Two-dimensional titanium carbide-doped sodium aluminum hydride hydrogen storage material and preparation method thereof

A two-dimensional titanium carbide and sodium aluminum hydride technology, which is applied in titanium carbide, chemical instruments and methods, and various metal hydrides, can solve the problems of poor hydrogen desorption kinetics, different catalytic effects, and high dehydrogenation temperature. Achieve the effects of improving hydrogen storage performance, reducing induction period, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing a two-dimensional titanium carbide-doped sodium aluminum hydride hydrogen storage material, comprising the following steps:

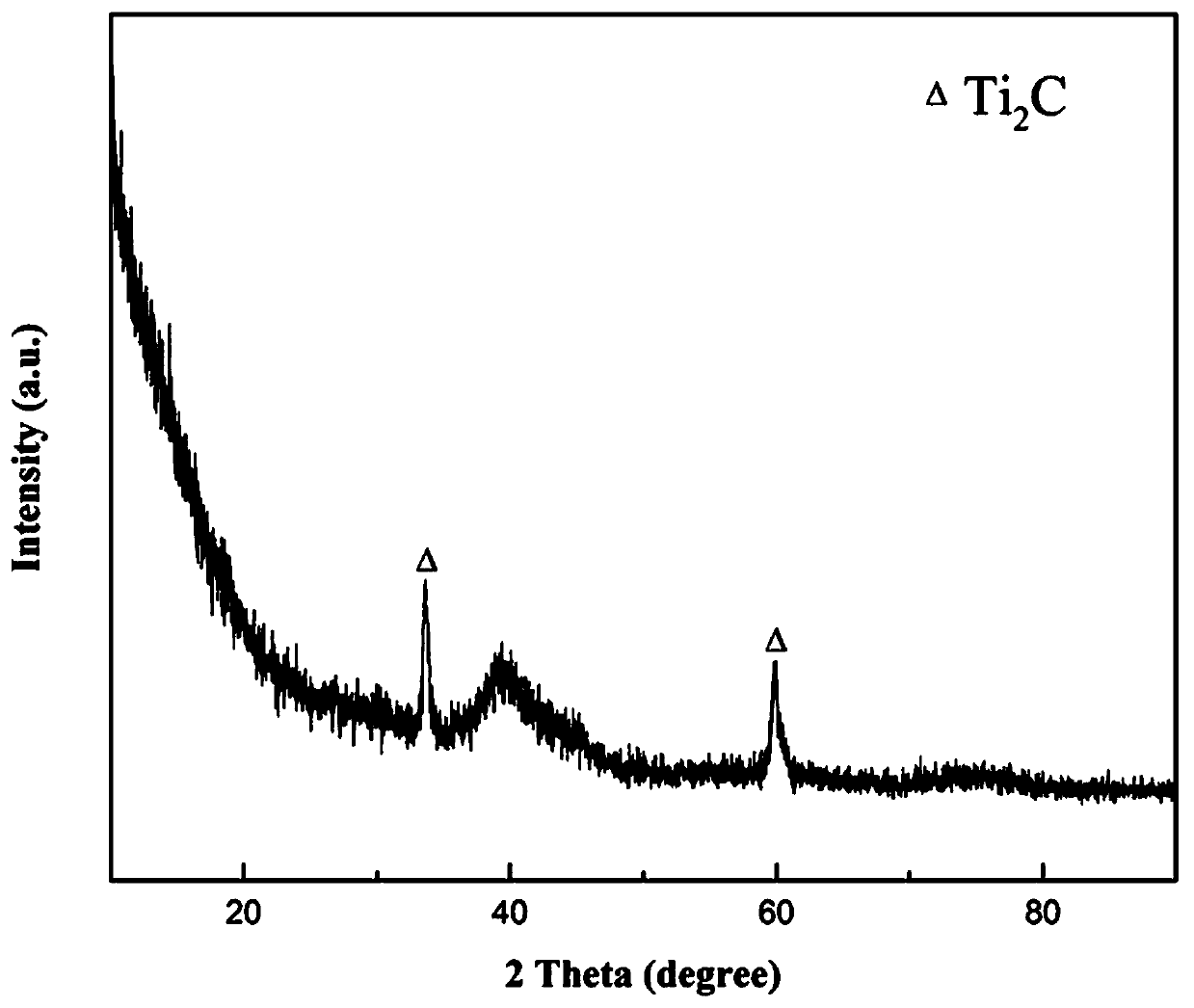

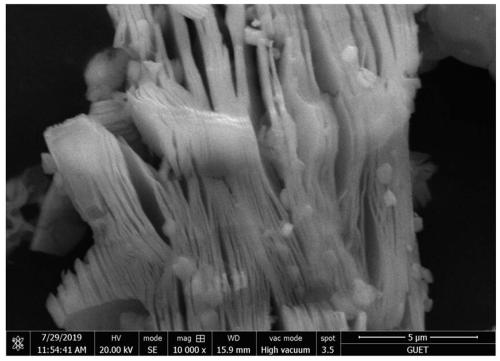

[0046] Step 1) 2D Ti 2 C prepared from Ti with a particle size of 10 μm 2 AlC ceramic powder as raw material, with Ti 2 The addition concentration of AlC ceramic powder is 0.1 g / ml, and Ti 2 The AlC ceramic powder was immersed in a hydrofluoric acid solution with a concentration of 15 wt%, and reacted under the condition of magnetic stirring for 10 h at a reaction temperature of 30 °C, washed with deionized water until the pH of the solution was 7, and pumped under reduced pressure. filter, and dry in vacuum at 80 °C for 12 h to obtain two-dimensional titanium carbide Ti 2 C;

[0047] Step 2) two-dimensional titanium carbide doped sodium aluminum hydride hydrogen storage material (Ti 2 C content is 1wt%) preparation, under the protection of argon, weigh 0.005 g step 1 obtained two-dimensional layered titanium carbide T...

Embodiment 2

[0059] A two-dimensional titanium carbide doped sodium aluminum hydride hydrogen storage material (Ti 2 C content is the preparation method of 7 wt%), and the step of not specifying is identical with embodiment 1, and difference is: in described step 2.1, Ti 2 The amount of C added was 7 wt%, and 0.035 g of two-dimensional titanium carbide Ti was weighed in an argon atmosphere glove box. 2 C and 0.465 g NaAlH 4 .

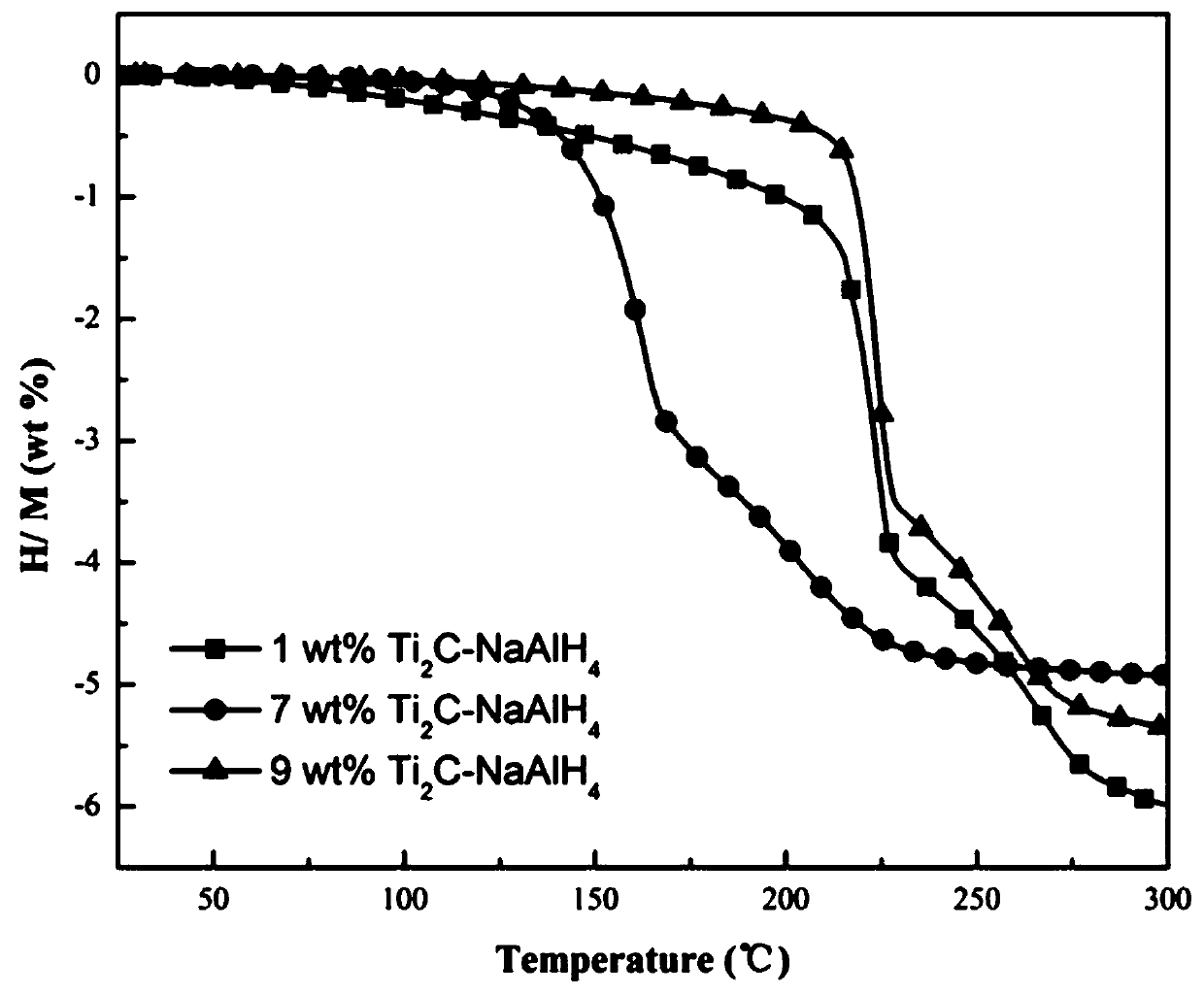

[0060] Will get Ti 2 The sodium aluminum hydride hydrogen storage material with a C content of 7 wt% was subjected to a temperature-rising dehydrogenation test, the test method was the same as in Example 1, and the test results were as follows image 3As shown, the initial hydrogen desorption temperature is 75 ℃, and the hydrogen desorption amount is 4.9 wt% when the temperature rises to 300 ℃.

Embodiment 3

[0062] A two-dimensional titanium carbide doped sodium aluminum hydride hydrogen storage material (Ti 2 C content is the preparation method of 9 wt%), and the steps not specified in particular are the same as in Example 1, except that: in the step 2.1, Ti 2 The amount of C added was 9 wt%, and 0.045 g of two-dimensional titanium carbide Ti was weighed in an argon atmosphere glove box. 2 C and 0.455 g NaAlH 4 .

[0063] Will get Ti 2 The sodium aluminum hydride hydrogen storage material with a C content of 7 wt% was subjected to a temperature-rising dehydrogenation test. The test method was the same as in Example 1, and the test results were as follows image 3 As shown, the initial hydrogen desorption temperature is 92 ℃, and the hydrogen desorption amount is 5.4wt% when the temperature rises to 300 ℃.

[0064] Therefore, Ti 2 The hydrogen desorption performance of sodium aluminum hydride hydrogen storage material with C content of 1 wt% is the best. Such as image 3 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com