Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Improved hydrogen release performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pt/ZIF-67 composite used for catalyzing hydrolysis of ammonia borane for hydrogen production

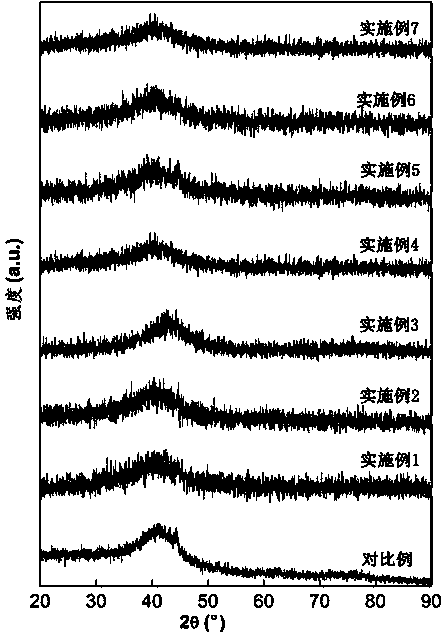

InactiveCN107930697AImproved hydrogen release performanceHigh TOF valueOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionReaction rateMetal-organic framework

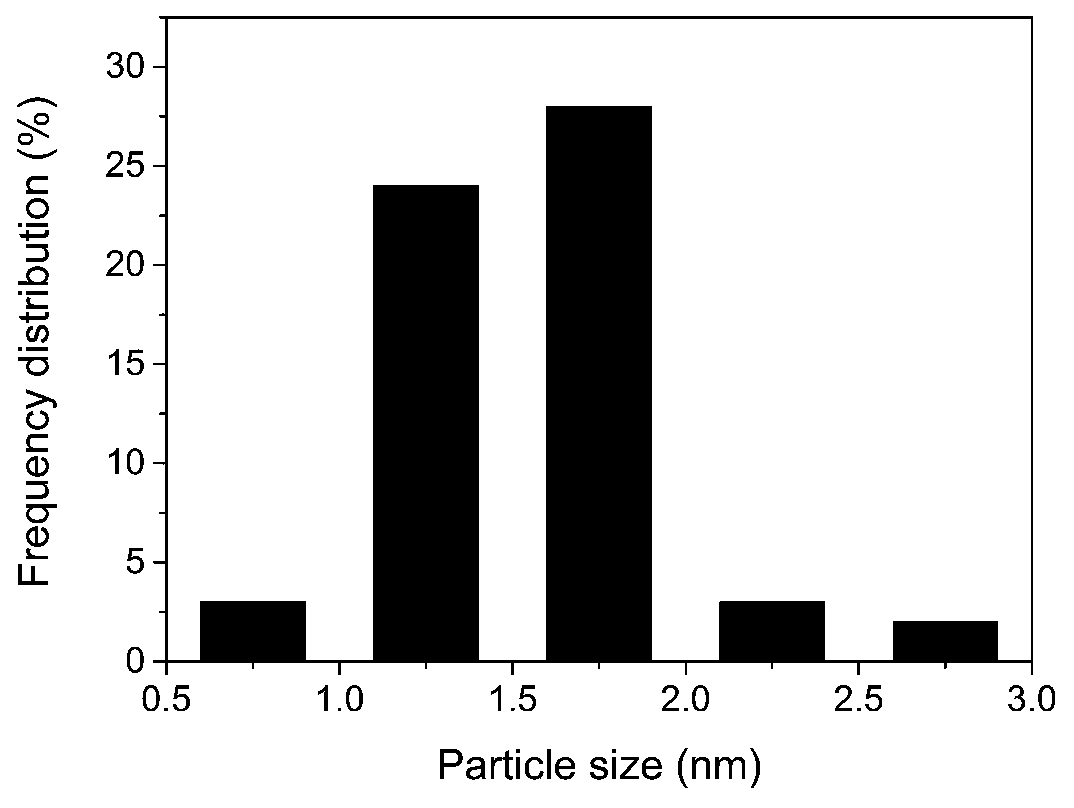

The invention discloses a Pt / ZIF-67 composite used for catalyzing hydrolysis of ammonia borane for hydrogen production. The Pt / ZIF-67 composite is prepared by mixing chloroplatinic acid with a metal organic framework ZIF-67 and then carrying out one-step reduction. The structure of the Pt / ZIF-67 composite retains the frame structure of ZIF-67; the average size of Pt nanoparticles is 1-2 nm, the Ptnanoparticles are uniformly distributed, and no obvious Pt metal characteristic diffraction peak occurs according to XRD detection results. A preparation method comprises the following steps: step 1)preparation and activation of the ZIF-67; and step 2) loading of the Pt nanoparticles: adding the activated ZIF-67 into water for ultrasonic dispersion, adding chloroplatinic acid, and then adding anaqueous NaBH4 solution drop by drop, and subjecting a product to filtering, washing and drying. As the Pt / ZIF-67 composite is applied to catalysis of the hydrolysis of ammonia borane for hydrogen production, the turn over frequency (TOF) of a reaction rate reaches 70-100 mol H2 min<-1> Pt mol<-1>, and activation energy is 30-40 kJ mol<-1>. The synergistic effect of the ZIF-67 and the Pt nanoparticles brings in better catalytic performance. Therefore, the Pt / ZIF-67 composite has good application prospects in the field of hydrogen production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

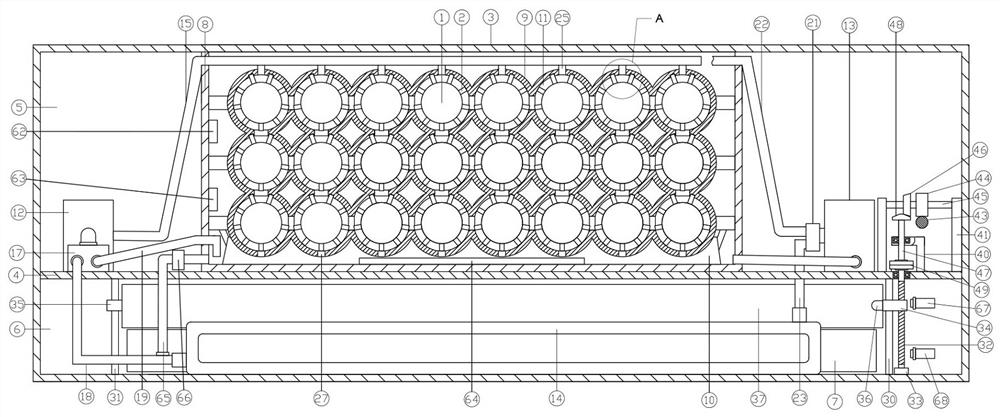

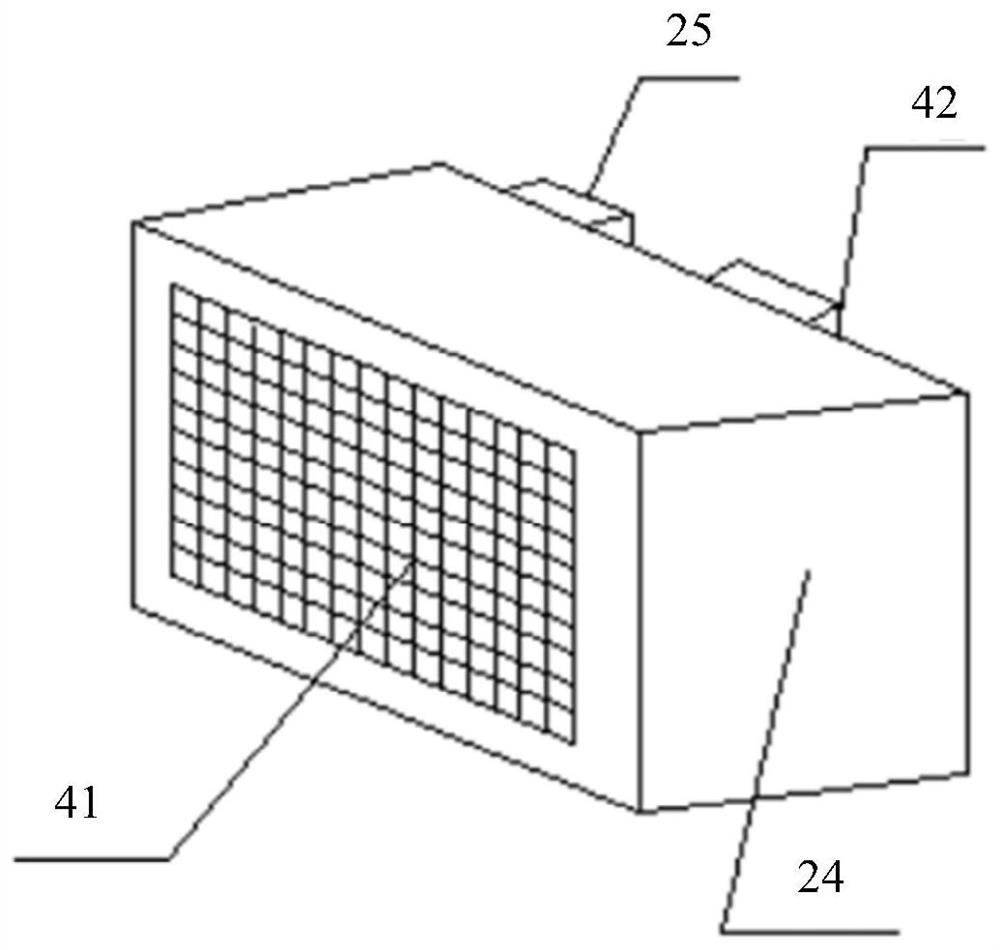

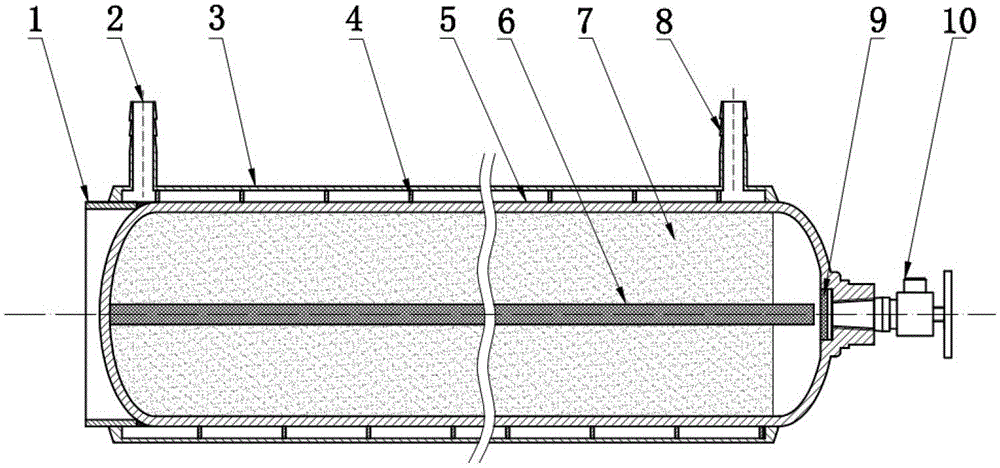

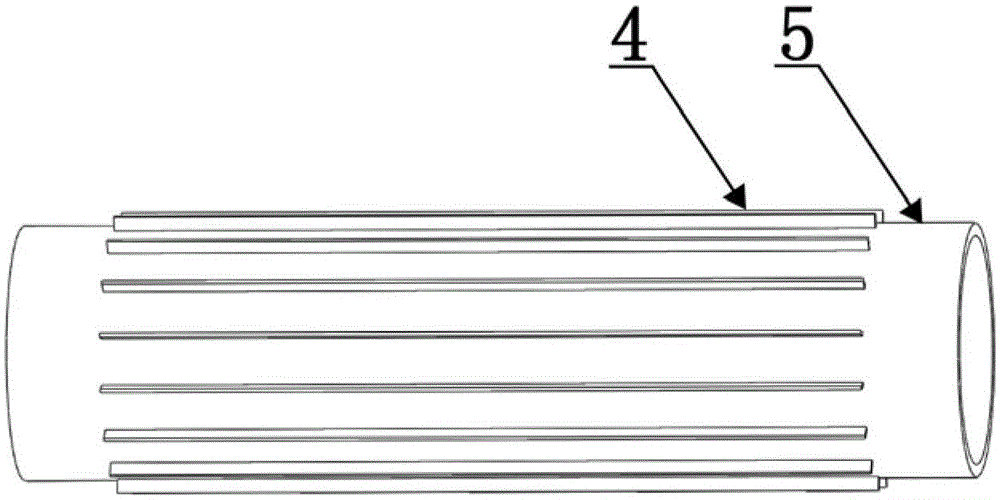

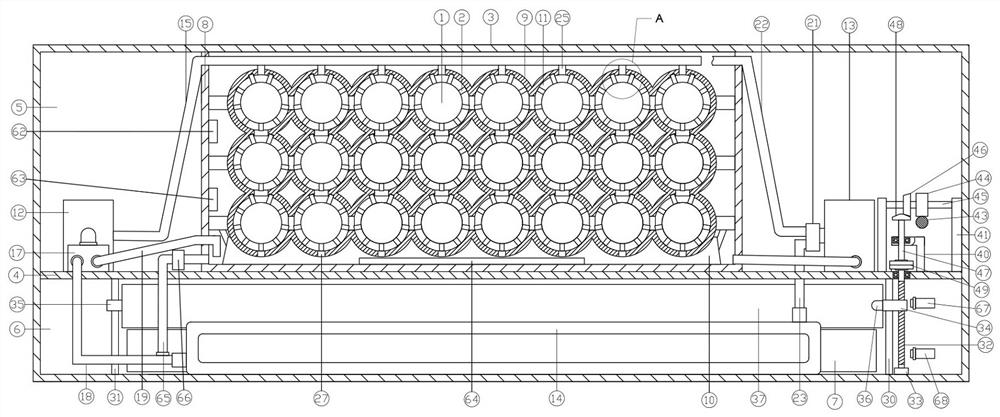

Metal hydride hydrogen storage device

InactiveCN104676239ASimple structureEasy to processContainer filling methodsPressure vesselsEngineeringHeat transfer efficiency

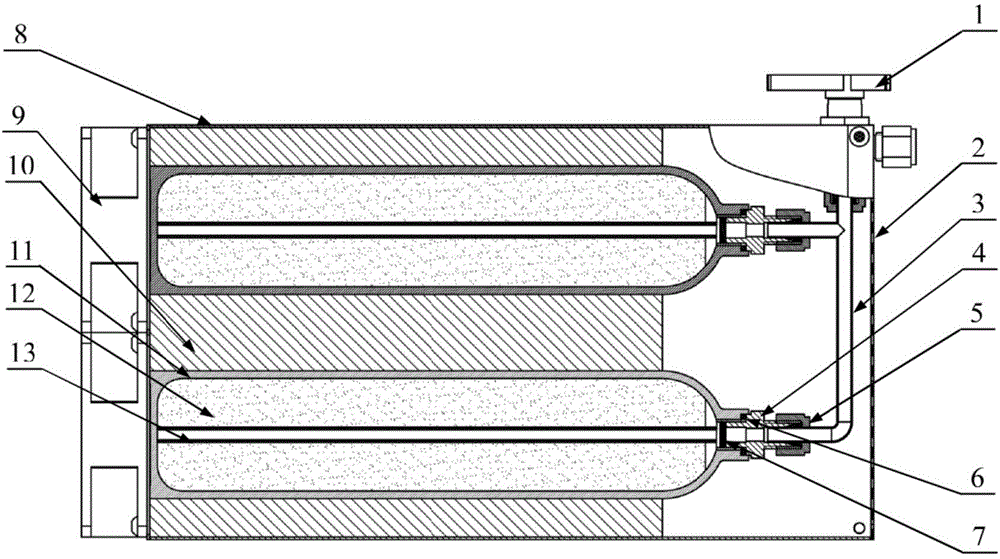

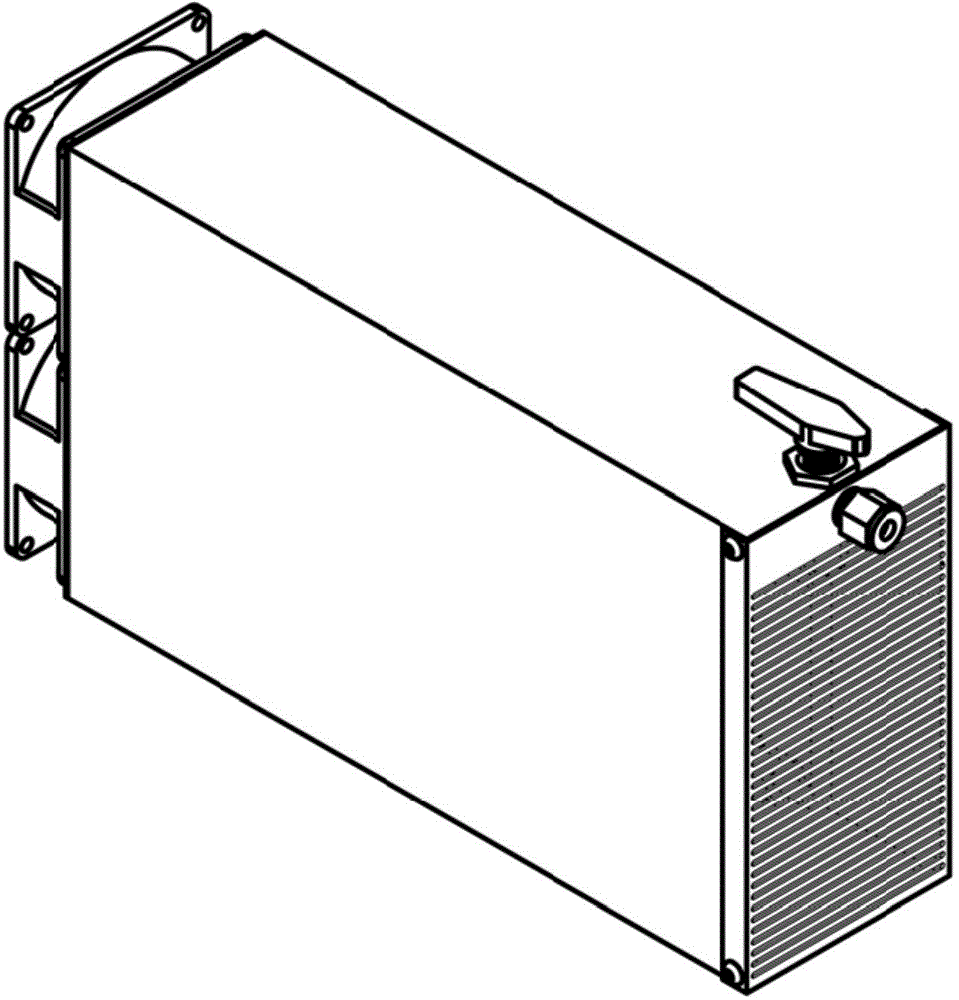

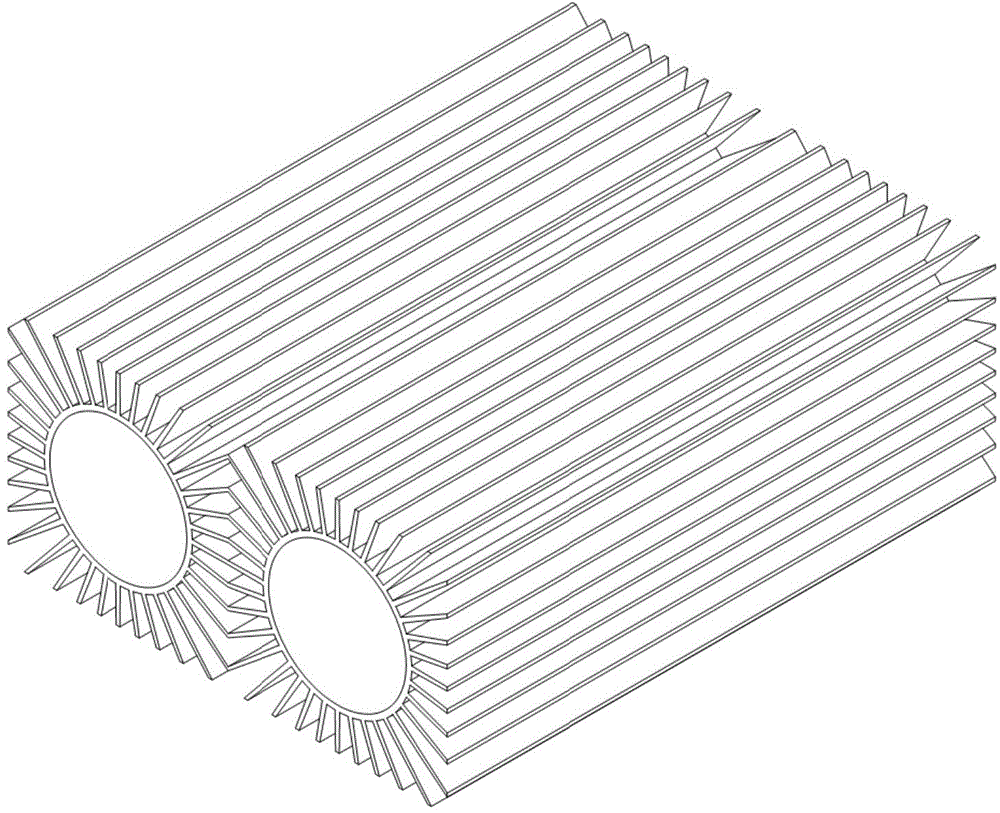

The invention discloses a metal hydride hydrogen storage device, which belongs to the technical field of hydrogen storage. The device is composed of a valve, a front cover, a gas path tube, a bottleneck connector, a clamping sleeve, a sealing gasket, a filter disc, a shell, two fans, a longitudinal heat transfer finned tube, a hydrogen storage container, a hydrogen storage material bed body, and a porous gas guide tube, wherein the bottleneck connector is connected with a hydrogen storage bottle body and the gas path tube by the sealing gasket and the clamping sleeve; the gas path tube is connected with the porous gas guide tube and the valve by the filter disc; the front cover and the two fans are arranged on the shell, and the longitudinal heat transfer finned tube and a hydrogen storage bottle are arranged in the shell; and the hydrogen storage material bed body and the porous gas guide tube are arranged in the hydrogen storage bottle body. The metal hydride hydrogen storage device disclosed by the invention is simple in structure, and easy to manufacture and process; and the longitudinal heat transfer finned tube can ensure the uniform heat transfer of the hydrogen storage container while the heat transfer efficiency of the hydrogen storage container is improved, so that the uniformity of hydrogen desorption of the hydrogen storage material bed body in the hydrogen storage container is ensured, and the hydrogen desorption performance is significantly improved.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

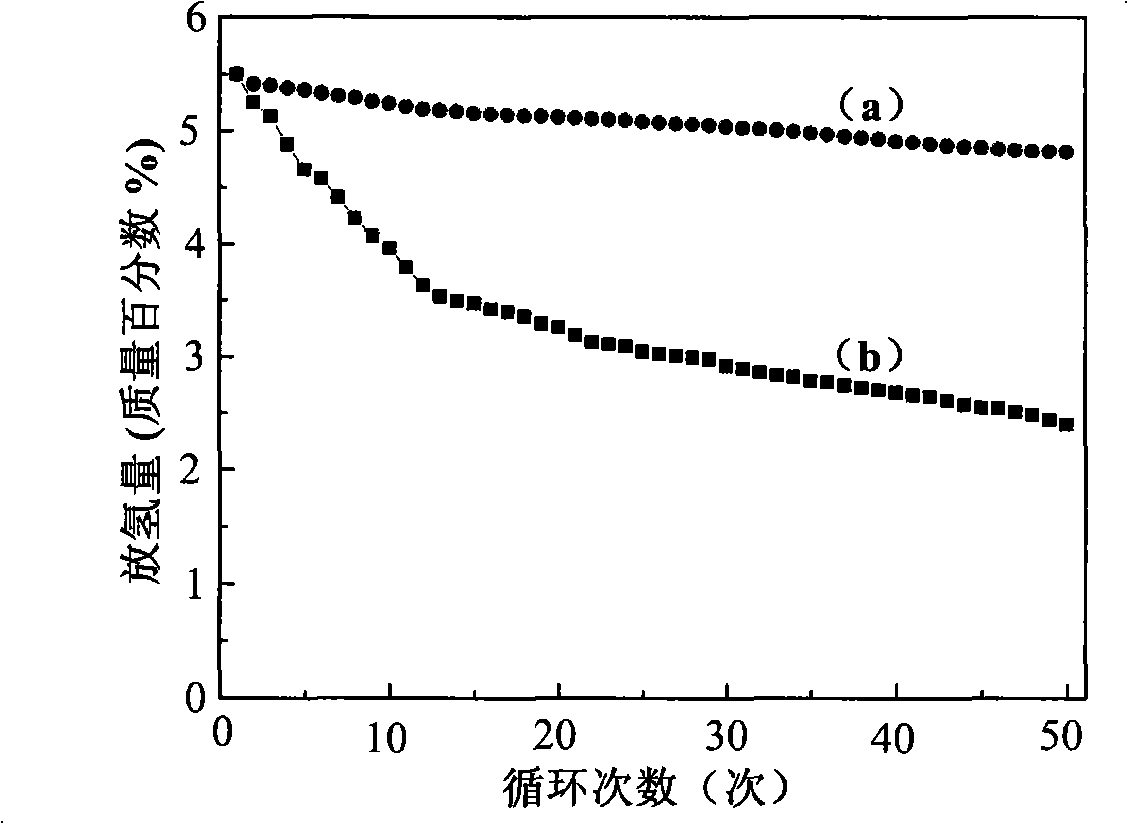

Nanometer TiF3 catalyzed high-volume hydrogen-storing alloy and preparation method thereof

InactiveCN103667837AReduced thermal stabilityImprove hydrogen desorption capacityCell electrodesRare-earth elementYttrium

The invention discloses nanometer TiF3 catalyzed high-volume hydrogen-storing alloy and a preparation method thereof. The compositions of the alloy are shown as the following: La2-xRExMg17-yNiy+100 wt% Co+z wt% TiF3, wherein 0.2<x<0.5, 1<y<3, 3<z<10, RE is at least one of rare earth elements neodymium, yttrium and samarium. The preparation method comprises: in the protection of inert gas, employing induction heating for melting, injecting fused alloy into a copper mold to obtain cylinder ingots; filling a quartz tube with the ingots, performing induction heating fusion, continuously spraying liquid alloy on the surface of a rotating water-cooling copper roller by a slit nozzle at the bottom of the quartz tube to obtain rapid-quenched alloy; and mixing fragmented alloy powder and cobalt powder, performing ball milling, adding trace TiF3 catalyst and continuing to perform ball milling to obtain the alloy powder. Through composition design and structure adjusting, the thermal stability of alloy hydride is reduced and the hydrogen adsorption / desorption capacity and the dynamic performances of the alloy are improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

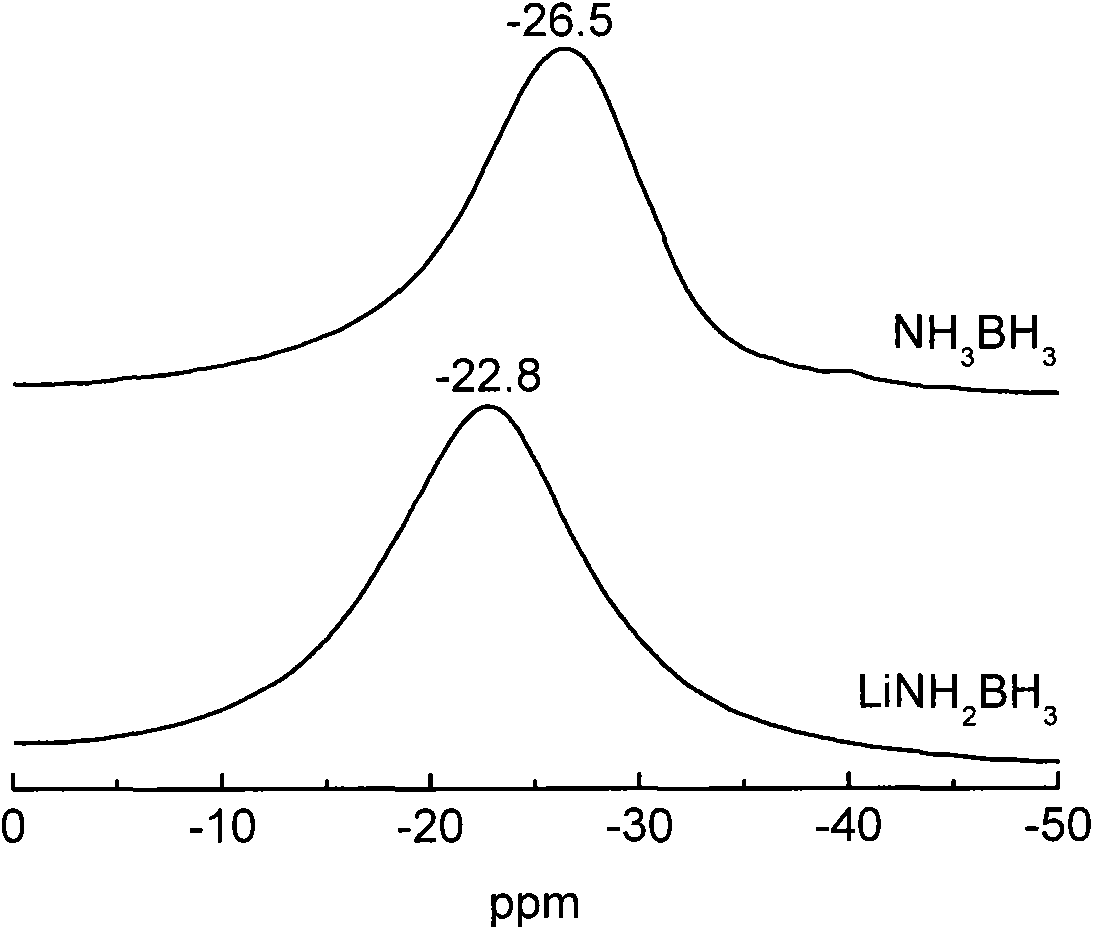

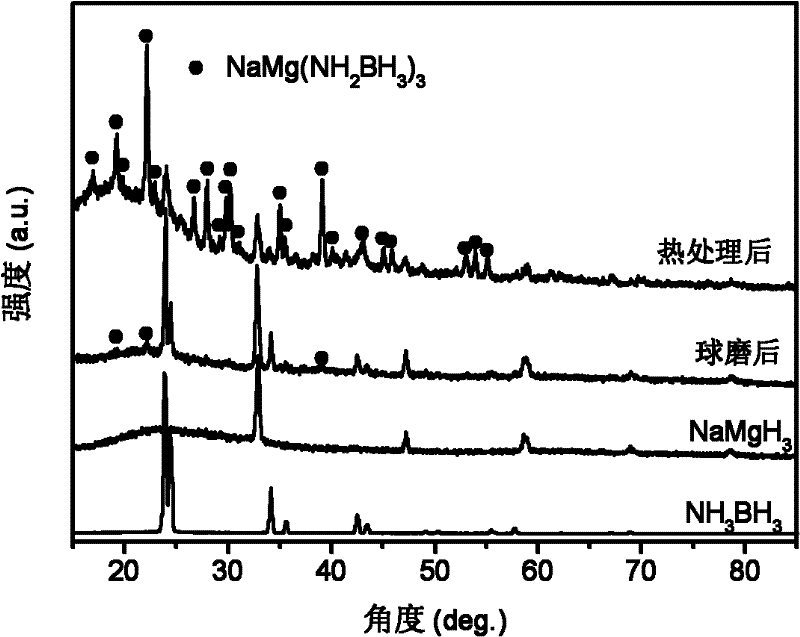

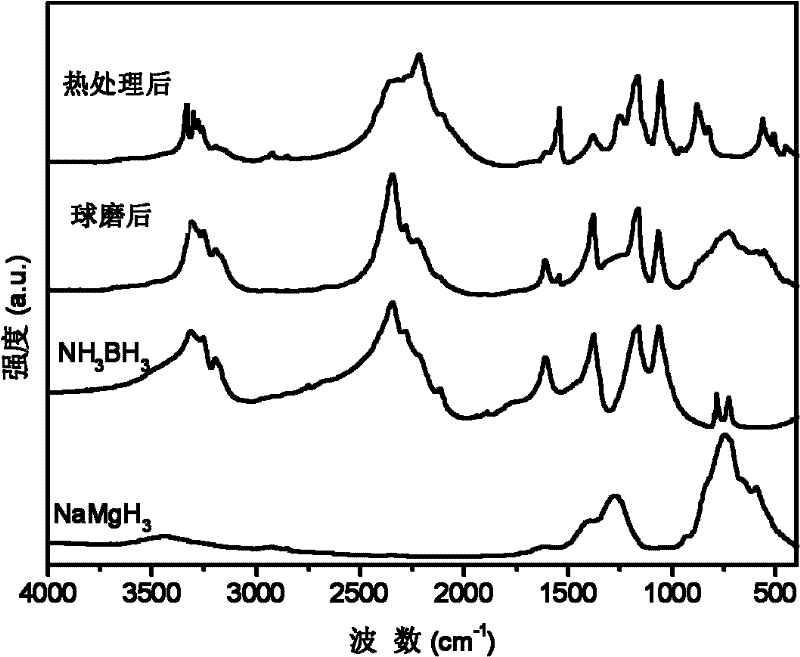

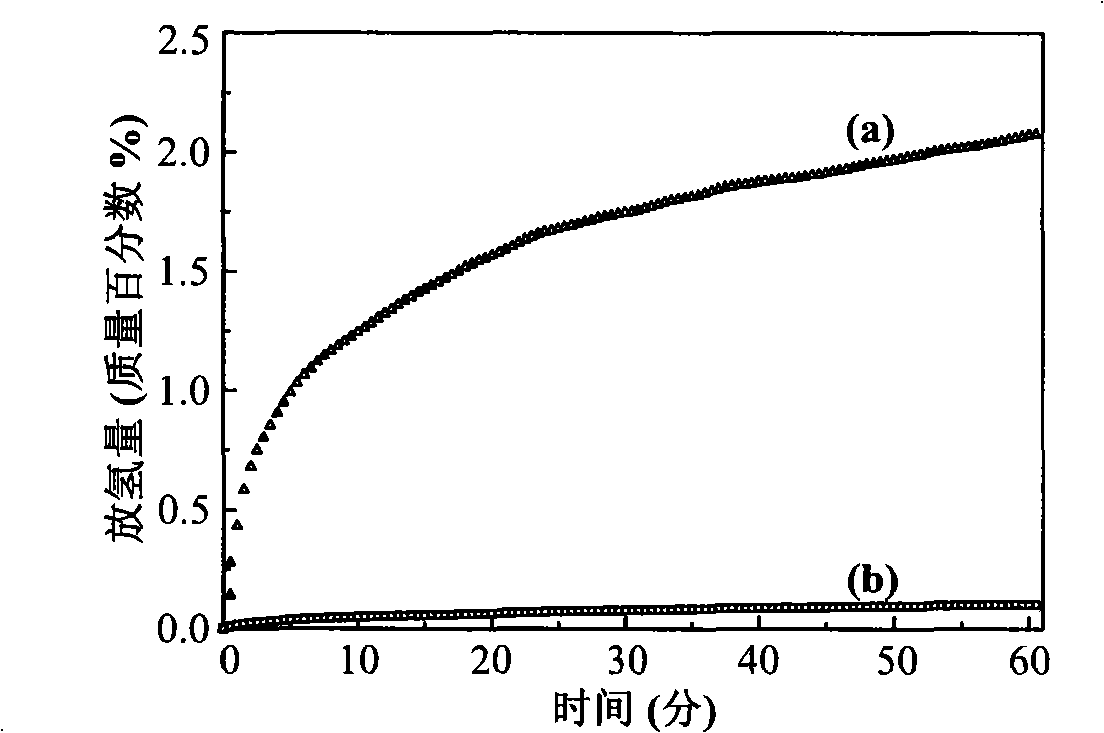

Metal ammonia borane compound hydrogen storage material and preparation method thereof

InactiveCN101613083AImproved hydrogen release performanceStrong donating abilityHydrogen productionMetal hydridesHydrogen atmosphereImpurity

The invention relates to a material and technology for storing hydrogen, in particular to a novel metal ammonia borane compound hydrogen storage material and a preparation method thereof. The novel metal ammonia borane compound hydrogen storage material is prepared by taking the mixture of ammonia borane NH3BH3 and metal M or metal hydride NHy as an initial raw material and performing ball milling on the raw material in an inert protective atmosphere or a reactive hydrogen atmosphere. The molecular formula of the novel metal ammonia borane compound hydrogen storage material is MxNH(3-nx)BH3, wherein x is more than 0 and less than or equal to 1, and n is more than or equal to 1 and less than or equal to 3. The mole ratio of NH3BH3 to M or NHy in the phase composition of the raw material is 1-50:1. The preparation method provided by the invention has high efficiency and simple and easy operation. The novel metal ammonia borane compound hydrogen storage material provided by the invention has the advantages of high hydrogen storage capacity, low hydrogen production temperature, fast hydrogen production dynamics, no impurities, no gaseous pollutants and the like and has the application prospective of automobile-mounted hydrogen storage.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

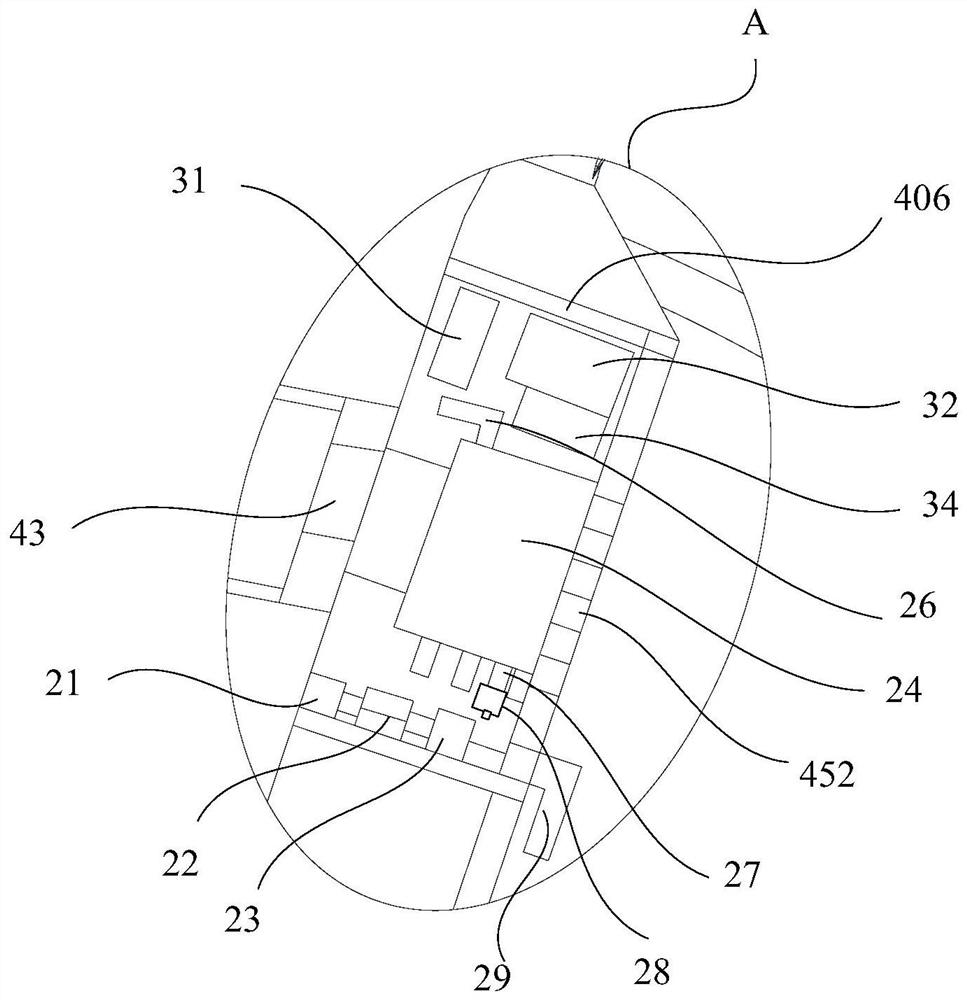

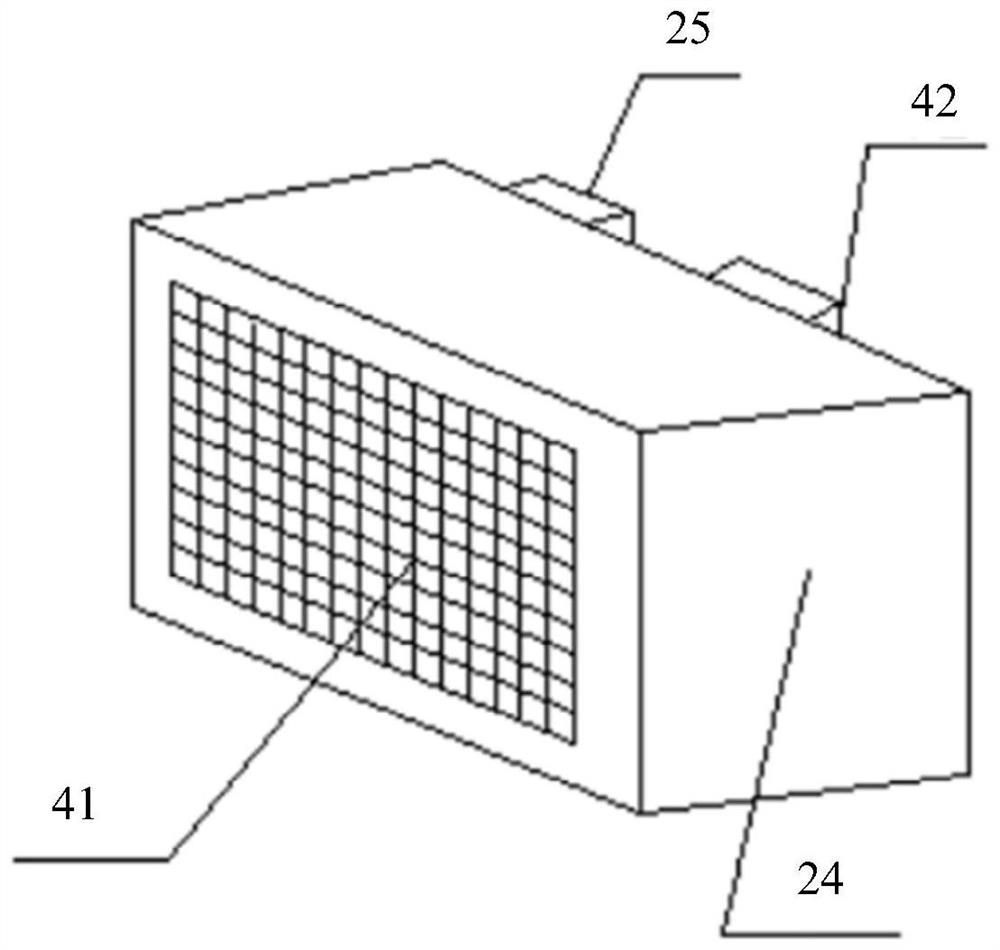

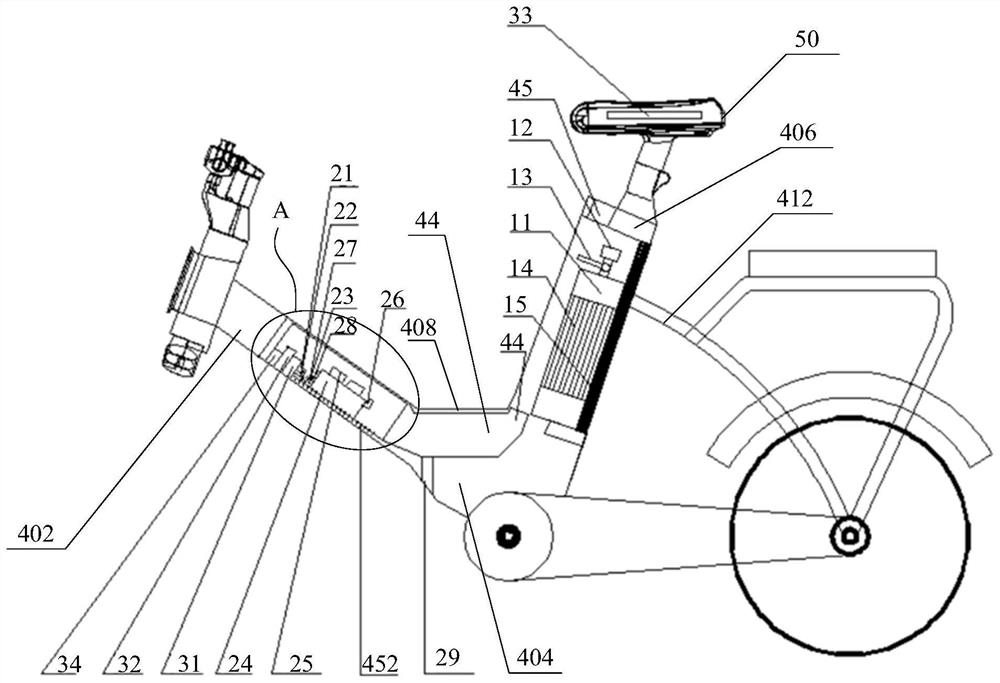

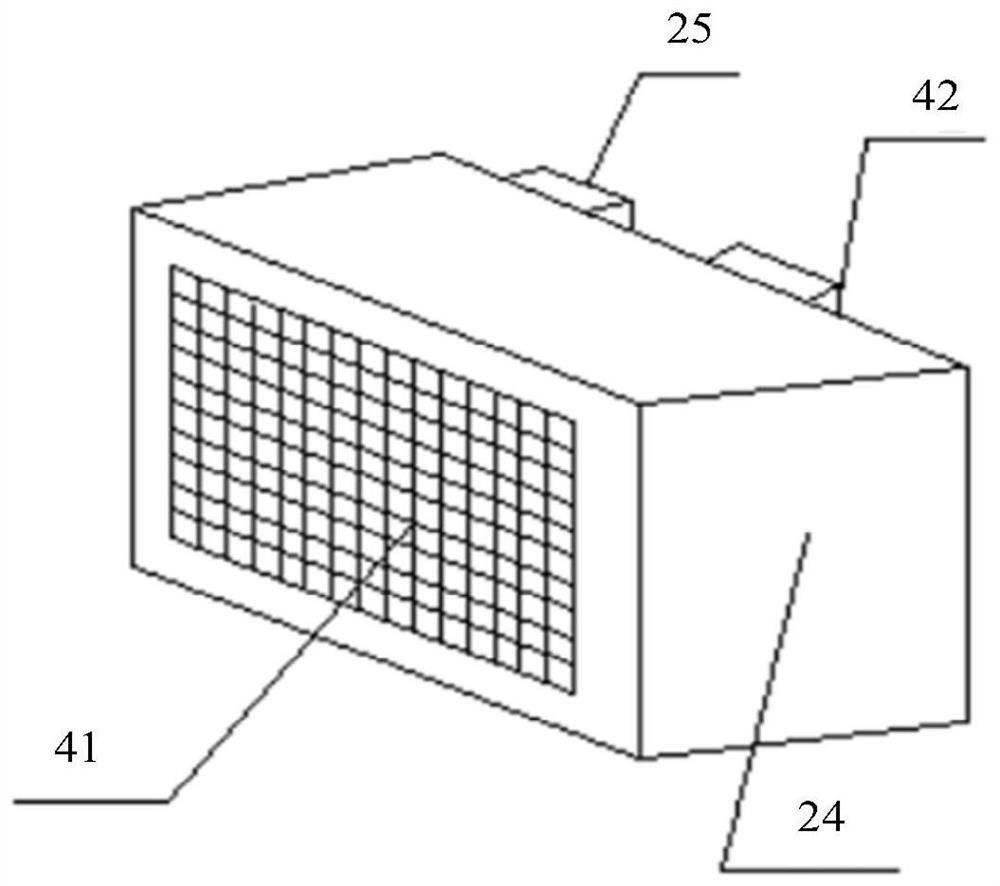

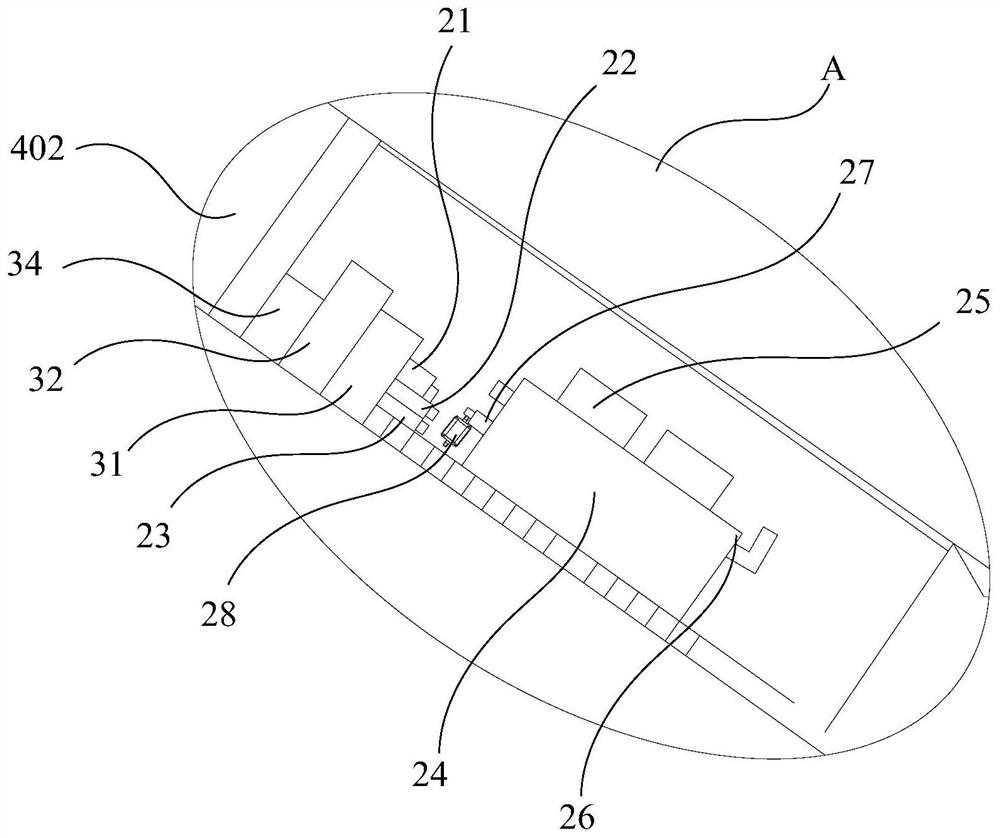

Power system of hydrogen fuel cell power-assisted bicycle

PendingCN111993909AImproved hydrogen release performanceReduce energy lossReactant parameters controlPropulsion by batteries/cellsThermodynamicsHydrogen fuel cell

The invention provides a power system of a hydrogen fuel cell power-assisted bicycle. The system comprises a hydrogen storage tank, a fuel cell device and a control device, the hydrogen storage tank is used for storing a solid hydrogen storage alloy material; the hydrogen storage tank supplies hydrogen to the fuel cell device through a hydrogen supply pipeline, and the fuel cell device can supplyelectric energy to the movement of the power-assisted bicycle. The fuel cell device supplies power to the hydrogen storage tank and the control device through power supply lines, and the control device can start and stop the fuel cell device. According to the technical scheme, waste heat generated during the operation of a fuel cell stack can be utilized, and thermal self-compensation is achieved.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

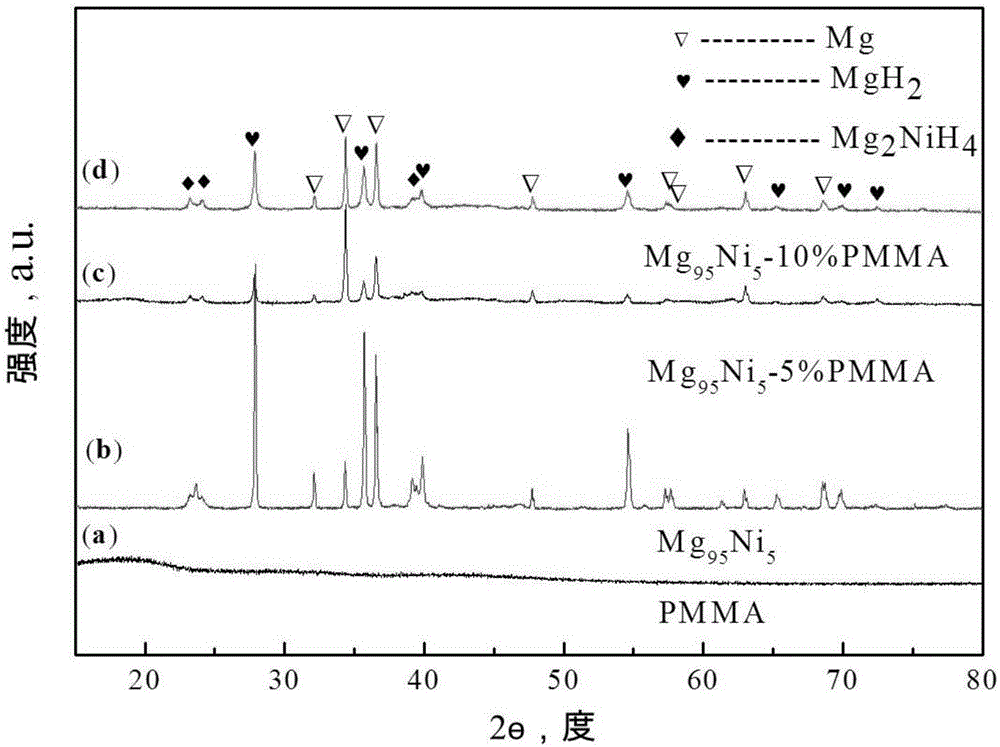

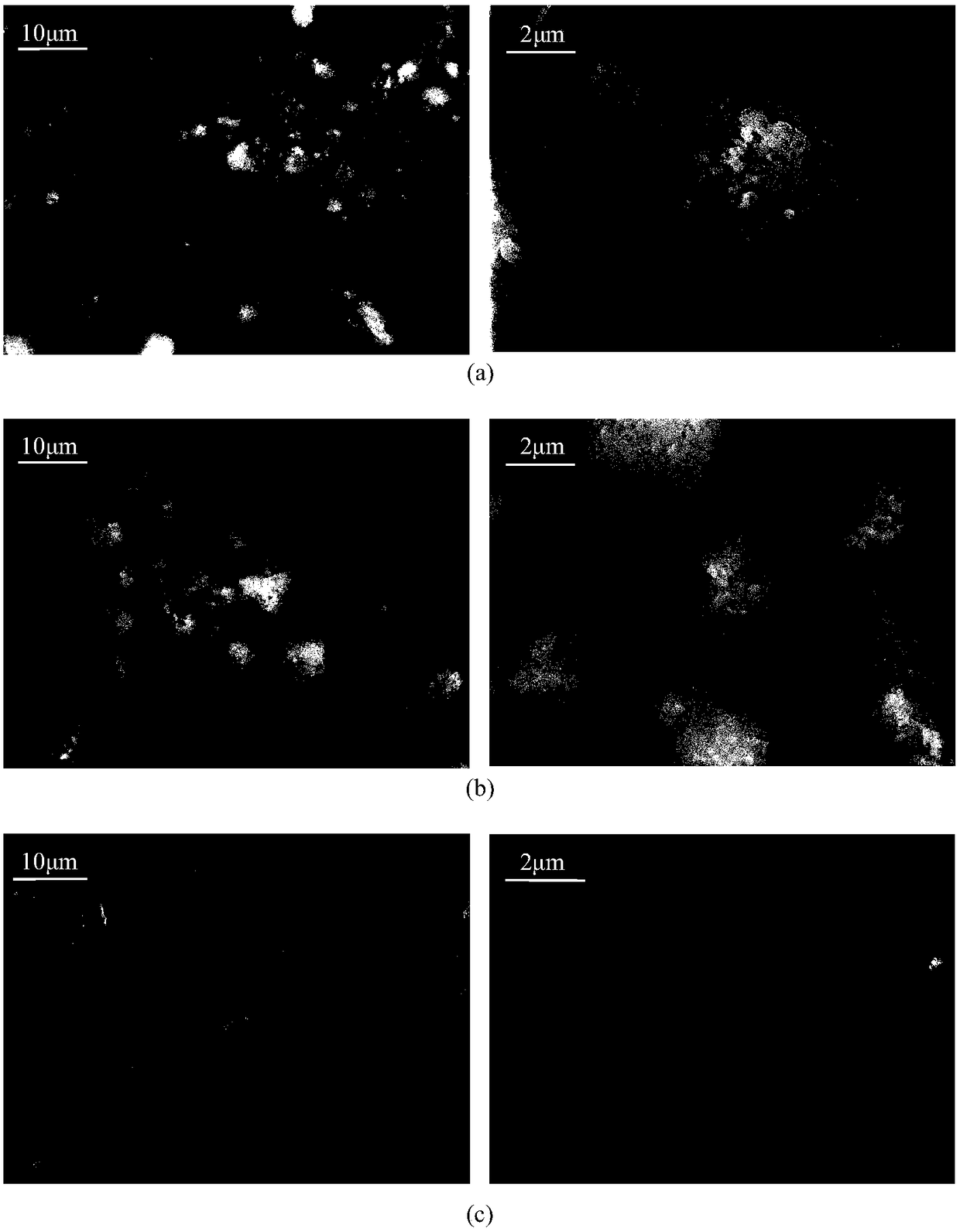

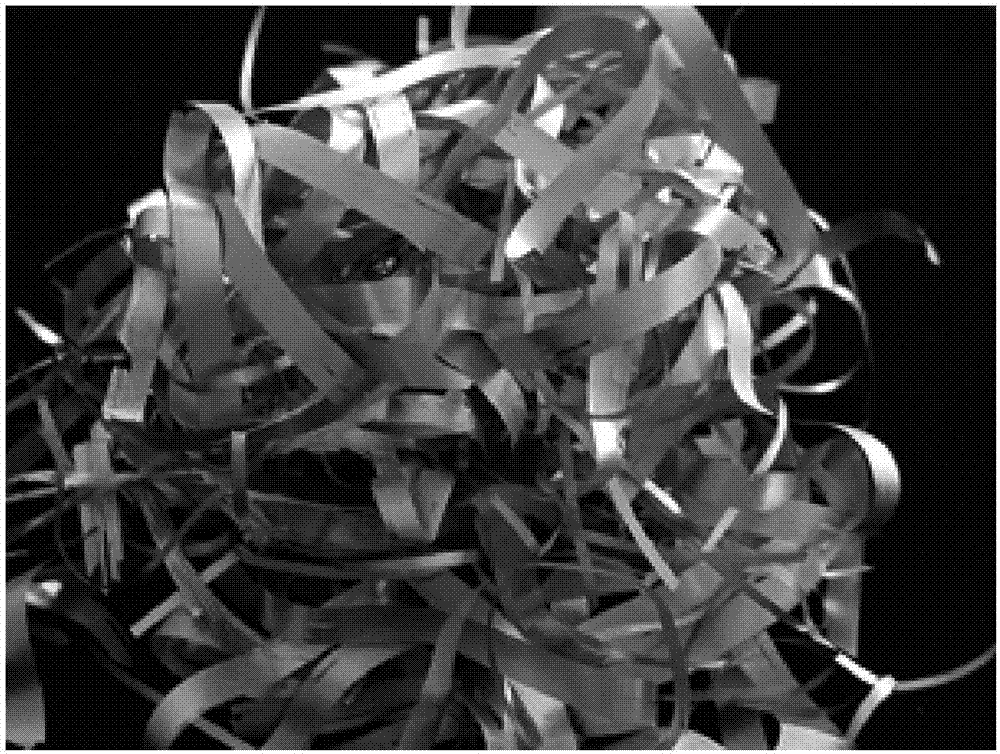

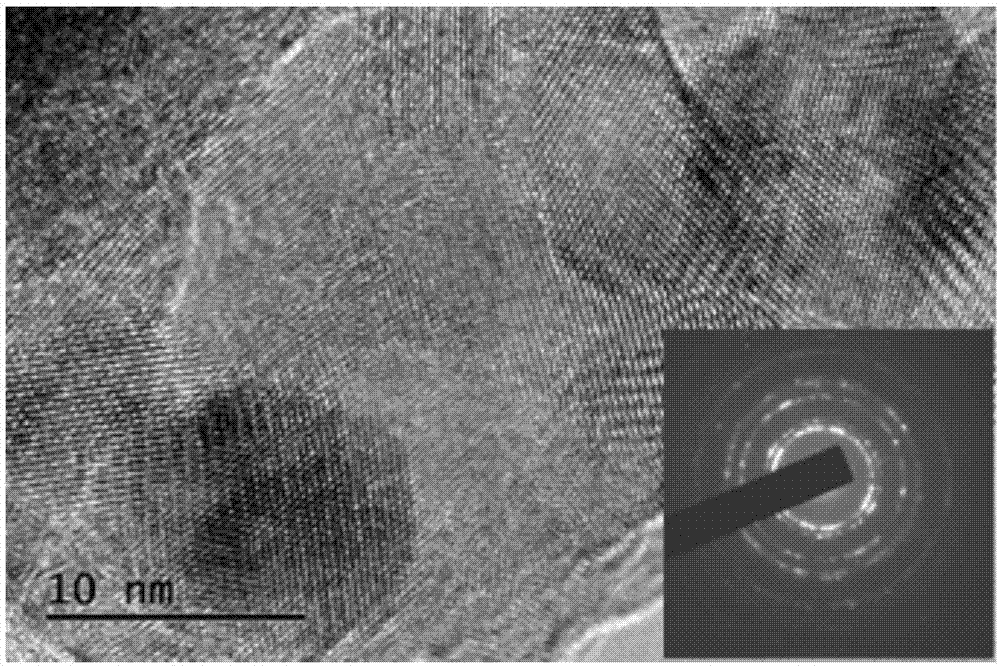

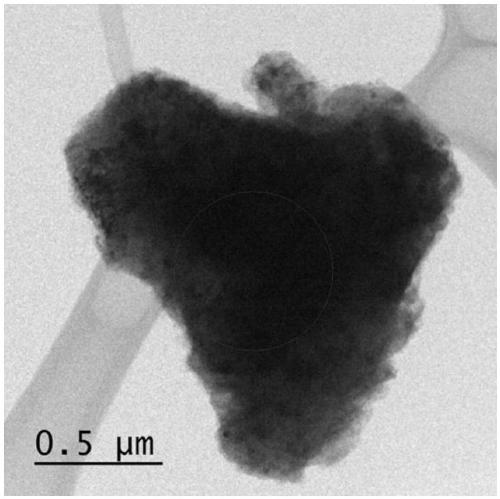

Polymer wrapped nano magnesium based hydrogen storage material and preparation method thereof

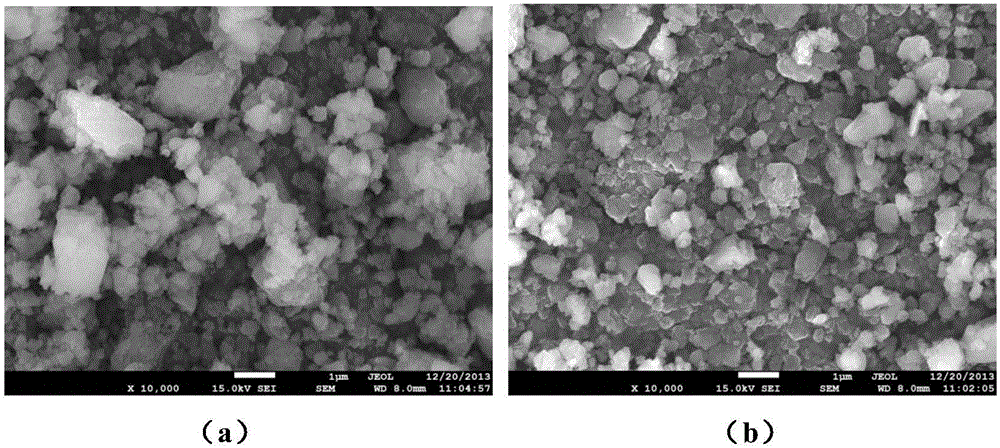

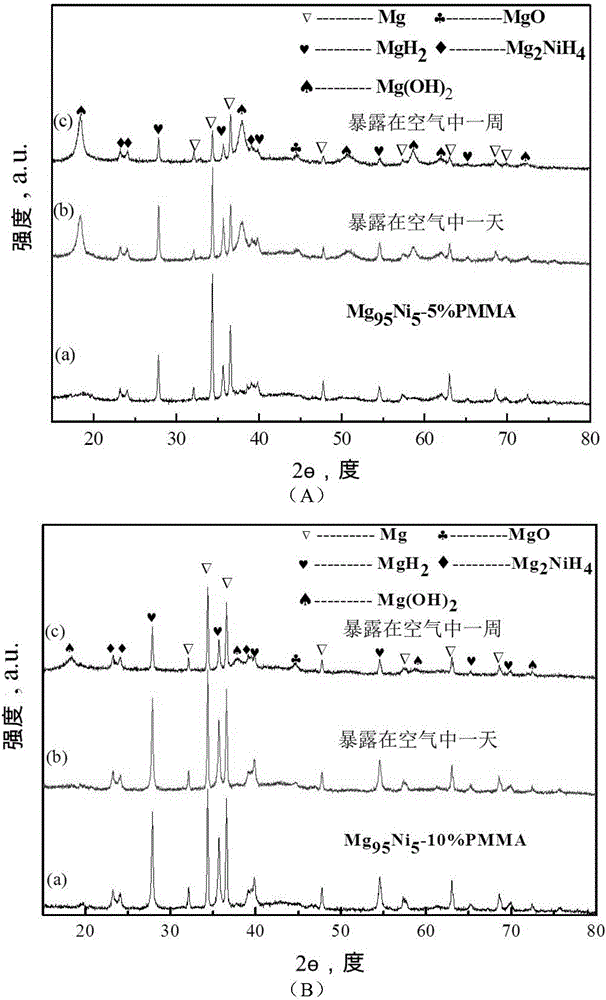

ActiveCN106566965AAnti-oxidation and chalking resistanceExcellent hydrogen absorption and desorption performance at low temperatureTransportation and packagingMetal-working apparatusMaterials preparationPolymer science

The invention relates to a polymer wrapped nano magnesium based hydrogen storage material and a preparation method thereof, and belongs to the technical field of hydrogen storage material preparation. The hydrogen storage material is prepared from the following components in percentage by weight: 80 to 98% of magnesium-nickel alloy, and 2 to 20% of polymer. Magnesium powder and nickel powder are taken as the raw materials and then are mixed and preprocessed; the mixture is hydrogenated, burned, and synthesized, and finally the product and polymers are fiercely and mechanically ball-milled to prepare the hydrogen storage material. The hydrogen storage material has excellent low temperature hydrogen absorption / desorption dynamics performances: at a temperature of 473K, the hydrogen absorption amount can reach 3.73 wt.% with 60 minutes; the hydrogen desorption amount can reach 1.02 wt.% within 120 minutes; at a temperature of 523 K, the hydrogen absorption amount is as high as 4.04 wt.% within 60 minutes, and the hydrogen desorption amount can reach 2.18 wt.% within 120 minutes. The hydrogen storage material can be used to store / transport hydrogen and prepare hydrogen fuel battery.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Multi-metal ammonia borane compound hydrogen storage material and preparation and composite hydrogen release method thereof

InactiveCN102530872AIncrease energy densityAdjustable ionic propertiesMonoborane/diborane hydridesHydrogen productionHydrogen atmosphereHydrogen storage system

The invention relates to the field of hydrogen storage material and hydrogen production, in particular to a multi-level ammonia borane compound hydrogen storage material and preparation and composite hydrogen release method thereof. The mixture of ammonia borane NH3BH3 and multi-metal hydride M1Mm2nHx is used as the starting material, and the multi-level ammonia borane compound hydrogen storage material is prepared by ball milling or auxiliary heat treatment in an inertia protection atmosphere or reactive hydrogen atmosphere, wherein the molecular formula of the multi-level ammonia borane compound hydrogen storage material is M1mM2n(NH2BH3)x, wherein 0<m<=4, 0<n<=4 and 1<=x<=10; the starting material comprises the phases of NH3BH3 and M1mM2nHx at a molar ratio of (1-10):1. The multi-level ammonia borane hydrogen storage material provided by the invention has obvious advantages of relatively high hydrogen storage capacity, low hydrogen release temperature, no impurity gas pollutant and the like. The composite hydrogen release technology provided by the invention effectively integrates the synthesis reaction and decomposition reaction of the multi-level ammonia borane so that the hydrogen storage system can realize high-capacity and fast hydrogen release in a proper temperature, and has application prospect in vehicular hydrogen storage.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

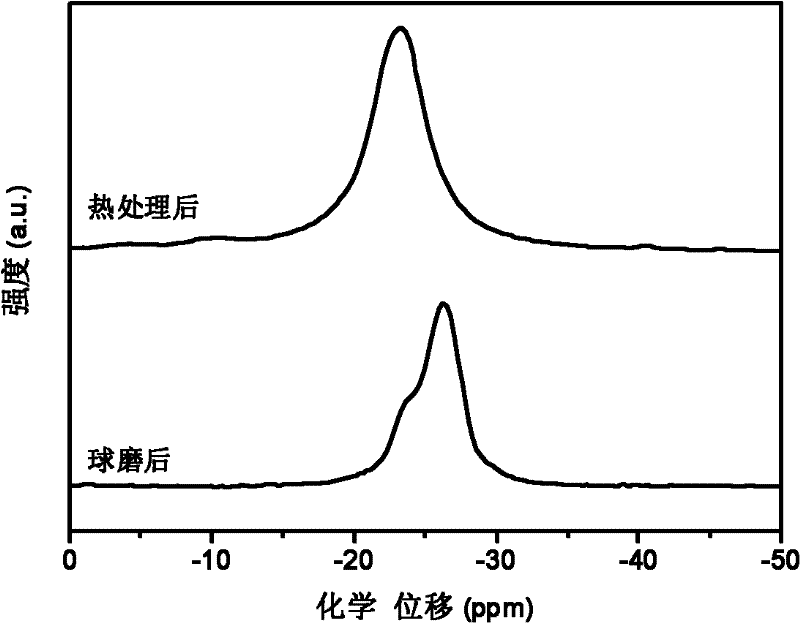

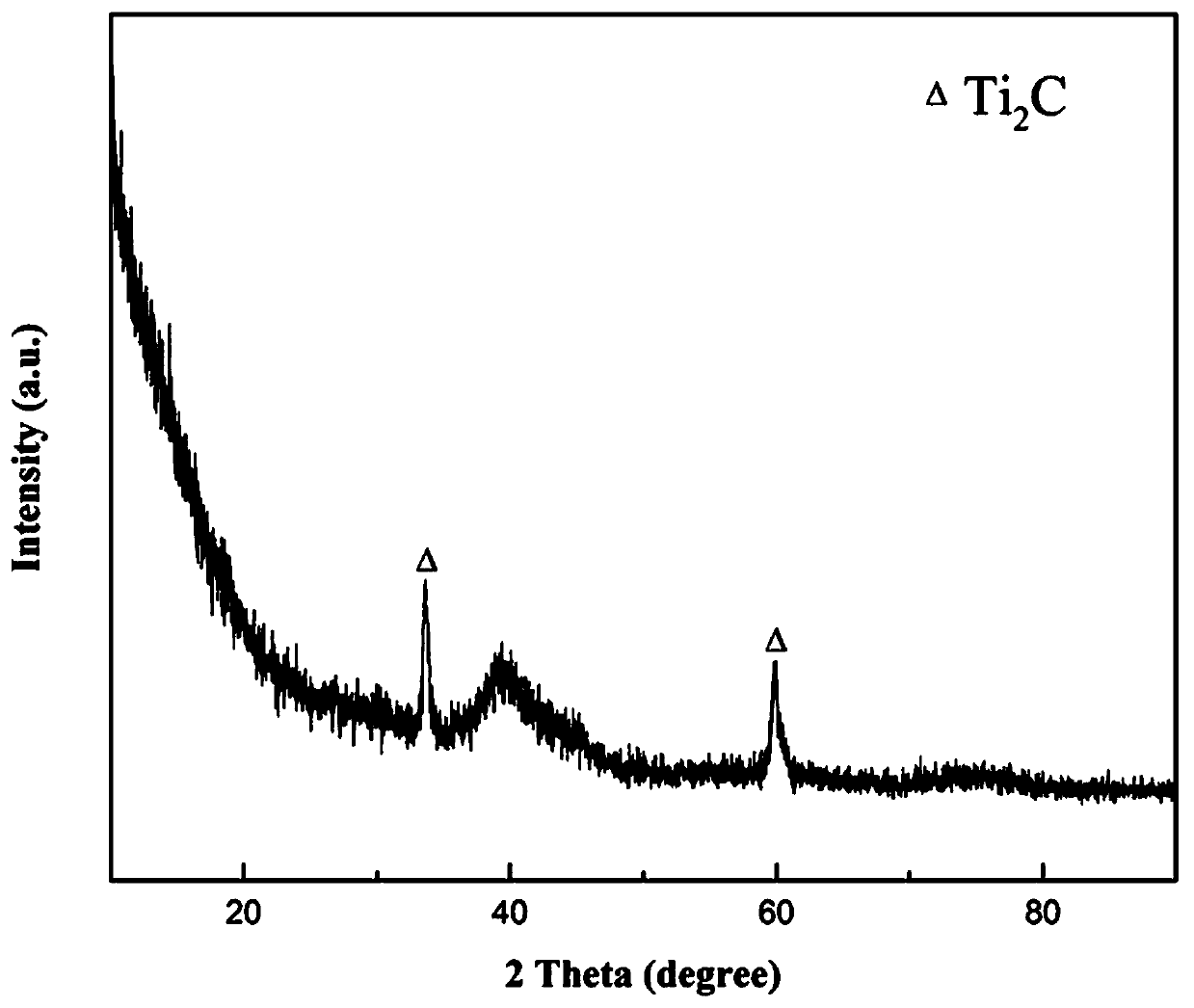

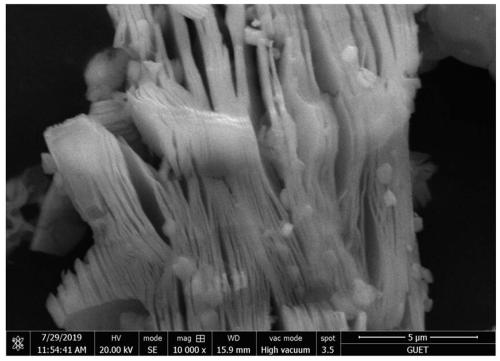

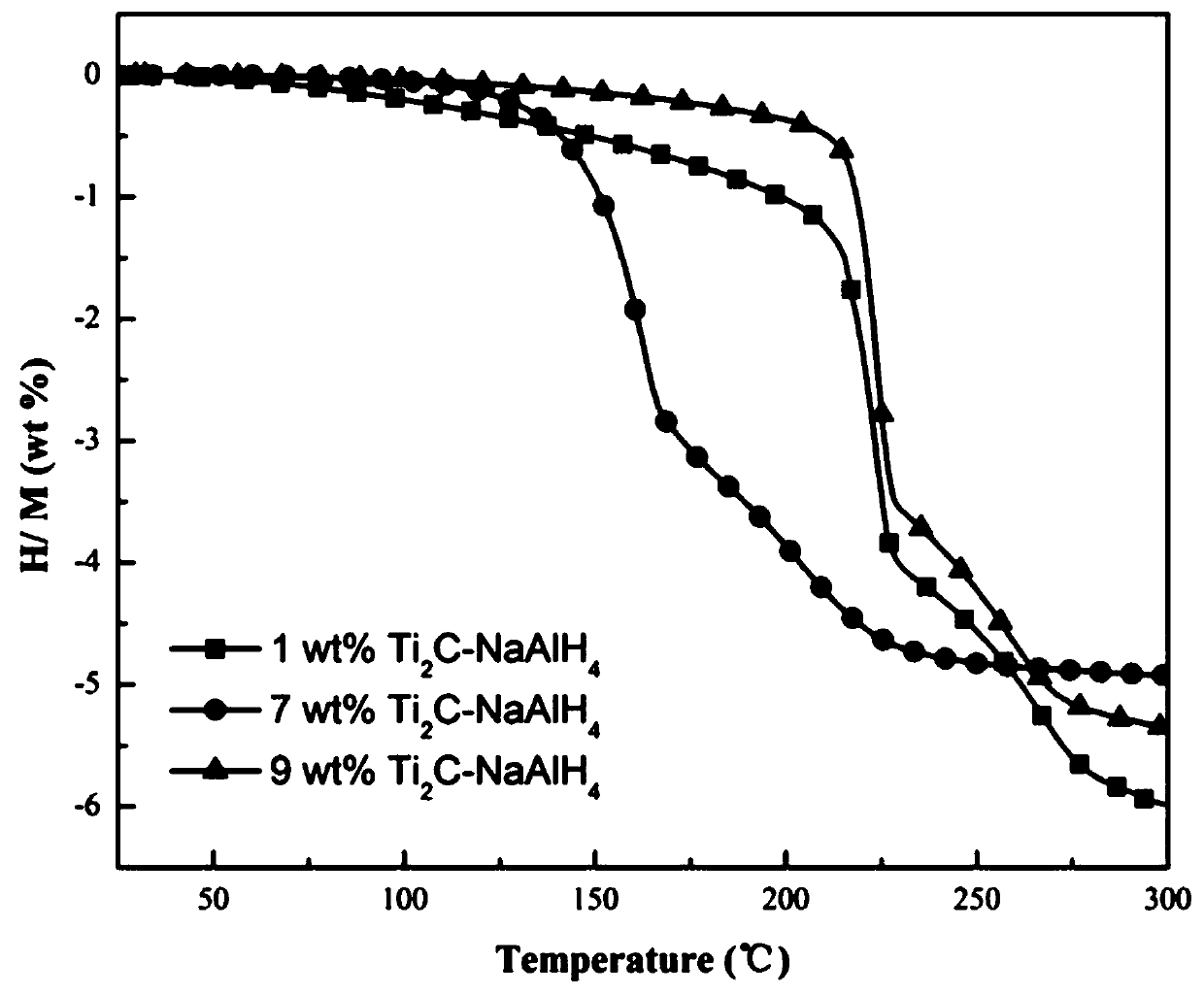

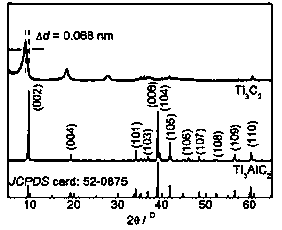

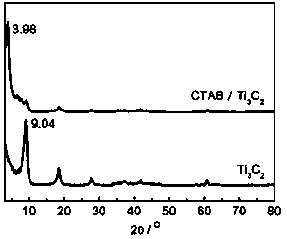

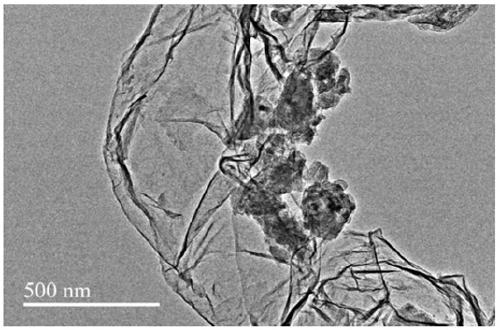

Two-dimensional titanium carbide-doped sodium aluminum hydride hydrogen storage material and preparation method thereof

ActiveCN110436408AImprove hydrogen storage performanceHigh hydrogen storage capacityHydrogenMultiple metal hydridesSodium aluminium hydrideTitanium carbide

The invention discloses a two-dimensional titanium carbide-doped sodium aluminum hydride hydrogen storage material. The hydrogen storage material is prepared by mixing and ball milling of sodium aluminum hydride and two-dimensional titanium carbide (Ti2C); and the two-dimensional titanium carbide (Ti2C) has a two-dimensional sheet stacking structure. The preparation method comprises the followingsteps: 1) preparation of two-dimensional Ti2C; and 2) preparation of the two-dimensional titanium carbide-doped sodium aluminum hydride hydrogen storage material. When the material is applied to the hydrogen storage field and the doping amount of a catalyst is 1 wt%, the hydrogen evolution temperature of the system drops to 45 DEG C, and the hydrogen evolution amount reaches 6.0 wt%; and when thedoping amount of the catalyst is 9 wt%, the hydrogen evolution temperature of the system drops to 92 DEG C and the hydrogen evolution amount reaches 5.4 wt%. The preparation method has the following advantages: 1, the hydrogen evolution performance of sodium aluminum hydride is effectively improved, the doped sodium aluminum hydride material has a high hydrogen storage capacity and a high hydrogenevolution rate under mild conditions, the initial hydrogen evolution temperature drops to 45 DEG C, and the hydrogen evolution amount reaches 6.0 wt%; 2, Ti2C used as a catalyst is matched with the sodium aluminum hydride hydrogen storage material; and 3, the preparation method has the characteristics of low cost, simple preparation process, controllable reaction and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

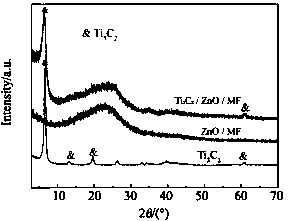

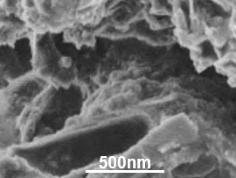

Preparation method of Ti3C2MXene composite hydrogen storage material

InactiveCN109467047AAlleviate volume effectImprove cycle stabilityHydrogenHydrogen desorptionBiological activation

The invention provides a preparation method of a Ti3C2MXene composite hydrogen storage material. The preparation method comprises the following steps: step one, firstly stripping Ti3AlC2 through HF acid to form Ti3C2; step two, then obtaining Ti3C2 / SnS through a hydrothermal reaction and high-temperature activation treatment; and step three, synthesizing a Ti3C2 / SnS / MF composite material through an impregnation method, then using the Ti3C2 / SnS / MF composite material to adsorb a tetrahydrofuran solution of PMMA-LiBH4 so as to form a PL / Ti3C2 / SnS / MF composite material. The PL / Ti3C2 / SnS / MF composite material synthesized by the simple method has good hydrogen desorption performance and certain hydrophobicity, the initial hydrogen desorption temperature of the PL / Ti3C2 / SnS / MF composite materialis as low as 80 DEG C, the main hydrogen desorption temperature is 300 to 400 DEG C, the hydrogen desorption amount within 1 h at the temperature of 350 DEG C reaches 6.3wt%, and the hydrogen desorption performance of the PL / Ti3C2 / SnS / MF composite material is higher than the hydrogen desorption performance of a PL / SnS / MF composite material, so that the hydrogen desorption performance of PMMA-LiBH4is improved through the synergism of Ti3C2 and the PL / SnS / MF hydrogen storage composite material.

Owner:DONGGUAN UNIV OF TECH

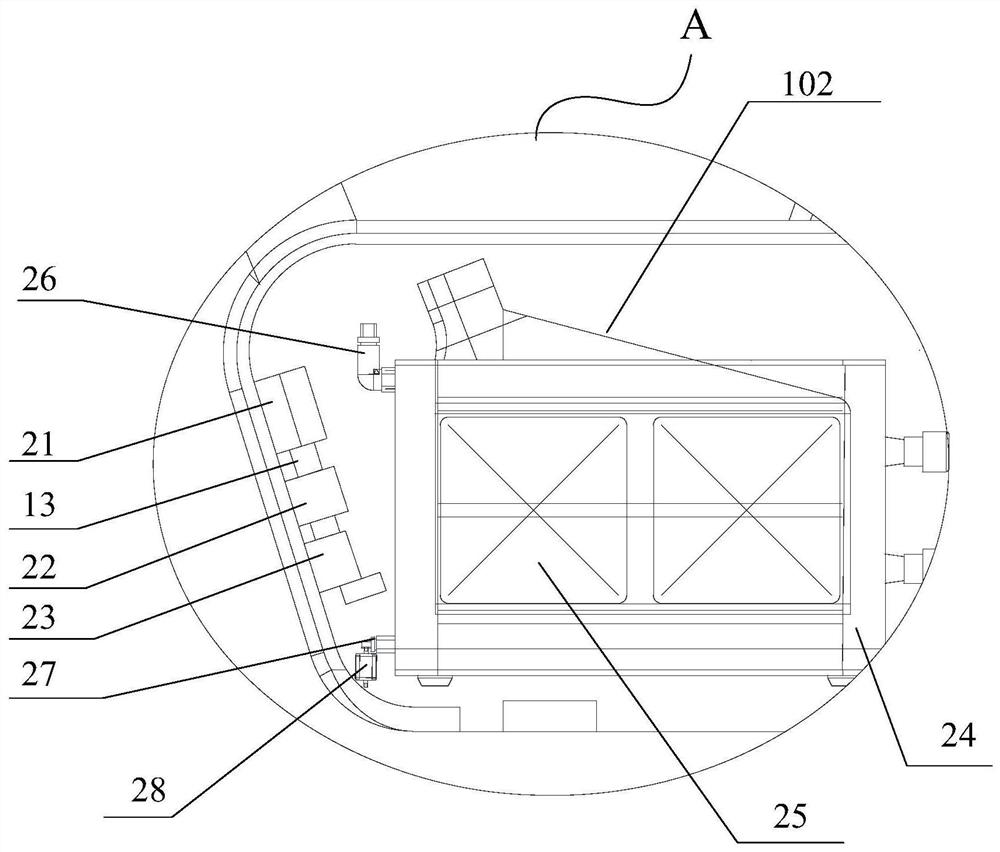

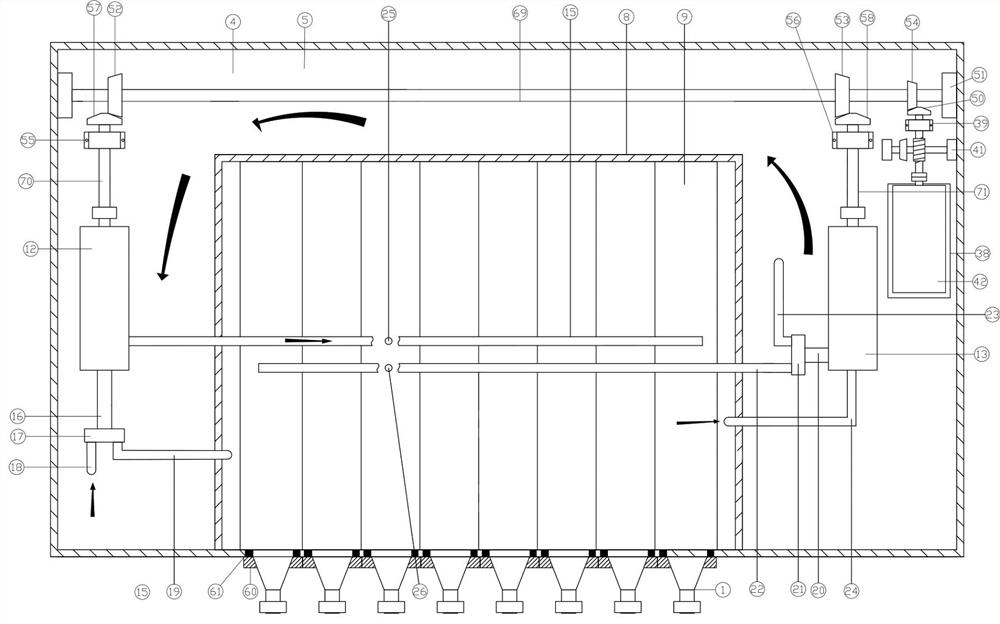

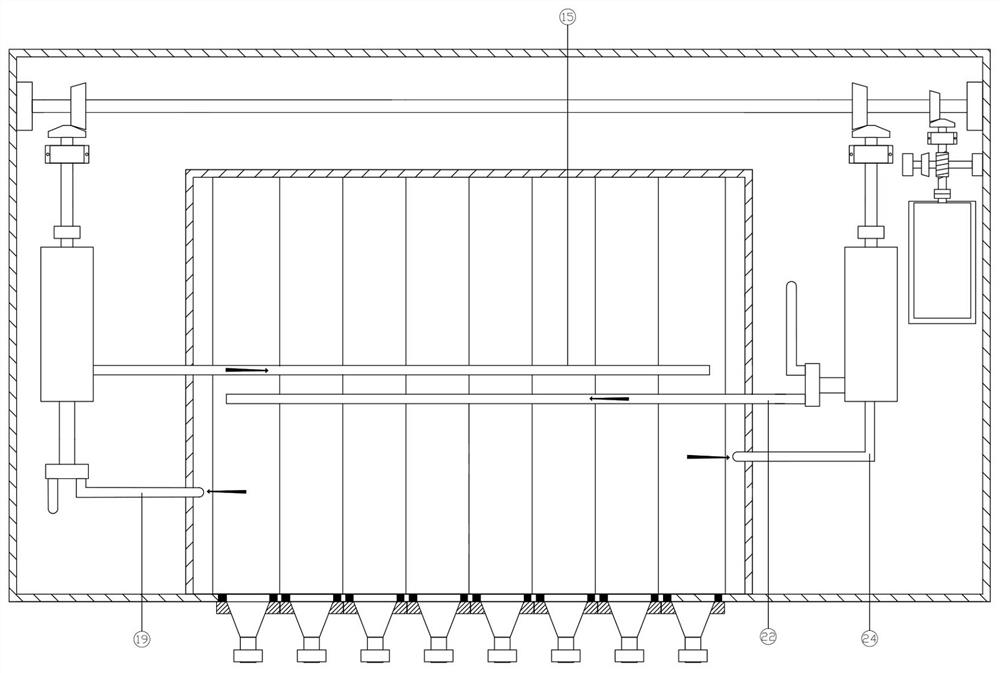

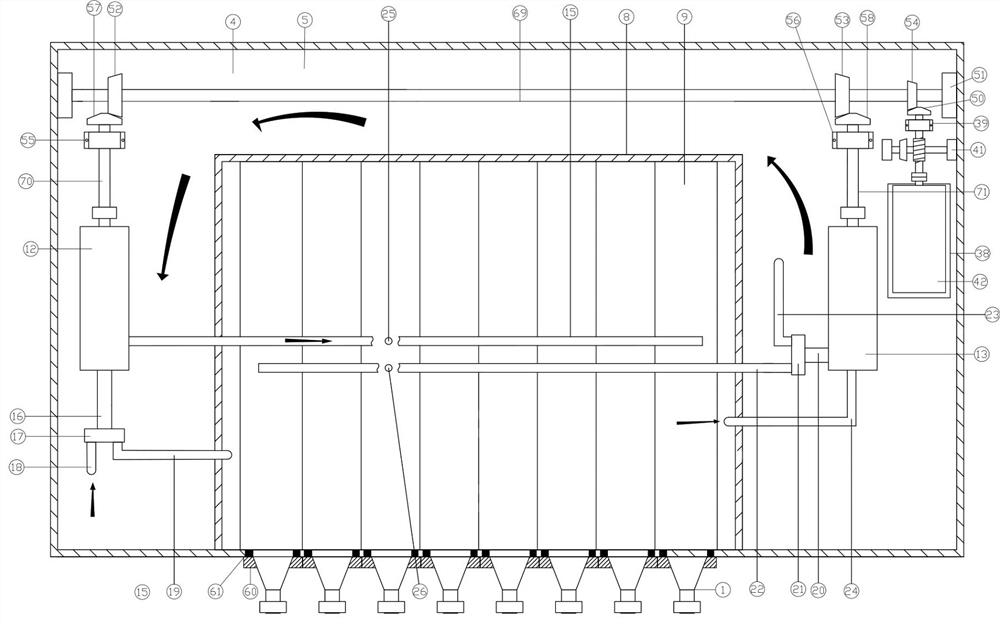

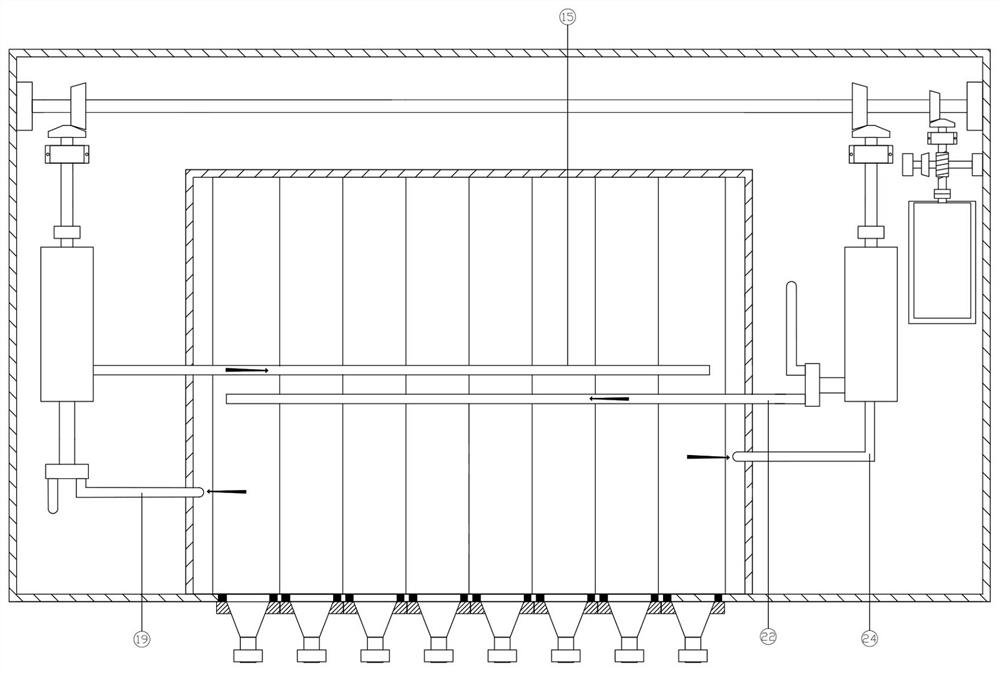

Water bath heat exchange type hydrogen storage device for hydrogen kinetic energy engine vehicle

ActiveCN111816893AFast hydrogen absorption rateImproved hydrogen release performanceFuel cell heat exchangeCooling chamberHydrogen desorption

The invention discloses a water bath heat exchange type hydrogen storage device for a hydrogen kinetic energy engine vehicle. The device comprises an alloy hydrogen storage tank, an outer shell, an inner shell, a heat exchange shell, a water bath circulation heat exchange mechanism, a door sealing mechanism, a driving mechanism and a sealing cover. A plurality of long-strip-shaped heat exchange pieces are fixed to the outer wall of the alloy hydrogen storage tank in the circumferential direction, and the length direction of the heat exchange pieces is the same as the axis direction of the alloy hydrogen storage tank; a hydrogen storage chamber and an air cooling chamber are arranged in the outer shell; the inner shell is fixedly mounted in the hydrogen storage chamber; the heat exchange shell is internally provided with a plurality of heat exchange cavities which are communicated with one another, and the alloy hydrogen storage tank is installed in the heat exchange cavities. The alloyhydrogen storage tank is cooled and subjected to heat exchange during hydrogen filling in a circulating water cooling mode, and the heat dissipation rate and the hydrogen absorption rate of the hydrogen storage tank are increased; the alloy hydrogen storage tank is subjected to water bath heating during hydrogen desorption, the heat absorption rate and the hydrogen desorption rate of the alloy hydrogen storage tank are increased, uniform heat exchange is guaranteed, and the energy efficiency and the output power of the whole hydrogen kinetic energy engine system can be improved.

Owner:河北柒壹壹玖工业自动化技术有限公司

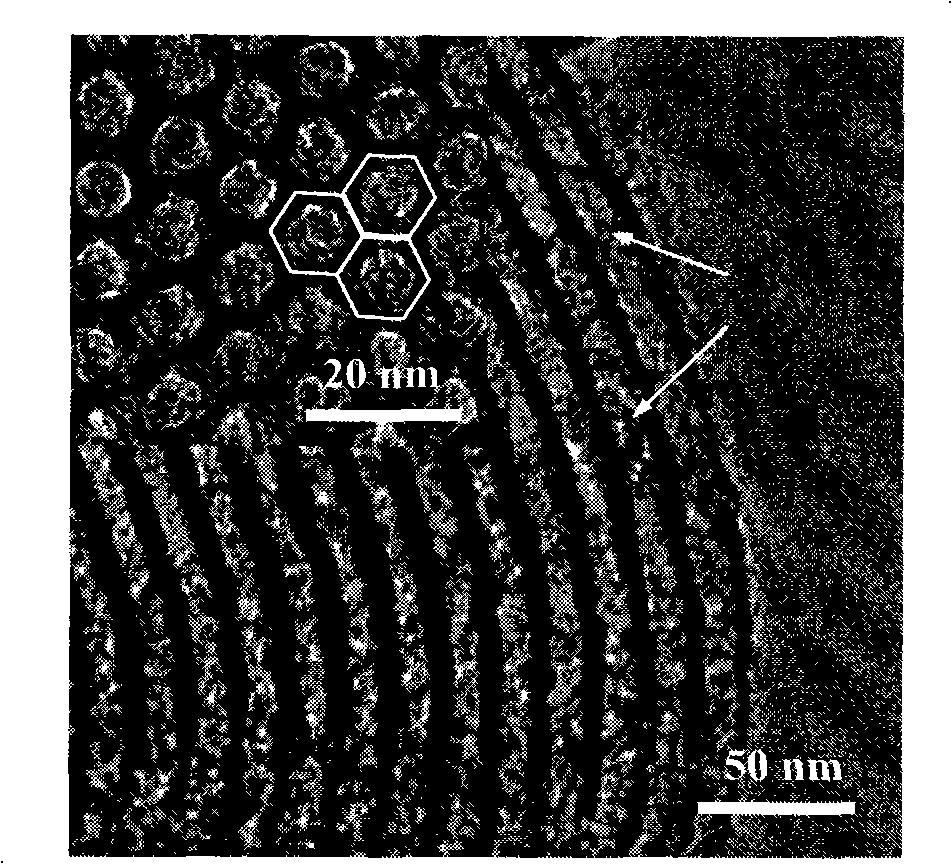

Ordered laminar magnesium-based alloy hydrogen storage material for fuel cell and preparation method

InactiveCN108832138AGood effectImproved hydrogen release performanceMaterial nanotechnologyCell electrodesFuel cellsReactive site

The invention provides an ordered laminar magnesium-based alloy hydrogen storage material for a fuel cell and a preparation method. The preparation method comprises the following steps: after mixing transition metal salt and an organic phase, adding a mixture into de-ionized water; meanwhile, adding a binding agent auxiliary agent to form a net-shaped structure gel material; taking the gel material as a substrate and uniformly spraying high-temperature magnesium steam on the substrate under the protection of nitrogen gas; after finishing spraying, carrying out subsequent processing to obtain asheet-shaped magnesium-based alloy hydrogen storage sheet. The magnesium-based alloy hydrogen storage sheet prepared by the invention has a magnesium-transition metal-magnesium composite laminar structure; a metal hydrogenation active site is formed between alloy layers under the synergistic effect of transition metal and magnesium metal, so that hydrogen absorption and hydrogen releasing capabilities of the magnesium metal are effectively improved; the defect of a traditional magnesium-based hydrogen storage material that the hydrogen absorption and hydrogen releasing capabilities are relatively poor is overcome. The magnesium-based alloy hydrogen storage sheet prepared by the preparation method has the advantages of moderate hydrogen absorption and hydrogen releasing conditions, good material stability and simple preparation technology, and is suitable for being used as a hydrogen source in fuel cell automobiles.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Method for increasing aluminum-containing complex compound hydrogen-storing material circulation stability

InactiveCN101259952AImproved hydrogen release performanceImprove cycle stabilityHydrogen productionPorous carbonPorous channel

The invention belongs to the functional material technical field, in particular to a method for improving the circulatory stability of aluminiferous complex hydrogen storage materials. The method comprises the following steps that: aluminiferous complex hydrogen storage materials MA1H4(M represents Li, Na or K) are dissolved in a solvent, and the generated MA1H4 solution is loaded in a porous channel of a porous matrix by the infiltration technique, wherein the porous matrix is of porous materials such as meso-porous materials(SiO2), meso-porous materials(Al2O3), porous carbon, meso-porous carbon or zeolite; and the MA1H4 solution has the solution removed by drying, obtaining the nano sized MA1H4 which is filled in the porous channel of the porous matrix; the nano sized MA1H4 hydrogen storage materials are good in absorb-release hydrogen circulatory stability. The method is simple and low in cost, and high in commercial value for preparing hydrogen storage materials with high circulatory stability .

Owner:FUDAN UNIV

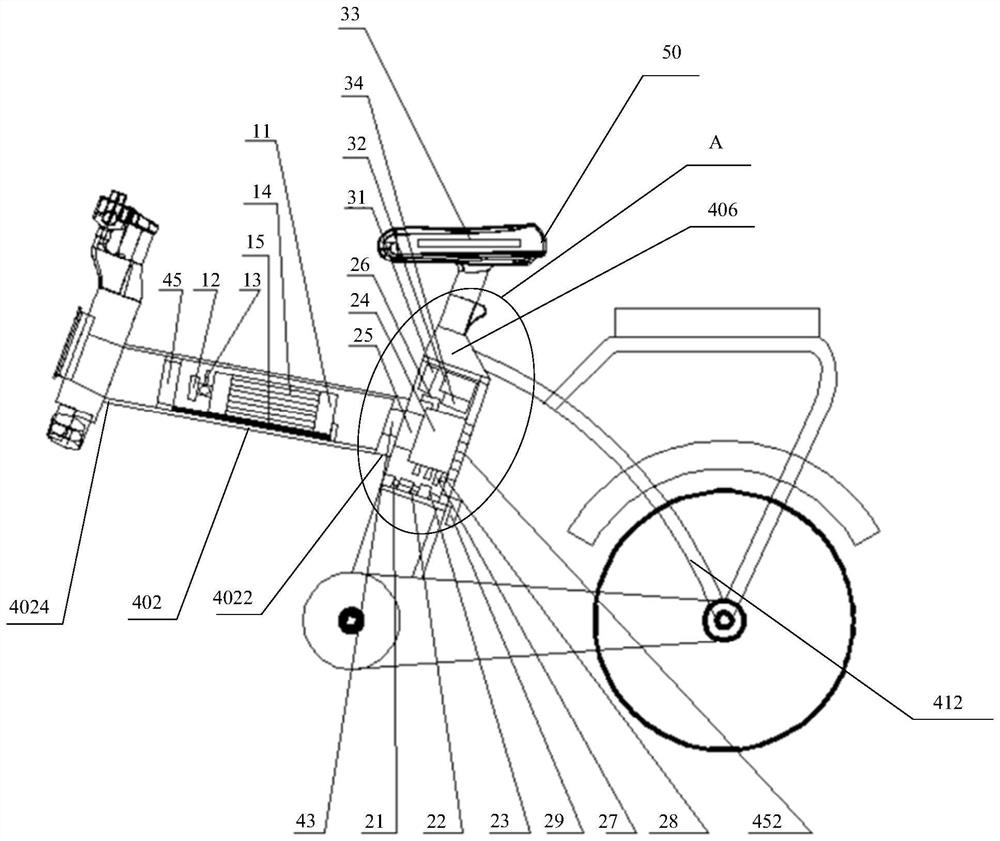

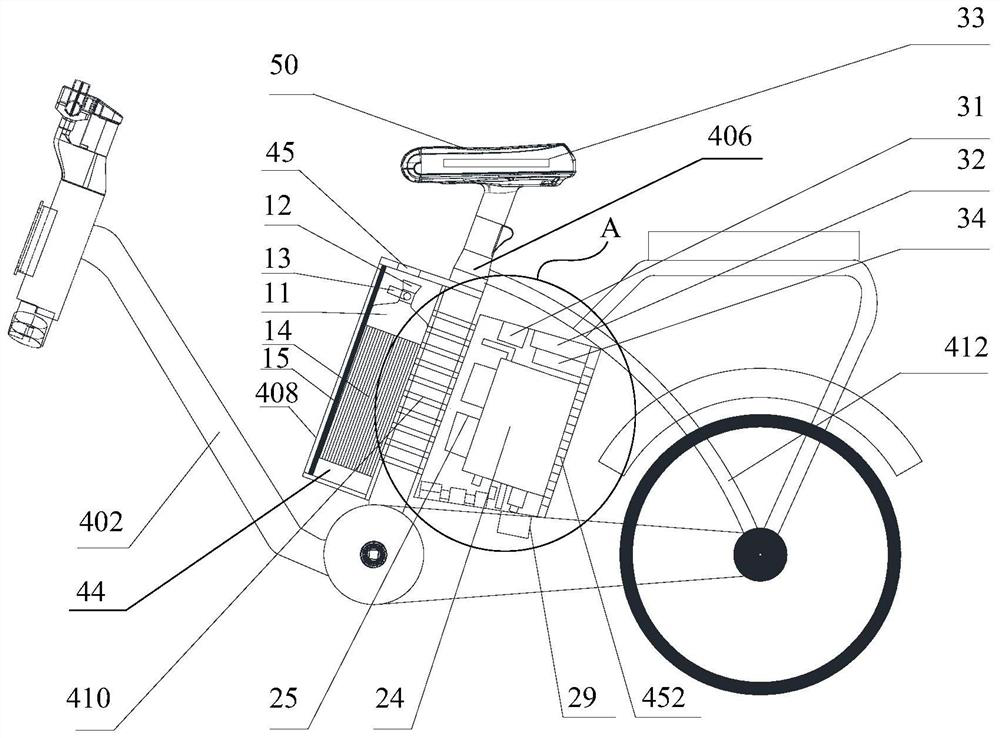

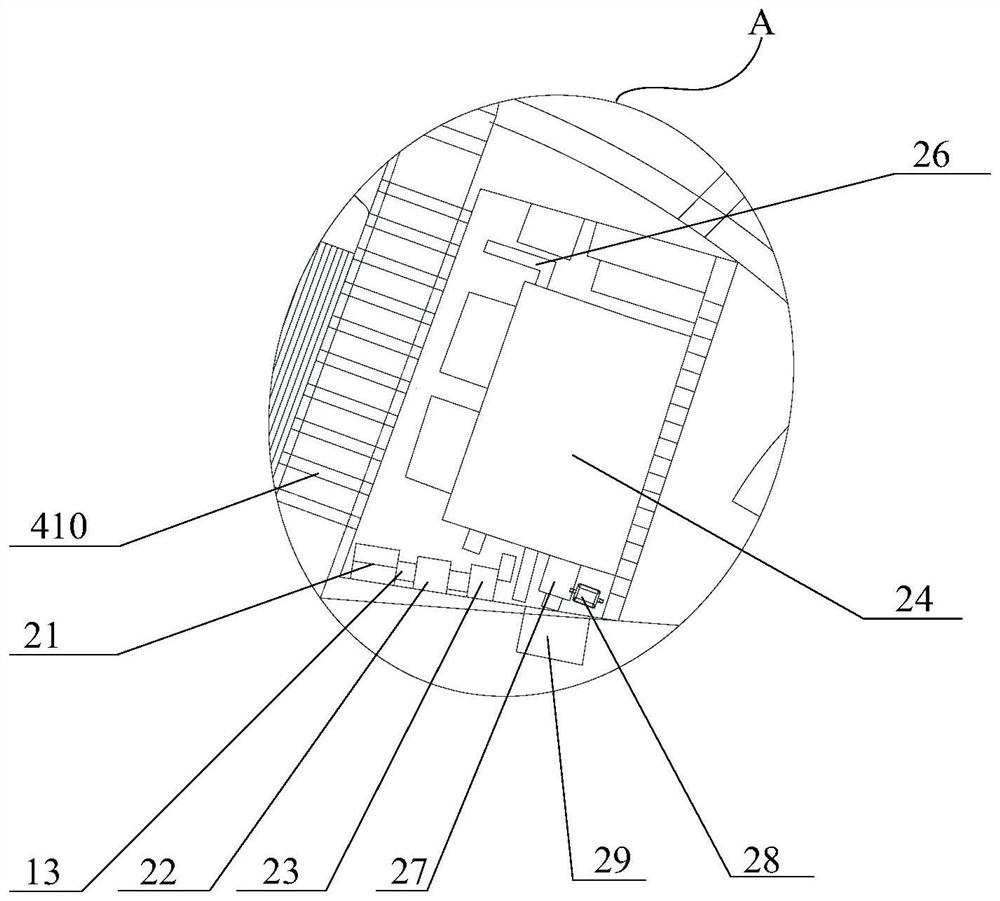

Hydrogen fuel cell power-assisted bicycle

PendingCN111890957AAdaptableImprove hydrogen release performanceReactant parameters controlPropulsion by batteries/cellsHot blastVehicle frame

The invention provides a hydrogen fuel cell power-assisted bicycle. The bicycle comprises a power system and a frame, the power system comprises a hydrogen storage tank, a fuel cell device, a controldevice and a driving device; the frame specifically comprises a cross beam and a main vertical pipe, the rear end of the cross beam is connected with the main vertical pipe, the cross beam and the main vertical pipe are hollow, the rear end of the cross beam is provided with a ventilation opening communicating with the cross beam and the inner space of the main vertical pipe, and the side wall ofthe cross beam close to the front end of the cross beam is provided with an air outlet. The hydrogen storage tank is arranged in the cross beam, the fuel cell stack is arranged in the main vertical pipe, and an air outlet of the fuel cell stack is communicated with the ventilation opening, so that hot air exhausted by the fuel cell stack enters the cross beam through the ventilation opening and isexhausted from the air outlet after flowing through the outer surface of the hydrogen storage tank. Waste heat generated during operation of the fuel cell stack is utilized to realize thermal self-compensation.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

Tubular TiO2 synthesis method and application of tubular TiO2

InactiveCN103265070ASimple production processReaction conditions are easy to controlMaterial nanotechnologyPhysical/chemical process catalystsHydrogenAlcohol

The invention provides a tubular TiO2 synthesis method. The tubular TiO2 synthesis method comprises the following steps of: (2) dissolving TiOSO4 in mixed alcohol, and then adding diethyl ether to the mixed alcohol; (2) transferring the solution to a high-pressure reactor, and carrying out heating constant-temperature reaction in a homogeneous reactor to generate white precipitates; (3) sequentially centrifuging, washing, drying in vacuum and calcining the generated precipitates at high temperature, thus obtaining a finished product; and (4) mixing the prepared powder and LiBH4 to prepare the TiO-LiBH4. The synthesized tubular TiO2 can be used as a catalyst for hydrogen generation of LiBH4 and a range-limited carrier. The tubular TiO2 synthesis method has the advantages that the production process is simple, reaction conditions are easy to control, a template agent and a surface active agent are not needed, and the prepared tubular TiO2 can be used for greatly improving the hydrogen generation performance of LiBH4.

Owner:NANKAI UNIV

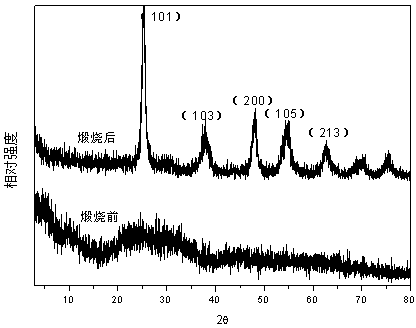

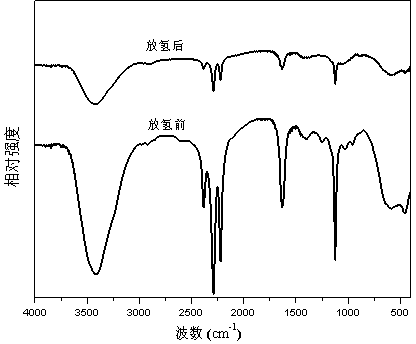

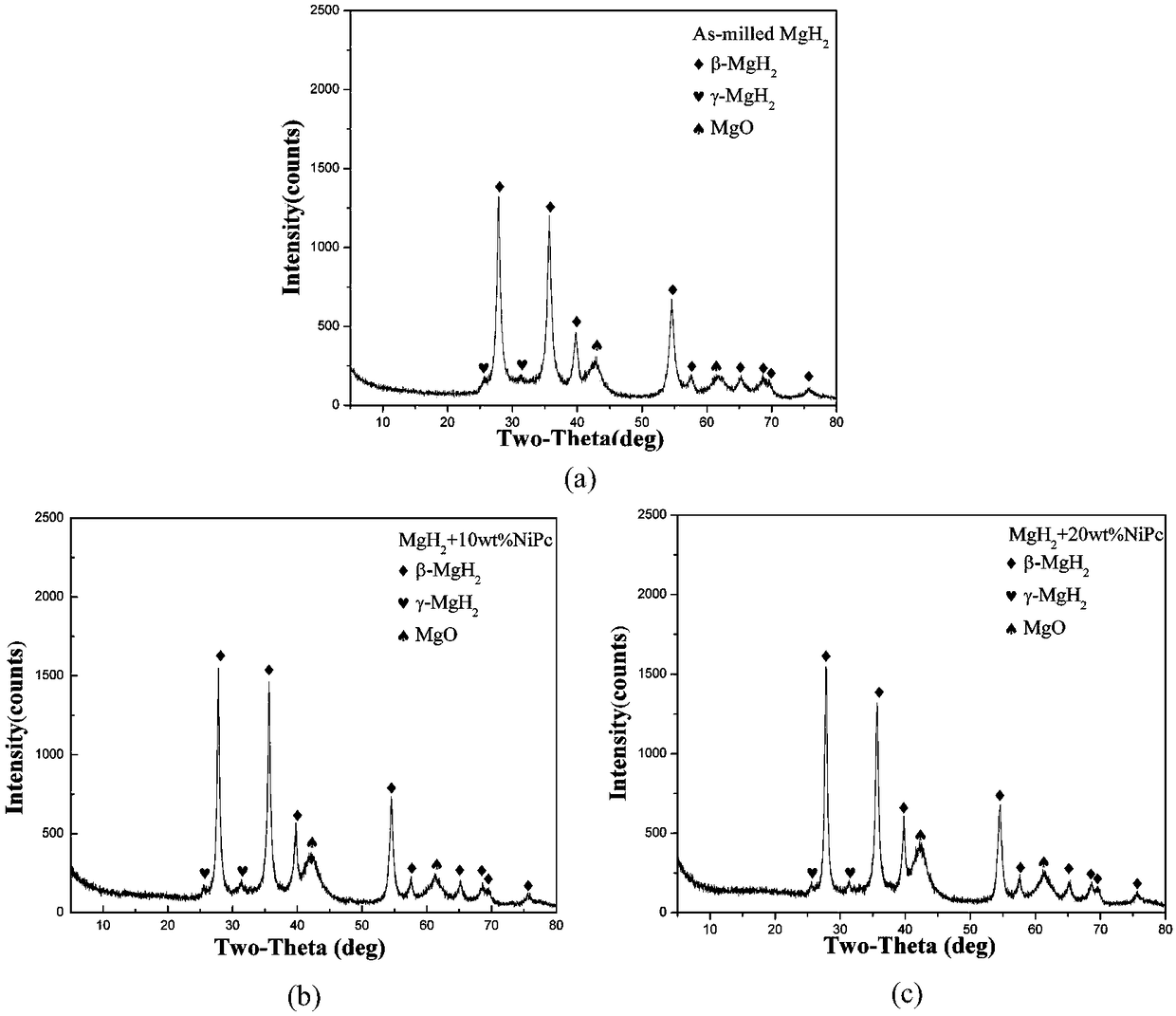

Magnesium hydride/metal phthalocyanine hydrogen storage composite material and preparation method thereof

ActiveCN108622853AImprove hydrogen release performanceThe initial hydrogen release temperature decreasesHydrogenHydrogen atmosphereHigh energy

The invention discloses a magnesium hydride / metal phthalocyanine hydrogen storage composite material and a preparation method thereof. The hydrogen storage composite material is formed by using a metal phthalocyanine compound MePc as an additive and performing high-energy ball milling compounding on the metal phthalocyanine compound and magnesium hydride MgH2; the metal phthalocyanine compound isselected from one or two kinds of materials from FePc (iron phthalocyanine), CoPc (cobalt phthalocyanine), NiPc (nickel phthalocyanine) and the like. The preparation method is mainly characterized inthat metal phthalocyanine MePc and magnesium hydride MgH2 are mixed according to a proportion of 10:100-20:100; the mixture is subjected to ball milling by a high-energy ball milling method under theinert gas protection or hydrogen atmosphere condition; the rotating speed of a ball grinding mill is 800 to 1000r / min; the ball material ratio is 30:1-50:1; the ball grinding time is 2 to 4h; after each ball grinding is performed for 0.5 to 1h, the ball grinding mill stops for 15 to 30min. The obtained magnesium hydride / metal phthalocyanine hydrogen storage composite material has the advantages that the unique high catalytic activity of metal phthalocyanine compound MePc is utilized; the initial hydrogen release temperature of magnesium hydride MgH2 is greatly reduced; the preparation processand the equipment are simple; the energy consumption is low; the cost is low; ideal application prospects are realized.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

LaCl3 catalyzed high-capacity hydrogen storing alloy powder and preparation method thereof

ActiveCN107385300AImproved hydrogen absorption and desorption kineticsExcellent hydrogen absorption and desorption kineticsReactant parameters controlRare earthHydrogen desorption

The invention relates to LaCl3 catalyzed high-capacity hydrogen storing alloy powder. The chemical formula composition of the powder is Mg50-x-yTixAlyLa6-zREzNi4-m-nCumCon+Q wt.%LaCl3. According to the LaCl3 catalyzed high-capacity hydrogen storing alloy powder, titanium and aluminum are used for partially replacing magnesium in rare earth magnesium alloy, multicomponent rare earth, nickel, copper and cobalt are added, and a rapid quenching alloy ribbon with a nanocrystalline+non-crystalline structure is obtained through a rapid quenching process. A trace of LaCl3 catalyst is added, the thermal stability of alloy hydride can be obviously reduced through ball milling, the hydrogen desorption capacity of alloy at low temperature is improved, and the hydrogen absorption and desorption dynamics is further improved. The prepared hydrogen storing alloy powder has high hydrogen absorption and desorption capacity and excellent hydrogen absorption and desorption dynamics and has good hydrogen absorption and desorption cycling stability.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

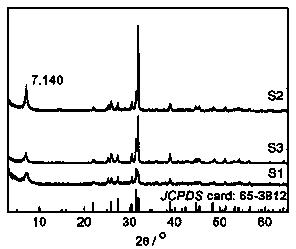

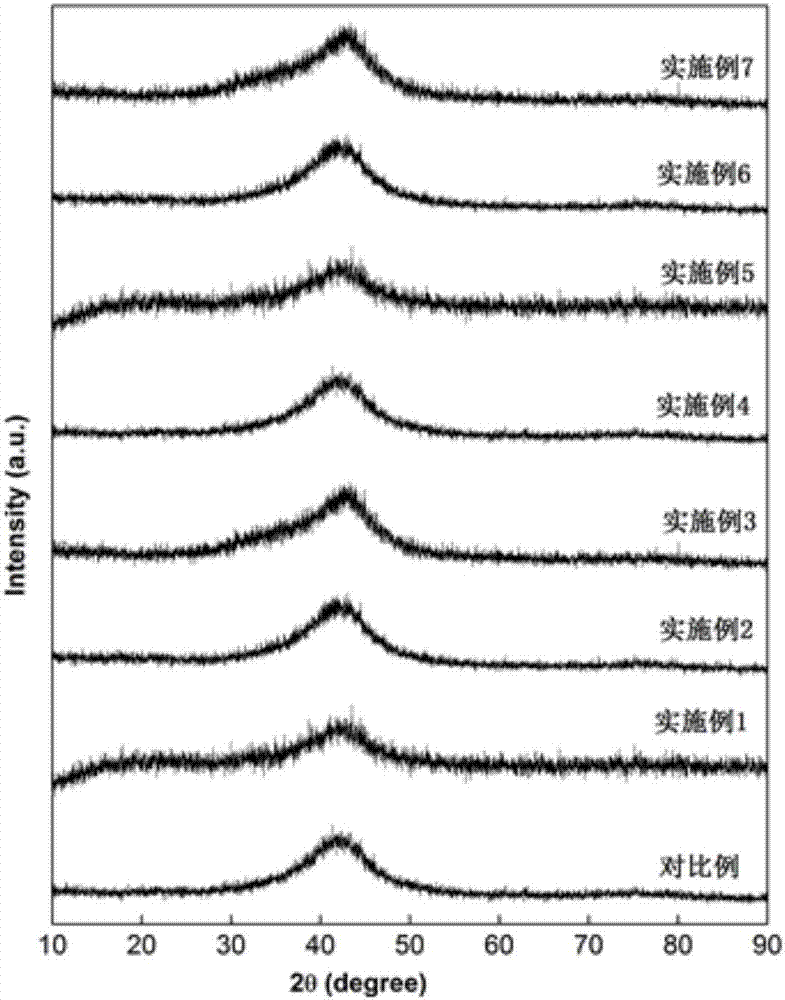

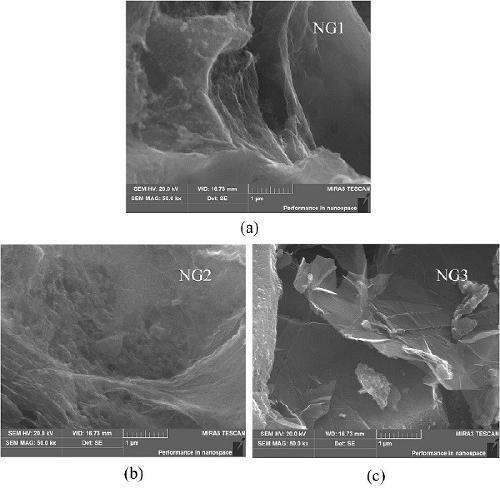

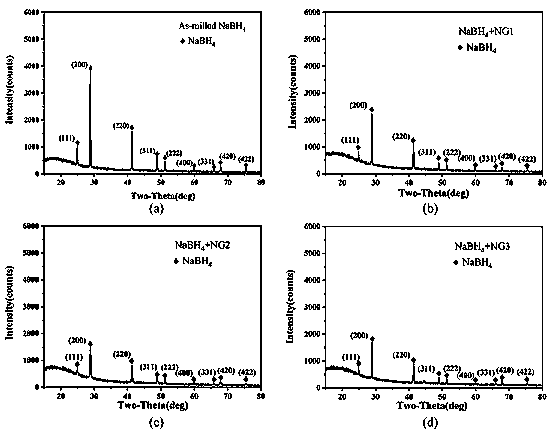

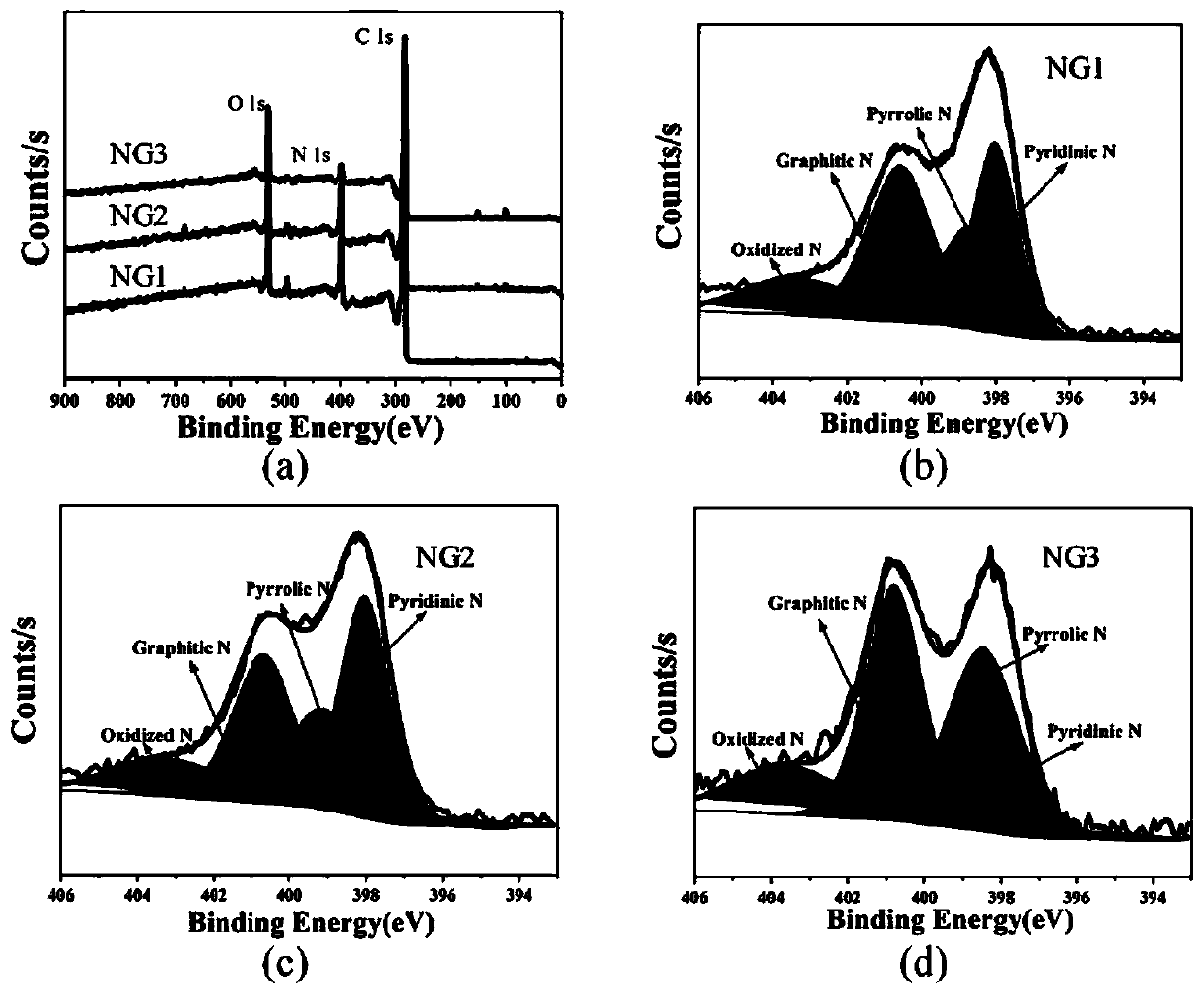

Sodium borohydride/nitrogen-doped graphene hydrogen storage composite material and preparation method thereof

ActiveCN111268642AImproved hydrogen release performanceThe initial hydrogen release temperature decreasesHydrogenDoped grapheneDehydrogenation

The invention discloses a sodium borohydride / nitrogen-doped graphene hydrogen storage composite material and a preparation method thereof. The hydrogen storage composite material is prepared by takingnitrogen-doped graphene NG as an additive and compounding the additive with sodium borohydride NaBH4, wherein the mass ratio of NaBH4 to NG is 9:1. The preparation method comprises the following steps: firstly, respectively adding three different nitrogen sources (melamine C3N3(NH2)3 + pyrrole C4H5N); C3N3(NH2)3; C4H5N), thereby obtaining three different nitrogen-doped graphene NGX (X = 1, 2, 3);then respectively mixing NaBH4 with the three NGXs in a ratio of 9:1 by adopting a ball milling method in an argon atmosphere to obtain the NaBH4 / NGX hydrogen storage composite system, wherein the rotating speed of the ball mill is 1000 r / min, the ball-to-material ratio is 30:1, andthe ball milling time is 2h, wherein the machine is shut down for 15 min after every ball milling operation for 1 h.The initial hydrogen desorption temperature of the composite material is remarkably reduced compared with that of pure NaBH4 under the same ball milling condition, and rapid dehydrogenation can be achieved. The method is simple in preparation process, wide in raw material source and low in cost, and is a method for effectively improving the hydrogen storage performance of NaBH4.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

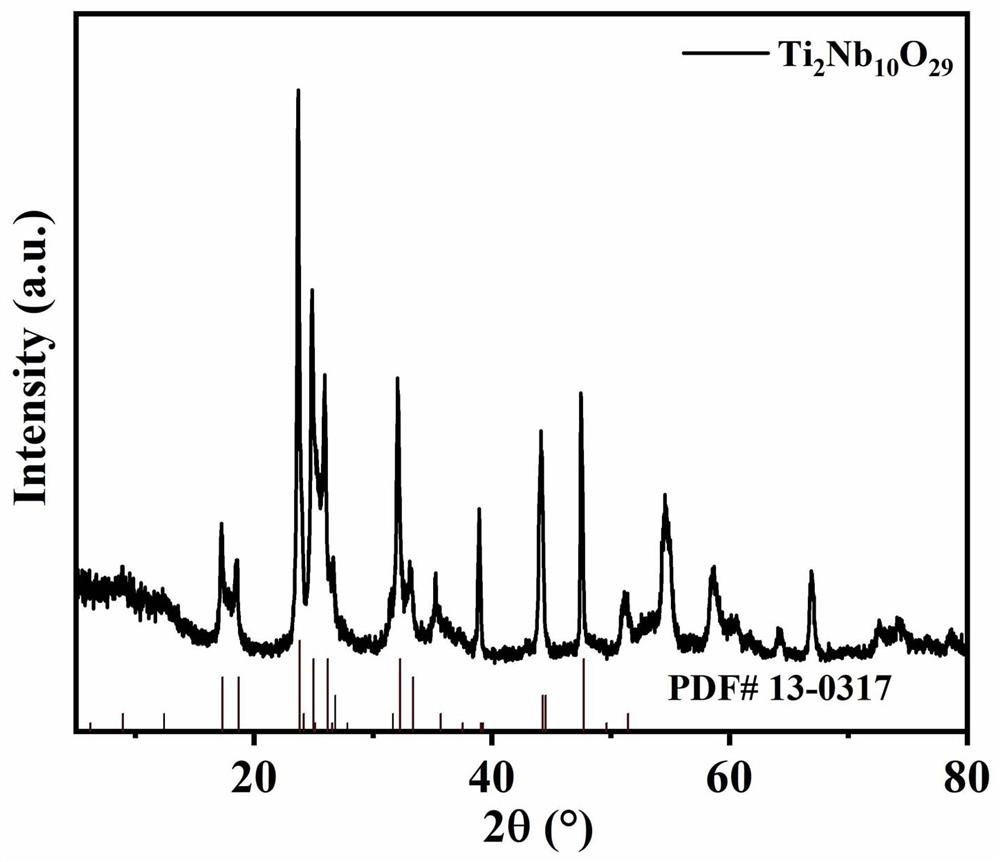

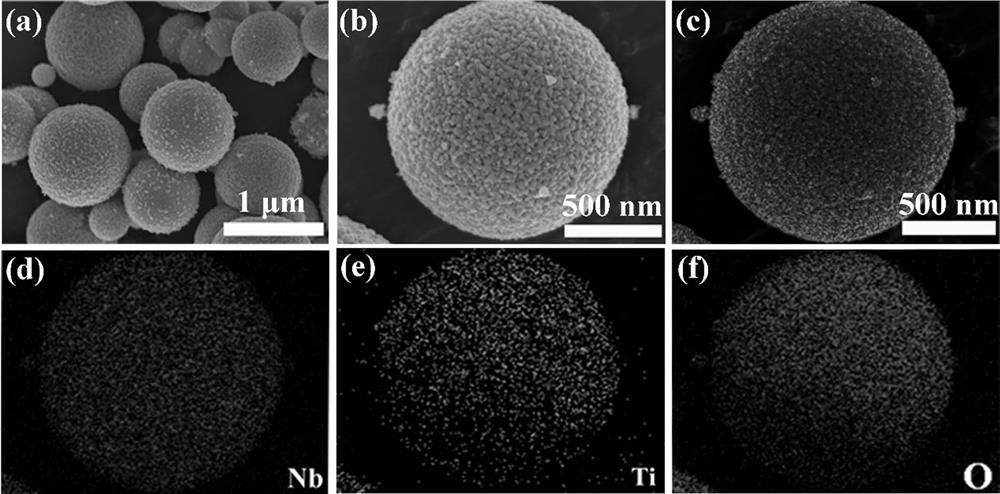

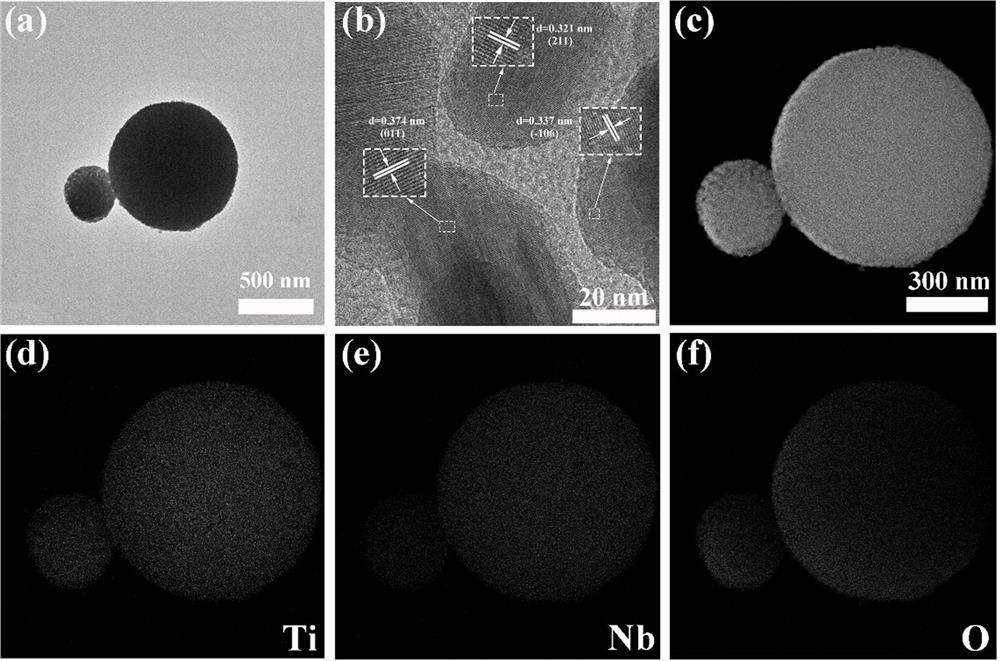

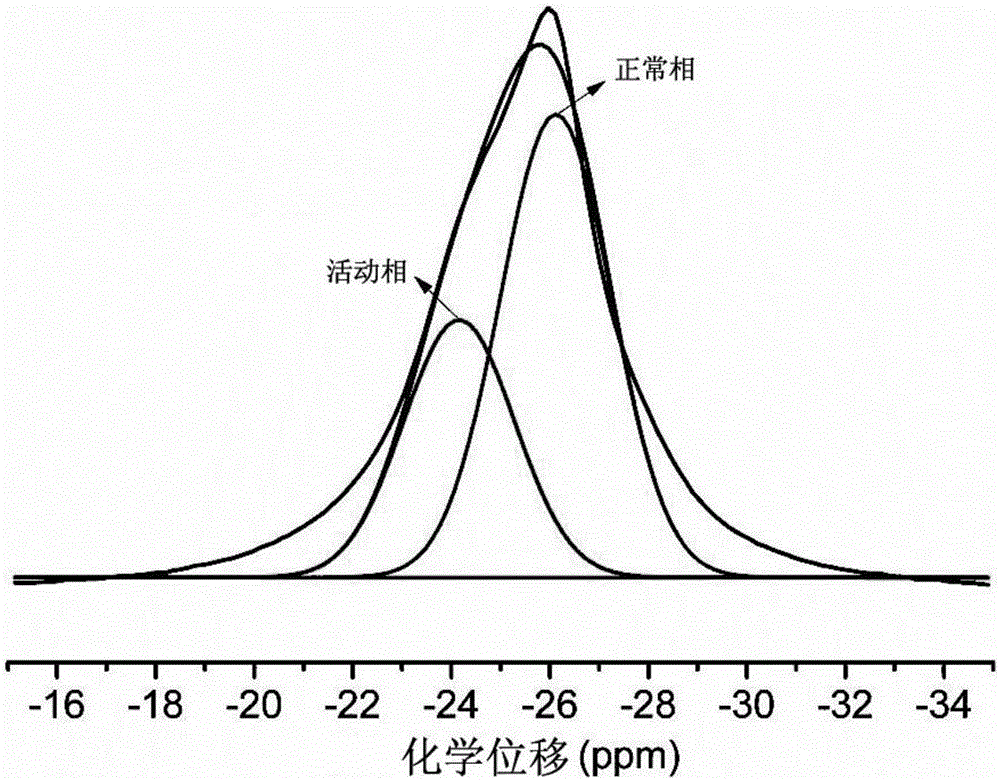

Magnesium hydride hydrogen storage material based on graded porous microspheres Ti-Nb-O and preparation method thereof

PendingCN114590774AEasy to getSimple processHydrogen productionNiobium compoundsMagnesium hydrideMagnesium

The invention discloses a magnesium hydride hydrogen storage material based on graded porous microspheres Ti-Nb-O. The magnesium hydride hydrogen storage material is prepared by mixing and mechanically ball-milling magnesium hydride and graded porous microspheres Ti-Nb-O, the graded porous microspheres Ti-Nb-O are prepared by a solvothermal method and a calcining method; the diameter is 1-2 [mu] m, the microstructure is spherical, the specific surface area is 27.63 m < 2 > / g, and the pore size distribution is 38-40 nm. The preparation method comprises the following steps: 1, preparing a hierarchical porous microsphere Ti-Nb-O precursor; 2, preparation of a graded porous microsphere Ti-Nb-O; and 3, preparing the magnesium hydride hydrogen storage material based on the graded porous microspheres Ti-Nb-O. As the application in the field of hydrogen storage, the initial hydrogen desorption temperature of the system is reduced to 189 DEG C, and the hydrogen desorption amount reaches 6.96 wt%; the isothermal complete hydrogen desorption temperature is 300 DEG C, and the hydrogen desorption amount within 60 min reaches 6.82 wt%; and under the condition that the isothermal hydrogen absorption temperature is 50 DEG C, 1.78 wt% of hydrogen is absorbed within 60 min. The activation energy of catalytic hydrogen desorption is Ea (des) = 92.7 kJ / mol, and the activation energy of catalytic hydrogen absorption is Ea (abs) = 26.0 kJ / mol; the desorption reaction enthalpy change Hd is equal to 69.6 kJ / mol. And the cycle retention rate is 92.3%.

Owner:GUILIN UNIV OF ELECTRONIC TECH

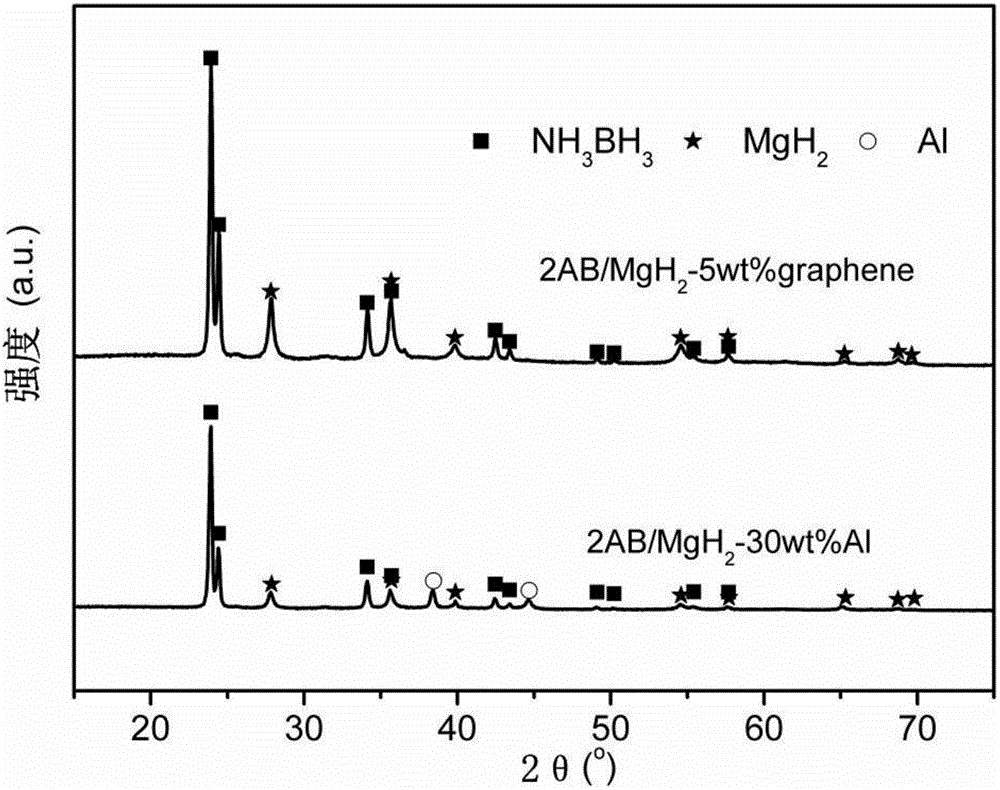

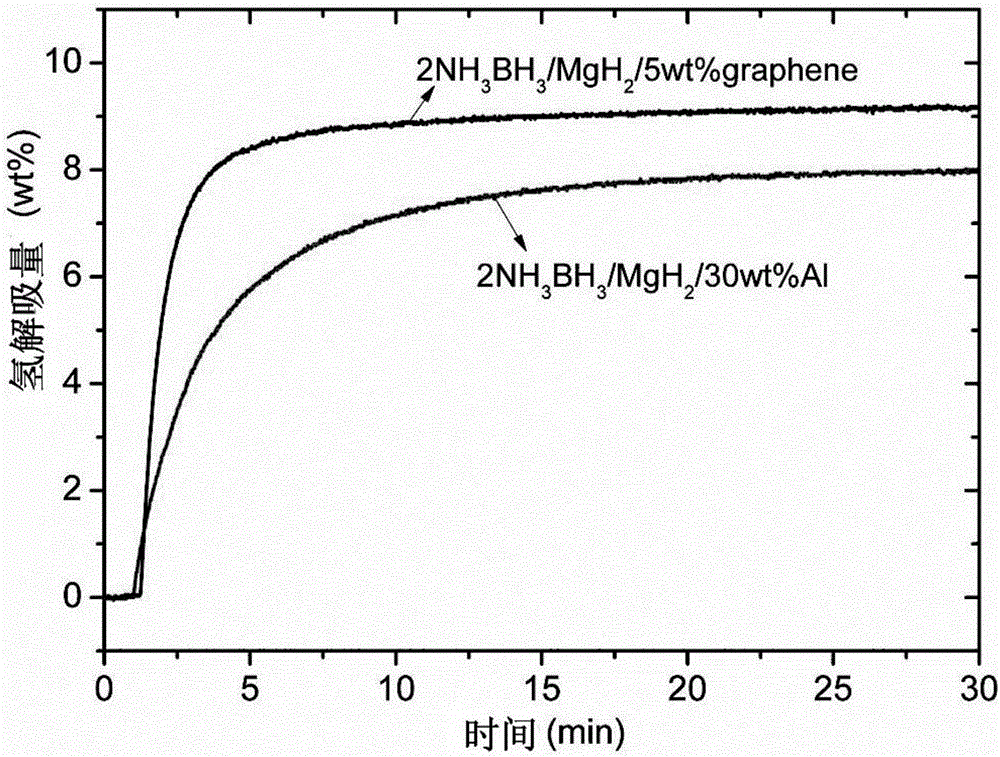

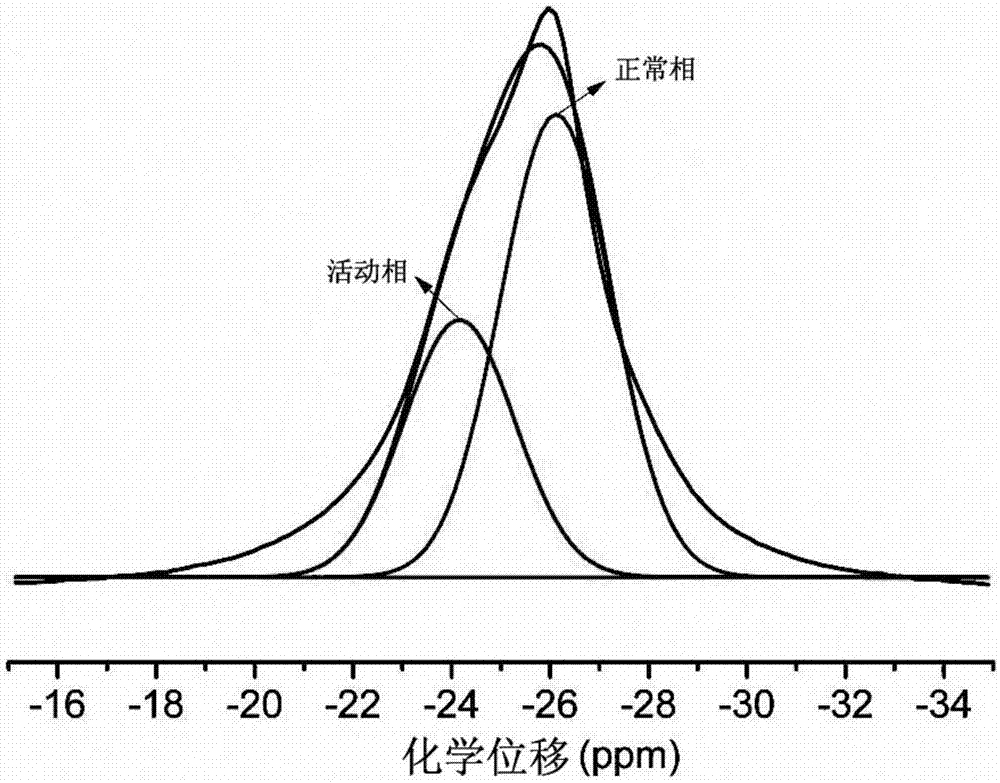

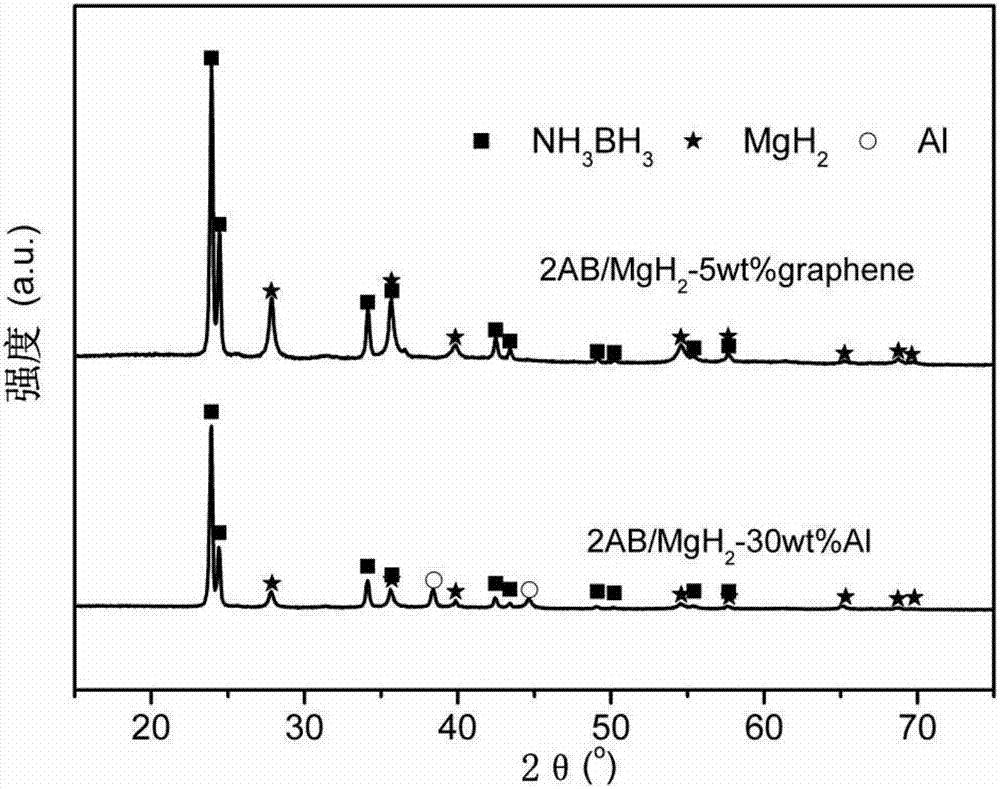

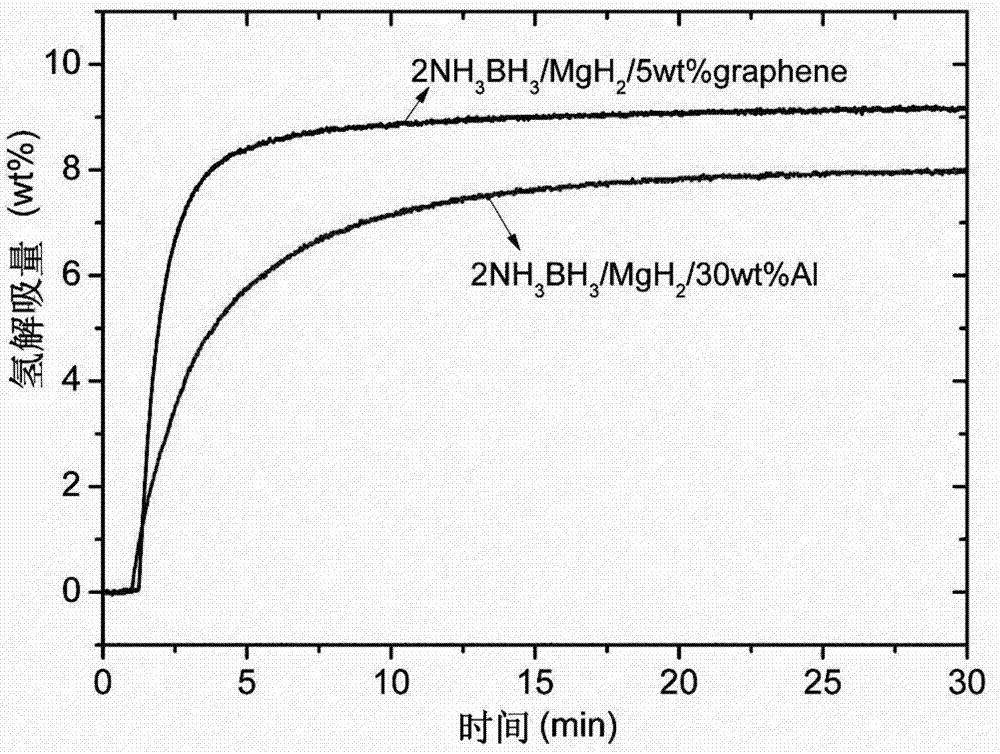

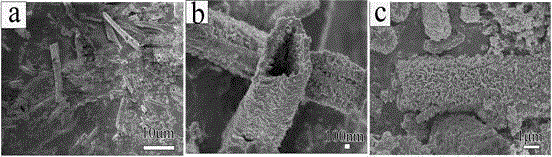

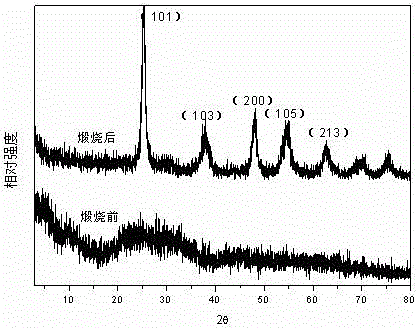

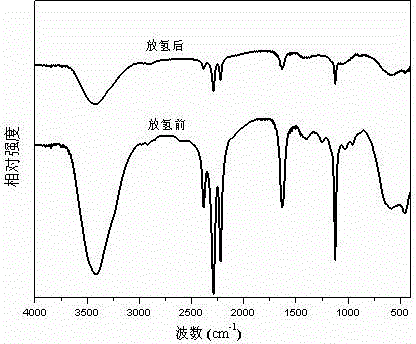

Ammonia borane/magnesium hydride/heat conduction agent compound hydrogen storage material and preparing and hydrogen desorption methods thereof

InactiveCN106276786AImproved hydrogen release performanceQuick releaseHydrogen productionMetal hydridesHydrogen fuel cellRoom temperature

The invention discloses an ammonia borane / magnesium hydride / heat conduction agent compound hydrogen storage material. The material is composed of magnesium hydride, a heat conduction agent, and ammonia borane subjected to partial phase change after being placed at room temperature for six months or more or thermally treated for 10-30 min, wherein the molar ratio of ammonia borane to magnesium hydride is 2:(0.8-1), and the mass of the heat conduction agent is 5-30 wt% of the sum of the mass of ammonia borane and that of magnesium hydride. The invention further provides preparing and hydrogen desorption methods of the compound hydrogen storage material. Through combination of component optimization and hydrogen desorption condition control, high-capacity hydrogen desorption of the compound hydrogen storage material under the low-temperature condition is well achieved, and then application requirements are met. Commercial application in the fields such as hydrogen refueling stations, hydrogen cell automobiles and mobile hydrogen sources can be achieved. Therefore, the ammonia borane / magnesium hydride / heat conduction agent compound hydrogen storage material has high practical value and popularization value.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

Power system of thermal self-compensation type hydrogen fuel cell power-assisted bicycle

PendingCN112026544AImproved hydrogen release performanceReduce energy lossReactant parameters controlPropulsion by batteries/cellsInterior spaceHydrogen fuel cell

The invention provides a power system of a thermal self-compensation type hydrogen fuel cell power-assisted bicycle. The power system comprises a hydrogen storage tank, a fuel cell stack, a control device and a driving device. The power-assisted bicycle is provided with a bicycle frame, and the bicycle frame specifically comprises a front oblique beam, a vertical pipe, a first shell arranged on the front side of the vertical pipe and a second shell arranged on the rear side of the vertical pipe which are connected. The interior of the first shell and the interior of the second shell are both hollow, an air outlet is formed in the first shell, an air inlet is formed in the second shell, the internal space of the first shell is connected with the internal space of the second shell through aplurality of air pipelines, a first air flow channel is formed in the first shell, and a second air flow channel is formed in the internal space of the multiple air pipelines; and the hydrogen storagetank is arranged in the first air flow channel, the fuel cell stack is arranged in the second shell, and hot air exhausted by the fuel cell stack enters the first air flow channel through the secondair flow channel and is exhausted from the air outlet after flowing through the hydrogen storage tank. Waste heat generated during operation of the fuel cell stack is utilized to realize thermal compensation.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

Power system of battery-assisted bicycle

PendingCN111942185AImproved hydrogen release performanceReduce energy lossReactant parameters controlPropulsion by batteries/cellsFuel cellsVehicle frame

The invention provides a power system of a battery-assisted bicycle. The power system of the battery-assisted bicycle comprises a hydrogen storage tank, a fuel cell stack, a control device, a drivingdevice and a bicycle frame, the bicycle frame comprises a front oblique beam, a connecting pedal and a main vertical pipe, the two ends of the connecting pedal are connected with the lower end of thefront oblique beam and the lower end of the main vertical pipe respectively, and the front oblique beam and the main vertical pipe are hollow. An exhaust channel communicating with the inner space ofthe front oblique beam and the inner space of the main vertical pipe is arranged in the connecting pedal, and an exhaust outlet is formed in the top of the main vertical pipe. The fuel cell stack is arranged in the front oblique beam, the hydrogen storage tank is arranged in the main vertical pipe, and hot air exhausted by the fuel cell stack enters the main vertical pipe through the exhaust channel, flows through the outer surface of the hydrogen storage tank and then is exhausted from the exhaust outlet. Waste heat generated during operation of the fuel cell stack is utilized to realize thermal compensation.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

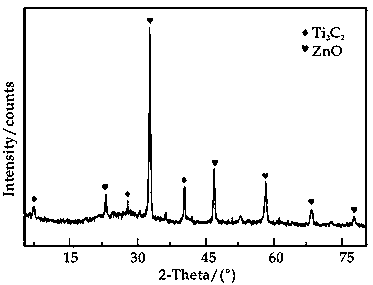

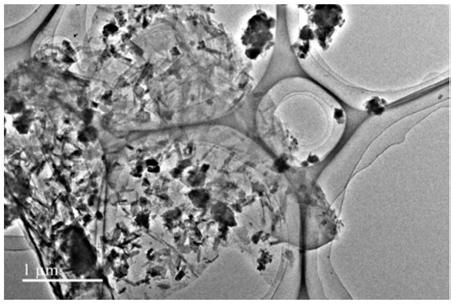

Method for preparing Ti3C2 loaded ZnO composite hydrogen storage material

InactiveCN109399559AGood catalytic hydrogen storage performanceImprove hydrogen storage performanceZinc oxides/hydroxidesTitanium carbideEvaporationTitanium

The invention discloses a method for preparing a Ti3C2 loaded ZnO composite hydrogen storage material. According to the method, firstly, a Ti3C2 loaded ZnO two-dimensional composite hydrogen storage material is synthesized from Ti3C2, Zn(NO3)2.6H2O, NaOH and SDBS, which serve as raw materials, under the condition of different zinc-titanium ratios by adopting a hydrothermal method, then, a Ti3C2 / ZnO composite material solution is absorbed by using melamine foam through a dipping method, and finally, the Ti3C2 / ZnO composite material solution is compounded with PMMA-LiBH4 through a dipping-evaporation method and is loaded to the surface of Ti3C2 / ZnO and branches of the melamine foam; the structure of the material cannot be destroyed through the dipping method, and meanwhile, the hydrogen release performance of the PMMA-LiBH4 is greatly improved. The PL / Ti3C2 / ZnO / MF composite hydrogen storage material prepared by the method has the initial hydrogen release temperature of 72 DEG C, and thehydrogen release volume in 3h at the temperature of 350 DEG C reaches 8.1wt%.

Owner:DONGGUAN UNIV OF TECH

A hydrogen storage tank with an external heat exchange structure

ActiveCN103883874BSimple structureEasy to processPressure vesselsContainer discharging from pressure vesselsFiberHydrogen desorption

The invention discloses a hydrogen storage tank with an external heat exchanging structure, and belongs to the hydrogen storage technical field of the hydrogen energy field. The hydrogen storage tank comprises the following structure: a skirt support is disposed at the bottom of a tank body; a hydrogen storage material bed is disposed in the tank body; a gas guide tube is disposed at the center position in the tank body and pass straight through the tank mouth from the tank bottom; a filter is installed in the tank mouth, and a hydrogen cylinder valve is installed at the external of the tank mouth; a housing is disposed at the external of the tank body, two ends of the housing are respectively provided with a heat conduction liquid inlet and a heat conduction liquid outlet; and a heat exchanging structure is arranged in an annular chamber between the housing and the tank body. The heat exchanging structure is in the shape of a straight flow, a winding flow, a single spiral or multiple spirals, and the hydrogen storage material bed is a uniform mixed body of a hydrogen storage material and heat conduction fiber. The provided hydrogen storage tank is simple in structure, easy for preparation and processing, and low in cost. Compared with conventional hydrogen storage tanks, the hydrogen storage tank provided by the invention has relatively excellent heat exchanging effect and relatively excellent hydrogen desorption performance.

Owner:GRIMAT ENG INST CO LTD

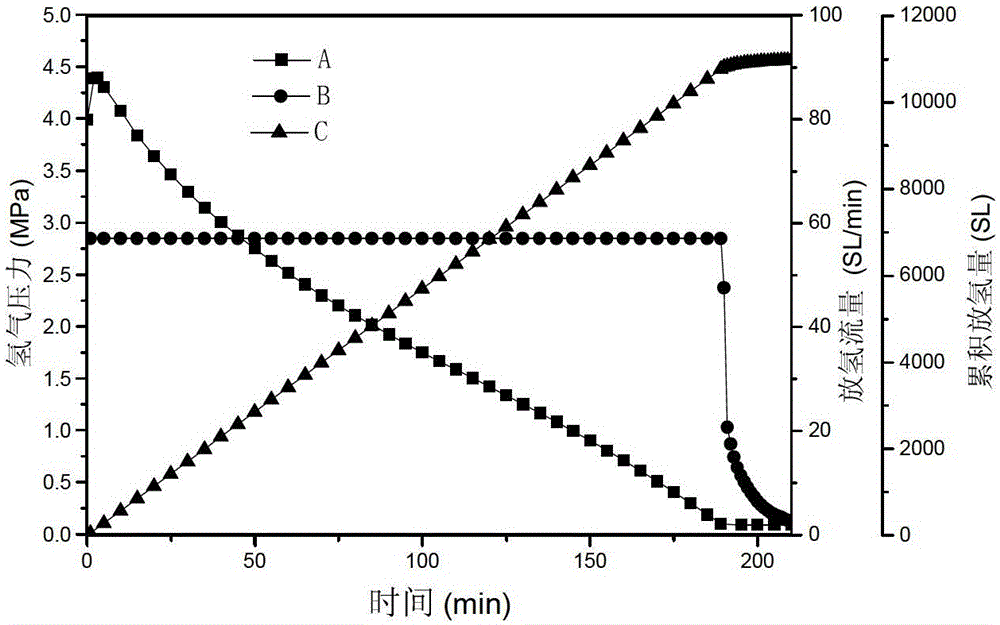

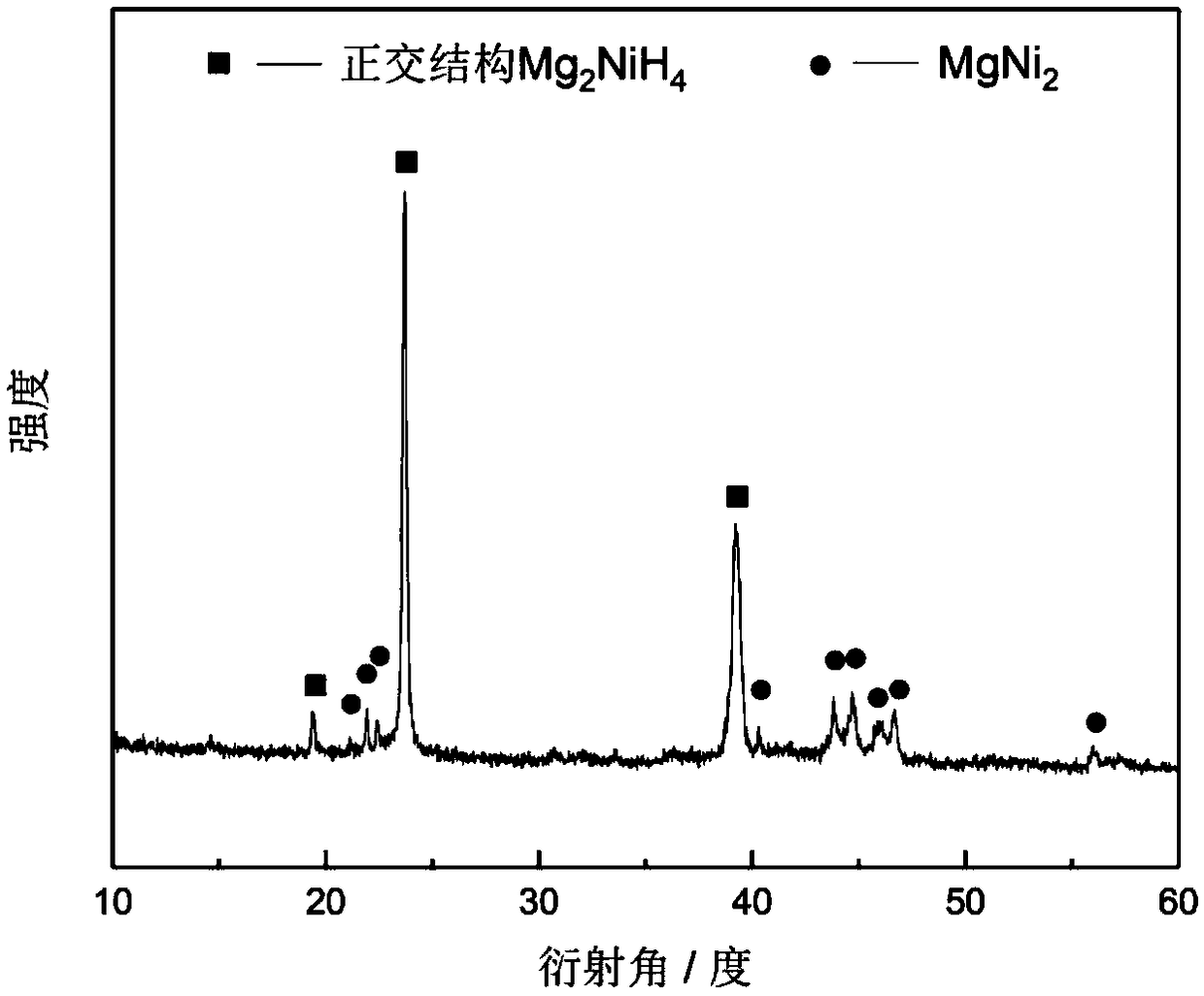

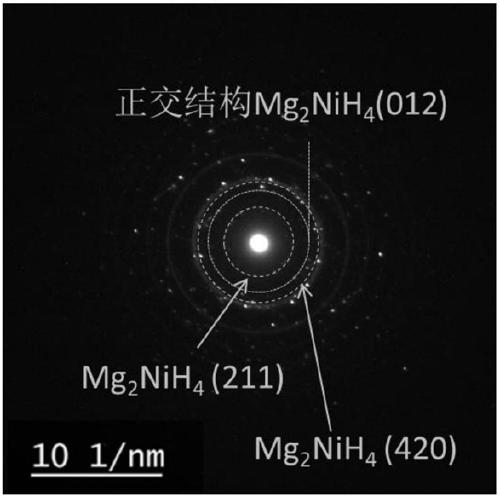

A Mg2NiH4 material and a preparing method thereof

ActiveCN109019506AAvoid Mixed Phase SituationsAchieving controllable generationHydrogenInorganic material magnetismRoom temperatureHydrogen absorption

A Mg2NiH4 material and a preparing method thereof are disclosed. The Mg2NiH4 material is a Mg2NiH4 material having an orthogonal structure at room temperature. The method includes firstly subjecting Mg2Ni alloy powder obtained by smelting to ball milling treatment, adding the alloy powder into a reaction kettle, feeding hydrogen into the reaction kettle, heating the reaction kettle to a certain temperature, then maintaining the temperature, vacuumizing the reaction kettle with the temperature of the reaction kettle unchanged, repeating ball milling and hydrogen absorption steps, and finally cooling the reaction kettle to room temperature to obtain a Mg2NiH4 powder material. An embodiment of the method achieves controllable generation of the Mg2NiH4 only having the orthogonal structure, andthe prepared Mg2NiH4 material having the orthogonal structure shows a ferromagnetic property so as to allow application of Mg2NiH4 as a magnetic material to be possible, and has excellent hydrogen release performance. The Mg2NiH4 having the single structure that is adopted as a hydrogen storage alloy has a wide application prospect in the field of magnetic materials.

Owner:SHANGHAI UNIV

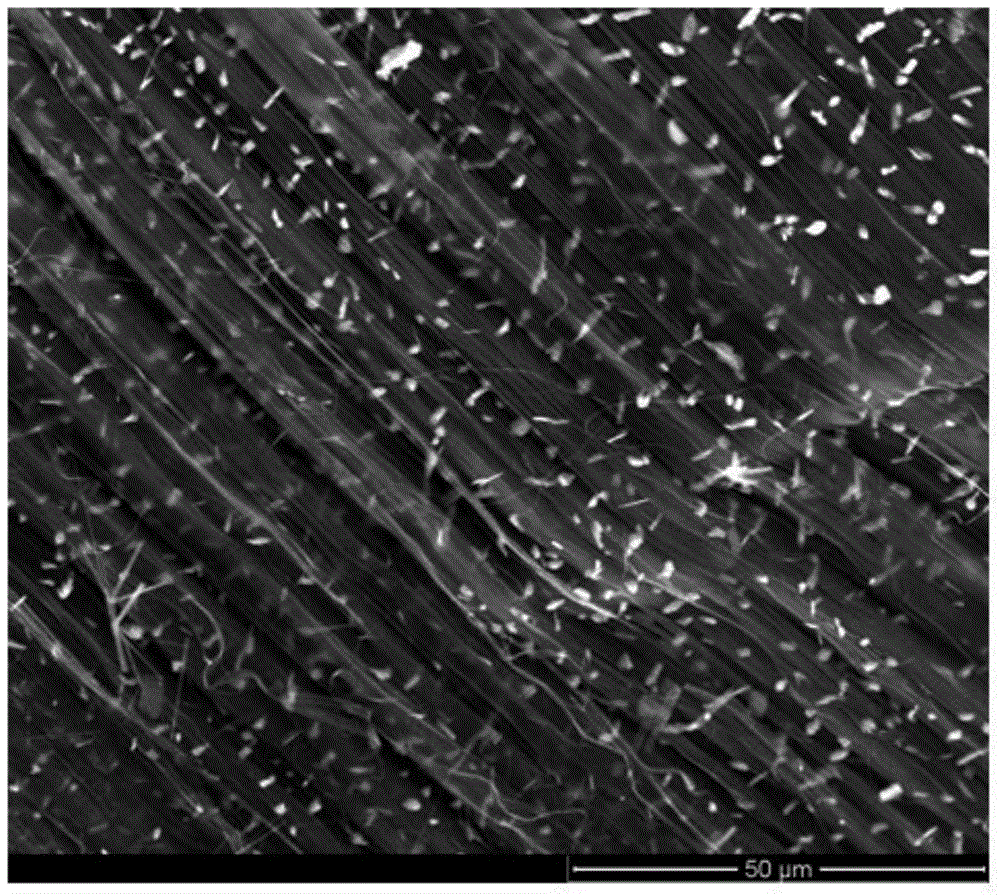

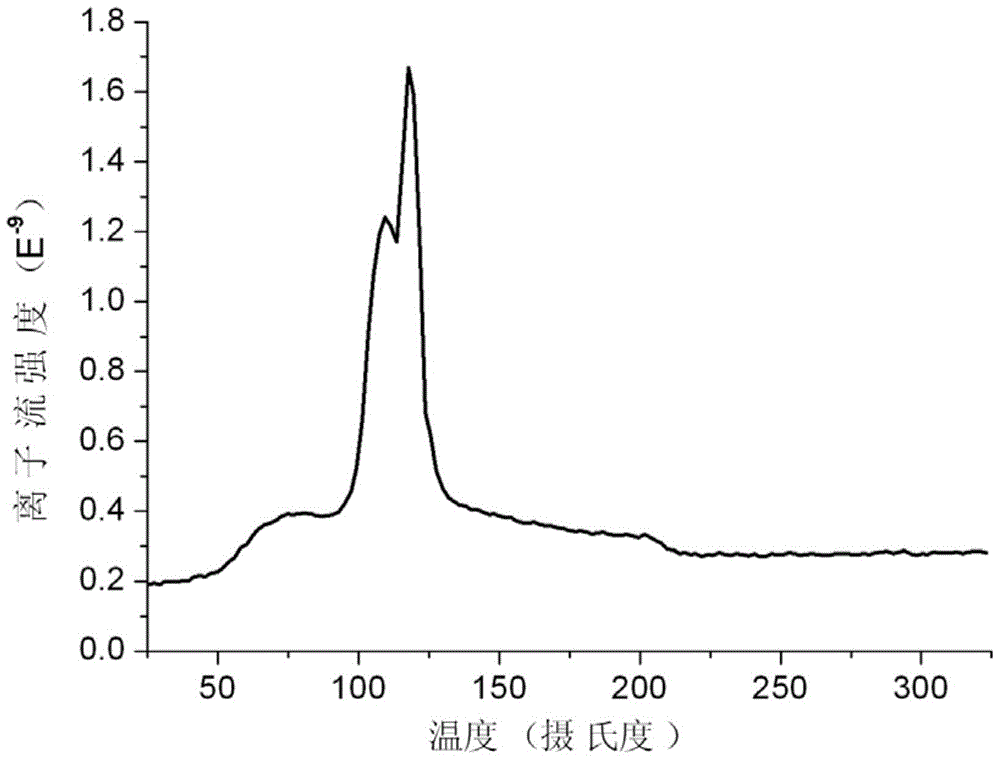

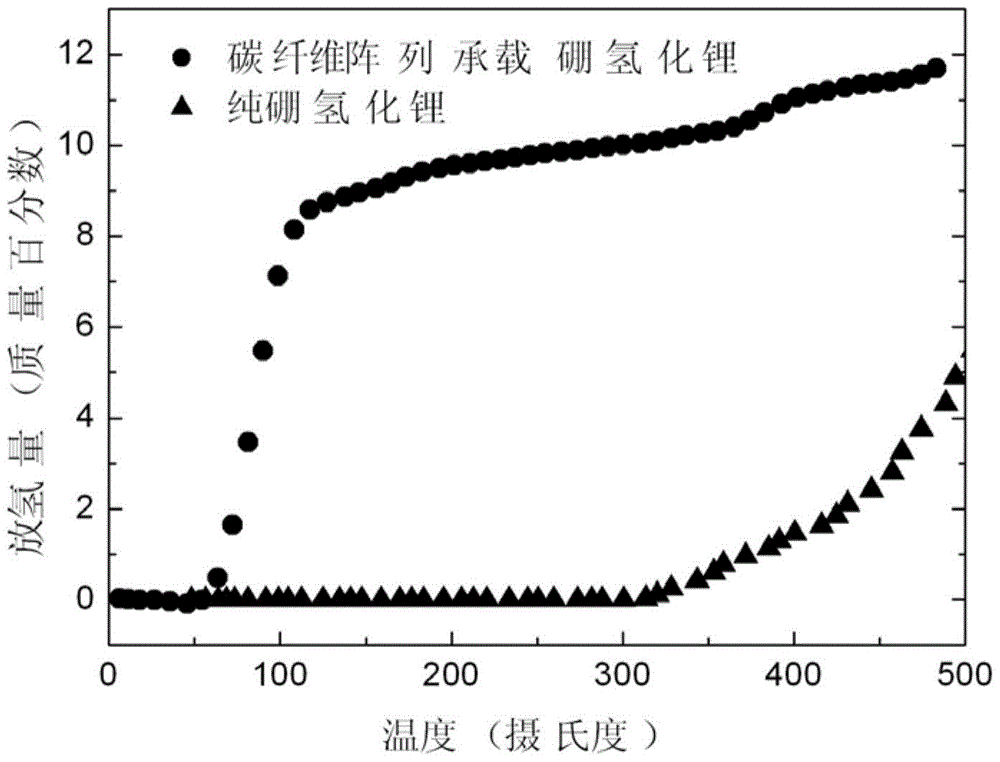

A method for improving lithium borohydride dehydrogenation

ActiveCN105060246BImproved hydrogen release performanceSimple processHydrogen productionHydrogenFiber array

The invention discloses a method for improving lithium borohydride hydrogen, which comprises steps: lithium borohydride solid powder is stirred in 40 DEG C anhydrous ether liquid until to be completely dissolved, and obtains solution A, the solution A is uniformly dropt to a carbon fiber array to obtain a product B, solvent in the product B is pumped in a vacuum mode in 20-90 DEG C, thereby obtaining lithium borohydride hydrogen which is born through the carbon fiber array. The method for improving the lithium borohydride hydrogen can obviously improve performance of the lithium borohydride hydrogen, reduces desorption temperature to 60 DEG C from 300 DEG C, discharges hydrogen which is not lower than 10wt% in 300 DEG C, and is simple in process, easy to achieve and moderate in cost.

Owner:中国船舶重工集团公司第七一二研究所 +1

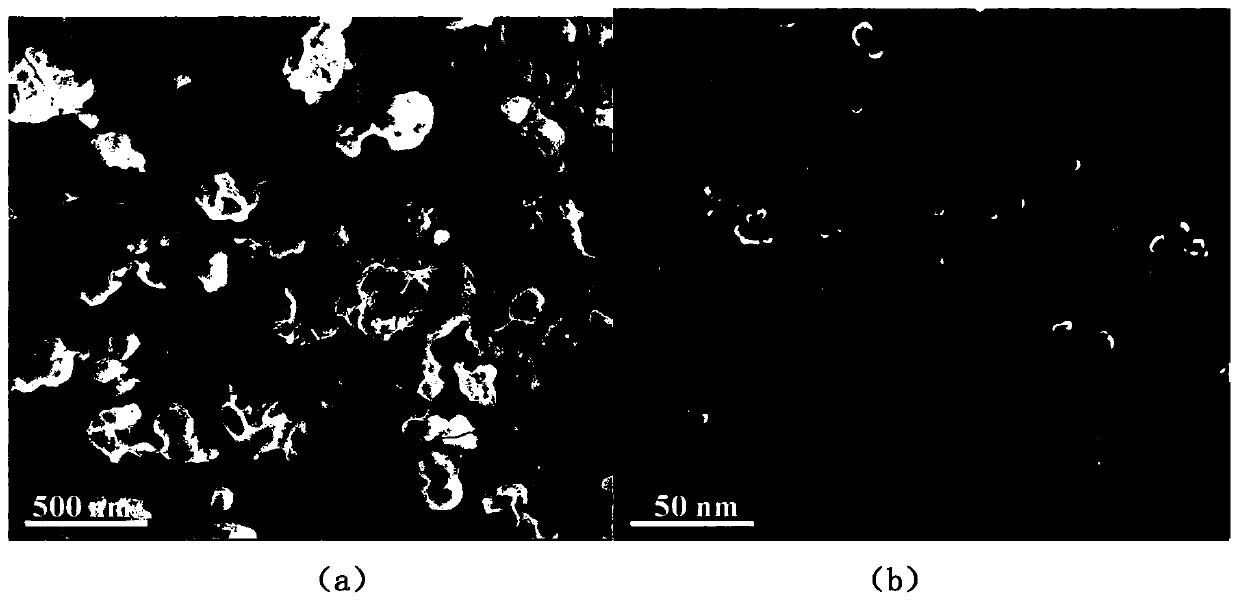

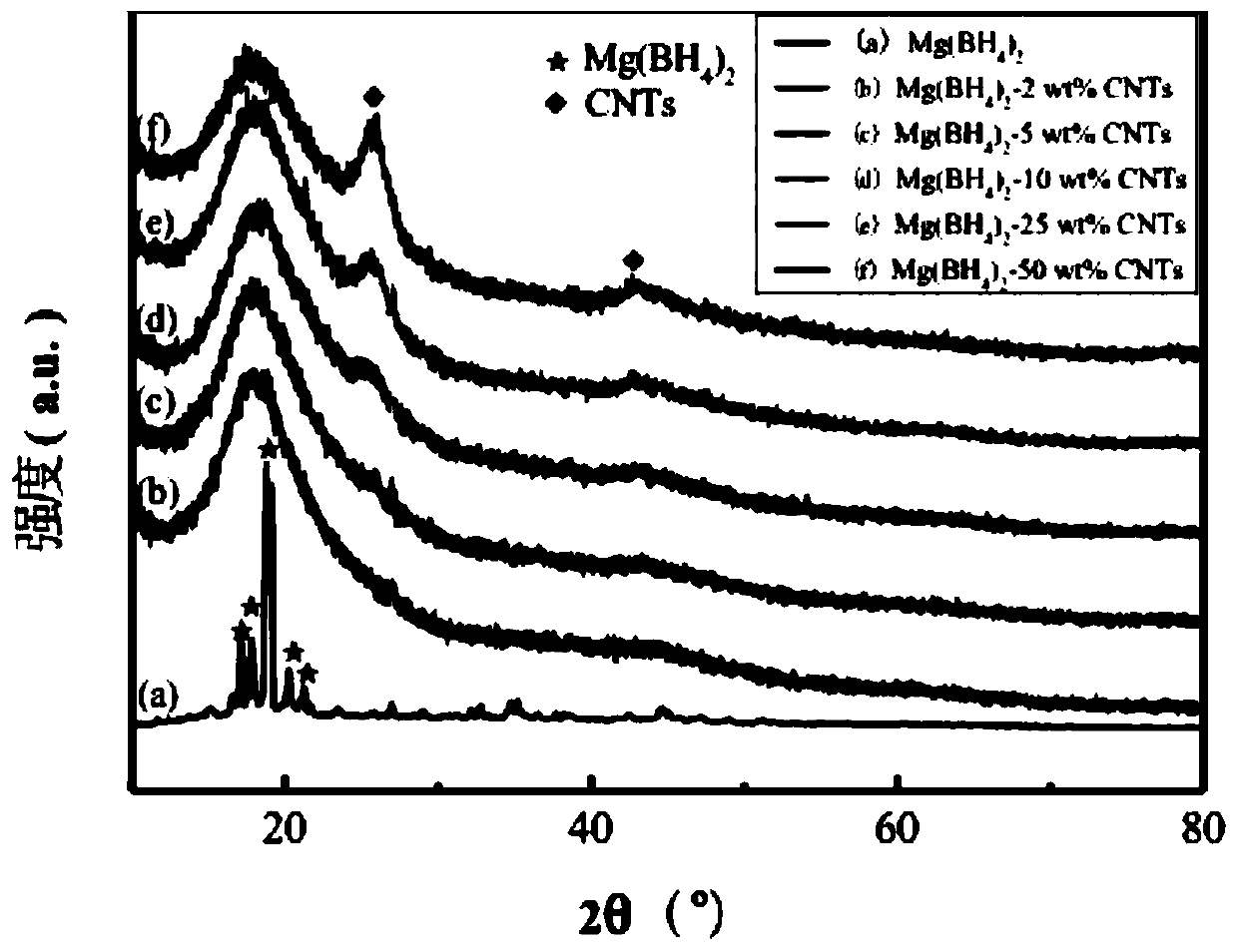

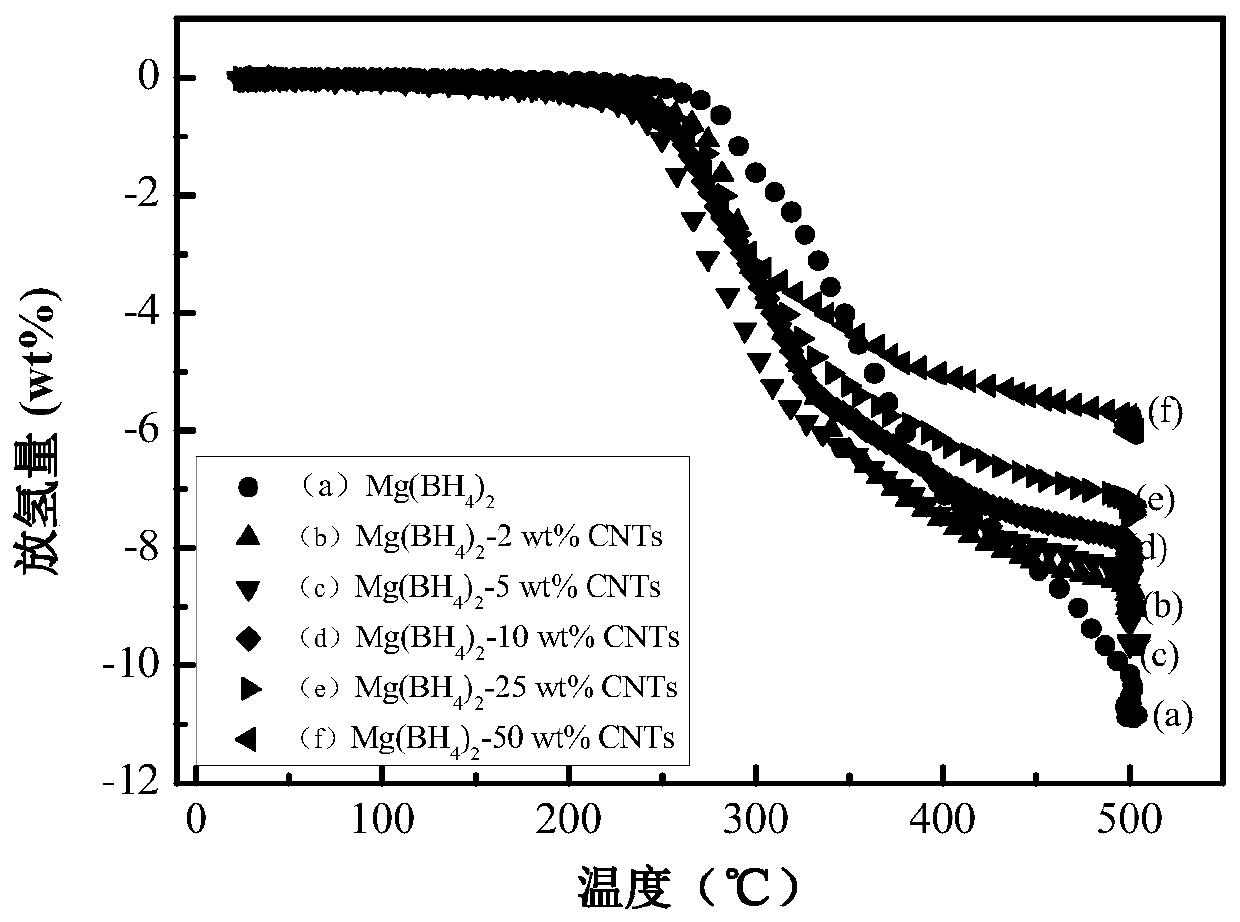

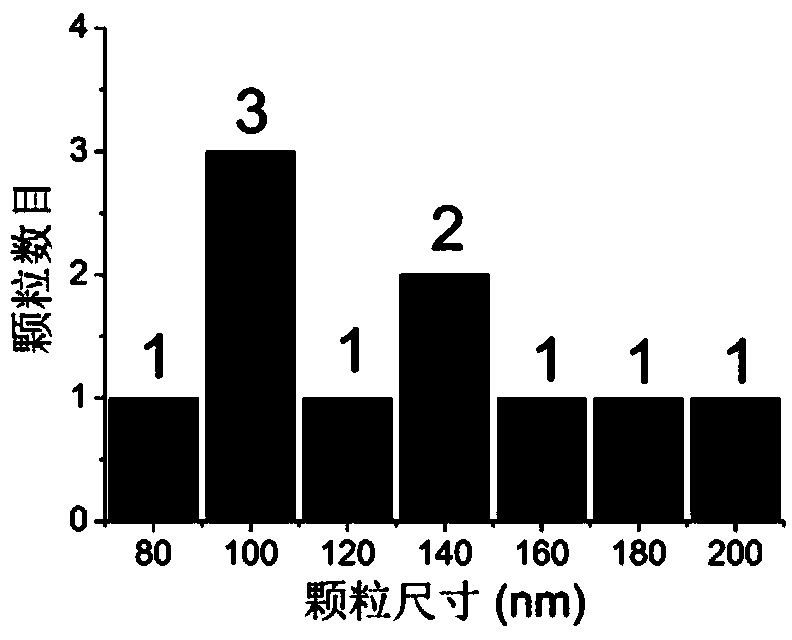

mg(bh 4 ) 2 -xcnts system hydrogen storage material and preparation method thereof

InactiveCN108455523BEasy to buyEasy to makeMaterial nanotechnologyHydrogen productionFuel cellsMetallurgy

The invention relates to a Mg(BH4)2-xCNTs system hydrogen storage material and a preparation method thereof, and belongs to the technical field of a hydrogen storage material for a fuel battery. The preparation method comprises the following steps: a material mixing step: performing mixing treatment on a Mg(BH4)2 powder and CNTs according to a certain proportion to obtain a uniform mixture; and ahigh-energy ball-milling step: putting the mixture obtained in the material mixing step into a ball-milling tank and performing high-energy ball-milling treatment to obtain the Mg(BH4)2-xCNTs system hydrogen storage material. The raw materials in the preparation method are commercialized products and are easy to purchase, the raw materials are subjected to mechanical alloying by a high-energy ball-milling process, and the preparation process is simple and convenient to operate; the prepared products are mainly CNTs and Mg(BH4)2 phases, the granules have regular shapes, the size is nanometer and uniform, and the initial hydrogen discharge temperature is low; and rapid hydrogen discharge kinetic performance is achieved and the reversible performance is improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

A water bath heat exchange type hydrogen storage device for hydrogen kinetic energy engine vehicles

ActiveCN111816893BFast hydrogen absorption rateImproved hydrogen release performanceFuel cell heat exchangeCooling chamberStorage tank

The invention discloses a water bath heat exchange type hydrogen storage device for a hydrogen kinetic energy engine vehicle, comprising: an alloy hydrogen storage tank, a plurality of elongated heat exchange fins fixed on the outer wall of the alloy hydrogen storage tank, The length direction is the same as the axial direction of the alloy hydrogen storage tank; the outer shell, the outer shell is equipped with a hydrogen storage room and the air cooling room; the inner shell is fixedly installed in the hydrogen storage room; the heat exchange shell is equipped with several mutual A connected heat exchange chamber, an alloy hydrogen storage tank is installed in the heat exchange chamber; and a water bath circulation heat exchange mechanism, a door sealing mechanism, a driving mechanism and a sealing cover. The invention adopts circulating water cooling method to cool and exchange the alloy hydrogen storage tank during hydrogen charging, so as to improve the heat dissipation rate and hydrogen absorption rate of the hydrogen storage tank; to heat the alloy hydrogen storage tank during hydrogen discharge, so as to improve the hydrogen storage capacity of the alloy. The heat absorption rate and hydrogen release rate of the tank ensure uniform heat exchange, which helps to improve the energy efficiency and output power of the entire hydrogen kinetic energy engine system.

Owner:河北柒壹壹玖工业自动化技术有限公司

Ammonia borane/magnesium hydride/heat conducting agent composite hydrogen storage material and its preparation and hydrogen release method

InactiveCN106276786BImproved hydrogen release performanceQuick releaseHydrogen productionMetal hydridesHydrogen fuel cellRoom temperature

The invention discloses an ammonia borane / magnesium hydride / heat conduction agent compound hydrogen storage material. The material is composed of magnesium hydride, a heat conduction agent, and ammonia borane subjected to partial phase change after being placed at room temperature for six months or more or thermally treated for 10-30 min, wherein the molar ratio of ammonia borane to magnesium hydride is 2:(0.8-1), and the mass of the heat conduction agent is 5-30 wt% of the sum of the mass of ammonia borane and that of magnesium hydride. The invention further provides preparing and hydrogen desorption methods of the compound hydrogen storage material. Through combination of component optimization and hydrogen desorption condition control, high-capacity hydrogen desorption of the compound hydrogen storage material under the low-temperature condition is well achieved, and then application requirements are met. Commercial application in the fields such as hydrogen refueling stations, hydrogen cell automobiles and mobile hydrogen sources can be achieved. Therefore, the ammonia borane / magnesium hydride / heat conduction agent compound hydrogen storage material has high practical value and popularization value.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

Tubular TiO2 synthesis method and application of tubular TiO2

InactiveCN103265070BSimple production processReaction conditions are easy to controlMaterial nanotechnologyPhysical/chemical process catalystsHydrogenAlcohol

The invention provides a tubular TiO2 synthesis method. The tubular TiO2 synthesis method comprises the following steps of: (2) dissolving TiOSO4 in mixed alcohol, and then adding diethyl ether to the mixed alcohol; (2) transferring the solution to a high-pressure reactor, and carrying out heating constant-temperature reaction in a homogeneous reactor to generate white precipitates; (3) sequentially centrifuging, washing, drying in vacuum and calcining the generated precipitates at high temperature, thus obtaining a finished product; and (4) mixing the prepared powder and LiBH4 to prepare the TiO-LiBH4. The synthesized tubular TiO2 can be used as a catalyst for hydrogen generation of LiBH4 and a range-limited carrier. The tubular TiO2 synthesis method has the advantages that the production process is simple, reaction conditions are easy to control, a template agent and a surface active agent are not needed, and the prepared tubular TiO2 can be used for greatly improving the hydrogen generation performance of LiBH4.

Owner:NANKAI UNIV

Preparation method for two-dimensional supported nanometer magnesium hydride hydrogen storage material

The invention discloses a preparation method for a two-dimensional supported nanometer magnesium hydride hydrogen storage material. The preparation method comprises the following steps of (1) by taking a magnesium metal-contained organic compound and graphene as raw materials, under argon shield, performing ball milling at a room temperature and a hydrogen atmosphere, and performing hydrogenationon the magnesium metal-contained organic compound to obtain suspension liquid of graphene supported magnesium hydride as a reaction product; and (2) performing suction filtration and drying on the obtained reaction product to obtain the two-dimensional supported nanometer magnesium hydride hydrogen storage material. The preparation method provided by the invention has the advantages of reduced cost, simplified synthetic method, simple technological process, high production efficiency, low energy consumption, high process safety and relatively large yield; and in addition, the two-dimensional supported nanometer magnesium hydride prepared by the preparation method has high hydrogen storage capacity and excellent cycling stability, has very large potential on the aspects of hydrogen storageand conveying, fuel cells and the like and is a hydrogen storage material with great application prospect.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com