Sodium borohydride/nitrogen-doped graphene hydrogen storage composite material and preparation method thereof

A technology of nitrogen-doped graphene and composite materials, which is applied in the field of sodium borohydride/nitrogen-doped graphene hydrogen storage composite materials and its preparation, achieving the effects of low preparation cost, cheap price, and improved hydrogen desorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

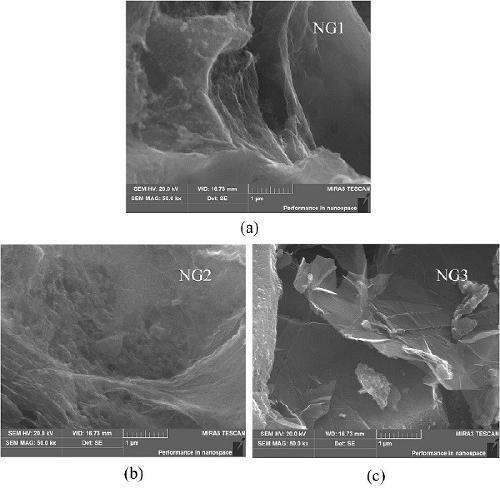

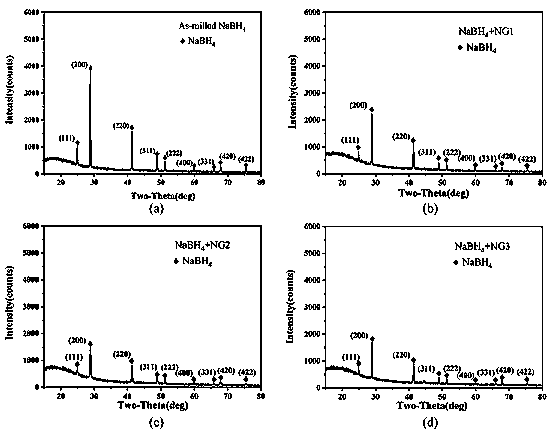

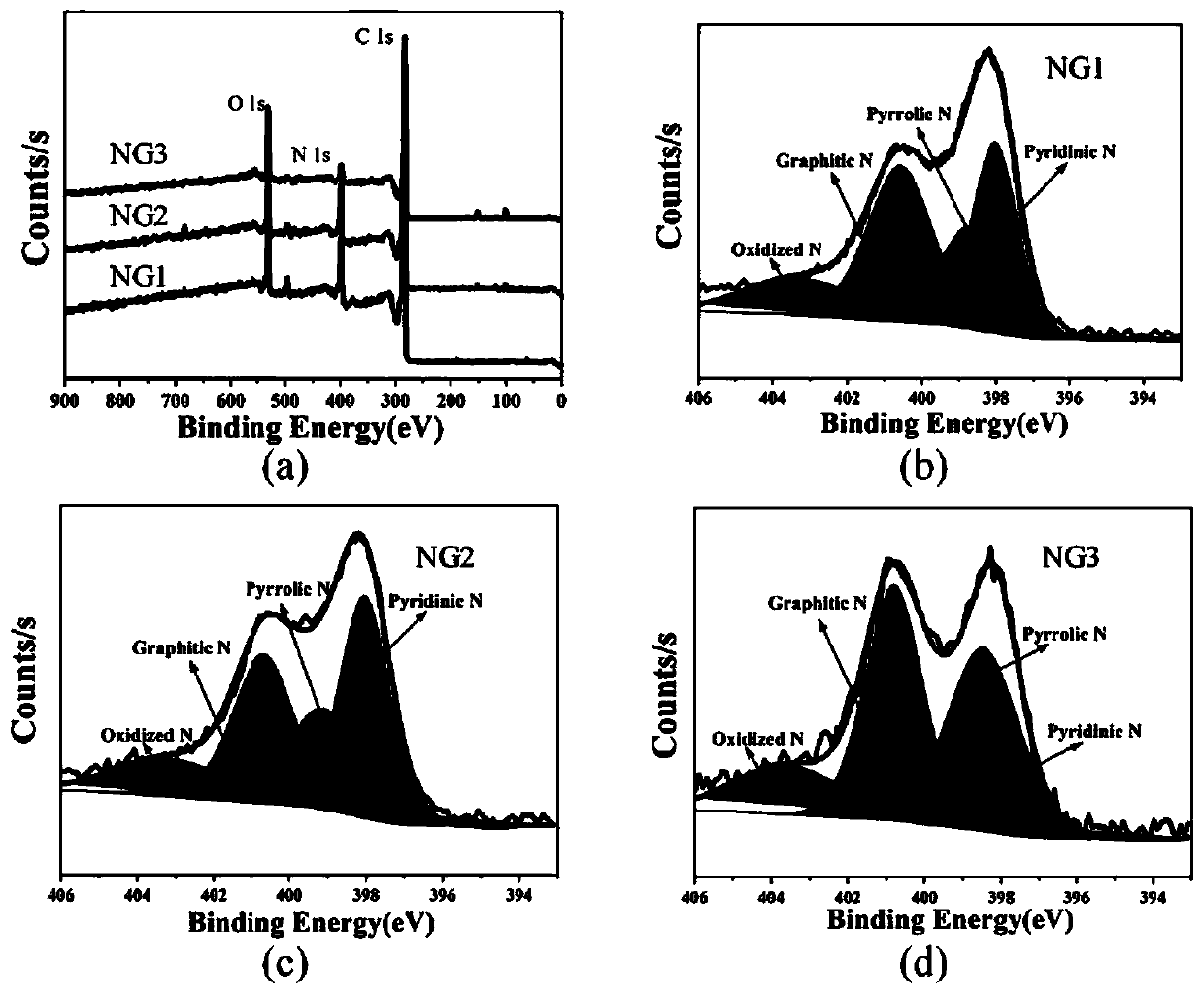

[0036] The raw material is commercially available sodium borohydride powder (NaBH 4 , Purity 99 wt%), melamine (C 3 N 3 (NH 2 ) 3 , The purity is 99wt%) and pyrrole (C 4 H 5 N, purity of 99.7 wt%), graphene G dispersion was prepared by a modified Hummers oxidation-reduction method; firstly, 75.53 mLG of dispersion was combined with three nitrogen sources (0.05molC) under ultrasonic vibration. 3 N 3 (NH 2 ) 3 +0.05molC 4 H 5 N,; 0.1mol C 3 N 3 (NH 2 ) 3 ; 0.1mol C 4 H 5 N) Mix thoroughly; then, transfer the three different mixed samples obtained to a hydrothermal autoclave and calcinate at 180°C for 5 hours; then filter, wash and dry the obtained three sets of mixtures at 80°C ; Then the three sets of powder samples obtained are placed in a tube furnace in sequence, and annealed in an argon (Ar) atmosphere at 500 ℃ for 8 hours to obtain three different nitrogen-doped graphene NGX (X=1 , twenty three). The SEM images of three NGX (X=1, 2, 3) prepared by the above hydrothermal meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com