Preparation method for nickel sulfide/graphene/carbon nano tube/cobalt sulfide three-dimensional composite hydrogen storage material

A carbon nanotube, three-dimensional composite technology, applied in nickel sulfide and other directions, can solve the problem that cobalt sulfide composite materials cannot be used as electrochemical hydrogen storage electrodes, etc., and achieve the effect of improving hydrogen storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

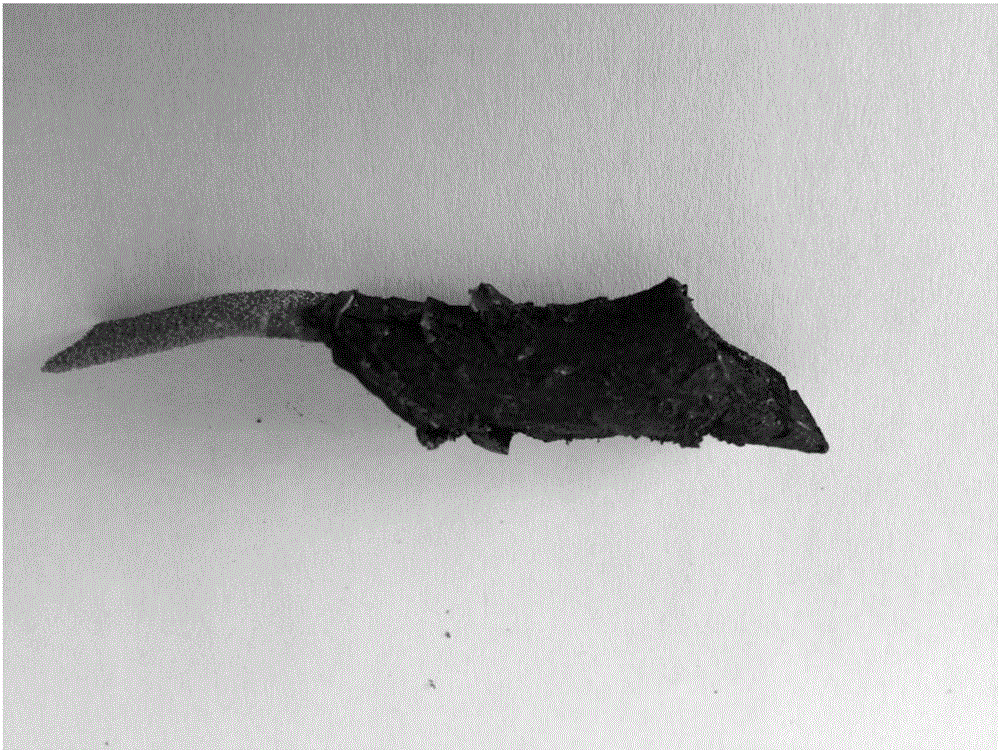

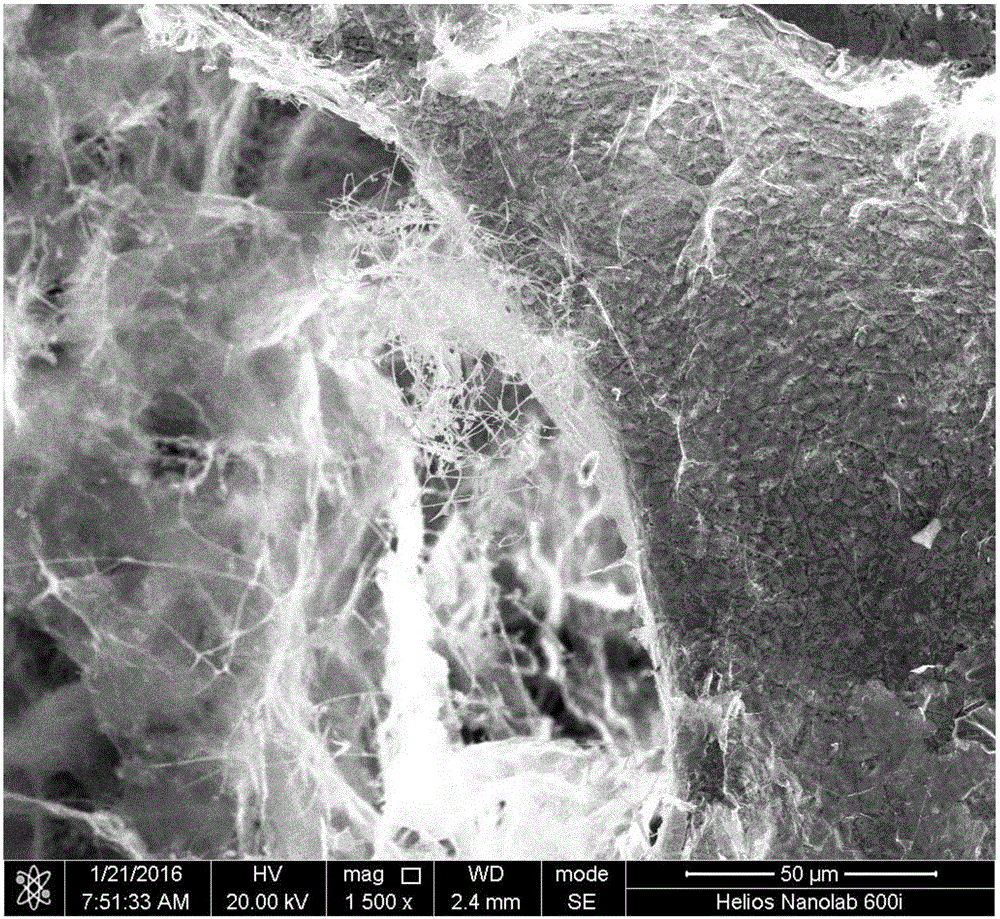

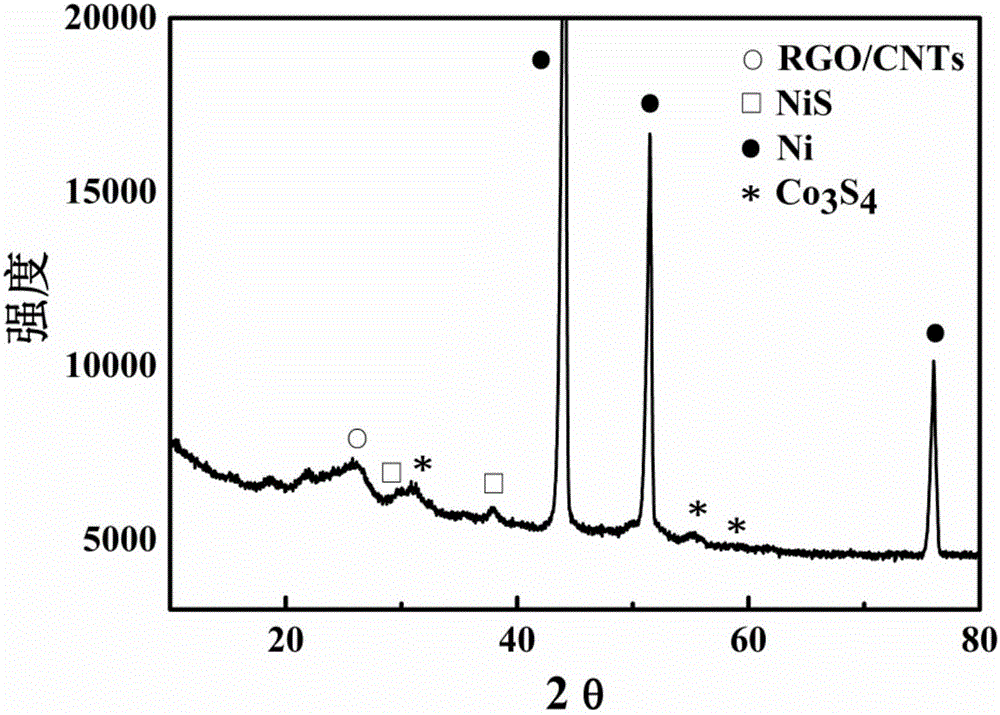

[0023] Specific embodiment one: the preparation method of a kind of nickel sulfide / graphene / carbon nanotube / cobalt sulfide three-dimensional composite hydrogen storage material of the present embodiment is carried out according to the following steps:

[0024] 1. Prepare a graphene oxide dispersion solution by the Hummers method, adjust the concentration to 2.2-2.5mg / ml, then add carbon nanotubes and mix evenly to obtain a graphene oxide / carbon nanotube dispersion; wherein the carbon nanotubes and graphene oxide The mass ratio is 1:(1~1.5);

[0025] Two, cobalt acetate and sulfur are 1:(3~4) join in graphene oxide / carbon nanotube dispersion liquid with molar ratio, continue to stir until uniform, obtain mixed liquor; Wherein the mass ratio of cobalt acetate and graphene is 1: (0.2~0.5);

[0026] 3. Press ZrO 2 The mass ratio of the grinding ball to the mixed solution is 1: (10-15), and the ZrO 2 Grinding balls and mixed liquid loaded with ZrO 2 Fill the lined ball milling ...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of the graphene oxide dispersion solution in step 1 is 2.4 mg / ml. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the mass ratio of carbon nanotubes to graphene oxide in step 1 is 1:1.2. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com