A hydrogen storage tank with an external heat exchange structure

A technology of heat exchange structure and hydrogen storage tank, which is applied in the field of hydrogen storage in the field of hydrogen energy, can solve the problems of high production cost, poor air heat exchange, and difficult processing, and achieve easy production and processing, excellent hydrogen release performance, and improved The effect of the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

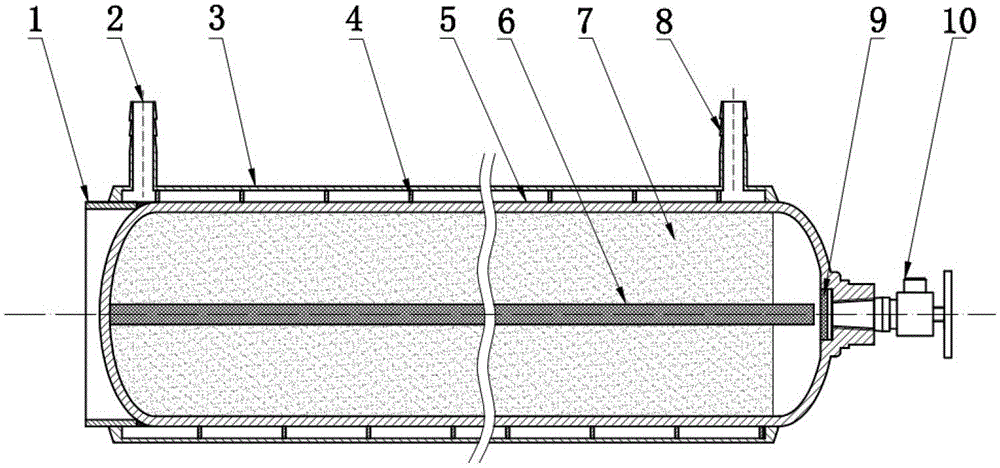

[0024] like figure 1 As shown, the structure of a hydrogen storage tank with an external heat exchange structure is as follows:

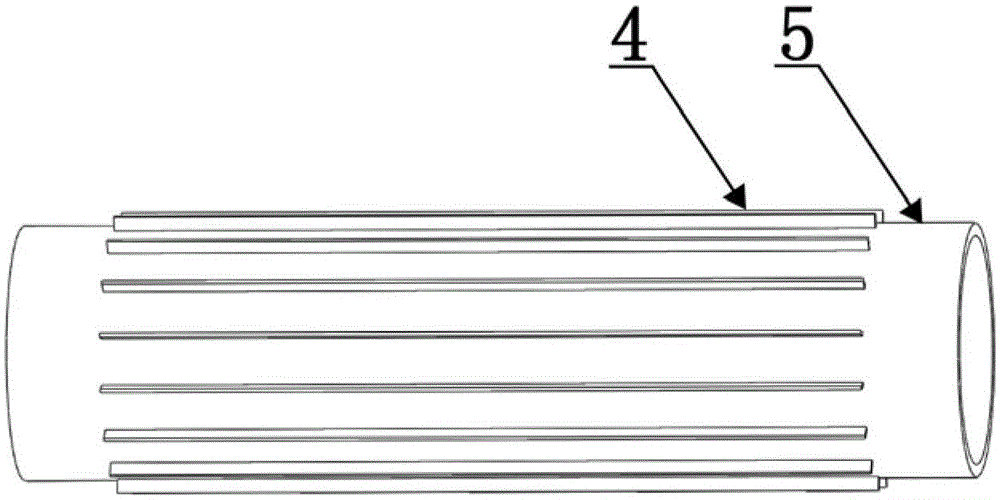

[0025] The skirt 1 is located at the bottom of the tank body 5; the hydrogen storage material bed 7 is located in the tank body 5; the gas guide pipe 6 is located at the center of the tank body 5, and runs directly from the bottom of the tank body 5 to the tank mouth; the inside of the tank mouth is equipped with a filter sheet 9, a hydrogen cylinder valve 10 is installed outside the tank mouth; the shell 3 is located outside the tank body 5, and the shell 3 is provided with a thermal fluid inlet 2 and a thermal fluid outlet 8; between the shell 3 and the tank body 5 A heat exchange structure 4 is arranged in the annular cavity; the hydrogen cylinder valve 10 and the tank body 5 are sealed with a raw material belt; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com