Magnetic grinding disc, device and method for crowned tapered roller rolling surface finish machining

A tapered roller, surface finishing technology, applied in the direction of metal processing equipment, grinding/polishing equipment, grinding equipment, etc., can solve the unfavorable convex tapered roller rolling surface shape accuracy and dimensional accuracy, which is difficult to effectively improve Dispersion and improvement of the diameter of the rolling surface of the machined convex tapered roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0207] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The embodiments described by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention. In addition, the dimensions, materials, shapes, and relative arrangements of components described in the following embodiments are not intended to limit the scope of the present invention unless otherwise specified.

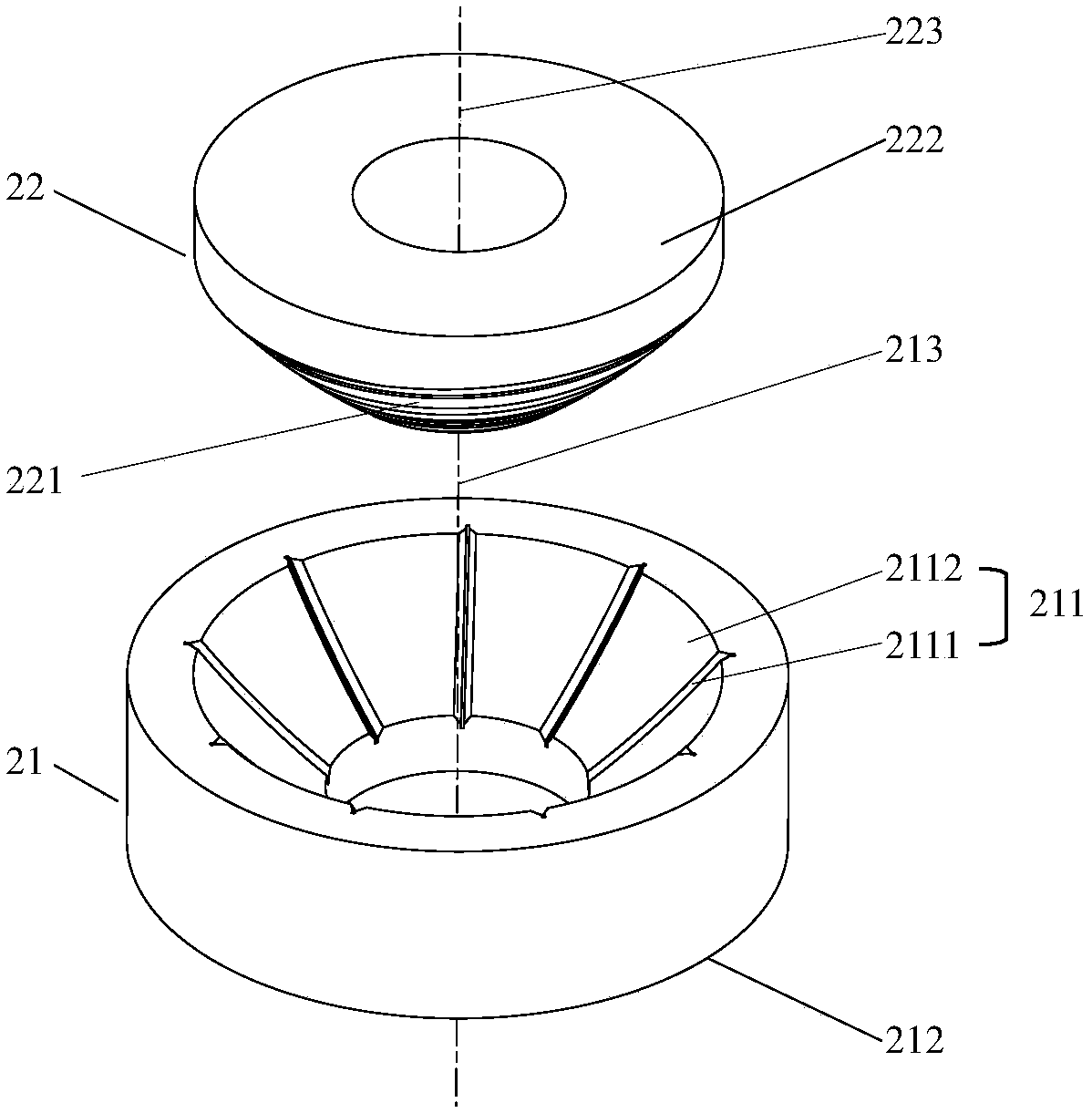

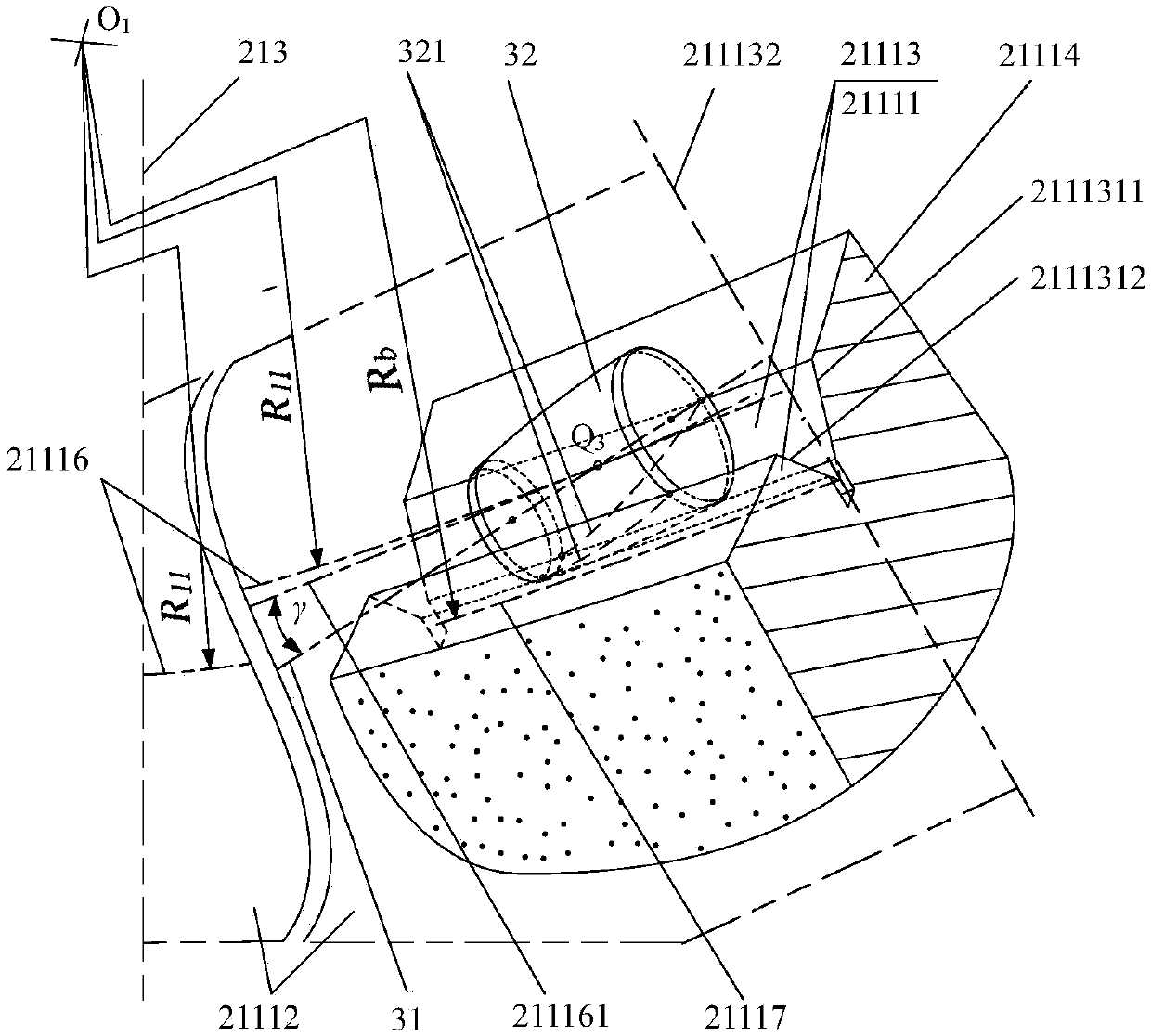

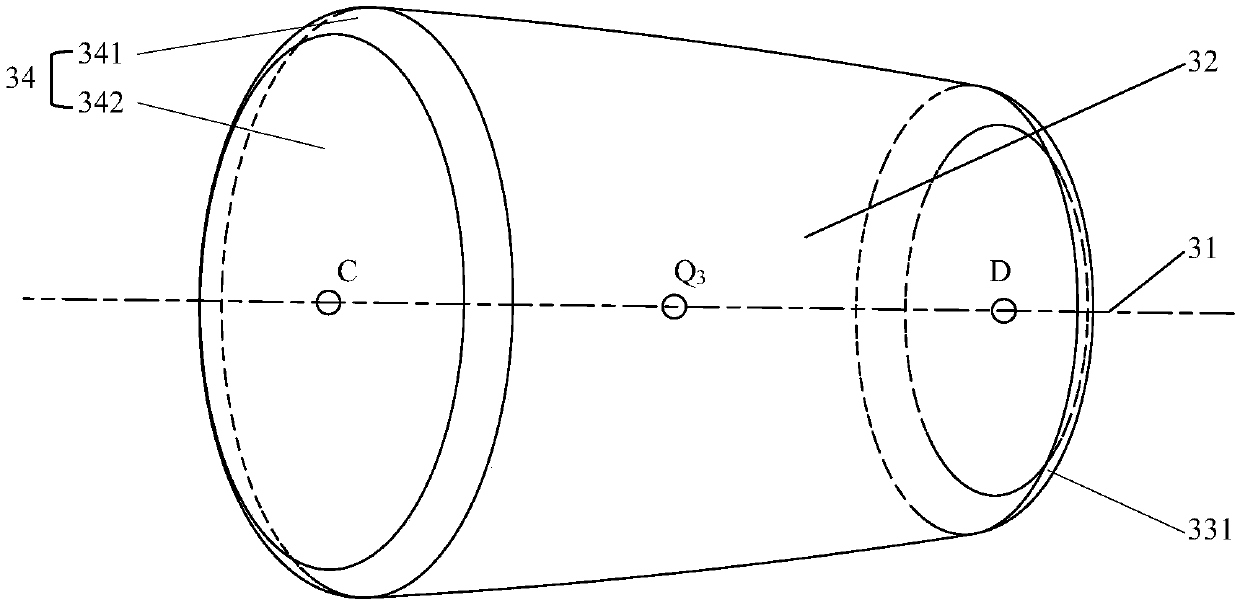

[0208] The present invention proposes a set of magnetic grinding discs for finishing the rolling surface of convex tapered rollers of ferromagnetic materials (such as GCr15, G20CrNi2MoA, Cr4Mo4V, etc.), including a pair of coaxial first grinding discs 213 and 223 And the second grinding disc 22, the front 211 of the first grinding disc 21 is arranged opposite to the front 221 of the second grinding disc 22, as figure 1 As shown, the reference numeral 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com