A method for improving lithium borohydride dehydrogenation

A lithium borohydride and carbon fiber technology, which is applied in the field of hydrogen storage technology and material modification, can solve the problems of storage and transportation danger, low hydrogen storage capacity, and high energy consumption, and achieves improved hydrogen release performance, moderate cost, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Stir 75mg of lithium borohydride solid powder in 15mL of anhydrous diethyl ether at 20°C until completely dissolved.

[0017] The above ether solution of lithium borohydride was uniformly dropped onto the carbon fiber array with an average diameter of 90 nm and an average length of 3 mm.

[0018] At 40° C., the ether was vacuum-dried to obtain the lithium borohydride carried by the carbon fiber array.

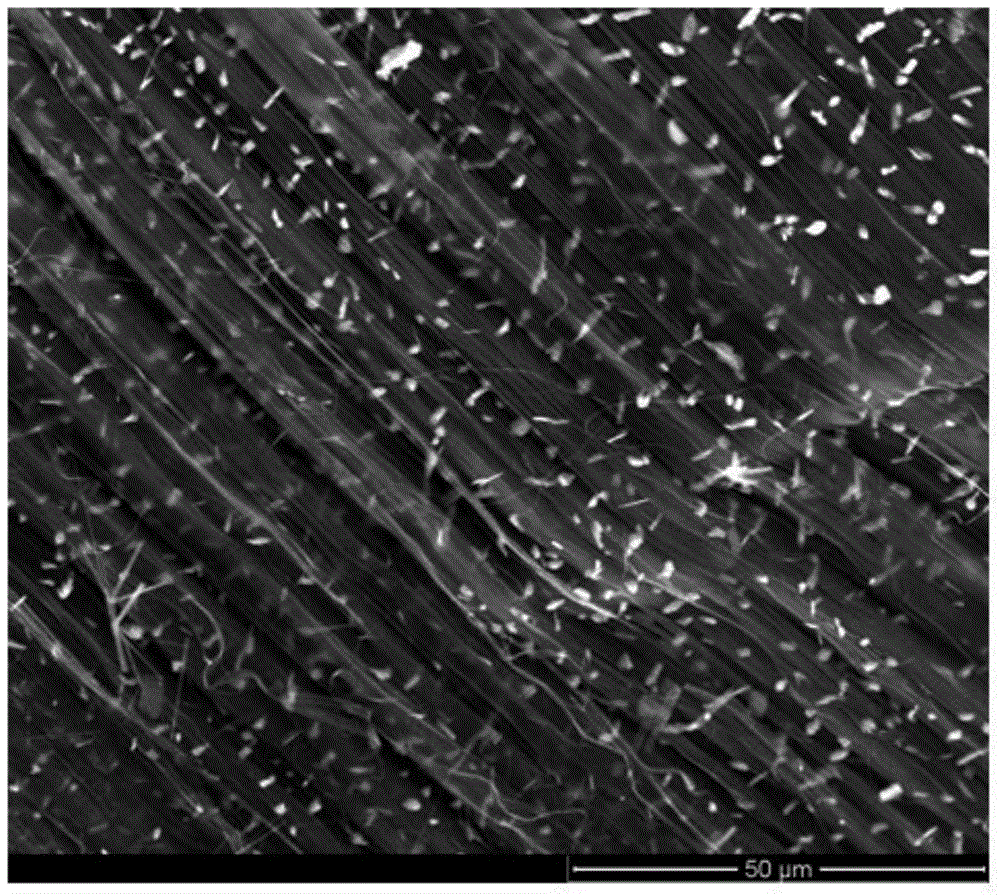

[0019] The SEM photos of carbon fiber arrays carrying lithium borohydride are as follows: figure 1 shown.

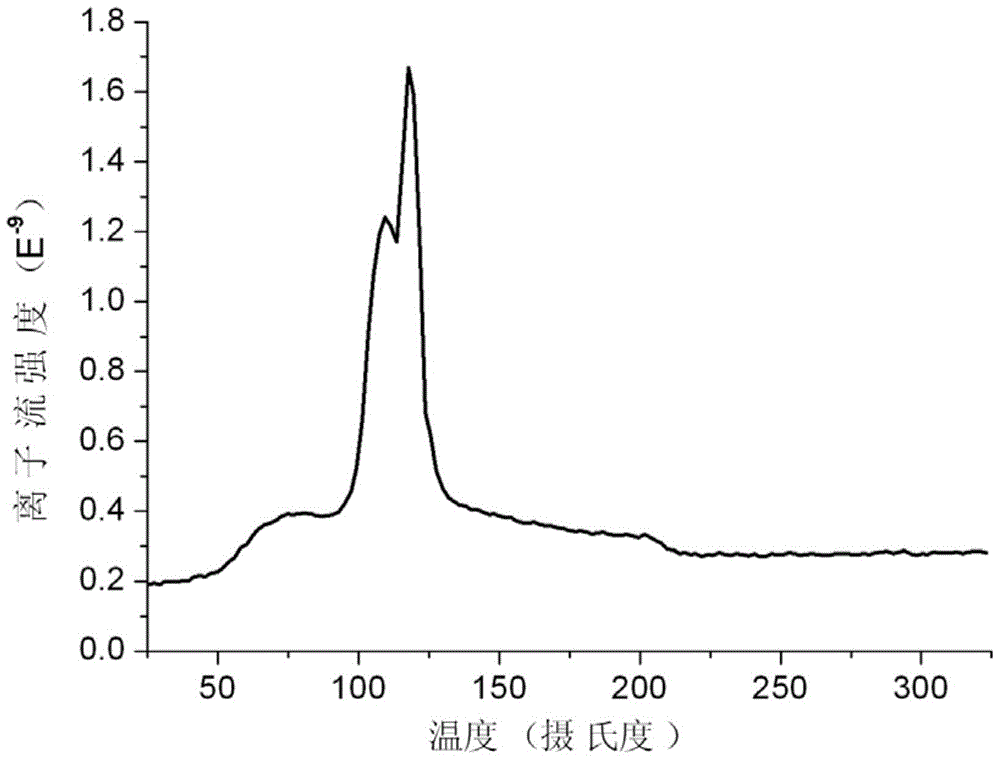

[0020] The thermal decomposition hydrogen mass spectrum curve of carbon fiber array carrying lithium borohydride is as follows: figure 2 Shown, wherein the heating rate is 5 degrees Celsius / minute.

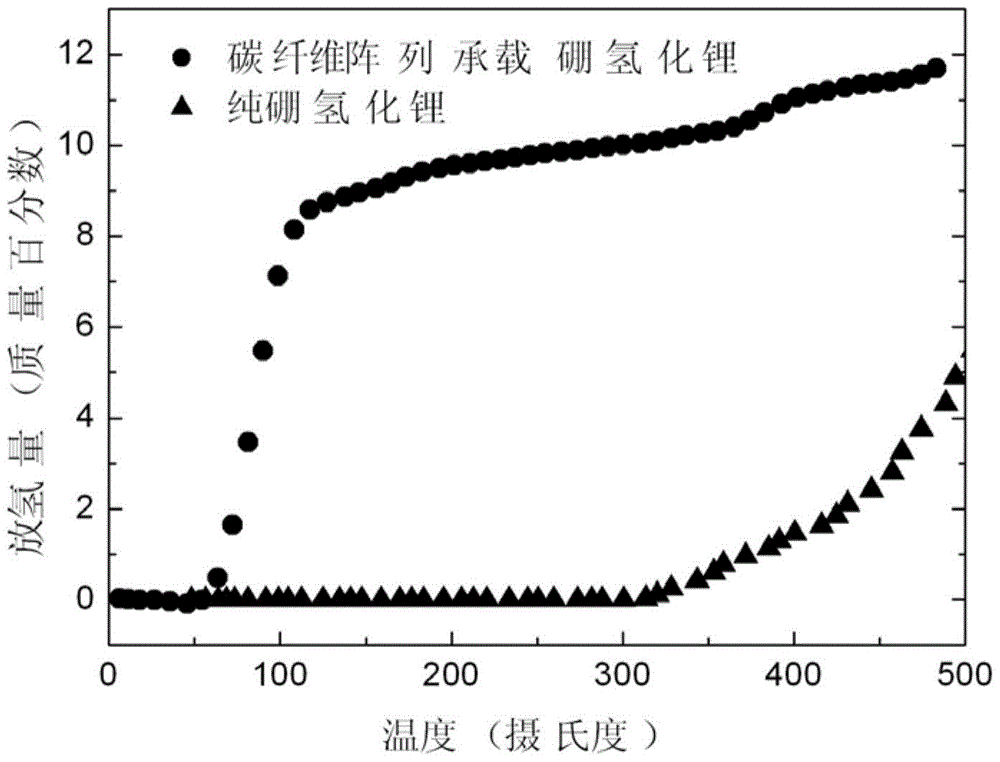

[0021] The hydrogen desorption curves of carbon fiber array loaded lithium borohydride and pure lithium borohydride are as follows: image 3 Shown, wherein the heating rate is 5 degrees Celsius / minute.

Embodiment 2

[0023] Stir 50 mg of lithium borohydride solid powder in 12 mL of anhydrous propyl ether at 40°C until completely dissolved.

[0024] The above-mentioned propyl ether solution of lithium borohydride was uniformly dropped on the carbon fiber array with an average diameter of 130 nm and an average length of 1.5 mm.

[0025] At 90° C., propyl ether was vacuum-dried to obtain the lithium borohydride carried by the carbon fiber array.

Embodiment 3

[0027] Stir 50 mg of lithium borohydride solid powder in 20 mL of anhydrous propyl ether at 10°C until completely dissolved.

[0028] The above-mentioned butyl ether solution of lithium borohydride is evenly added dropwise on the carbon fiber array with an average diameter of 200nm and an average length of 5mm;

[0029] At 20° C., the butyl ether was vacuum-dried to obtain the lithium borohydride carried by the carbon fiber array.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com