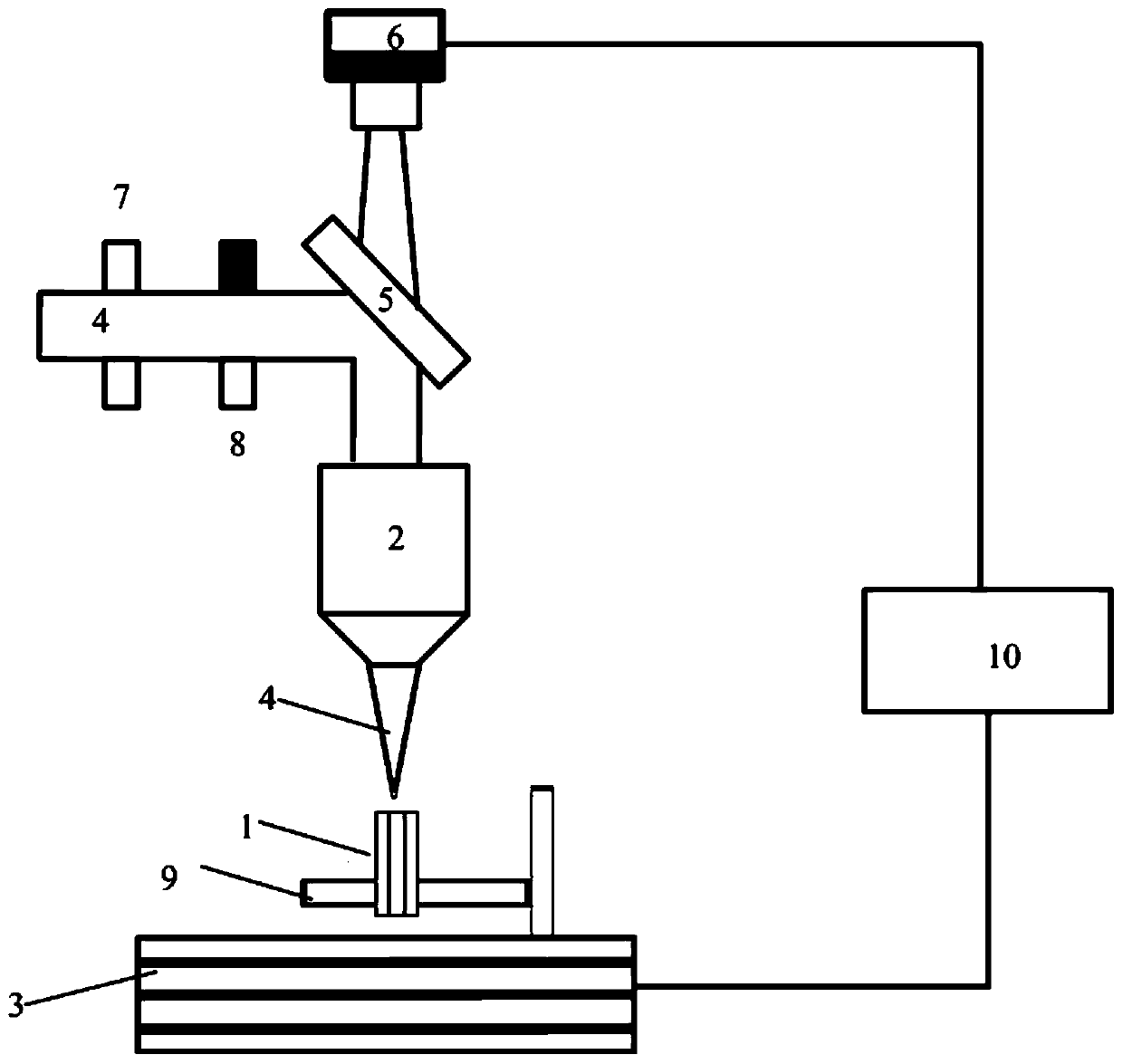

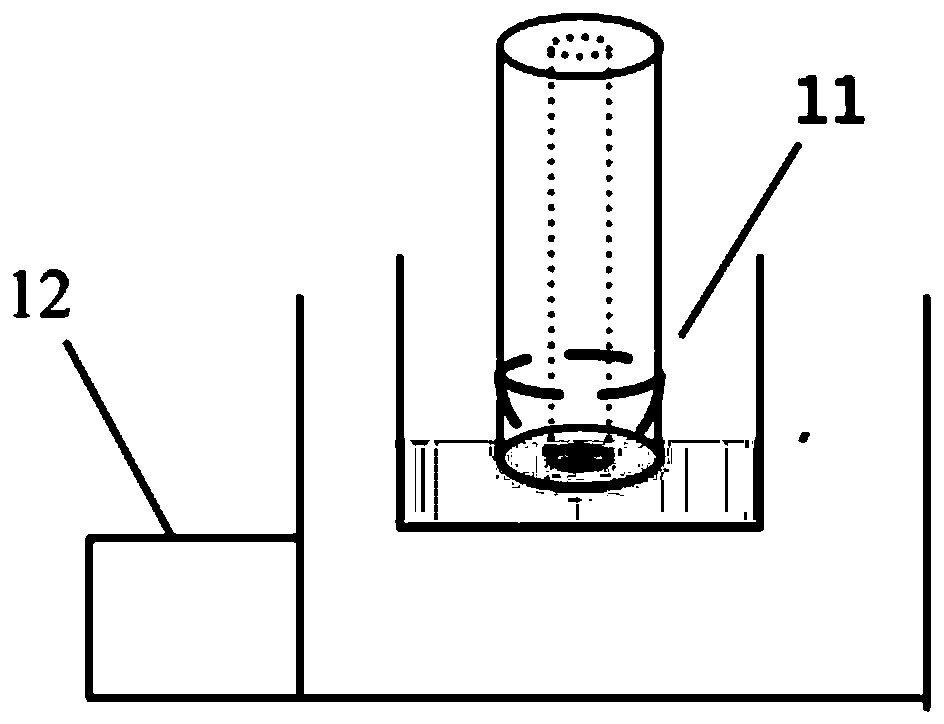

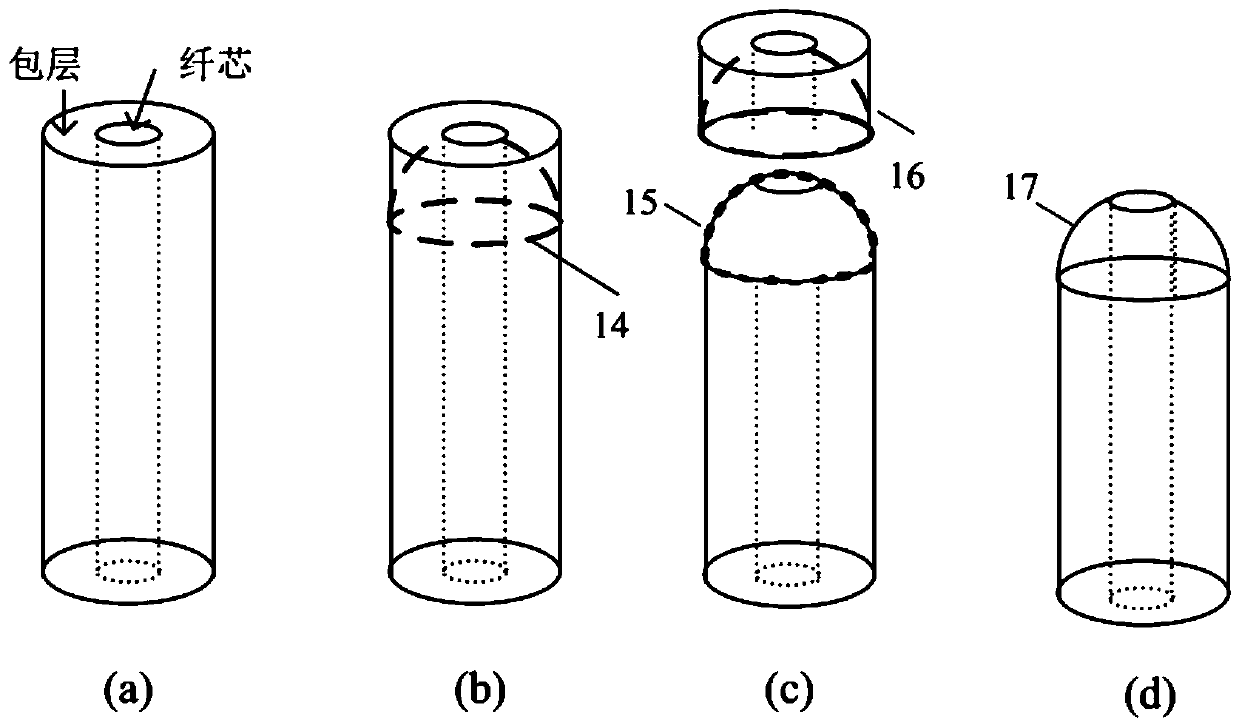

Femtosecond laser processing method of optical fiber lens

InactiveCN110405354AImprove machining accuracyGood symmetryCladded optical fibreOptical waveguide light guideThermal ablationCorrosion

The invention discloses a femtosecond laser processing method of an optical fiber lens. The femtosecond laser processing method comprises the following steps that a focused femtosecond laser is utilized for conducting scanning on an optical fiber according to the profile of a to-be-prepared lens, and a laser focus point irradiation area is subjected to material modification or etching removal; theend face of the treated optical fiber is partially soaked in a hydrofluoric acid solution, and through selective corrosion removal of materials in the modification area, the optical fiber outside theprofile of the lens is separated to form an optical fiber lens prototype; the corrosion time is controlled, so that the surface of the obtained optical fiber lens prototype tends to be smooth, and then the optical fiber lens is formed. According to the processing method, the processing working procedures are simple, the shape of the optical fiber lens is flexible, no heating effect exists duringprocessing, convex-face optical fiber lenses and concave-face optical fiber lenses in various shapes can be prepared on the end face of the optical fiber, the problems of stress damage and thermal ablation deformation occurring to existing preparing methods are solved, and the femtosecond laser processing method an be applied to optical fiber sensing, optical fiber laser devices and other fields requiring optical fiber coupling.

Owner:XI AN JIAOTONG UNIV +1

Grinding disc and equipment and method for accurate machining of rolling surface of cylindrical roller

PendingCN108908094ARemove comprehensivelyRemove lessLapping machinesLapping toolsEngineeringBase plane

The invention discloses grinding equipment for accurate machining of the rolling surface of a cylindrical roller and a grinding disc kit. The grinding equipment comprises a main machine, the grindingdisc kit and a roller circulation disc external system, wherein the main machine comprises a substrate, a vertical column, a transverse beam, a sliding table, an upper tray, a lower tray, an axial loading device and a main shaft device; the roller circulation disc external system comprises a roller collecting device, a roller conveying system, a roller arrangement mechanism and a roller feeding mechanism; the grinding disc kit comprises a first grinding disc and a second grinding disc which are coaxial, and the fronts of the first grinding disc and the second grinding disc are arranged oppositely; the front of the first grinding disc comprises a group of linear grooves which are radially distributed on the base plane (right circular conical surface) of the first grinding disc; the front ofthe first grinding disc comprises one or multiple spiral grooves which are distributed on the base plane (right circular conical surface) of the second grinding disc; and the sum of the flaring angles of the base planes of the first grinding disc and the second grinding disc are 360 degrees. The grinding equipment has the capability of accurately machining the rolling surfaces of large quantitiesof cylindrical rollers.

Owner:TIANJIN UNIV

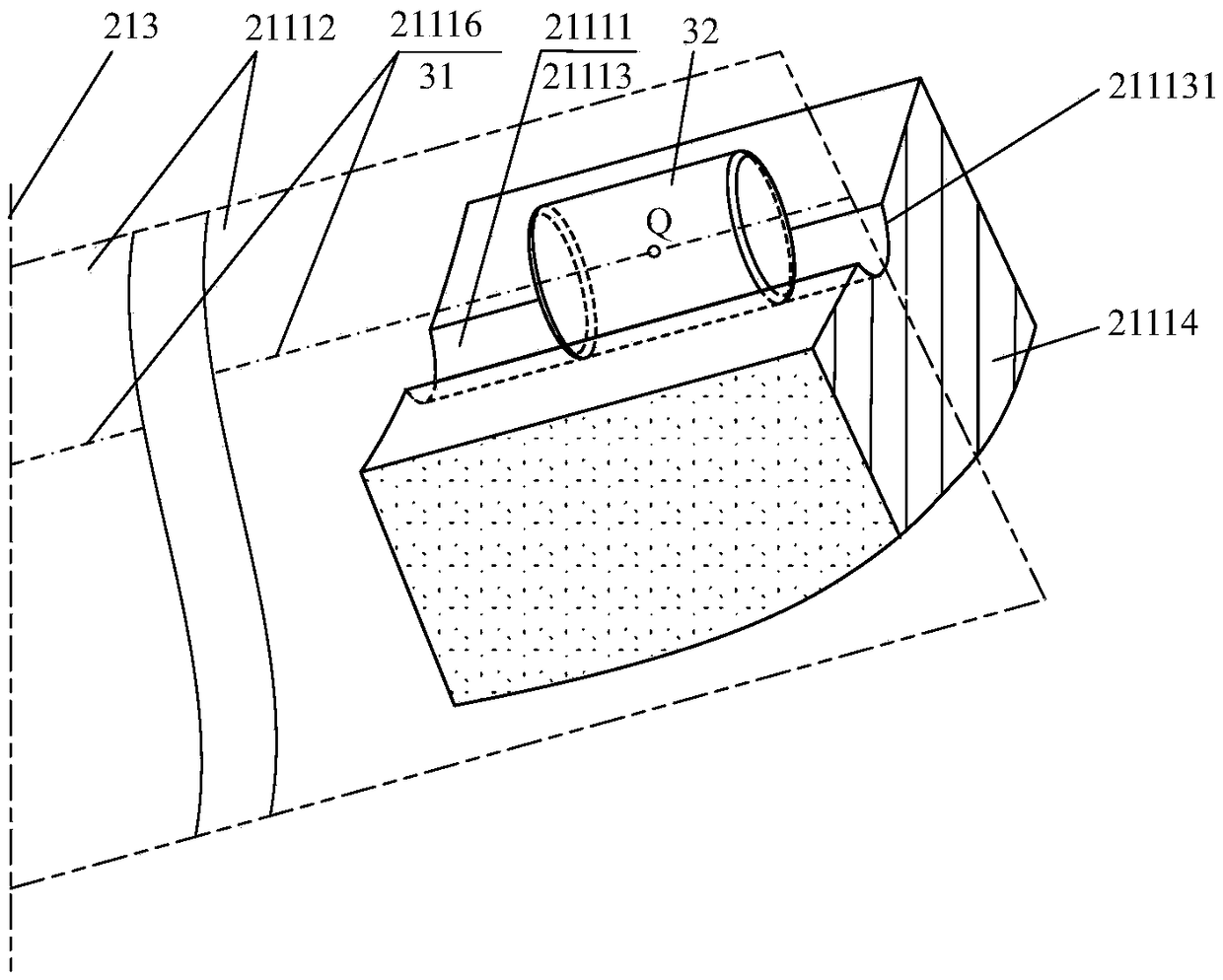

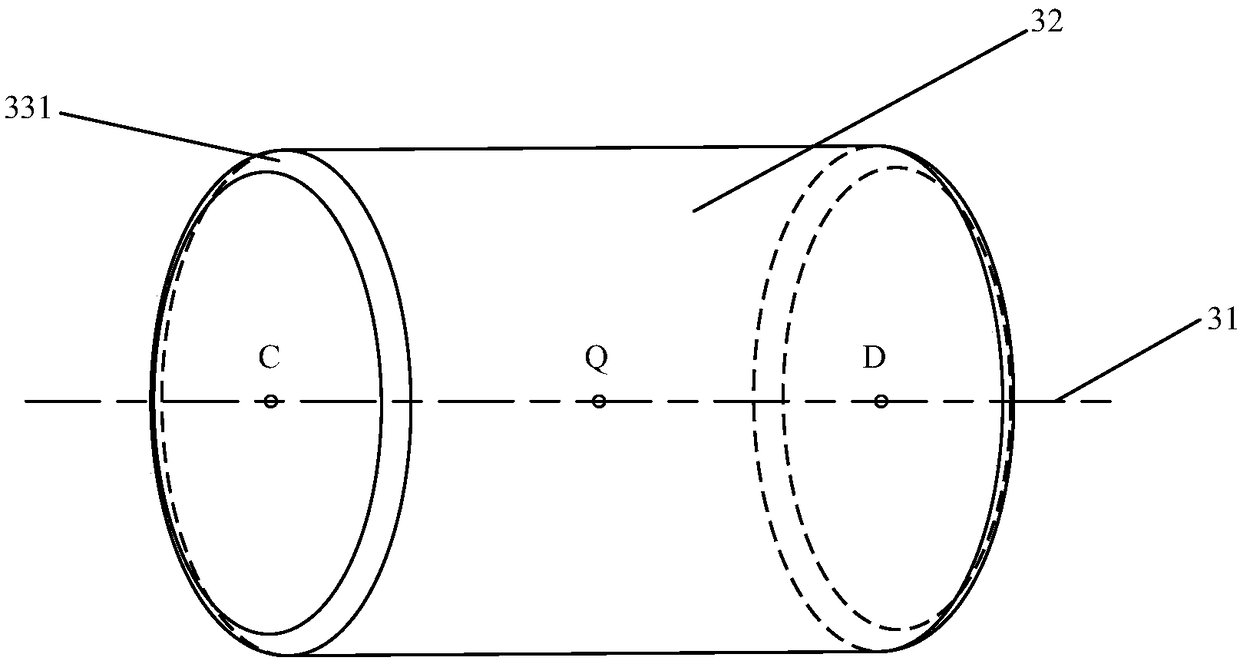

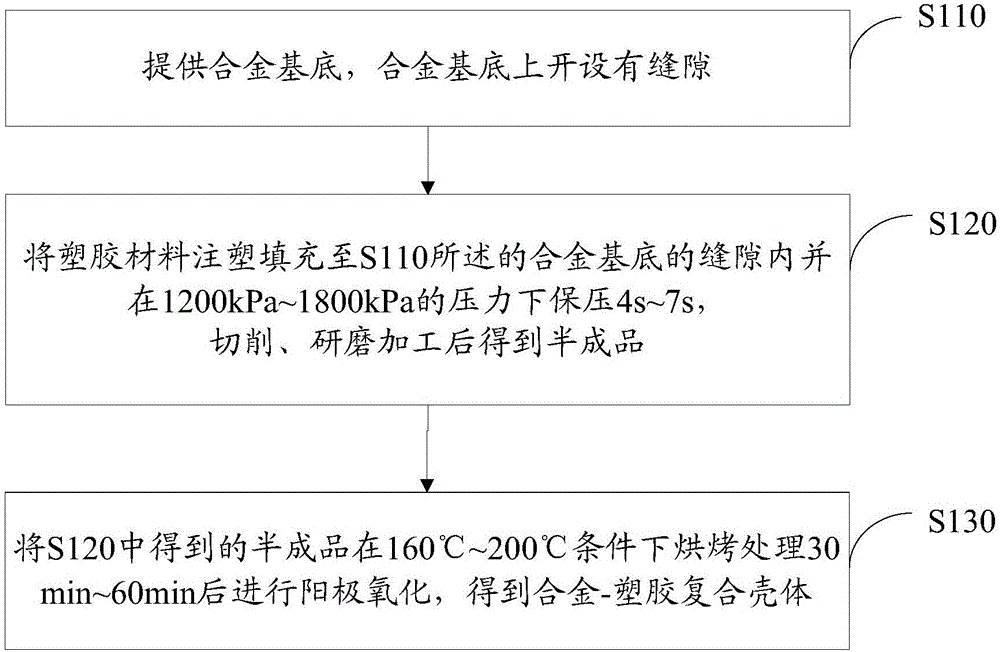

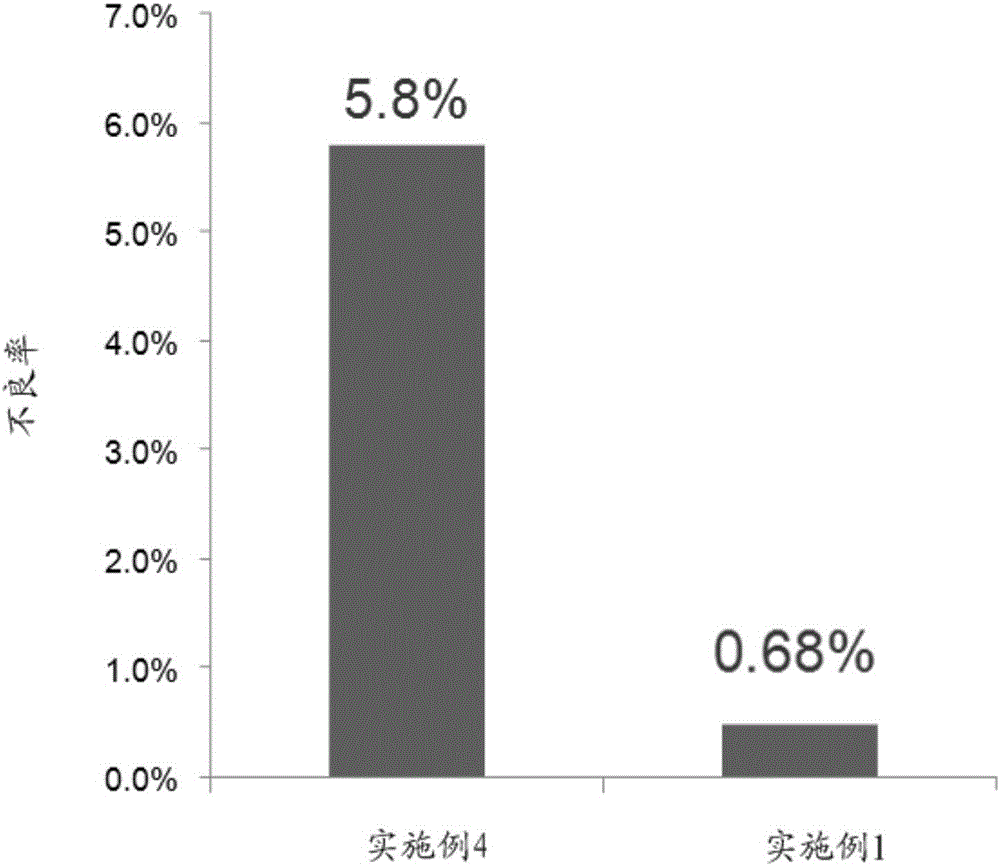

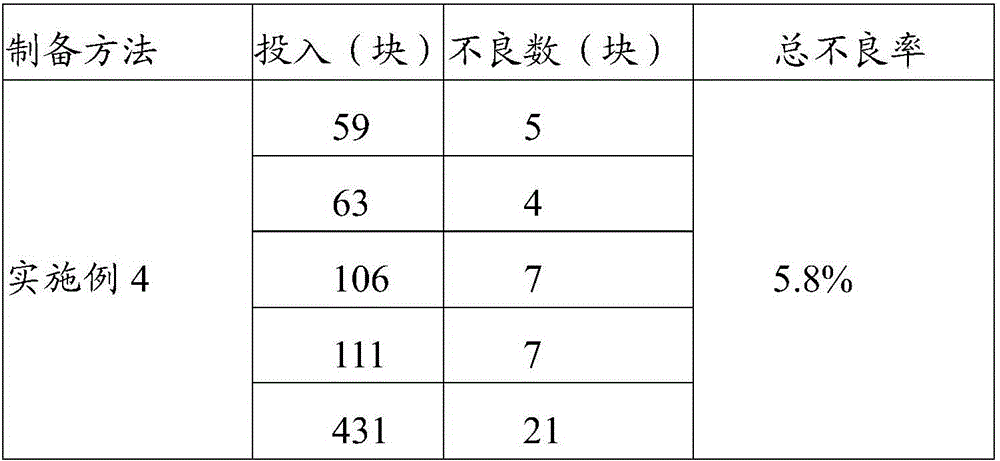

Preparation method alloy-plastic composite shell

The invention discloses a preparation method of an alloy-plastic composite shell. The preparation method of the alloy-plastic composite shell comprises the steps that a seam in an alloy substrate is filled with a plastic material through injection molding, and pressure maintaining is conducted for 4-7 s under the pressure of 1200-1800 kPa; the pressure maintaining time is prolonged and higher pressure is maintained, so that the plastic material continues to be injected into the seam, and the size of a small gap in the junction of the plastic material and alloy is reduced; and residual acid liquor is little after cutting and grinding and cannot overflow. After a semi-finished product is baked for 30-60 min at the temperature of 160-200 DEG C, anodic oxidation is conducted; the operation of braking treatment is adjusted to be conducted before the operation of anodic oxidation, the plastic material expands to squeeze the alloy after being baked at the high temperature, and the size of the small gap is slightly increased after cooling so that residual acid can be washed away more thoroughly in the anodic oxidation surface-conditioning procedure, residual acid is removed, and thus the situation of acid overflowing is restrained.

Owner:GUANGDONG EVERWIN PRECISION TECH

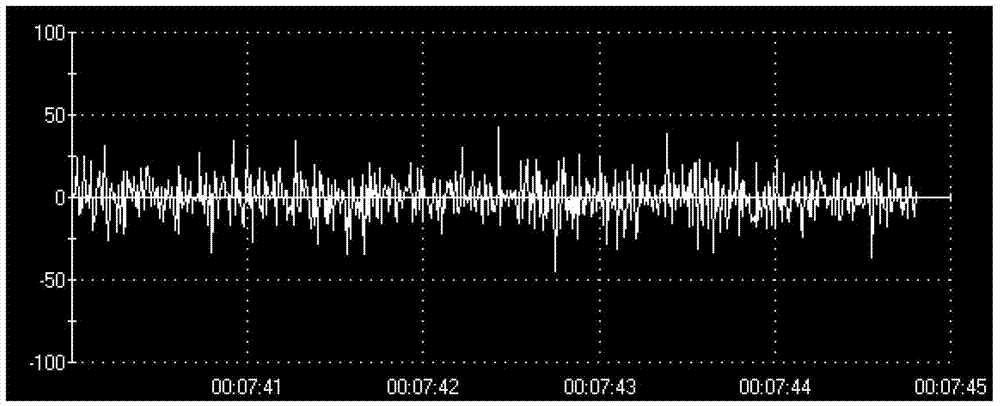

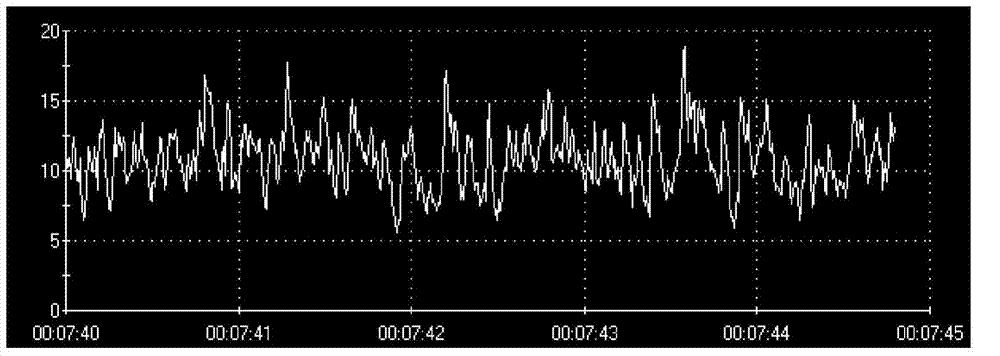

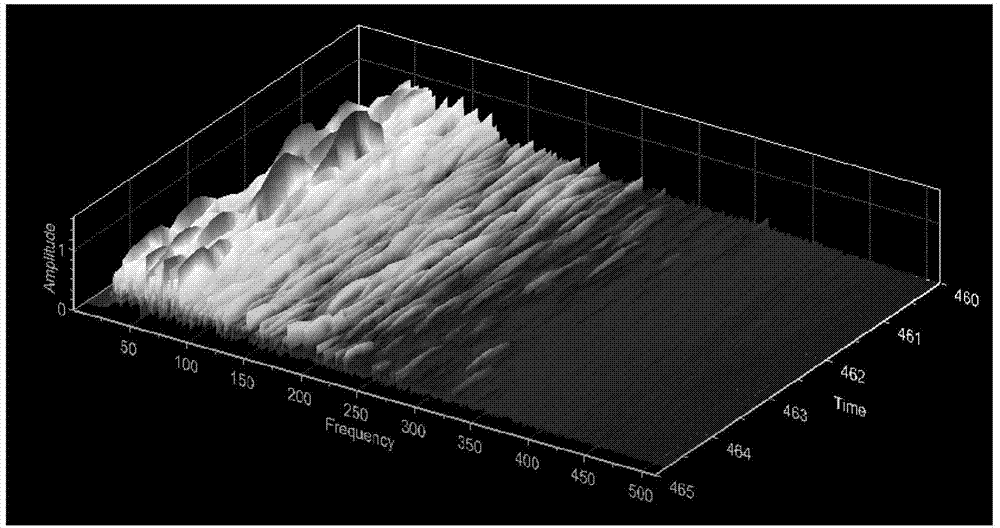

Method for indicating electromyographic signal interference and method for removing interference

The invention discloses a method for indicating electromyographic signal interference. The method comprises the following steps that (1) in a time frame t, the sampling value sequence x (t) of electromyographic signals is obtained, and t=1-10s; (2) the power spectrum P (f) and the total power Tp of the electromyographic signals are calculated; (3) in the bandwidth range of the electromyographic signals, the power values P50, P (n*50) of 50Hz and the frequency doubling (n*50) Hz are determined, and n is a natural number larger than 1; (4) the percent K of the sum of the power values of 50Hz and the frequency doubling (n*50) Hz accounted for in the total power Tp is calculated, and Q=100-K; (5) the value of K or the value of Q is indicated for a user. The invention further discloses a method for removing the electromyographic signal interference according to the indicating method. The method for indicating the electromyographic signal interference helps a doctor to judge the reliability of the signals and provides a basis for interference removal, and therefore the reliable signals can be obtained under the condition of removing 50Hz and the harmonic energy as less as possible.

Owner:NANJING VISHEE MEDICAL TECH

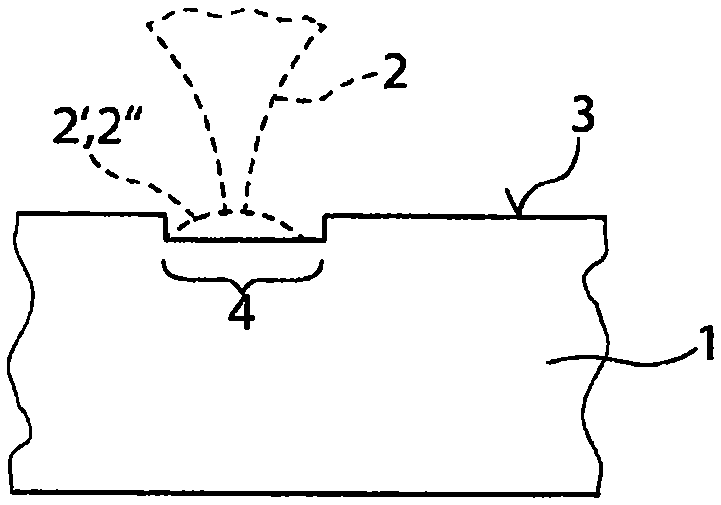

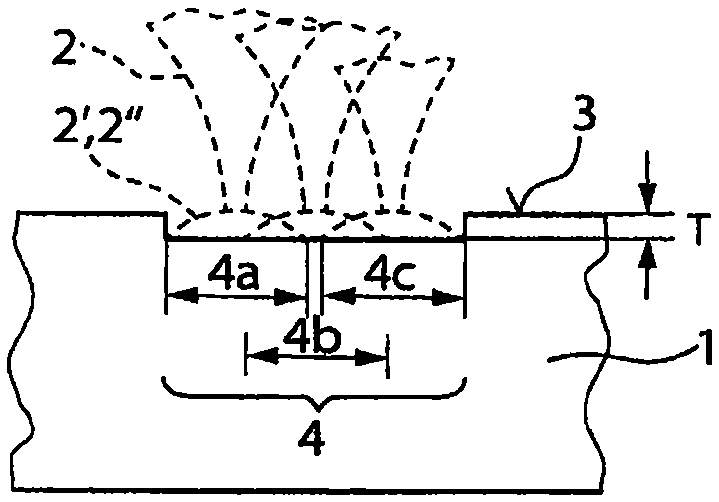

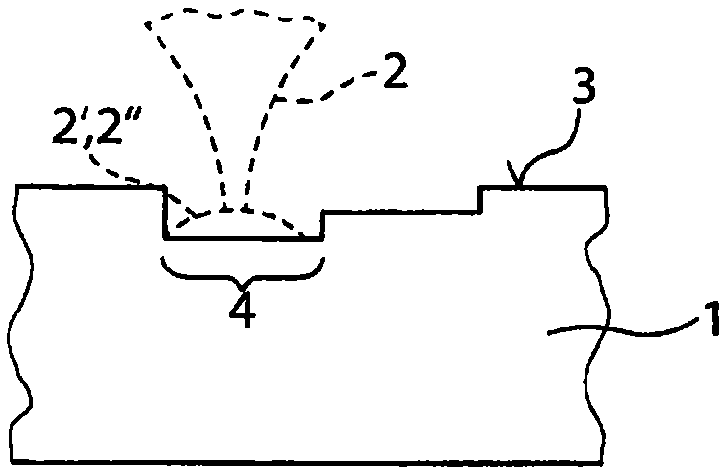

Method for the ablation cutting of a workpiece by means of a pulsed laser beam

ActiveCN105531072ARemove lessNo damageGlass severing apparatusWelding/soldering/cutting articlesOptoelectronicsPulsed laser beam

The method according to the invention for ablating an in particular transparent workpiece (1) by means of a pulsed laser beam (2) comprises the following steps: a) pretreating the workpiece surface (3) by moving the pulsed laser beam (2) over the workpiece surface (3) along a surface path (4), wherein consecutive laser pulses (2', 2") of the pulsed laser beam (2) have a first pulse overlap (61) on the workpiece surface (3a) in the path direction (5); and b) ablating the pretreated workpiece surface (3) by moving the pulsed laser beam (2) over the workpiece surface (3) along the surface path (4) multiple times, wherein consecutive laser pulses (2', 2") of the pulsed laser beam (2) have a second pulse overlap (62) on the workpiece surface (3) in the path direction (5), which second pulse overlap is less than the first pulse overlap (61).

Owner:TRUMPF LASERSYST FOR SEMICON MFG

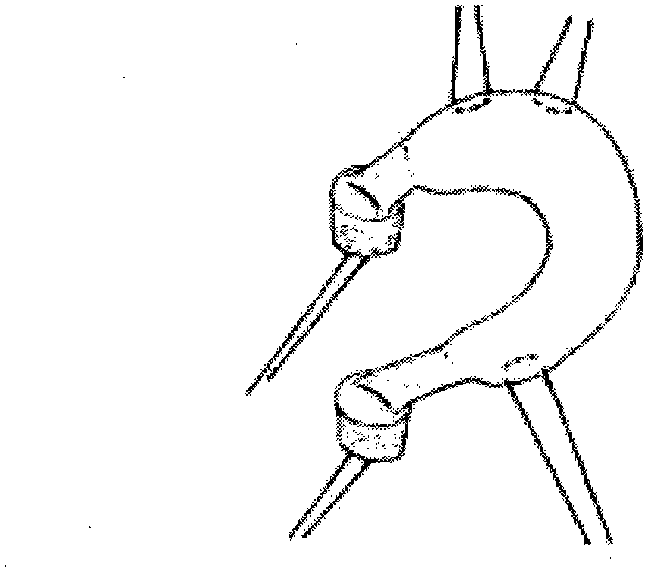

Meniscus transplanting bone bolt fixing technology and device

The invention relates to a meniscus transplanting bone bolt fixing technology and device and belongs to the field of medical devices. The meniscus transplanting bone bolt fixing device comprises two groups of components which are a group of bone bolts (bone bolt devices) for manufacturing standard sizes of allogenic meniscus front and rear angels and a group of bone tunnels (bone tunnel devices) for manufacturing the bone bolts for accommodating meniscus front and rear angles on a receptor tibial plateau. Each bone bolt device comprises a cone-shaped hollow drill (1) and a guide pin (2). Each bone tunnel device comprises an eccentric bone drill bit (3) and a drill bit (4). By X-rays and computed tomography (CT) scanning measurement, a donor which has the meniscus dimensions 10% larger than those of a receptor is selected, an allogenic inner side meniscus is made into front and rear angle dead point bone bolt belt completed meniscus on an operating table, and stitches which cannot be absorbed penetrate into drilled holes for reserve.

Owner:章亚东 +3

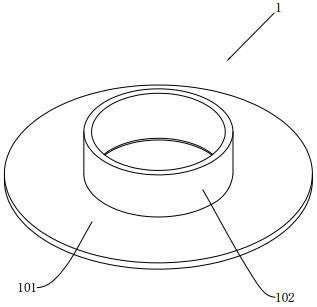

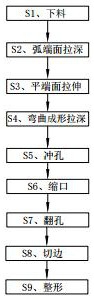

Processing technology of flange cover plate

InactiveCN114101480AReasonable size variationPrecise size controlShaping toolsPhysicsMachining process

The invention relates to a machining process of a flange cover plate. The machining process comprises the following steps that S1, blanking is conducted, specifically, an aluminum plate is selected to be blanked as a cover plate to be machined; s2, arc end face deep drawing, wherein an arc end face cover plate is machined; s3, flat end face stretching, wherein a flat end face cover plate is machined; s4, bending, forming and deep drawing are conducted, wherein a vertical wall cover plate is machined; s5, punching is conducted, specifically, a cover plate with holes is machined; s6, necking, wherein a necking cover plate is machined; s7, hole flanging is conducted, specifically, a hole flanging cover plate is machined; s8, edge cutting, wherein a cover plate to be shaped is machined; and S9, shaping is conducted, wherein a finished cover plate is obtained through machining. The method has the effects of high yield and high processing efficiency.

Owner:YANTAI ANXIN PRECISION MACHINERY

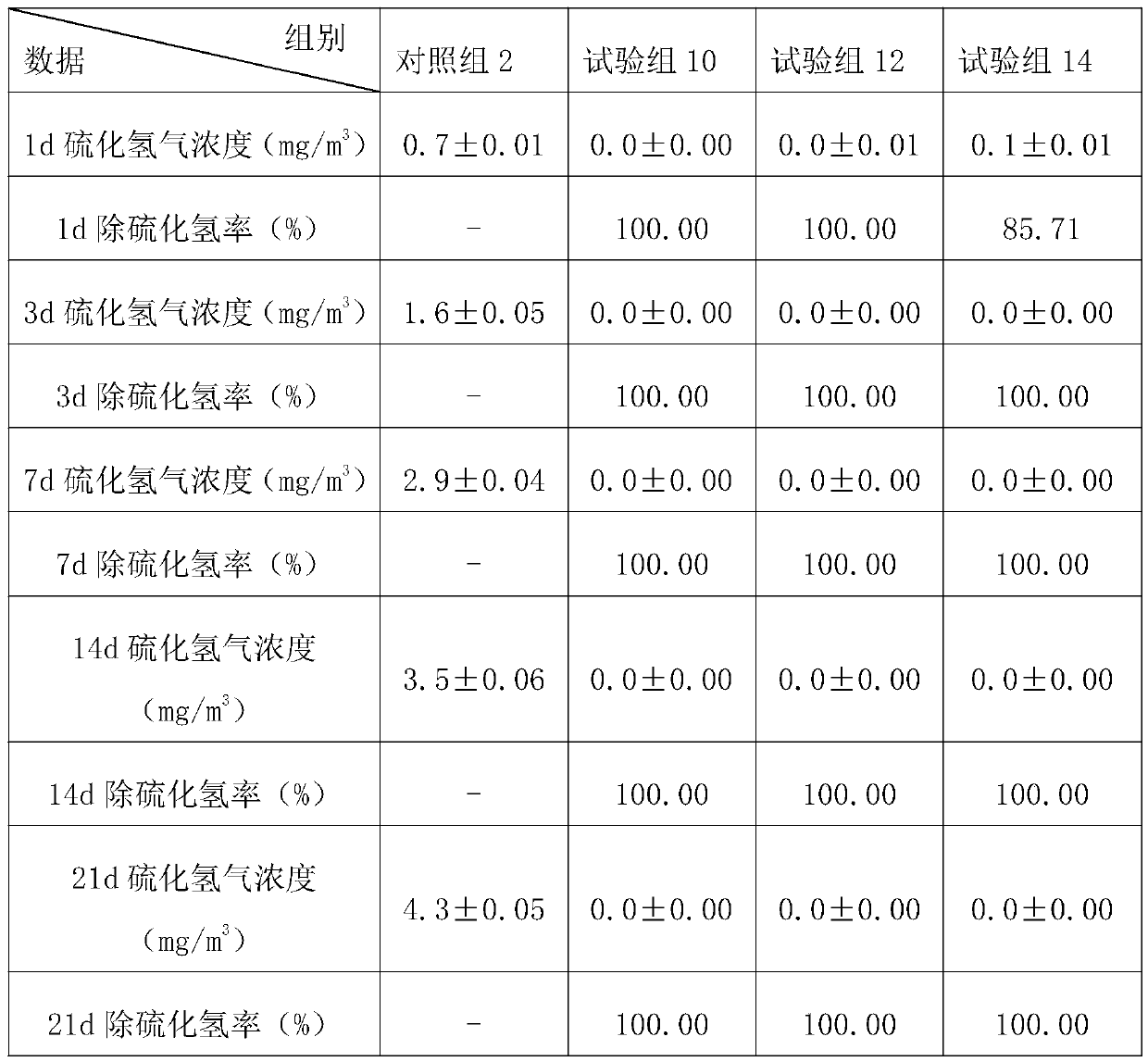

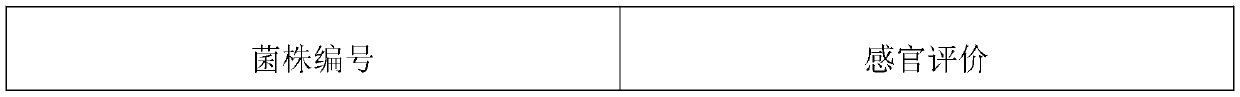

Application of microbial deodorant

ActiveCN110157644AGood environmentImprove immunity and growth rateBacteriaSpecific water treatment objectivesLivestockBacillus megaterium

The invention discloses bacillus flexus Z2 with the preservation number of CCTCC NO: M2018659 or / and a culture or / and a processed object thereof or / and bacillus megaterium Z3 with the preservation number of CCTCC NO: M2018660 or / and a culture or / and a processed object thereof. The two strains have an oxidation effect on ammonia gas and hydrogen sulfide and are resistant to high temperature. Bacillus flexus dry powder or bacillus megaterium dry powder or a bacillus flexus culture solution or a bacillus megaterium culture solution prepared from the strains is applied to livestock and poultry manure or landfill leachate or the bacillus flexus and the bacillus megaterium are evenly mixed in the proportion of (0-100):(0-100) to be applied to a to-be-treated object needing biological deodorization.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

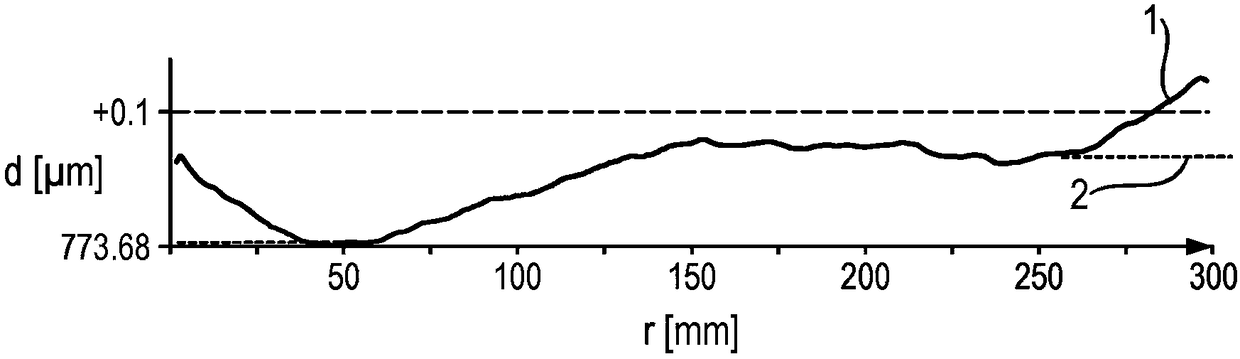

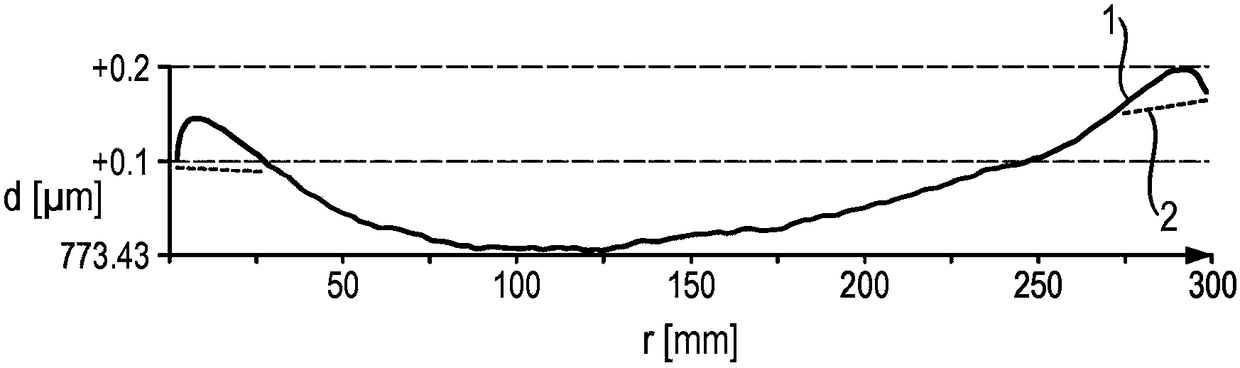

Monocrystalline semiconductor wafer and method for producing semiconductor wafer

ActiveCN108369895AImprove flatnessRemove lessSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingLiquid jetWafering

The invention relates to a monocrystalline semiconductor wafer having an average roughness Ra of at most 0.8 nm at a cut-off wavelength of 250 [mu]m. The wafer is characterized by an ESFQRavg of 8 nmor less at an edge exclusion of 1 mm. The invention further relates to a method for producing a monocrystalline semiconductor wafer. The method comprises the following steps in the specified order: polishing the semiconductor wafer on both sides simultaneously; locally processing at least part of at least one side of the semiconductor wafer in a material-removing manner by means of a liquid jet, which contains suspended hard-material particles and which is directed at a small area of the surface by means of a nozzle, wherein the nozzle is moved over the part of the surface to be treated in such a way that a predefined geometry parameter of the semiconductor wafer is improved; and polishing the at least one surface of the semiconductor wafer.

Owner:SILTRONIC AG

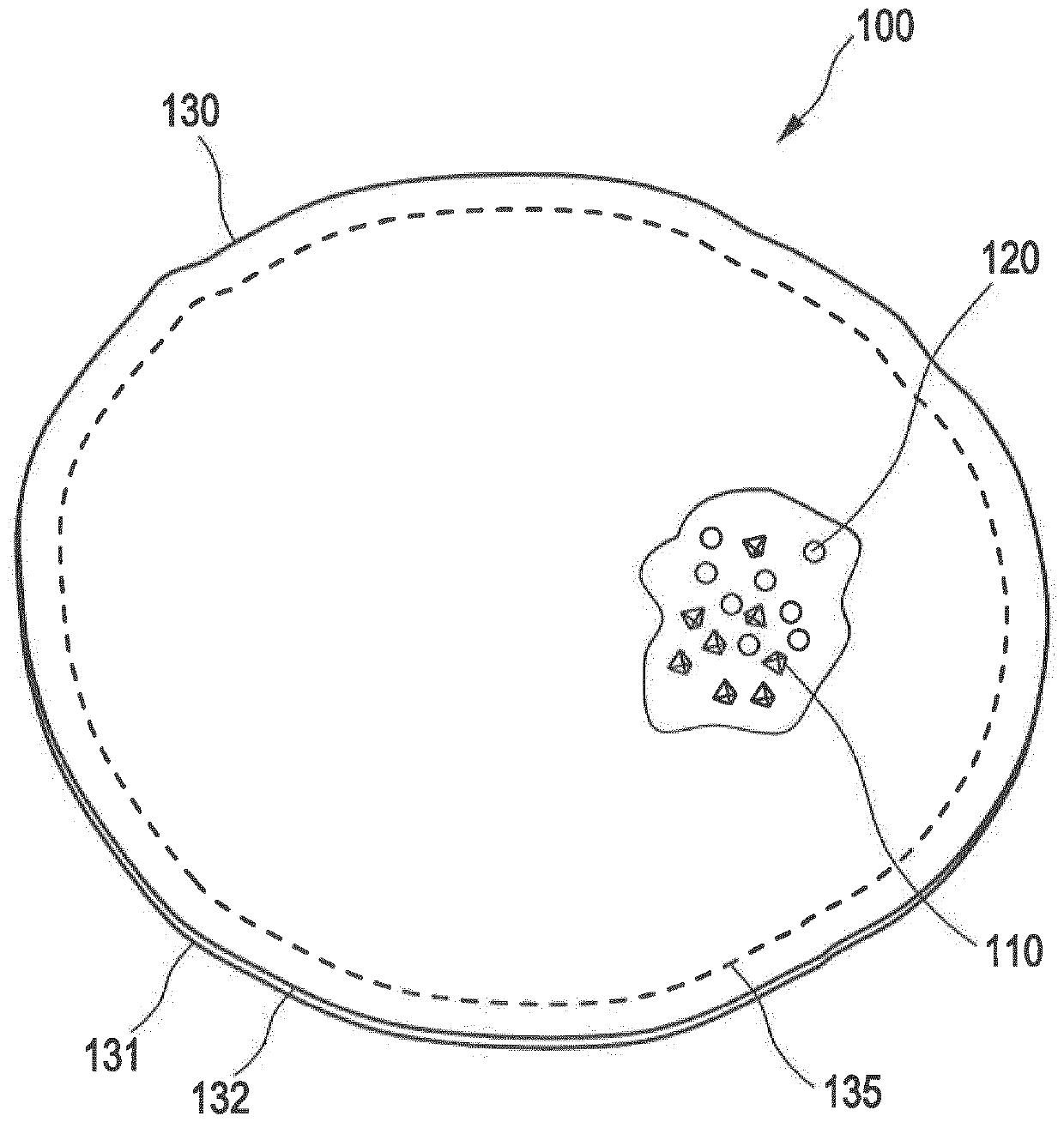

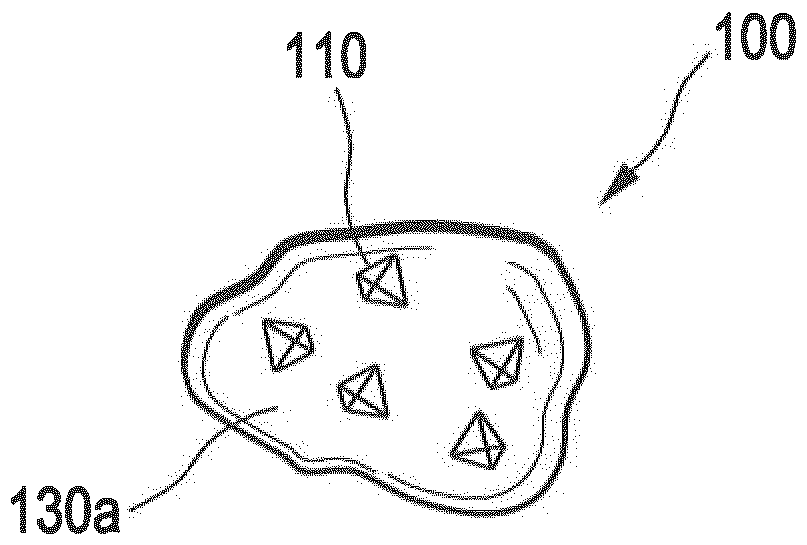

Implant and kit for treating bone defect

ActiveCN110167606AEnsure biological reconstructionAllowed to growBone implantSurgeryBone defectBiomedical engineering

The invention relates to an implant, especially for treating a bone defect. The implant has osteoconductive support bodies and an insertion aid. The insertion aid is designed for insertion of the osteoconductive support bodies into a bone defect and for holding together the osteoconductive support bodies. The invention also relates to a kit.

Owner:AESCULAP AG

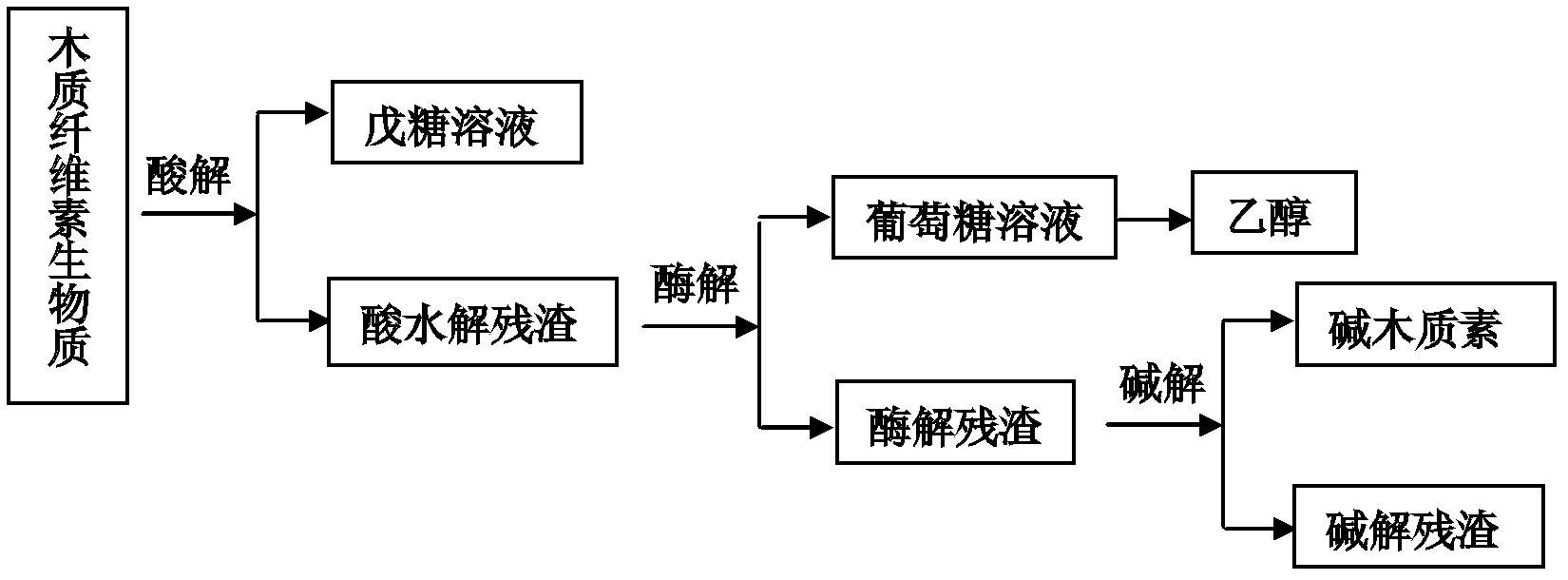

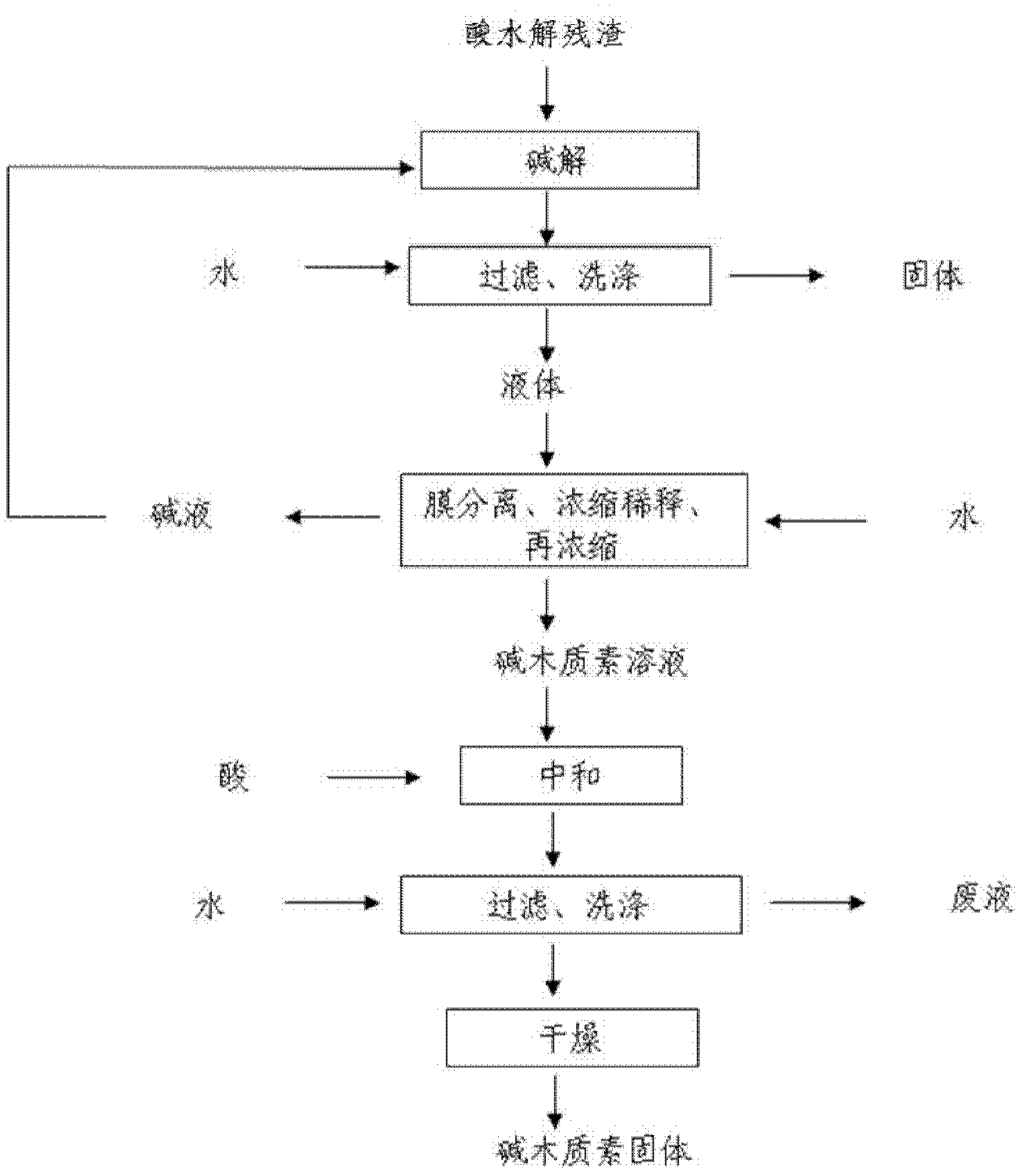

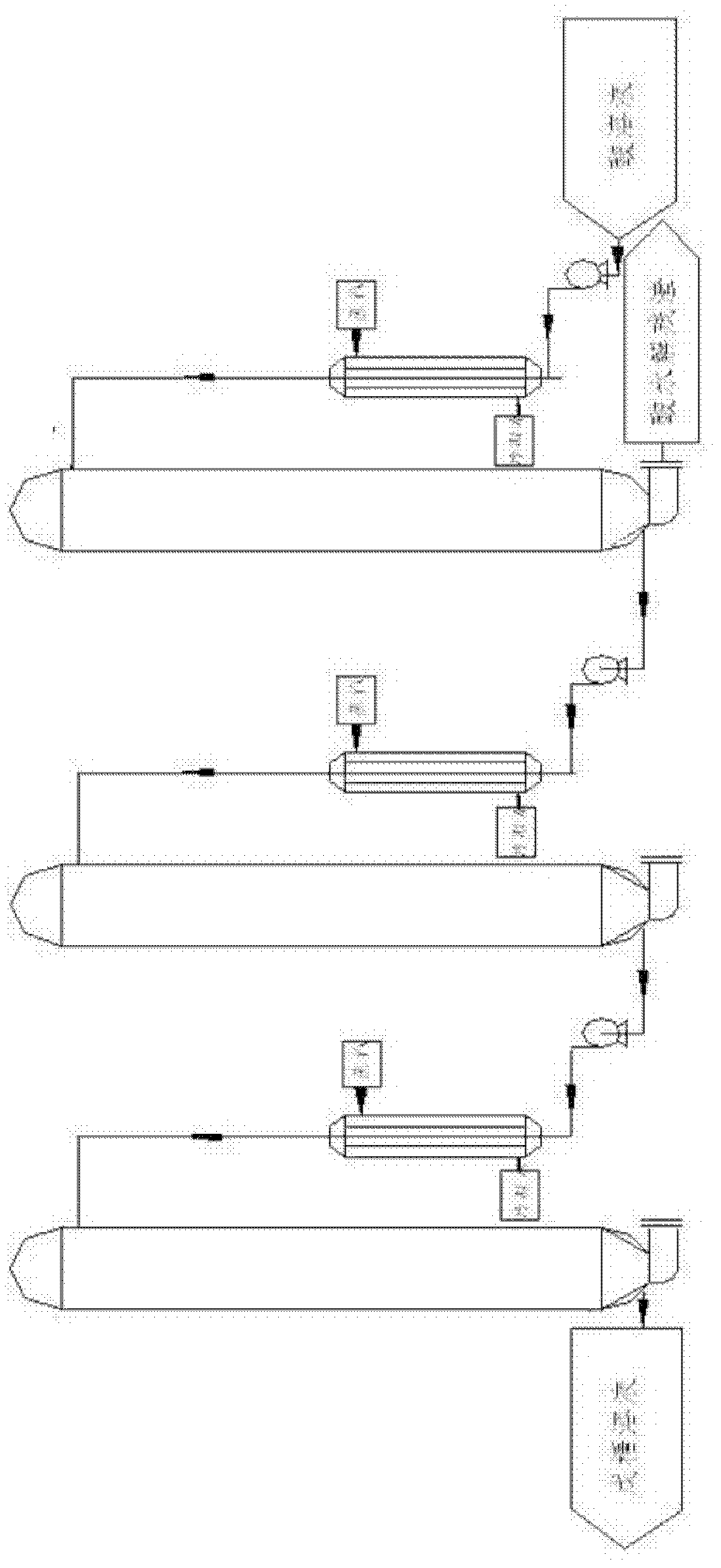

Comprehensive utilization method of lignocellulose biomass

ActiveCN103045691AReduce removalRemove lessMicroorganism based processesFermentationCelluloseEnzymatic hydrolysis

The invention relates to a comprehensive utilization method of lignocellulose biomass. The method comprises the following steps of (a) performing N-stage hydrolysis on the lignocellulose biomass, wherein reaction kettles of the N-stage hydrolysis are connected end to end, one of the reaction kettle is designed as a first stage and a final reaction kettle is designed as an N stage, a freshly prepared acid solution is added in the first stage reaction kettle, a final pentose solution obtained by hydrolysis is discharged from the N stage reaction kettle, final acid hydrolysis residues obtained by acid hydrolysis are discharged from the first stage reaction kettle, and new materials are loaded on the first stage reaction kettle, the first stage hydrolysis reaction time is 1-4 hours, the subsequent hydrolysis reaction time is reduced by 0.25-1.5 hours stage by stage, and N is an integer larger than or equal to 2; (b) performing enzymatic hydrolysis on the acid hydrolysis residues in the step (a) by using cellulose, so that a glucose solution and enzymatic hydrolysis residues are obtained; and (c) treating the enzymatic hydrolysis residues produced in the step (b) with an alkali solution, so that lignin in the enzymatic hydrolysis residues can be extracted. The above method realizes maximized resource utilization of the lignocellulose biomass.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Preparation method of cyperus esculentus protein extract beverage

The invention discloses a preparation method of a cyperus esculentus protein extract beverage. The preparation method comprises the following steps: step 1, raw material selection: selecting fresh cyperus esculentus with full grains and good maturity as a raw material; step 2, conducting cleaning and soaking; step 3, feeding cyperus esculentus and water into a pulping machine according to a volume ratio of 1: 5 for pulping; step 4, heating cyperus esculentus pulp to 80 DEG C or above and keeping the temperature for 10-15 minutes to inactivate a lipoxygenase in the cyperus esculentus pulp; step 5, conducting vacuum deodorization; Step 6, treating the deodorized cyperus esculentus pulp by using an improved TCA / acetone extraction method; step 7, conducting blending; step 8, conducting homogenizing; and step 9, conducting sterilizing and filling. The cyperus esculentus rich in amino acid variety and content is selected as the raw material, such that richness of plant protein is ensured; and The improved TCA / acetone extraction method is adopted in a preparation process, phenols, lipids and pigments can be well removed, polysaccharides can also be well removed, and more plant proteins can be obtained.

Owner:A BA TEACHERS UNIV

Magnetic abrasive disk for finishing rolling surface of cylindrical roller, apparatus and method

The invention discloses an abrasive device and a magnetic abrasive disk kit for finishing a rolling surface of a cylindrical roller made of ferromagnetic material. The grinding equipment includes a main machine, a magnetic grinding disc set and a roller circulating disc external system. The main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axialloading device and a spindle device, wherein the main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device. Theouter system of the roller circulating disk comprises a roller collecting device, a roller demagnetizing device, a roller conveying system, a roller finishing mechanism and a roller feeding mechanism.The magnetic abrasive disk kit includes a pair of first and second abrasive disks coaxially and oppositely disposed facing each other. The front surface of the first abrasive disk includes a set of linear grooves radially distributed on the base surface (right conical surface) of the first abrasive disk, the front surface of the second abrasive disk is the working surface (right conical surface)of the second abrasive disk, and an annular magnetic structure is embedded in the base body of the second abrasive disk. A lapping device of that invention has the finis machining capability of a large numb of cylindrical roller rolling surfaces made of ferromagnetic material.

Owner:TIANJIN UNIV

Magnetic grinding disc, device and method for crowned tapered roller rolling surface finish machining

PendingCN108723981AReduce removalIncrease contact stressLapping machinesLapping toolsSurface finishEngineering

The invention discloses a grinding device and magnetic grinding disc suite for ferromagnetic material crowned tapered roller rolling surface finish machining. The grinding device includes a main machine, the magnetic grinding disc suite and a roller recirculating disc external system. The main machine includes a base, upright columns, a beam, a sliding platform, an upper tray, a lower tray, an axial loading device and a main shaft device. The roller recirculating disc external system includes a roller collection device, a demagnetization device, a conveying device, a tidying mechanism and a feed-in mechanism. The magnetic grinding disc suite includes a pair of grinding discs including a first grinding disc and a second grinding disc, wherein the first grinding disc and the second grindingdisc are coaxially arranged, and the front faces of the first and second grinding discs are opposite. The front face of the first grinding disc includes a group of concave arc grooves which are radially formed in the base face (concave arc rotation face) of the first grinding disc; the front face of the second grinding disc includes one or more spiral grooves formed in the base face (convex arc rotation face) of the second grinding disc, and an annular magnetic structure is embedded in the base body of the second grinding disc. The grinding device for ferromagnetic material crowned tapered roller rolling surface finish machining has the capability of conducting finish machining on crowned tapered roller rolling surfaces of large-batch ferromagnetic materials.

Owner:TIANJIN UNIV

Magnetic grinding disks, device and method for finish machining of rolling surfaces of convex cylindrical rollers

ActiveCN108705444AAchieve removalRemove comprehensivelyLapping machinesLapping toolsDemagnetizing deviceEngineering

The invention discloses a grinding device and a magnetic grinding disk kit for finish machining of the rolling surfaces of ferromagnetic-material convexity cylindrical rollers. The grinding device comprises a main machine, the magnetic grinding disk kit and a roller circulating disk external system. The main machine comprises a base, stand columns, a cross beam, a sliding table, an upper tray, a lower tray, axial loading devices and a main shaft device. The roller circulating disk external system comprises a roller collecting device, a demagnetizing device, a conveying system, a sorting mechanism and a feed-in mechanism. The magnetic grinding disk kit comprises a pair of coaxial first and second grinding disks, and the front sides of the first grinding disk and the second grinding disk areoppositely arranged. The front side of the first grinding disk comprises a group of inside-sunken arc line grooves radially distributed on a first grinding disk base face (inside-sunken arc rotatingface); and the front side of the second grinding disk comprises one or more spiral grooves distributed on a second grinding disk base face (outside-protruding arc rotating face), and an annular magnetic structure is embedded in a base body of the second grinding disk. The grinding device has the capacity for finish machining of the rolling surfaces of the ferromagnetic-material convexity cylindrical rollers on a large scale.

Owner:TIANJIN UNIV

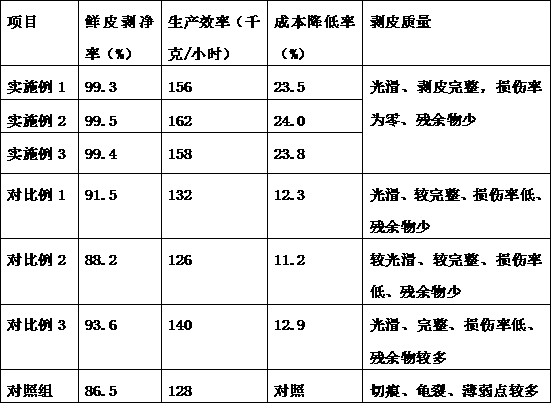

A kind of stripping method of weaving material for wicker

ActiveCN107379164BHas a lubricating effectSimple peelingWood treatment detailsReed/straw treatmentEngineeringAir bubble

The invention relates to the technical field of wickerwork crafts and discloses a peeling method for a weaving material for wickerwork. The peeling method includes the following steps that firstly, the fresh weaving material is put into newly-prepared limewater, a large amount of heat generated through the reaction is used for heating and permeating the peel of the weaving material, a tough peel part can be well peeled to form a layer, alkali liquor has a certain lubricating effect, a joint part cannot be damaged, and the bone and peel separation efficiency is high; secondly, the partly-peeled weaving material is put into self-made bubbling water to be soaked for several hours, a large amount of saponin and alkaloid are contained in the bubbling water, surface tension can be reduced, the surfaces of all bubbles in the solution can be surrounded by the saponin to form a film, the bubbles are durable and do not disappear, an antibacterial action is achieved, and the fresh peel peeling rate is further increased; and thirdly, the treated weaving material is peeled easily and is cleaned and cured after being peeled, few residues are removed, and sterilizing and softening functions are achieved as well.

Owner:FUNAN TENGBO ARTS & CRAFTS CO LTD

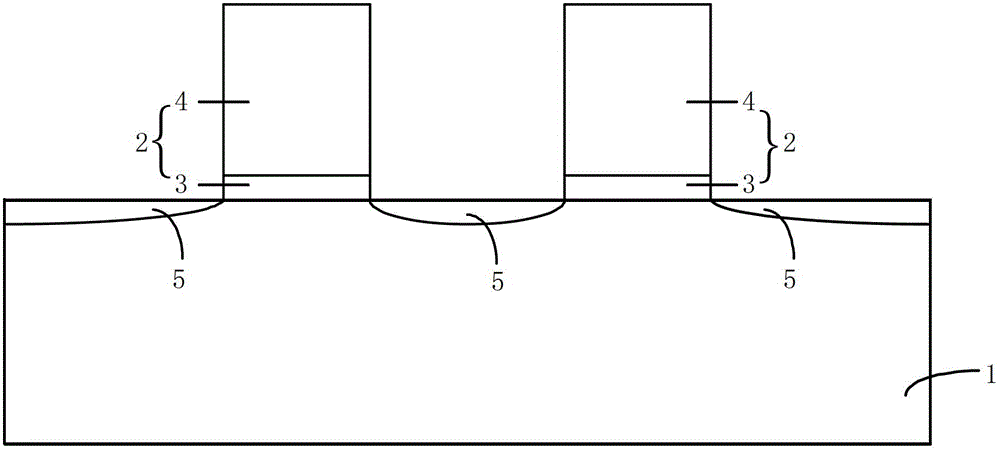

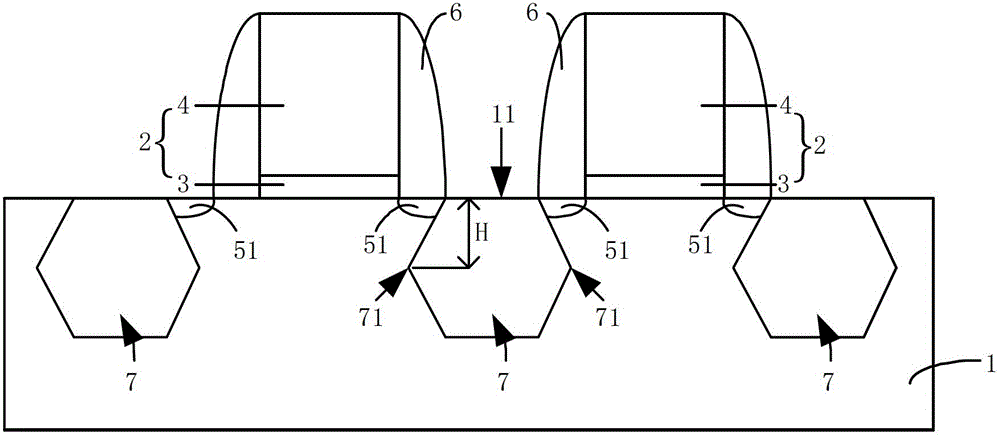

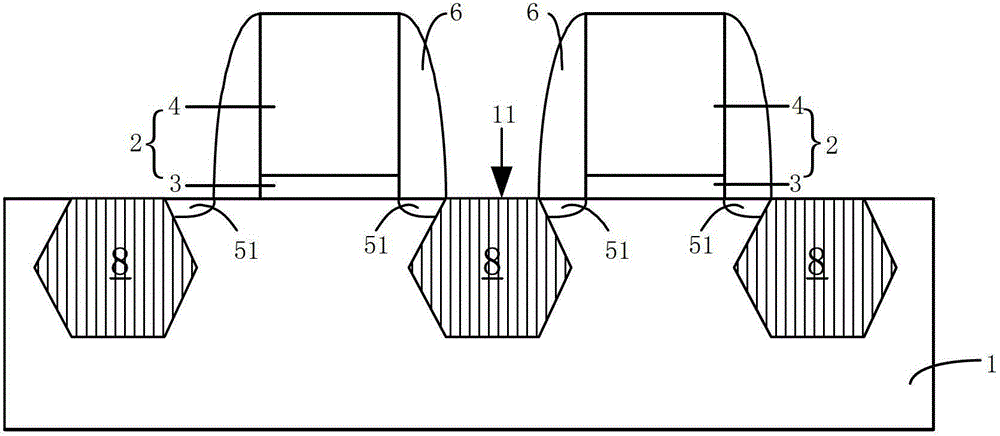

pmos transistor and method of forming the same

ActiveCN103545202BRemove lessImprove performanceTransistorSemiconductor/solid-state device manufacturingGate dielectricEngineering

Owner:SEMICON MFG INT (SHANGHAI) CORP

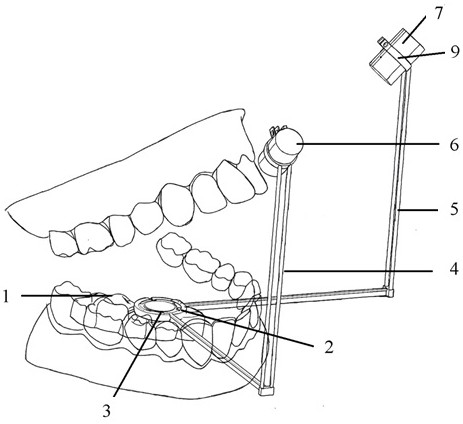

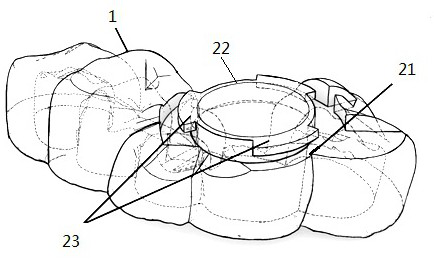

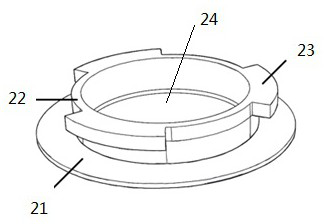

Laser-based three-dimensional positioning and guiding device for root canal therapy dental pulp opening passage

PendingCN112263345AThe effect is intuitive and visibleSimple and efficient operationDental toolsNerve needlesDentitionBiomedical engineering

The invention provides a laser-based three-dimensional positioning and guiding device for a root canal therapy dental pulp opening passage. The device comprises a tooth surface positioning assembly and a dental pulp opening guiding assembly, wherein the tooth surface positioning assembly is arranged on a dentition; the dental pulp opening guiding assembly is arranged on the tooth surface positioning assembly; the tooth surface positioning assembly comprises a positioning shell, an inner clamping ring piece and an outer clamping ring piece; a positioning guide hole is formed in the positioningshell; the outer clamping ring piece is arranged at the positioning guide hole of the positioning shell; the inner clamping ring piece is movably connected with the outer clamping ring piece; and thedental pulp opening guiding assembly comprises an X-direction support frame, a Y-direction support frame, an X-direction laser emitter and a Y-direction laser emitter. The device indicates the dentalpulp opening passage through laser, and the effect is intuitive and visual, so that the operation is controllable, and the device is simple and convenient to operate and easy to master. The device canguide more accurate dental pulp opening, the hard tissues of teeth are less removed, and the resistance and functionality of the affected teeth are preserved to the greatest extent, so that the service life of the teeth in the oral cavity is prolonged.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

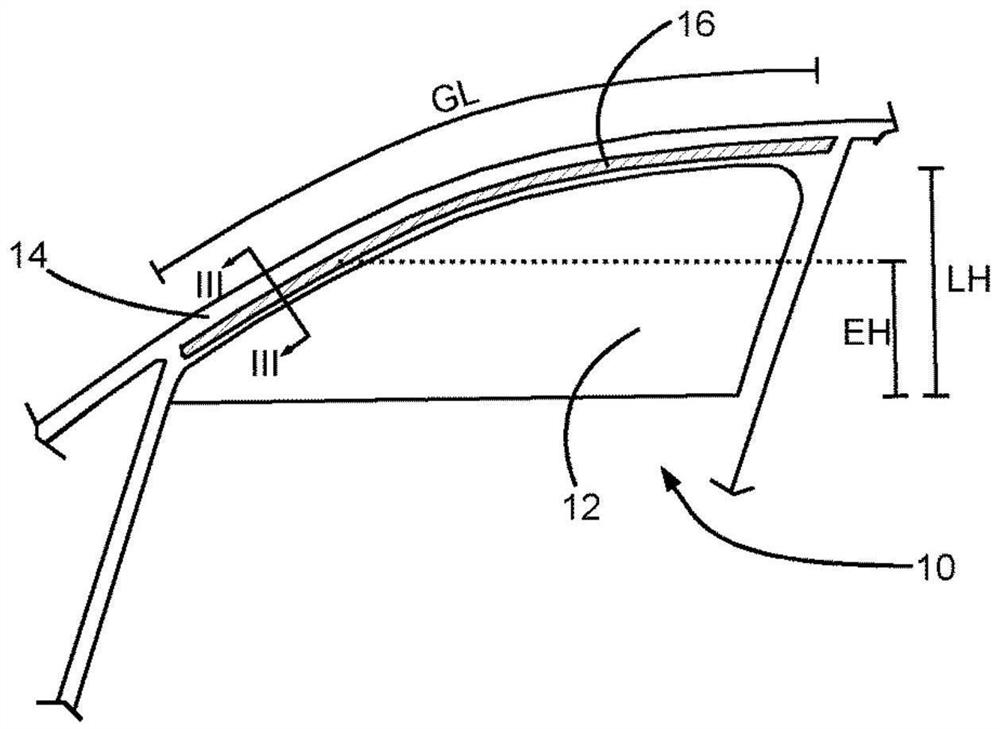

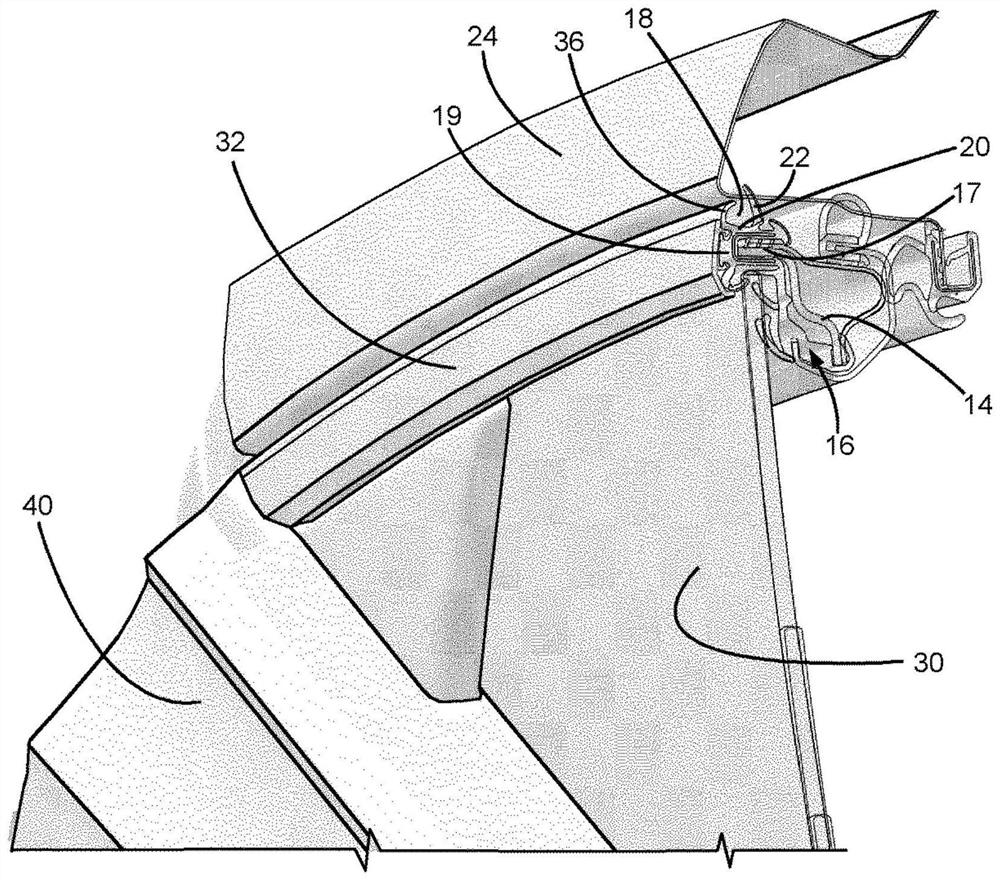

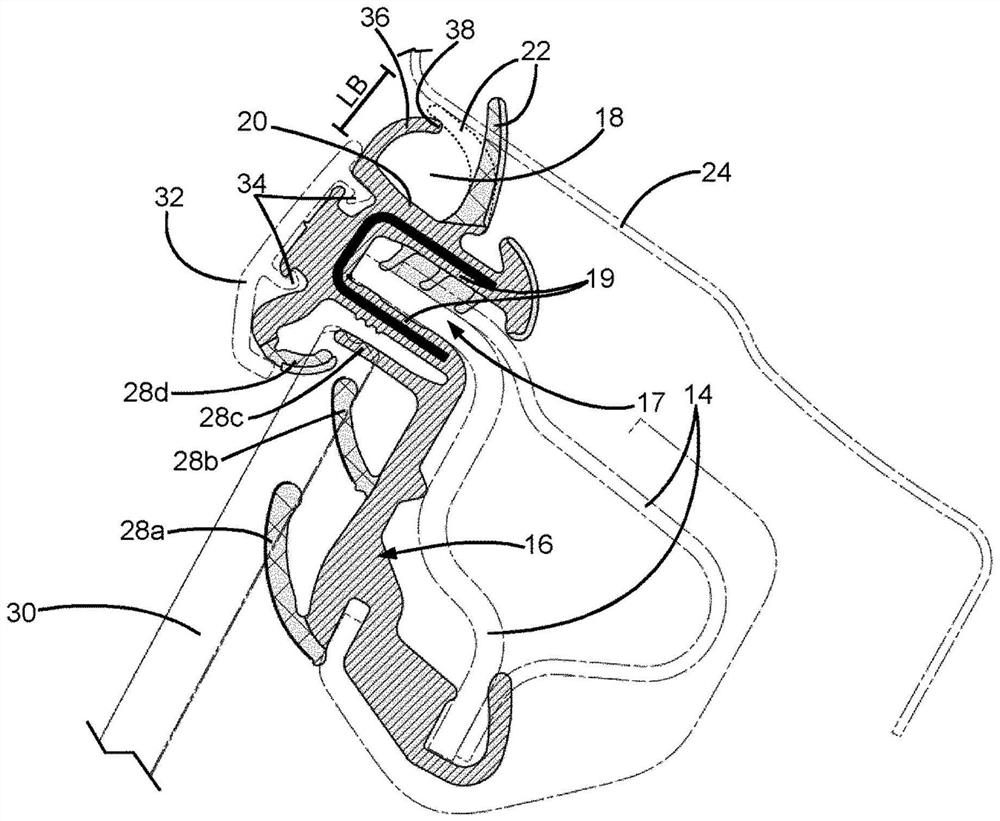

Sealing element having a cover section, vehicle door and vehicle having a sealing element, method for manufacturing a sealing element

PendingCN113613924APrevent outflowReliable importEngine sealsVehicle sealing arrangementsVehicle frameCar door

The invention relates to a sealing element for a front vehicle door (10) having at least one fastening section (19) by means of which the sealing element (16) can be fastened to a frame element (14) of the vehicle door (10), and having at least one channel section (18) which, in the mounted state on the vehicle door (10), is designed to form a drainage channel between the frame element (14) of the vehicle door and a side wall support (24) of the vehicle frame. According to the invention, the sealing element (16) has a cover section (36) which partially covers the channel section (18) towards the outside, and in particular covers at least half the clear width (LB) of the channel section (18). Furthermore, a vehicle having such a sealing element and a manufacturing method for such a sealing element are described.

Owner:AUDI AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com