Ammonia borane/magnesium hydride/heat conducting agent composite hydrogen storage material and its preparation and hydrogen release method

A hydrogen storage material, ammonia borane technology, applied in chemical instruments and methods, metal hydrides, inorganic chemistry, etc., can solve the problems of slow hydrogen release kinetics, release hydrogen capacity, etc., to improve hydrogen release performance, ensure Hydrogen release performance, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

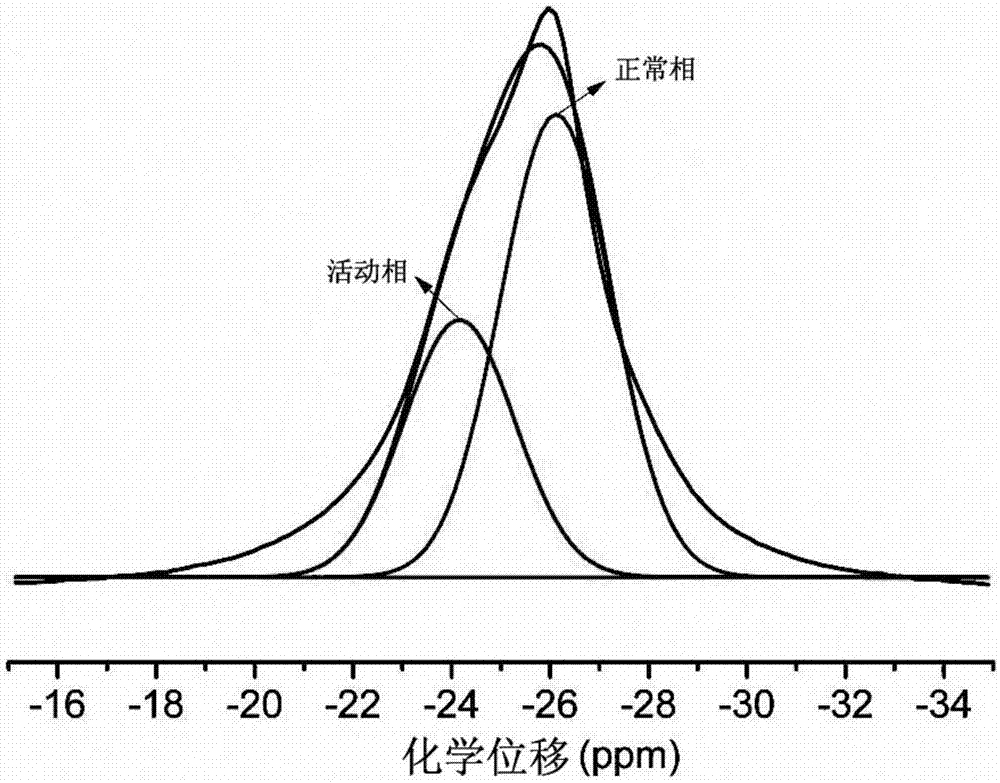

[0026] The invention provides a novel composite hydrogen storage material, which is composed of ammonia borane with a molar ratio of 2:0.8 to 1 (the optimal ratio is 2:1), magnesium hydride and a heat conducting agent, wherein ammonia borane It is ammonia borane that undergoes a partial phase transition after being placed at room temperature for more than 6 months or heat-treated at 80°C for 10 to 30 minutes. It contains both normal phase and active phase, such as figure 1 shown.

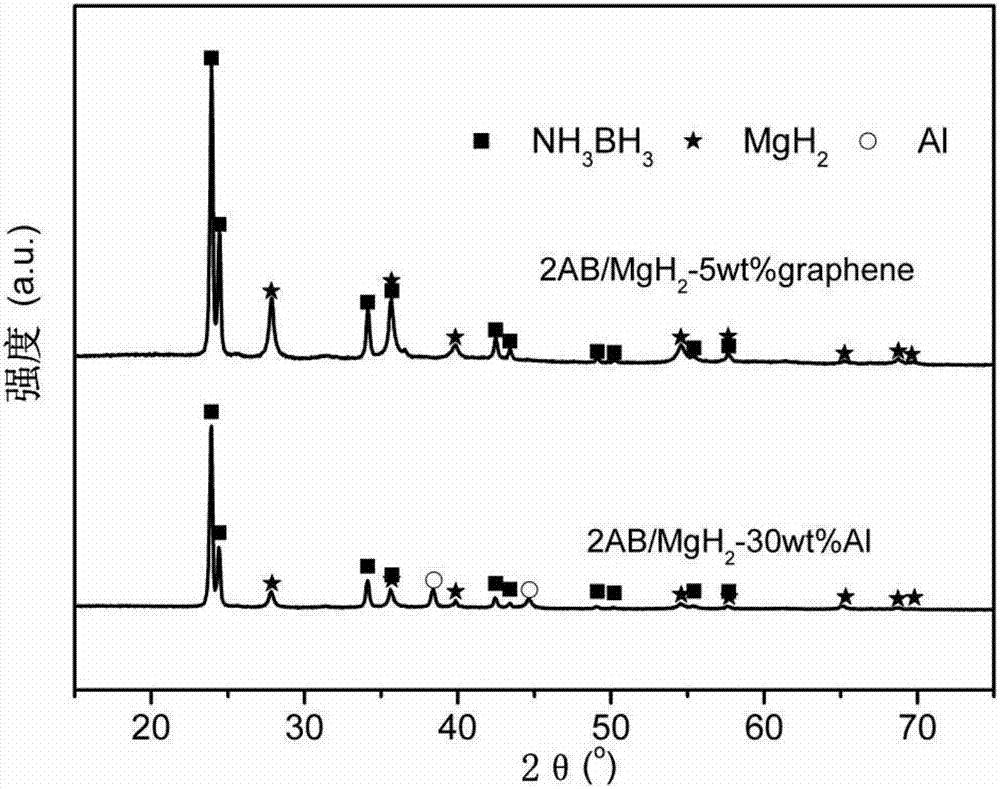

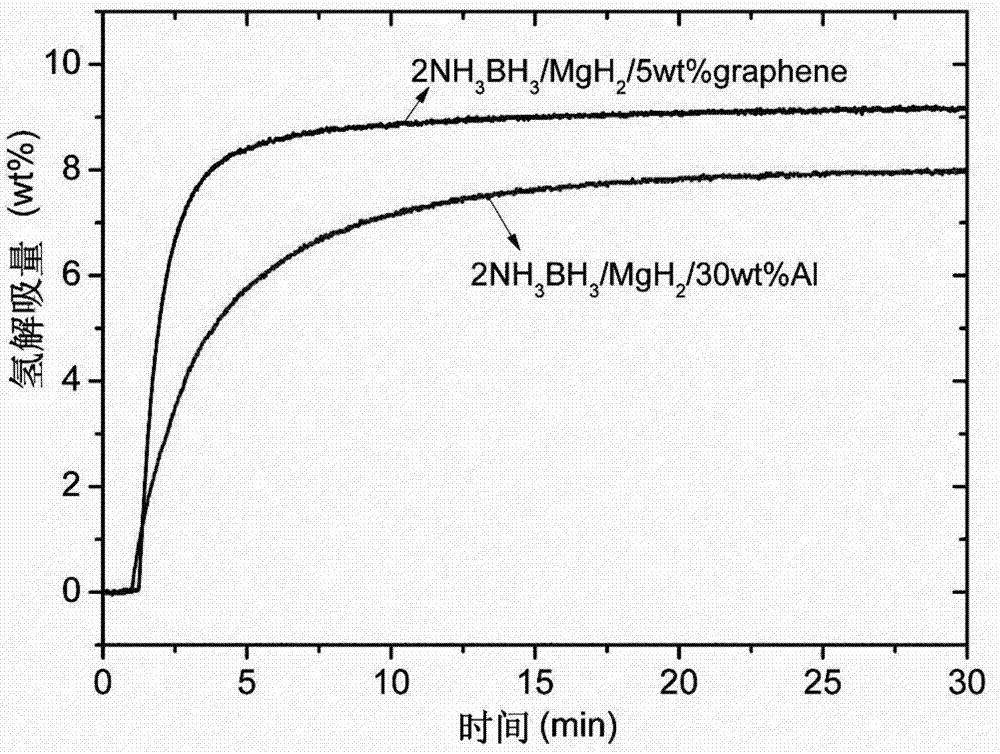

[0027] The process of preparing a composite hydrogen storage material is mainly to mix ammonia borane, magnesium hydride and a heat conducting agent and perform ball milling to obtain a powdered hydrogen storage material. In this embodiment, ammonia borane can be purchased from a chemical reagent company, or can be Self-prepared according to the literature method, the purity is generally required to be not less than 90%, and magnesium hydride and heat conduction agent can also be purchased from chem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com