Magnesium hydride hydrogen storage material based on graded porous microspheres Ti-Nb-O and preparation method thereof

A technology of hierarchical porous, hydrogen storage materials, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, hydrogen, etc., can solve the problem that the catalyst carrier does not have good catalytic performance and no special morphology , The catalyst does not have the problems of carrier and load, so as to reduce the enthalpy change of desorption reaction Hd, easily obtain, and improve the performance of hydrogen absorption and desorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] A preparation method of a magnesium hydride hydrogen storage material based on hierarchical porous microspheres Ti-Nb-O, the specific steps are as follows:

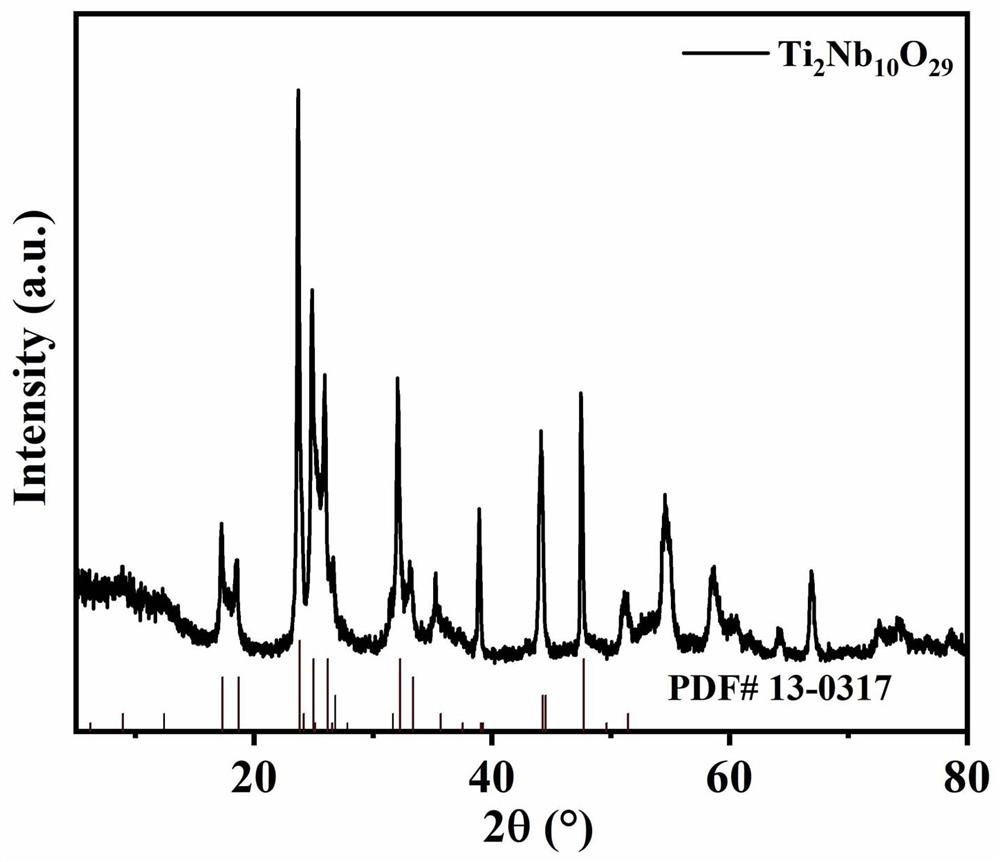

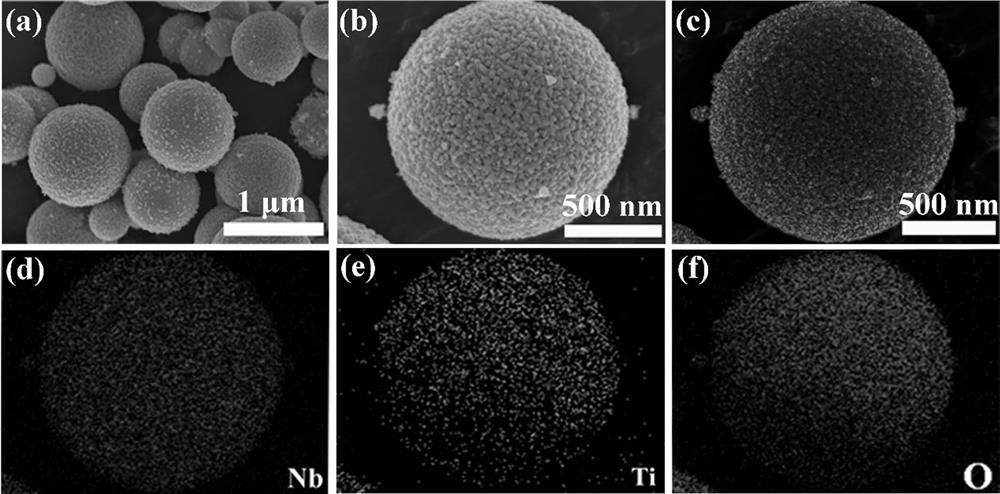

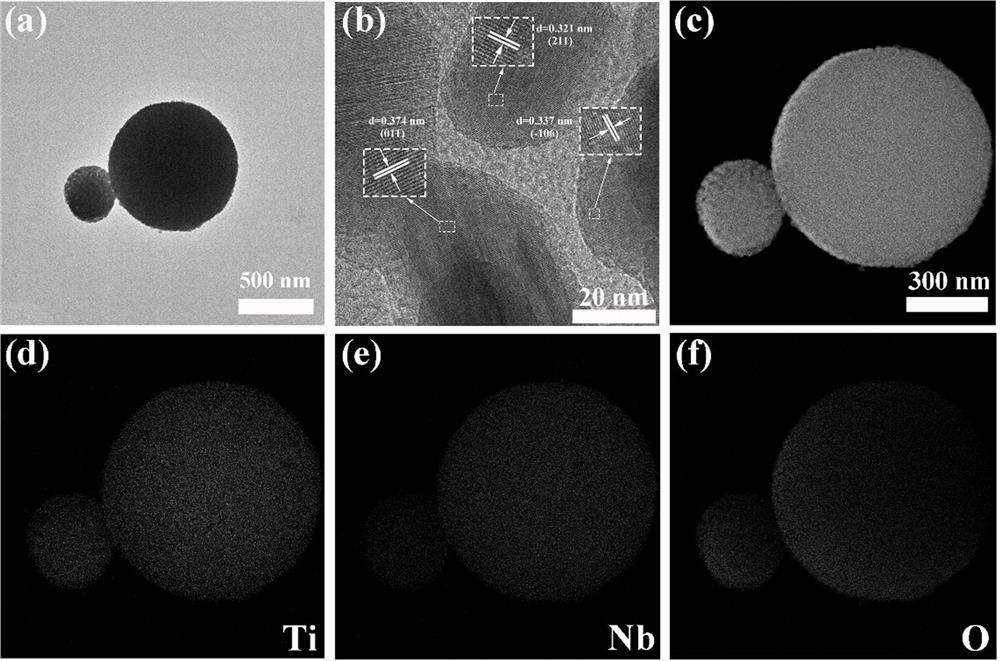

[0084] Step 1. Preparation of hierarchical porous microsphere Ti-Nb-O precursor. By solvothermal method, 0.6 g of P123 was first dissolved in 60 mL of absolute ethanol and vigorously stirred for 15 min to obtain solution A. Then, according to the substance The ratio of the amount of 0.568 g of titanium isopropoxide and 2.7 g of anhydrous niobium chloride was dissolved in solution A and stirred for 30 min to obtain a reaction solution; after that, the reaction solution was transferred to an autoclave, in The reaction temperature was 200 °C, and the reaction time was 24 h. The solvothermal reaction was carried out. Finally, the obtained precipitate was washed with deionized water and absolute ethanol and dried to obtain the hierarchical porous microsphere Ti-Nb-O precursor. ;

[0085] Step 2, the preparation of grad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com