Preparation method of Ti3C2MXene composite hydrogen storage material

A hydrogen storage material and powder technology, which is applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of electrode material powdering and falling off, large volume effect, and poor conductivity, so as to improve hydrogen storage performance and alleviate volume effect , improve the effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of Ti 3 C 2 The preparation method of MXene composite hydrogen storage material comprises the steps:

[0043] S1, Ti 3 C 2 Preparation: Weigh Ti with a purity greater than 98% 3 AlC 2 5g of powder, soak it in 50ml of HF acid with a mass fraction of 40%, stir for 24h, wash with deionized water for 3-5 times until the pH of the cleaning solution reaches 5~6, centrifuge to get the powder, and dry at 80°C for 12h Get powdered Ti 3 C 2 ;

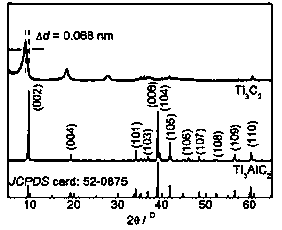

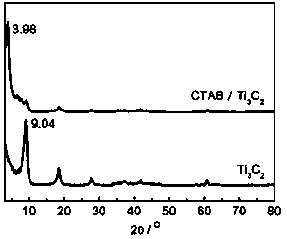

[0044] figure 1 is Ti before and after HF acid stripping 3 AlC 2 and Ti 3 C 2 The XRD spectrum of the figure shows that the raw material Ti 3 AlC 2 The XRD pattern of the standard Ti 3 AlC 2 The matching degree of the spectrum is very high, and the raw material has very good crystallinity; compared with the XRD pattern before HF stripping, the crystallinity and structural order of the sample after HF acid treatment decreased significantly; after HF acid stripping, the Ti 3 C 2 The position of the main peak (002) in...

Embodiment 2

[0059] PL / Ti by hydrogen storage tester 3 C 2 / SnS / MF composite hydrogen storage material samples for hydrogen storage performance test, the mass of the sample used for each test is about 0.2g, during the programmed temperature desorption test, the sample is loaded into the reactor, and then connected to the hydrogen storage tester for pumping Vacuum for testing; from room temperature to 500°C at a rate of 2°C / min. During the constant temperature dehydrogenation test, after vacuuming, it is necessary to fill the reactor with 100bar H2 and quickly heat it to the specified temperature. After stabilization, the constant temperature hydrogen desorption performance test was carried out.

[0060] Figure 9 for PL / Ti 3 C 2 / SnS / MF composite hydrogen storage material TPD curve of temperature-programmed hydrogen desorption, from Figure 9 It can be seen that PL / Ti 3 C 2 / SnS / MF (a) and PL / SnS / MF (b) all exhibit a three-step dehydrogenation process, in which PL / Ti 3 C 2 / SnS / MF...

Embodiment 3

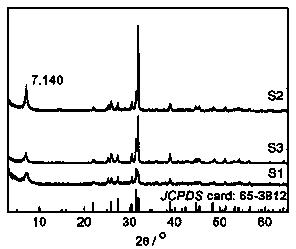

[0064] In order to examine PL / Ti 3 C 2 / SnS / MF composite hydrogen storage material hydrogen desorption reaction mechanism, for PL / Ti 3 C 2 The XRD and FTIR spectra of the / SnS / MF composite hydrogen storage material were tested at different temperatures, and the results are as follows Figure 12-13 shown by Figure 12 It can be seen that when the heating temperature reaches 100 °C, there is still LiBH 4 phase, and a new substance Li 3 BO 3 , indicating that at low temperature LiBH 4 React with PMMA to release a small amount of hydrogen, and Figure 9 Corresponding to the first dehydrogenation stage of the middle hydrogen desorption curve; continue to increase the temperature to 200 ° C, and observe LiBH in the XRD pattern 4 Decrease, there is a new substance LiB 5 o 8 appears, and Li 3 BO 3 still exists, indicating that LiBH 4 Further react with PMMA to release hydrogen; further increase the temperature to 300 ° C, almost no LiBH can be observed 4 phase (from Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com