A Mg2NiH4 material and a preparing method thereof

A composite material, room temperature technology, applied in the fields of magnetic materials, inorganic material magnetism, chemical instruments and methods, etc., can solve problems such as the inability to achieve controllable generation of alloys, and achieve the effect of low density and excellent hydrogen release performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

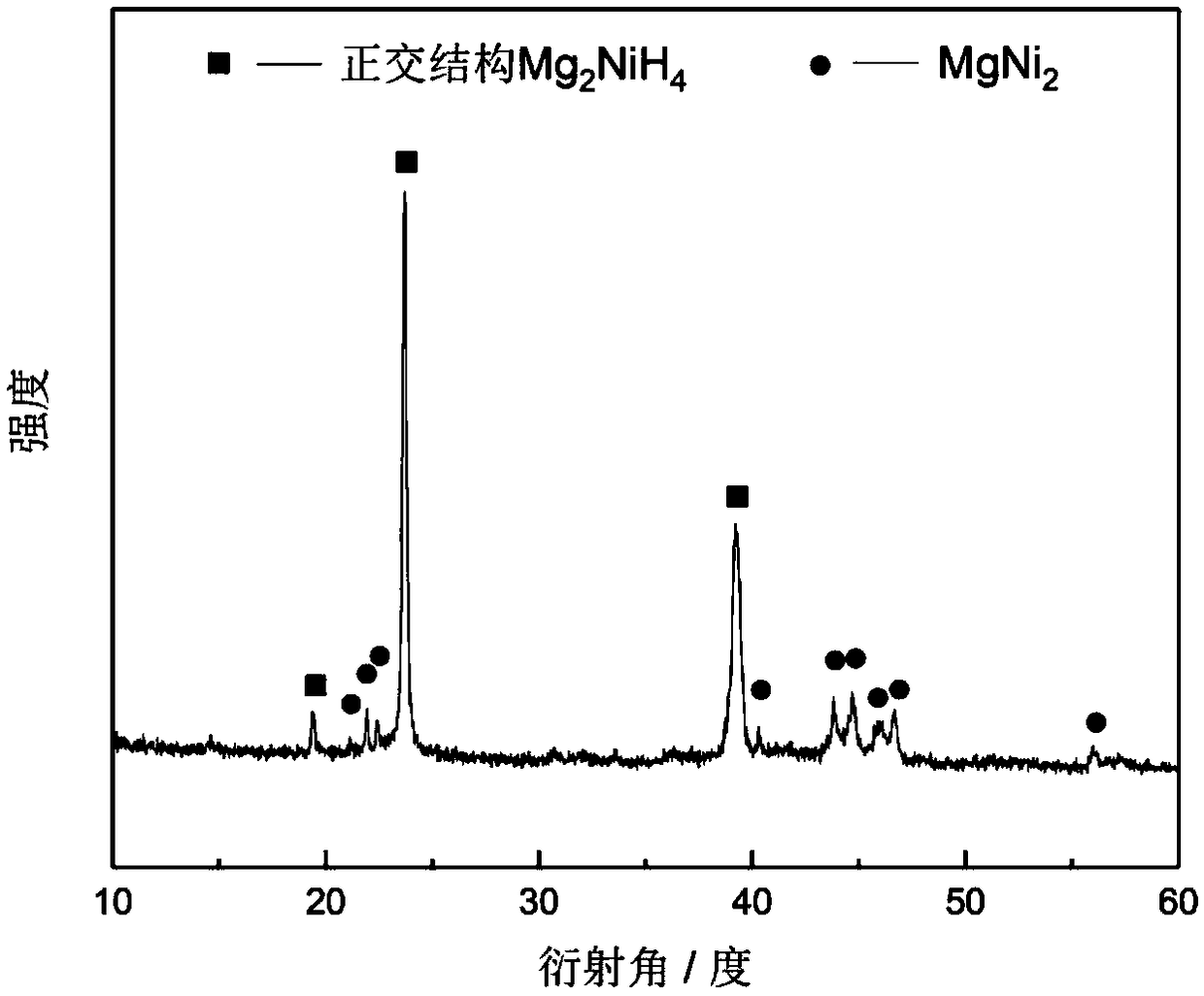

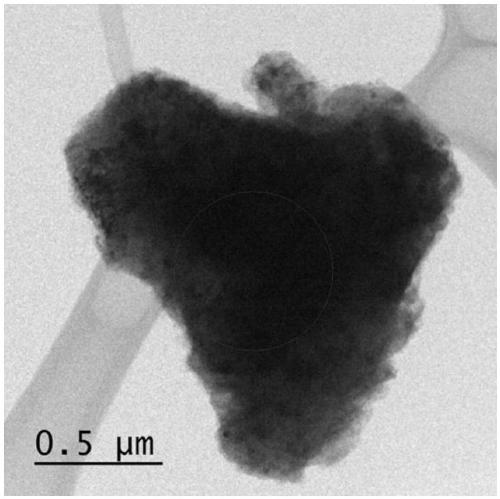

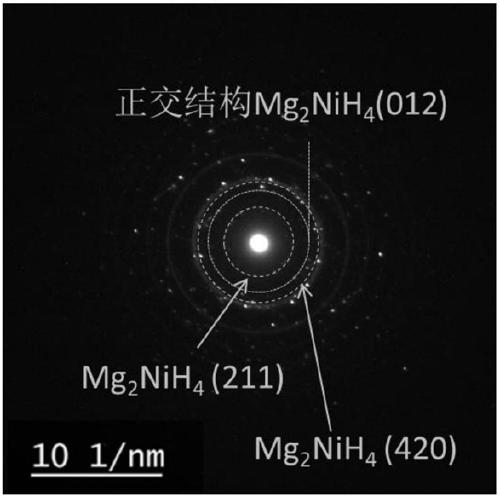

[0027] In this example, see Figure 1 to Figure 5 , a Mg 2 NeH 4 material, Mg with orthorhombic structure at room temperature 2 NeH 4 Material.

[0028] A kind of present embodiment Mg 2 NeH 4 The preparation method of material, comprises the steps:

[0029] Step 1): the Mg obtained by smelting 2 After the Ni alloy powder is ball milled for 15 hours, it is loaded in the reaction kettle;

[0030] Step 2): Carry out the hydrogen storage alloy hydrogen absorption process, pass hydrogen gas into the reaction kettle in step 1), make the hydrogen pressure in the reaction kettle 2.0MPa, heat to 350°C and keep warm for 2 hours;

[0031] Step 3): keep the temperature of the reaction kettle in step 2) constant, pump the reaction kettle to vacuum, and maintain the vacuum state for 1 hour to obtain the hydrogen storage alloy product;

[0032] Step 4): Take out the hydrogen storage alloy product in the reactor in step 3), and then repeat step 1) and step 2) successively for 0 time...

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, especially in that:

[0043] In this example, a Mg 2 NeH 4 The preparation method of material, comprises the steps:

[0044] Step 1): the Mg obtained by smelting 2 After the Ni alloy powder is ball milled for 30 hours, it is loaded in the reaction kettle;

[0045] Step 2): Carry out the hydrogen storage alloy hydrogen absorption process, pass hydrogen gas into the reaction kettle in step 1), make the hydrogen pressure in the reaction kettle 2.7MPa, heat it to 320°C and keep it warm for 1h;

[0046] Step 3): keep the temperature of the reaction kettle in step 2) constant, pump the reaction kettle to vacuum, and maintain the vacuum state for 2 hours to obtain the hydrogen storage alloy product;

[0047] Step 4): Take out the hydrogen storage alloy product in the reaction kettle in step 3), and then repeat the process times of step 1) and step 2) one time, when repeating the process of step 1) and step 2), make Th...

Embodiment 3

[0051] This embodiment is basically the same as the previous embodiment, and the special features are:

[0052] In this example, a Mg 2 NeH 4 The preparation method of material, comprises the steps:

[0053] Step 1): the Mg obtained by smelting 2 After the Ni alloy powder is ball milled for 10 hours, it is loaded in the reaction kettle;

[0054] Step 2): Carry out the hydrogen storage alloy hydrogen absorption process, pass hydrogen gas into the reaction kettle in step 1), make the hydrogen pressure in the reaction kettle 3.5MPa, heat it to 360°C and keep it warm for 1.5h;

[0055] Step 3): keep the temperature of the reaction kettle in step 2) constant, pump the reaction kettle to vacuum, and maintain the vacuum state for 1.5 hours to obtain the hydrogen storage alloy product;

[0056] Step 4): Take out the hydrogen storage alloy product in the reactor in step 3), then repeat the process times of step 1) and step 2) twice, when repeating the process of step 1) and step 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com