Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "No scarring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

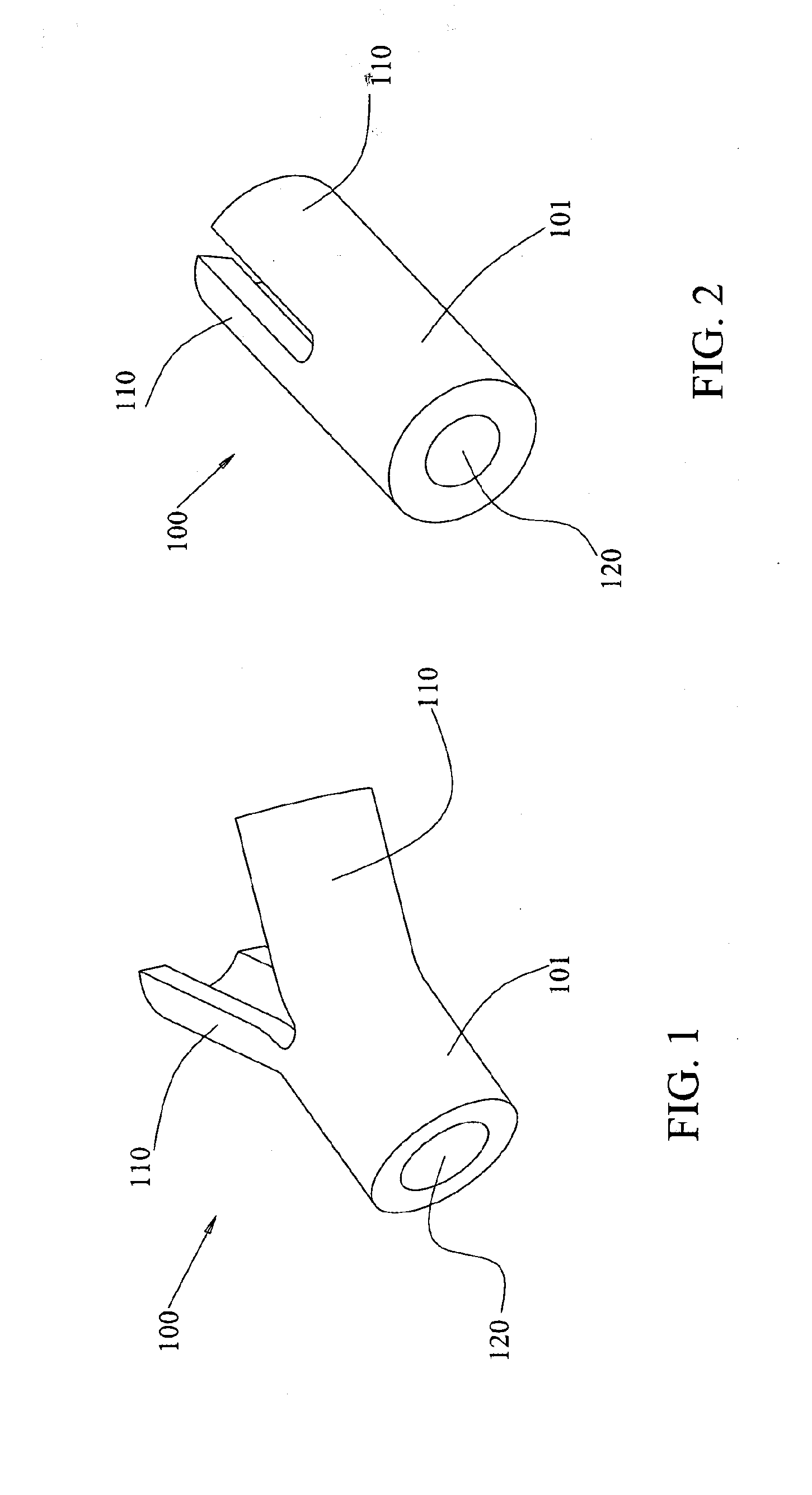

Hair implant anchors and systems and methods for use thereof

ActiveUS20120245612A1Easily implanted into target tissueEasy to useSuture equipmentsSkin implantsBiomedical engineeringHair implant

A hair implant anchor usable with a hair implant anchor deployment device for inserting one or more hairs into a tissue portion is provided. The hair implant anchor includes a holder configured to grip one or more hairs and one or more selectably deployable leaves formed with the holder. When the anchor is in its first configuration prior to implantation of the hairs, the leaves are constrained by the deployment device in a position generally parallel to an insertion axis, and in a second configuration, subsequent to implantation of the hair, the leaves adopt a position extended away from the insertion axis, thereby securing the holder and hair gripped thereby within the tissue portion. The invention also provides a method for use of the anchor, a hair implantation system, a multi-hair implantation system and a hair implantation assembly.

Owner:HAIRSTETICS

Mould sand

InactiveCN101468382AReduce pollutionTake advantage ofFoundry mouldsFoundry coresSodium BentoniteBrick

The invention relates to a moulding sand, which consists of the following component by weight percentage: 0.6 to 0.8 percent of bentonite, 0.4 to 1.0 percent of coal dust, 3.5 to 4.5 percent of water, and the balance being dispersed coated sand. The moulding sand does not add new sand into the moulding sand, and the new sand is replaced by the dispersed coated sand, so as to not only guarantee the quality of products, but also greatly reduce the production cost. The dispersed coated sand can be reused, so as to save the energy and reduce the environmental pollution, the pumped dust can be used for preparing protective materials, and the waste sand can be used for producing bricks. The moulding sand fully utilizes waste and realizes harmless casting treatment.

Owner:西峡县内燃机进排气管有限责任公司

Desulfurizing method using soda waste liquid and calcium carbide waste residue

InactiveCN101306304AHigh desulfurization rateQuick responseDispersed particle separationLiquid wasteSlag

The invention discloses a method for removing SO2 by utilizing soda ash waste liquid and carbide waste slag. CaCl2 in the soda ash waste liquid is utilized to react with the SO2 in flue gas, white CaSO3 settlement is generated, HCl is released and dissolved in water to form hydrochloric acid with very low concentration; Ca(OH)2 in the carbide waste slag is used for neutralizing HCl and generating CaCl2 and water, and CaCl2 is recycled. The desulphurization process mainly consumes Ca(OH)2 in the carbide waste slag. If no local soda ash waste liquid, calcium chloride dehydrate (CaCl2*2HO) produced by the soda ash waste liquid can be purchased for preparing CaCl2 solution. The carbide waste slag can be replaced by lime. The process is characterized by one high, two low and three points of environmental protection. The process firstly has high desulphurization rate, secondly has low fixed-asset investment and low running costs and thirdly utilizes the waste liquid and the waste slag to reduce the environmental pollution. Compared with all prior desulphurization processes, the process has great advantages.

Owner:康仁

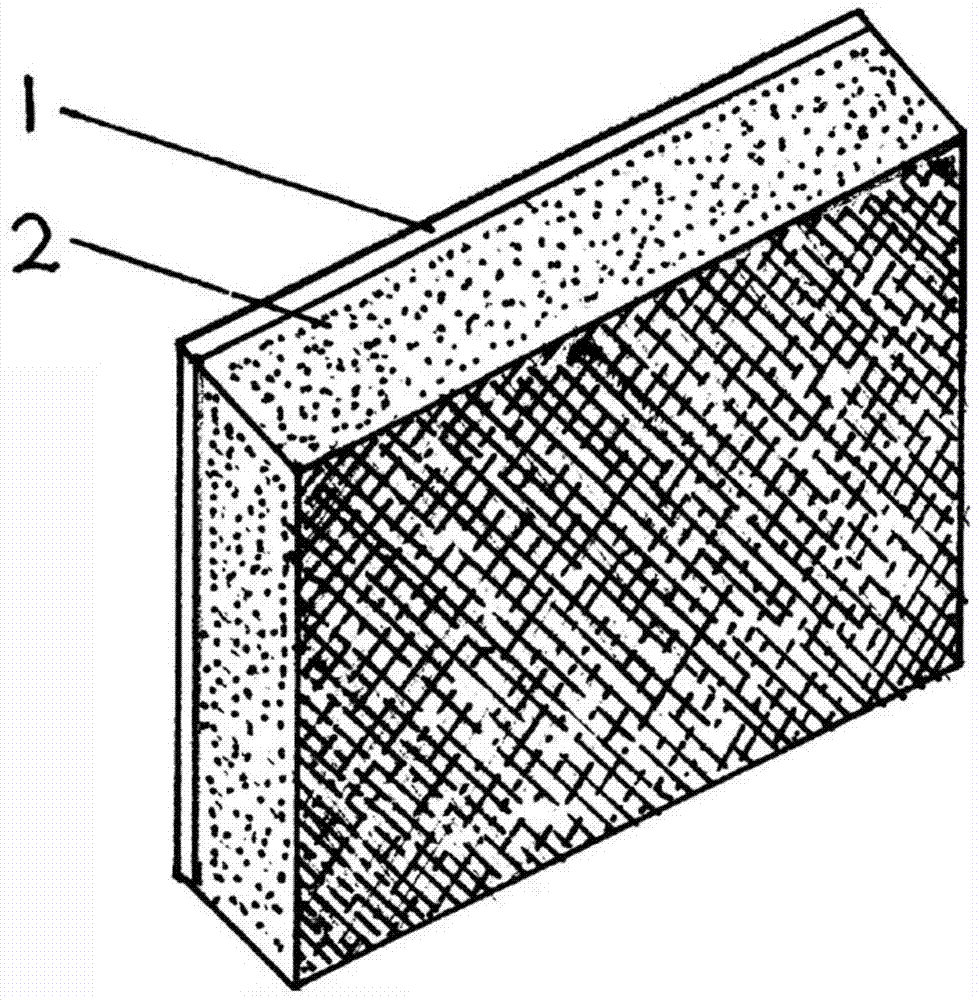

An alginate dressing for treating bedsore and a preparing method thereof

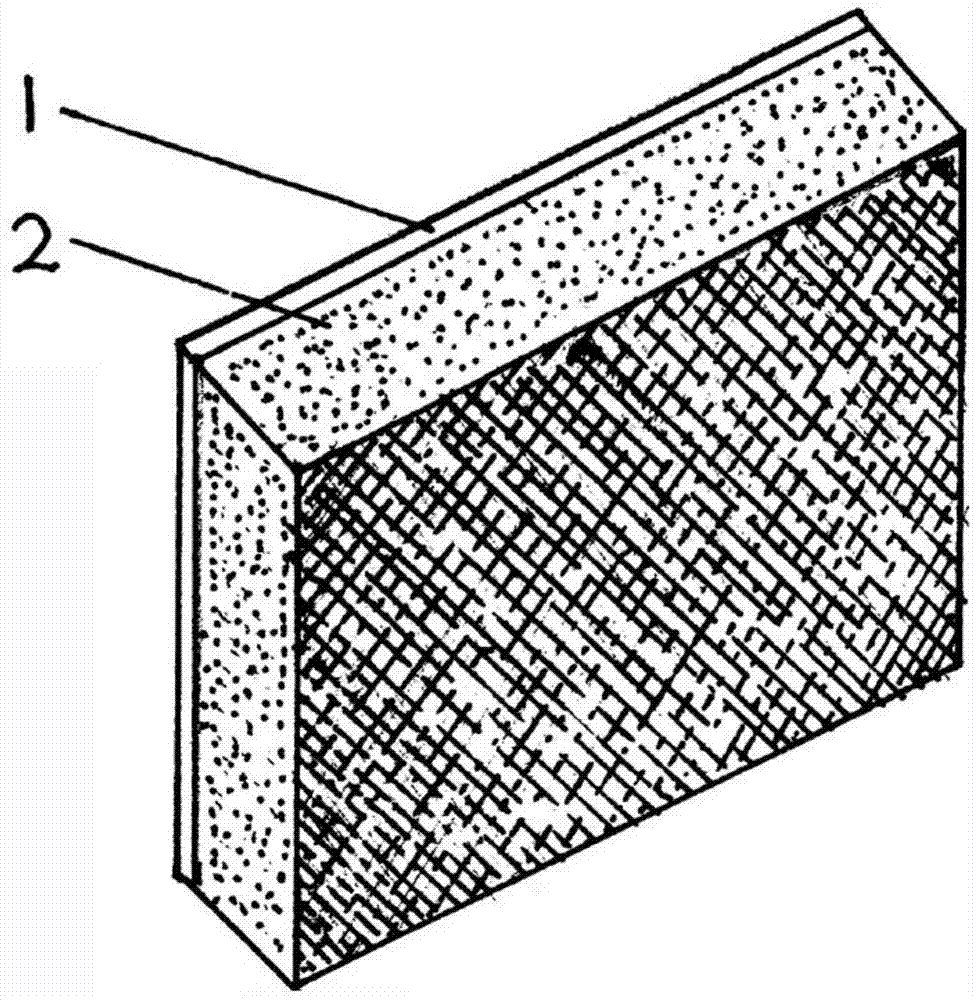

ActiveCN104758977APromote healingNo tissue proliferationAbsorbent padsBandagesPorosityComposite film

The invention relates to an alginate dressing for treating bedsore and a preparing method thereof. The dressing has a double-layer composite structure, namely the dressing comprises a base layer and a surface layer. The base layer is an alginate composite film layer. The surface layer is a natural rubber film layer. The preparing method includes following steps of: A) preparing a shark collagen solution, B) preparing a coaxial electrospinning outer layer solution, C) preparing a coaxial electrospinning core layer solution, D) spinning, E) crosslinking, F) dipping, G) preparing an epoxy natural rubber film, and H) compositing. The dressing has good biocompatibility, and has controllable growth regulation, good hygroscopicity, good anti-inflammation performance and good antibacterial performance of synthetic biological materials. The dressing is capable of improving local blood supply of wounds, promoting tissue growth and accelerating wound healing, shows good multifunctional properties, has good porosity, soft and comfort hand feeling, good compliance and using convenience, and can be used in the field of modern biomedicine, especially in the field of bedsore treatment and nursing, and the like.

Owner:HENAN YADU IND

Hair implant anchors and systems and methods for use thereof

ActiveUS9492196B2Easily implanted into target tissueEasy to useSuture equipmentsSkin implantsBiomedical engineeringHair implant

Owner:HAIRSTETICS

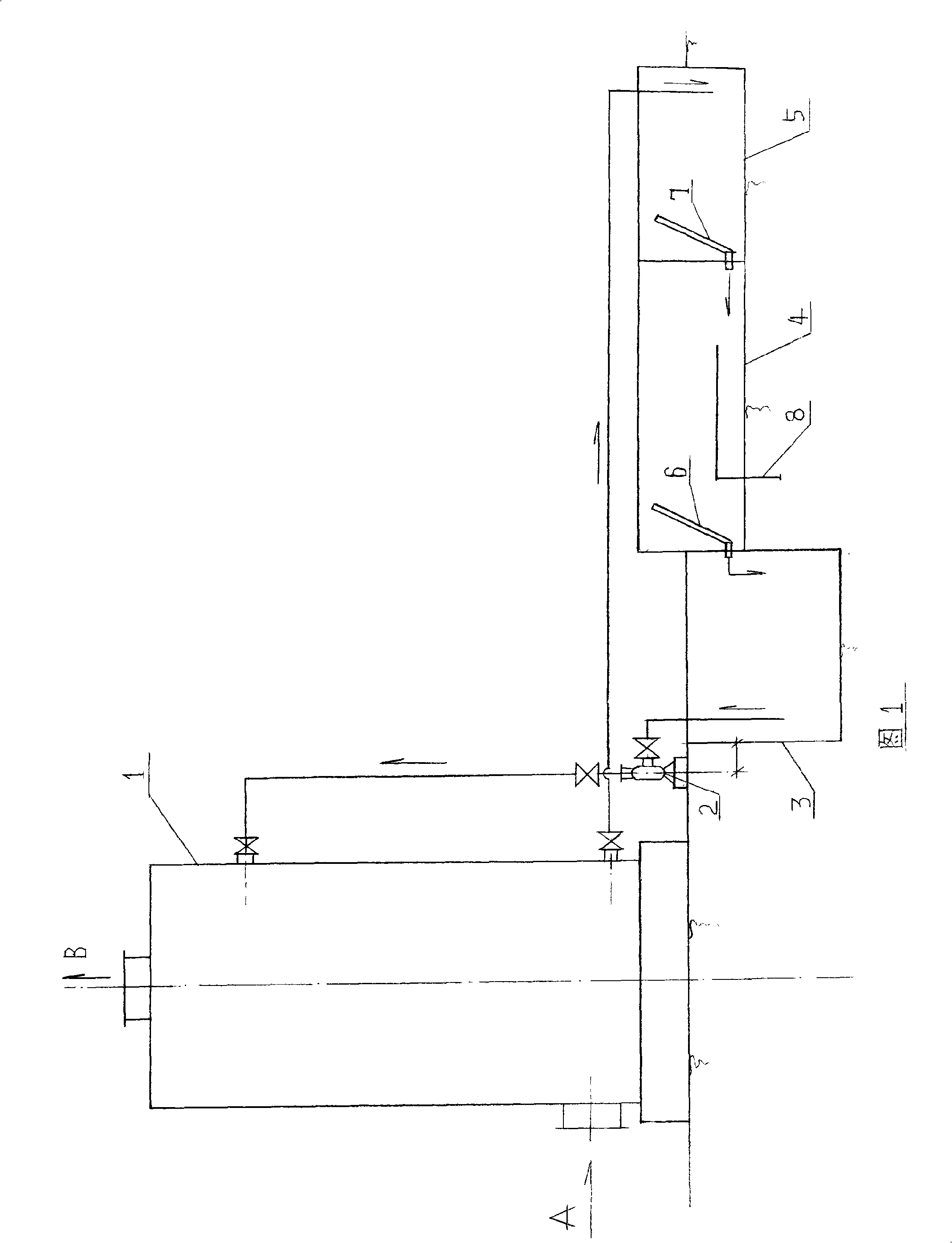

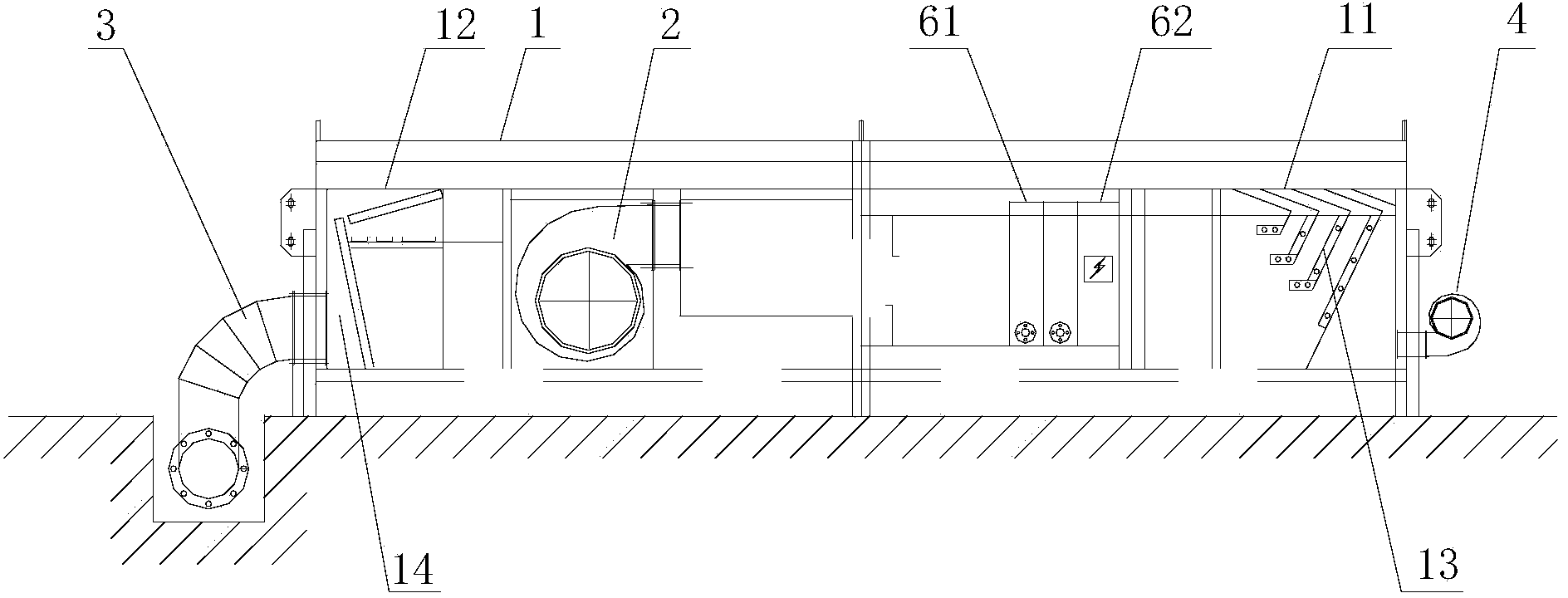

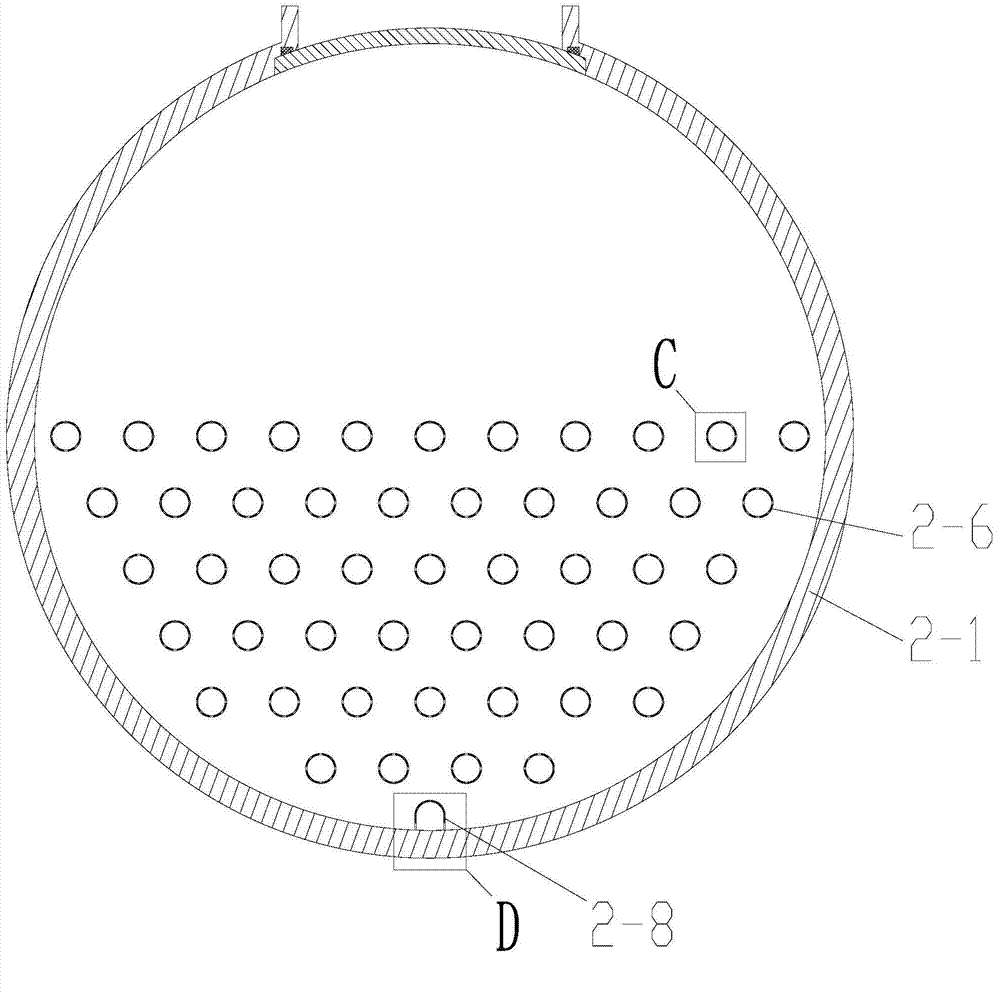

Tube array and remaining tank dissolving-out system and method for gibbsite bauxite

InactiveCN102249271ANo scarring effectSmall footprintAluminium oxides/hydroxidesProcess engineeringHeat conservation

The invention discloses a tube array and remaining tank dissolving-out system and a tube array and remaining tank dissolving-out method for gibbsite bauxite and belongs to the technical field of alumina production. The dissolving-out system comprises a circulating mother liquor groove, a heat preservation remaining tank, a flash evaporation device and a dilution device; the circulating mother liquor groove is communicated with a tube array heating device through a mother liquor feed pump; the tube array heating device is formed by connecting a first-level tube array preheater, a second-level tube array preheater and a third-level tube array preheater, a condensed water tube array preheater, and a live steam tube array preheater in series; the method comprises the following steps of: conveying the circulating mother liquor in the circulating mother liquor groove into the tube array heating device by using the mother liquor feed pump, heating to 180 to 190 DEG C, and feeding the circulating mother liquor into the heat preservation remaining tank; and conveying desilicication ore pulp in a desilicication groove into the heat preservation remaining tank, mixing the desilicication ore pulp and the circulating mother liquor, and dissolving out, feeding the pulp obtained after dissolving into the flash evaporation device and performing flash evaporation and then feeding into the dilution device. The system and the method can improve the treatment capacity of pulp, save energy sources, and reduce the production cost and equipment corrosion.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

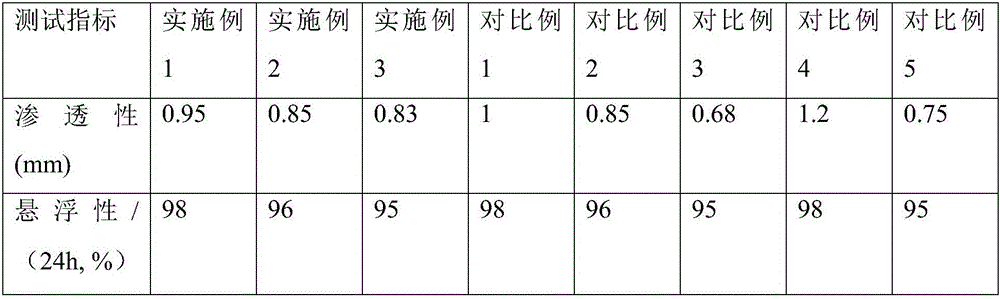

Self-hardening flame-retardant transfer coating for magnesium alloy sand casting and preparation method of self-hardening flame-retardant transfer coating

ActiveCN106270371AGood suspensionNot easy to precipitateFoundry mouldsFoundry coresPreservativeSuspending Agents

The invention relates to a self-hardening flame-retardant transfer coating for magnesium alloy sand casting and a preparation method of the self-hardening flame-retardant transfer coating. The self-hardening flame-retardant transfer coating is prepared from, by mass, 30-50 parts of heat-resisting aggregate, 0.5-2.5 parts of a suspending agent, 1-5 parts of a binder, 0.2-0.8 part of a coupling agent, 0.5-2.5 parts of a fire retardant agent, 0.1-1.5 parts of a defoaming agent, 0.01-0.03 part of preservative and 50-70 parts of water. The prepared coating has the good adhesion, coating performance and flame-retardant effect and is not prone to precipitating in the use process. In the casting process, a coating layer is not prone to cracking, the surface quality of a casting is good, dimensional precision is high, and the self-hardening flame-retardant transfer coating is suitable for the technical field of magnesium alloy casting.

Owner:SHANGHAI JIAO TONG UNIV

Glass fiber cloth secondary sizing drying device

ActiveCN103983092AEasy to cleanGuaranteed cleanlinessDrying gas arrangementsDrying machines with progressive movementsGlass fiberPulp and paper industry

The invention discloses a glass fiber cloth secondary sizing drying device which comprises a primary drying device and a secondary drying device. The primary drying device comprises a drying box, an air supply device, a heating device, an exhaust device and a cooling device. The drying box is divided into an upper layer and a lower layer which are arranged up and down, the air supply device and the heating device are arranged on the lower layer of the drying box, and two sides of the bottom of the upper layer of the drying box are respectively provided with an air inlet and an air outlet. An air source sent by the air supply device is converted into hot air through the heating device to enter the upper layer of the drying box through the air inlet to perform drying processing on products, the hot air finally takes out moisture on the products and is discharged out of the air outlet, and the secondary drying device is a plurality of continuously arranged drying drums. The glass fiber cloth secondary sizing drying device first performs non-contact type drying on the products and then perform contact type drying on the products, drying efficiency is high, the surfaces of the drying drums cannot be scarred, and production quality of the products is improved.

Owner:TAIJIA GLASS FIBER

Processing method of whole-grain cereals type macaroni series foods

The invention provides a processing method of whole-grain cereals type macaroni series foods, and belongs to the field of pasta processing methods. According to the processing method, the mixed grains and beans are adopted and used as the raw materials to produce the macaroni foods by the pasting molding technology based on the 'starch gelatinization' principle. The raw materials are treated to prepare a finished product by the processes, such as removing impurities and sieving once, cleaning and soaking, powdering, dosing, mixing the powder, pasting and molding, carrying out ageing treatment, cutting and receiving materials, drying, balancing the water, carefully selecting, metering, packaging and inspecting. The finished products produced by the processing method provided by the invention have the characteristics of being uniform and regular in lines, free from scar and twisting, smooth in surface, glittering and translucent, excellent in boiling fastness, free from turbidity, draining and adhering, chewy and rich in elasticity, low in broken bar rate, small in size output value, elastic, moisture and smooth in taste, high in flexibility, soft and palatable.

Owner:吉林市老爷岭农业发展有限公司

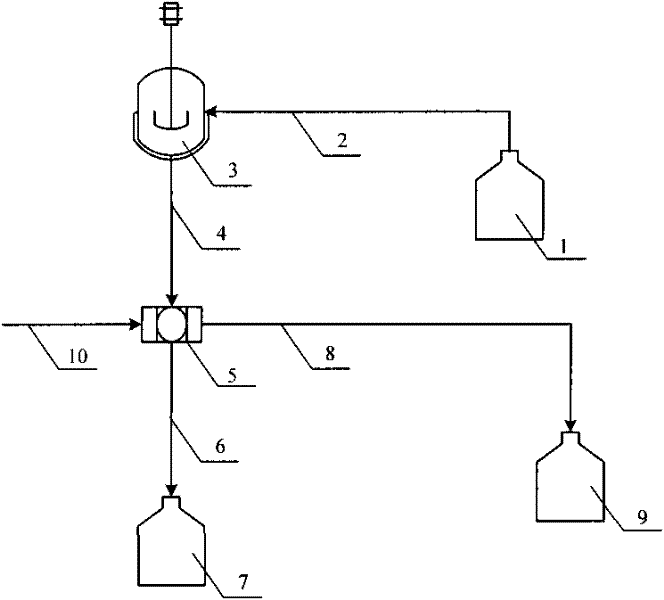

Multi-phase crystallization method

InactiveCN102188836AIncrease production capacityNo scarringSolution crystallizationSolubilityDiluent

The invention relates to a multi-phase crystallization method which is mainly used for solving the problems that in the prior art, crystallizer scares are serious and the production capability is low. In order to solve the problems in the prior art, the technical scheme adopted by the invention is as follows: the method comprises the following steps: performing crystallization on raw materials and a diluent in a crystallizer; separating crystal mush to obtain crystal and a mixture of the a thinner and crystallizing mother liquid; washing the crystal, and feeding the washed crystal into a product jar; separating the mixture of the thinner and the crystallizing mother liquid so as to obtain the crystallizing mother liquid and the thinner, feeding the crystallizing mother liquid into a mother liquid jar, and returning the thinner to a thinner storage jar, wherein the thinner is not subjected to separation by crystallization; and the weight ratio of the thinner and raw material in the crystallizer is (0.1-50):1, and the solubility of the thinner in the raw material is less than 1 g thinner / 100 g raw material. The method can be applied to industrial crystallization production.

Owner:CHINA PETROLEUM & CHEM CORP +1

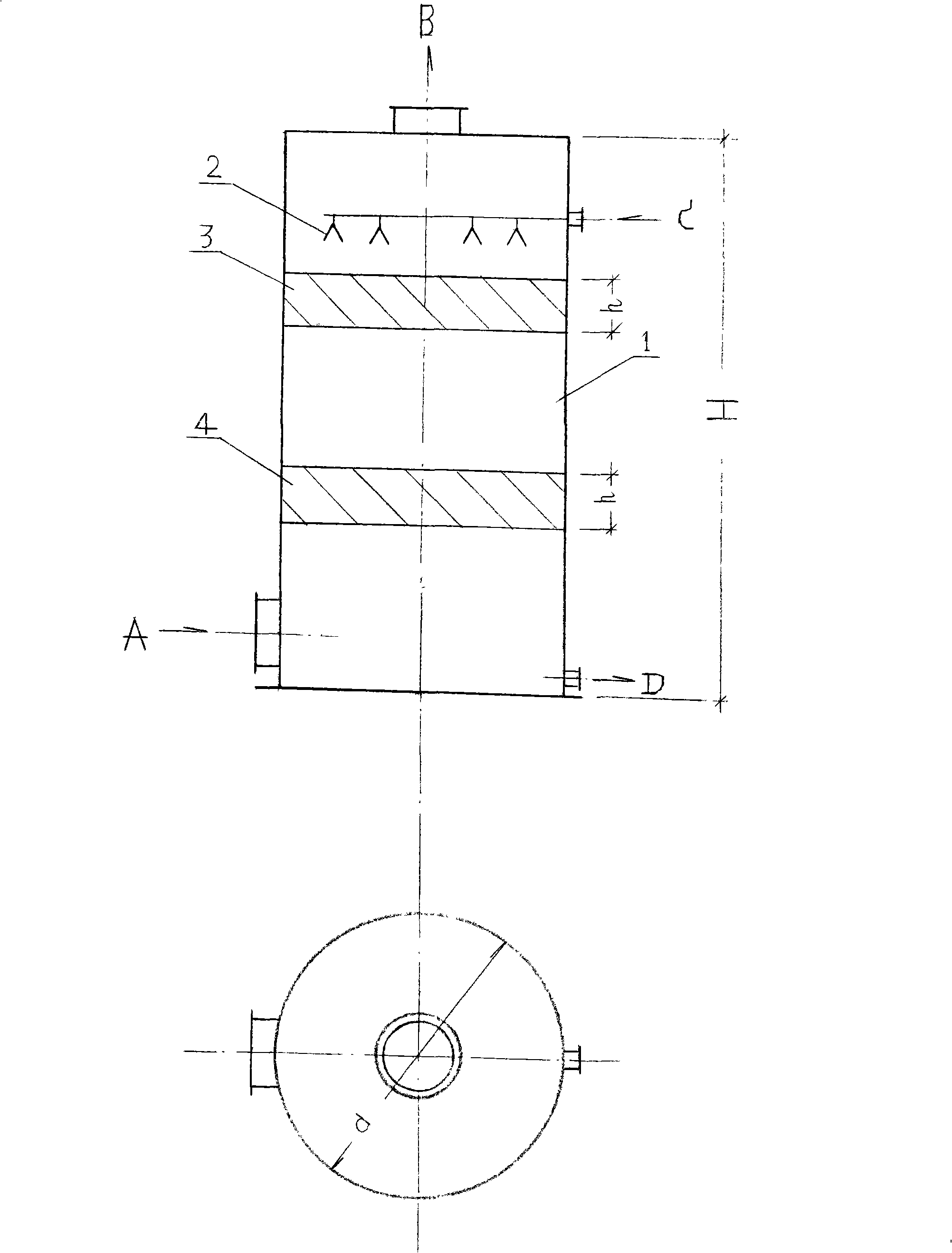

Energy-efficient and environment-friendly liquid sodium silicate production technology and processing equipment

ActiveCN104772054AHigh speedUniform concentrationRotating receptacle mixersTransportation and packagingFilling materialsSodium silicate

An energy-efficient and environment-friendly liquid sodium silicate production technology comprises the following steps: step A, filling materials; step B, dissolving; step C, detecting; step D, discharging materials; step E, cooling; and step F, purifying. Liquid sodium silicate processing equipment comprises a boiler, a liquid sodium silicate processing device is fixed on one side of the boiler, and a high-temperature liquid sodium silicate cooling and discharging device is arranged on one side of the liquid sodium silicate processing device. By arranging a liquid sodium silicate processing device and a high-temperature liquid sodium silicate cooling and discharging device on the side part of a boiler, a large amount of solid sodium silicate can be dissolved, cooled, and discharged. Compared with the conventional dissolution kettle and static pressure kettle, the liquid sodium silicate processing equipment has the advantages that the dissolution of sodium silicate is quick, the energy is saved, and no scale is generated in the dissolution container. Moreover, the sodium silicate with high modulus is dissolved by steam, thus very little high silicic acid polymer is generated, and the liquid sodium silicate is uniform after dissolution.

Owner:遂昌县三凡化工有限公司

Pharmaceutical delivery systems for treatment of substance abuse and other addictions

Disclosed are injectable pharmaceutical compositions that contain a therapeutically effective amount of an anti-addictive agent, an anti-inflammatory agent, and a pharmaceutically acceptable liquid carrier, methods of making the compositions, and uses thereof for treating addictions including substance abuse (or addiction to an abused substance) and addictive or compulsive behavior, by administering the composition to a subject in need thereof.

Owner:GOOBERMAN LANCE L

Assembly for doubly securing needlescopic instrument shafts to laparoscopic instrument heads

ActiveUS10835217B1Easy to attachPermit useSurgical needlesSurgical forcepsLess invasive surgeryEngineering

The present invention is directed to an assembly used in minimally invasive procedures whereby laparoscopic instrument heads, prepositioned in the abdomen of a patient are securely doubly attached and detached internally while under direct laparoscopic visualization. The present invention permits surgeons to utilize full sized laparoscopic instrument heads on needlescopic instrument shafts. Multiple locking structures are employed to securely attach the laparoscopic instrument heads to a needlescopic instrument.

Owner:NEW WAVE ENDO-SURGICAL CORP

Composite pre-heater

Owner:吕天宝 +1

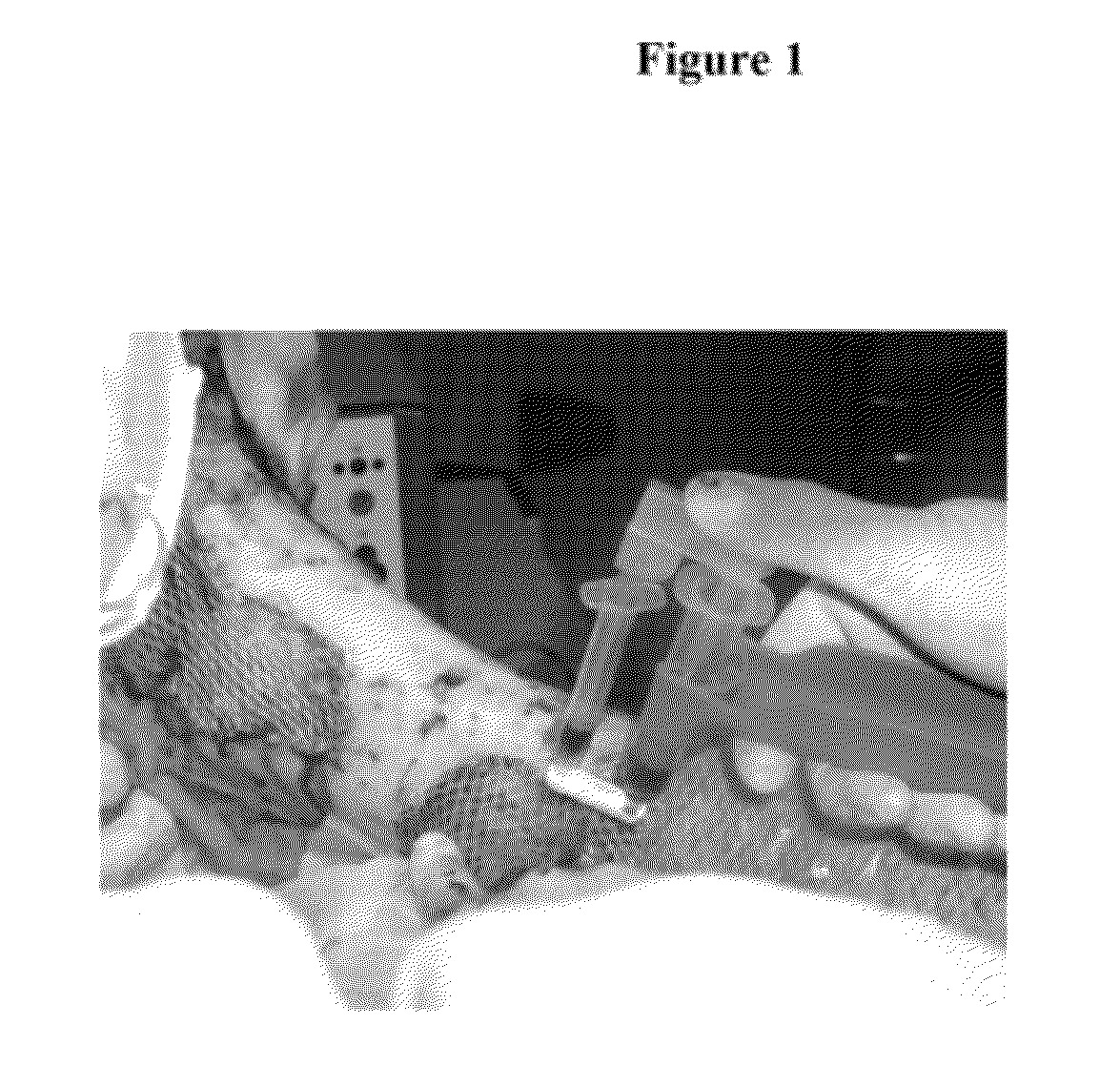

Treating burn injuries with reduced hypertrophic scarring

This document provides methods and materials involved in treating burn injuries. For example, methods and materials for using skin grafts (e.g., autologous skin grafts) treated with an autologous platelet concentrate and autologous thrombin to treat burn injuries (e.g., deep skin burn injuries) are provided.

Owner:UNIV HOSPITAL OSTRAVA

Methods and materials for treating burn injuries

InactiveUS20120156184A1Improve featuresHeal fastBiocideSkin implantsSkin graftingAutologous platelet

This document provides methods and materials involved in treating burn injuries. For example, methods and materials for using skin grafts (e.g., autologous skin grafts) treated with an autologous platelet concentrate and autologous thrombin to treat burn injuries (e.g., deep skin burn injuries) are provided.

Owner:UNIV HOSPITAL OSTRAVA

Welding process of quenching partition steel QP980 for automobile

ActiveCN111531261AAvoid lap weldingImprove welding efficiencyRectilinear seam weldingWeld seamManufacturing engineering

The invention discloses a welding process of quenching partition steel QP980 for an automobile. The welding process of the quenching partition steel QP980 for the automobile comprises the steps that:Step S1, a strip steel coil of the quenching partition steel QP980 and a strip steel coil of transitional carbon structural steel are obtained; Step S2, the tail steel part of a previous coil and thehead steel part of a next coil are cleaned; Step S3, welding parameters are adjusted and the tail steel part of the previous coil and the head steel part of the next coil are lap-welded; and Step S4,the strip steel coil of the quenching partition steel QP980 and the strip steel coil of the transitional carbon structural steel are alternately arranged and welded in sequence. A narrow lap welding machine can be used between the quenching partition steel QP980 and the transitional carbon structural steel. The transitional carbon structural steel is increased through intervals, so that the narrowlap welding machine can realize the connection between each coil of the quenching partition steel QP980 on a continuous annealing production line, and the welding efficiency is high, the welding seamarea is flat and smooth, the welding seam and welding wheel are not scarred, and is convenient for use in the automobile manufacturing industry.

Owner:攀钢集团西昌钢钒有限公司

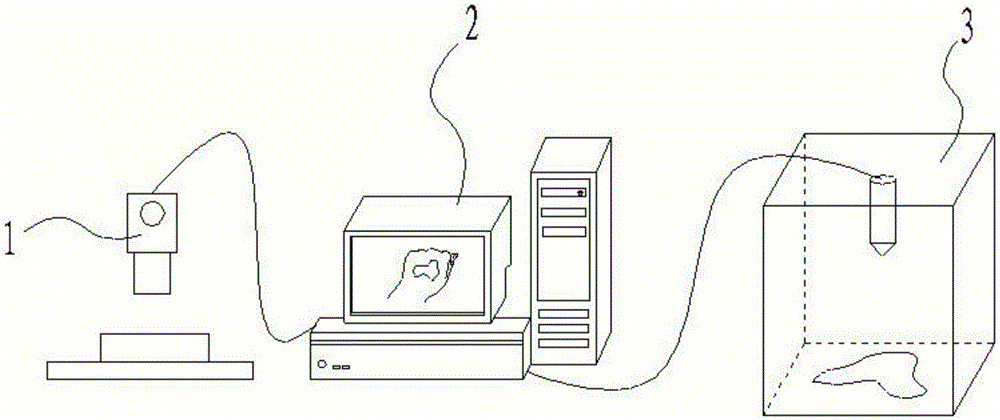

Individual negative pressure suction cup manufacturing method for leucoderma skin-grafting

ActiveCN106108984AHigh degree of shape matchingImprove transplanting efficiencyAdditive manufacturing apparatusSurgeryCuticleShape matching

The invention discloses an individual negative pressure suction cup manufacturing method for leucoderma skin-grafting. A front-end camera is used for performing image collection on a focal zone of a patient, then, collected images are processed through a computer, data of an obtained actual focal zone is imported into three-dimensional modeling software for negative pressure three-dimensional model generation, then, a negative pressure suction cup highly matched with the focal zone of the patient can be obtained through printing of a 3D printer, the blister suction frequency can be decreased to the largest extent by means of the negative pressure suction cup manufactured through 3D printing, the operation pain of the patient is relieved, the epidermis transplanting time efficiency is greatly improved, and the transplanted epidermis is highly matched with the shape of the focal zone, so that scars will not be formed, and the post-treatment skin appearance will not be affected.

Owner:FUZHOU UNIV

A kind of alginate dressing for treating decubitus and preparation method thereof

ActiveCN104758977BPromote healingNo tissue proliferationAbsorbent padsBandagesPorosityComposite film

Owner:HENAN YADU IND

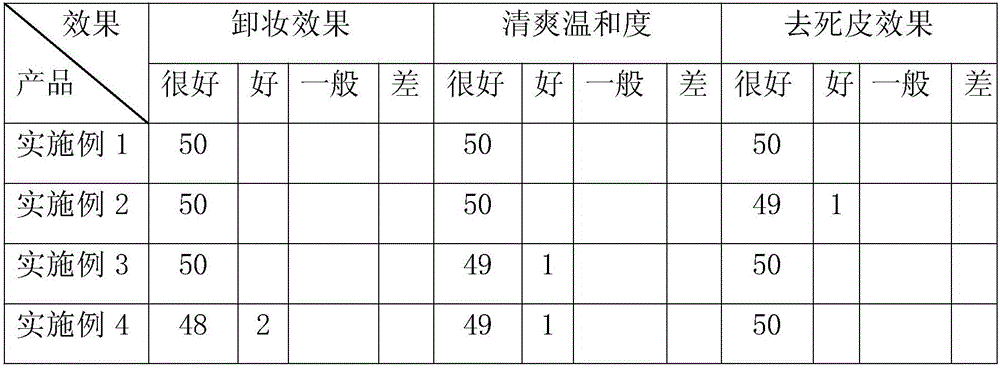

Safe makeup removing lotion and preparing method thereof

InactiveCN105997586AEasy to integrateNon-irritatingCosmetic preparationsMake-upCuticleAdditive ingredient

The invention provides a safe makeup removing lotion. The safe makeup removing lotion is prepared from, by weight, 5%-15% of plant-origin emulsion agent, 3%-6% of shea butter and / or ceramide, 2%-6% of tartaric acid, 1%-4% of brown alga activating enzymes, 2%-5% of kelp mannitol, 0.1%-5% of rosemary extract and 40%-80% of deionized water, wherein the sum of the weight percent of the components is 100%. The makeup removing lotion serves as a whole, and the ingredients are used in cooperation; as the content of the components is optimized, the final formula has the quite good makeup removing effect, the quite good cuticle removing effect, the quite good skin repairing effect and the quite good antisepsis and anti-inflammation effects; in addition, the safe makeup removing lotion is quite excellent in mobility, appearance, centrifugal stability, cold resisting stability and heat resisting stability, and meanwhile the invention provides a preparing method of the makeup removing lotion.

Owner:CANTON DAMEKISS DAILY CHEM FACTORY LIMITED

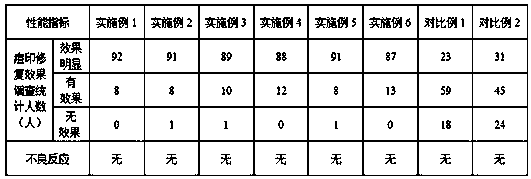

Beautifying gel with efficient acne mark repair function and preparation method

ActiveCN108653188AReduce adhesionPromote blood circulationCosmetic preparationsToilet preparationsSide effectVitamin C

The invention belongs to the technical field of beauty products and provides beautifying gel with an efficient acne mark repair function and a preparation method. The method comprises steps as follows: carbomer gel is prepared firstly, then a repair solution is prepared from fruit acid, TGC protease, vitamin C, vitamin E, white sugar and aloe infused oil as raw materials, the repair solution, thecarbomer gel, thiazone, iso-octyl palmitate, isopropyl myristate, propolis and tea polyphenol are kneaded, and the beautifying gel with the efficient acne mark repair function is prepared. Compared with product prepared with a traditional method, the beautifying gel prepared with the method can efficiently repair acne marks without scars, assists in fading pigment, prevents skin oxidation, improves blood circulation of skin, has natural preservative effect and is free of toxic and side effects, safe and environmentally friendly.

Owner:上海松皓生物科技有限公司

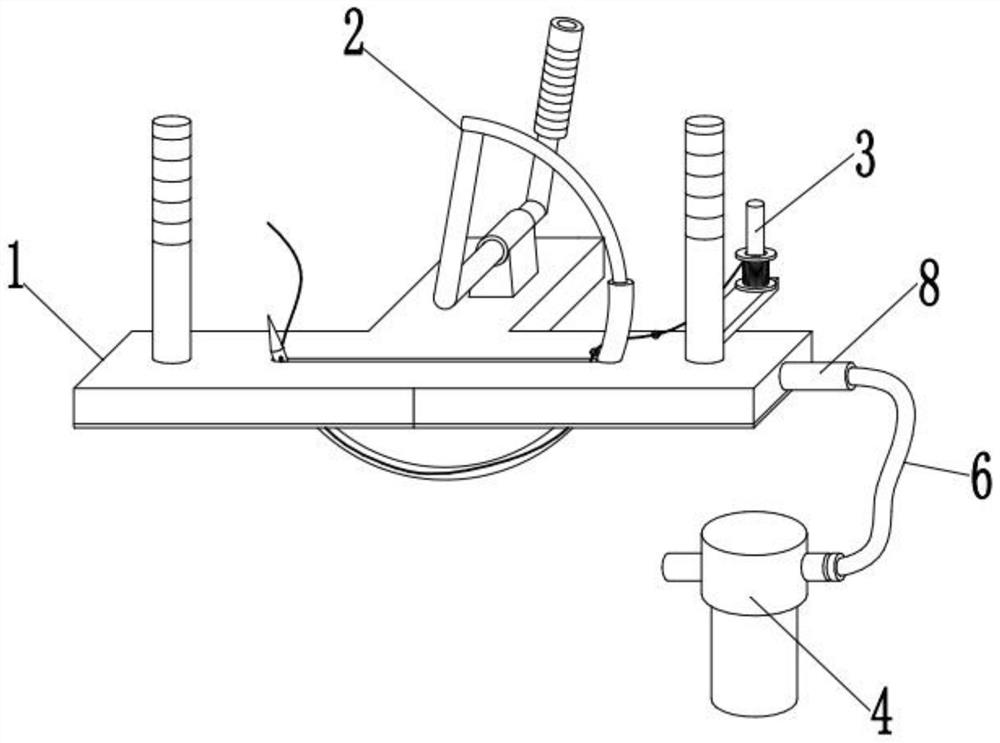

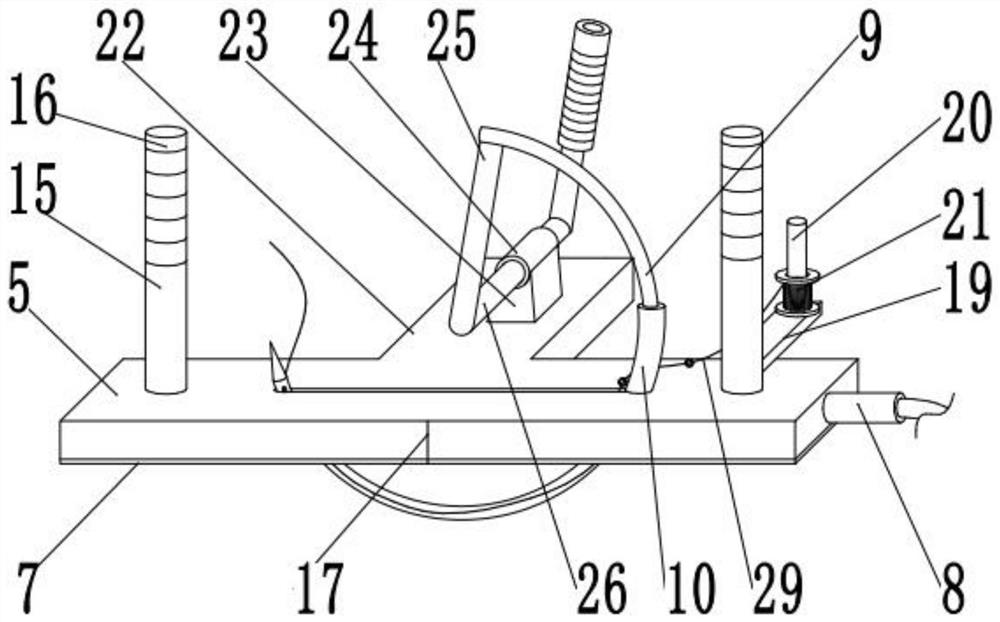

Auxiliary device for attractive suture of surgical incision

PendingCN113317834AHeal fastEasy to punctureSuture equipmentsSurgical needlesSurgical knifeBiomedical engineering

Owner:刘子儒

Manufacturing method of volute sand core

InactiveCN110976780AHigh strengthNo crackFoundry mouldsFoundry coresExpanded clay aggregateFirming agent

The invention discloses a manufacturing method of a volute sand core, and belongs to the technical field of volute casting. The sand core comprises, by weight, 40-56 parts of silicon dioxide crude sand, 30-42 parts of haydite sand, 20-25 parts of chromite sand, 1-2 parts of polyethylene resin, 1.7 parts of curing agents and 1.0-1.3 parts of calcium stearate. The manufacturing method of the volutesand core solves the problem that a volute which is complex in interior structure cannot be subjected to the mold opening manufacture, the processed datum plane of the volute can be free of burrs, theprocessing accuracy is guaranteed, and the product quality is improved.

Owner:西峡飞龙特种铸造有限公司

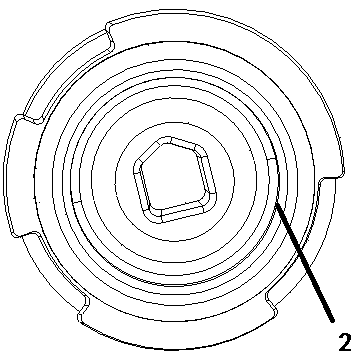

Medicine composition for healing wounds and preparation method thereof

InactiveCN101584746ATo promote metabolismPromote healingOrganic active ingredientsDermatological disorderDiabetes mellitusGranuloma

The invention discloses a medicine composition for healing wounds and a preparation method thereof. The medicine composition for healing wounds can be applied to the fields of diabetes mellitus, bedsore, wound, burn and scald, acne, whelk, operated skin repair and healing, cosmetic skin repair, and the like. The composition comprises 0.01-6 of scutellaria extraction, 0.1-25 of herba cntellae extraction and the balanced of additive according to the weight percent. The preparation method is realized by the following steps: extracting the herba cntellae extraction and the scutellaria extraction from a whole herba cntellae and the root of scutellaria, and then preparing the two extractions into the medicine composition. The medicine composition is used for healing chronic wounds and burn and scald wounds, can obviously enhance the hyperplasia of fiberblast when the chronic wounds heal, achieves the effect of healing wounds and can not roll skin or cause granuloma in the healing process.

Owner:毛玉麟

A kind of preparation method of coating for aluminum alloy low pressure casting metal mold

ActiveCN102366814BWide variety of sourcesLow costFoundry mouldsFoundry coresMetal coatingSodium Bentonite

The invention discloses a method for preparing a paint used for an aluminum alloy low pressure casting metal type. The paint prepared by the invention comprises the following components: 35-45% of mullite powder, 5-10% of alumina powder, 5.5-6.5% of sodium bentonite, 2.0-2.5% of polyvinyl alcohol, 0.8-1.0% of sodium alginate, 3.5-4.0% of silica sol, 0.8-1.0% of sodium dodecyl benzene sulfonate and the balance of water. The preparation method of the invention has the advantages of wide raw material source, low cost and simple paint preparation process. The paint is used for aluminum alloy low pressure casting metal type, the casting is easy to demould, and the surface of the casting is smooth without the defects of scabs forming and adhesion.

Owner:JIANGSU HIDA MARINE VALVE

Pharmaceutical delivery systems for treatment of substance abuse and other addictions

Disclosed are injectable pharmaceutical compositions that contain a therapeutically effective amount of an anti-addictive agent, an anti-inflammatory agent, and a pharmaceutically acceptable liquid carrier, methods of making the compositions, and uses thereof for treating addictions including substance abuse (or addiction to an abused substance) and addictive or compulsive behavior, by administering the composition to a subject in need thereof.

Owner:GOOBERMAN LANCE L

Ointment for treating burns and scalds and preparation method of ointment

InactiveCN107998287AGood treatment effectNo infectionAntibacterial agentsHydroxy compound active ingredientsDiseaseTherapeutic effect

The invention belongs to the technical field of Chinese herbal medicines and particularly relates to an ointment for treating burns and scalds and a preparation method of the ointment. The ointment comprises 3-10 parts of Japanese honeysuckle, 3-10 parts of fructus forsythiae, 3-5 parts of lumbricus, 3-10 parts of coptis root, 3-10 parts of radix scutellariae, 3-10 parts of amoorcorn tree bark, 3-5 parts of garden burnet, 3-10 parts of willow branch, 2-5 parts of gardenia, 2-5 parts of olibanum, 2-5 parts of myrrh, 2-5 parts of bletilla, 2-5 parts of radix angelicae, 2-5 parts of ampelopsis japonica, 3-10 parts of gypsum, 2-5 parts of yellow wax, 2-5 parts of borneol, 3-5 parts of burdockseed, 2-5 parts of sesame oil and 1-3 parts of flavouring essence. The preparation method comprises thesteps of soaking the Japanese honeysuckle, the fructus forsythiae, the radix scutellariae, the amoorcorn tree bark, the garden burnet, the willow branch and the burdockseed in the sesame oil and theflavouring essence, grinding the lumbricus, the gardenia, the olibanum, the myrrh, the bletilla, the ampelopsis japonica and the gypsum into powder and then soaking in the sesame oil and the flavouring essence, and decocting the traditional Chinese medicines to prepare the ointment. The ointment is good in treatment effect, the curing time is short, a disease does not recur after curing, and the treatment cost is low.

Owner:张立祥

Manufacturing process and application of medical absorbable cattle intestine suture line

InactiveCN113941024AGood biocompatibilityEffective absorptionSuture equipmentsCoatingsMuscle tissueBreaking strength

The invention discloses a manufacturing process of a medical absorbable cattle intestine suture line. The manufacturing process comprises the following production steps of material selection, degreasing, primary washing, secondary washing, thread twisting, airing, polishing, sterilization and packaging. The collagen content of the medical absorbable cattle intestine suture line reaches 95%, the tensile strength of sutures of various models meets the industrial standard requirement, the suture body is free of muscular tissue attachment and chemical component residues, the suture line is good in biocompatibility, the suture line can be effectively degraded and absorbed after body suture, the original physical and mechanical properties of the suture line material are kept, and the clinical use safety of the product is ensured; the postoperative suture is good in tissue compatibility and free of organism exclusion; the composition can be completely degraded and absorbed without forming scars; and after the operation, calcification and subcutaneous induration are avoided, and the carrying breaking strength and the knotting breaking strength of the suture line are high in the suture process.

Owner:山东康利达医用制品有限公司

Production technology and processing equipment of energy-saving and environment-friendly liquid sodium hydroxide

ActiveCN104772054BHigh speedUniform concentrationRotating receptacle mixersTransportation and packagingSilicic acidLiquid state

An energy-saving and environment-friendly liquid sodium bicarbonate production process, the specific steps are as follows: A. charging, B. melting, C. detection, D. discharging, E. cooling, F. purification; a liquid sodium bicarbonate processing equipment, It includes a boiler, a liquid sodium sodium processing device is fixed on one side of the boiler, and a high-temperature liquid sodium sodium cooling output device is fixed on one side of the liquid sodium sodium processing device. The present invention utilizes the installation of a liquid sodium natron processing device and a high-temperature liquid sodium sodium cooling output device on the side of the boiler, so that a large amount of solid sodium sodium can be melted, and high-temperature and high-pressure liquid sodium silicate can be cooled and output. Compared with the traditional dissolution kettle and static autoclave, the liquid sodium sodium processing equipment has the advantages of fast dissolution of solid sodium hydroxide, energy saving, no scarring in the dissolution container, and for the dissolution of high modulus solid sodium carbonate, Due to the use of steam for dissolution, high silicic acid polymers are rarely produced, and the dissolved liquid sodium bicarbonate has a uniform concentration.

Owner:遂昌县三凡化工有限公司

Traditional Chinese medicine reducing solution for preventing green wound from generating scar and preparation method of traditional Chinese medicine reducing solution

InactiveCN105878778AAvoid infectionFacilitate depositionAnthropod material medical ingredientsPharmaceutical delivery mechanismWolfiporia extensaBombyx

The invention provides a traditional Chinese medicine reducing solution for preventing a green wound from generating a scar and a preparation method of the traditional Chinese medicine reducing solution. The traditional Chinese medicine reducing solution is prepared from the following raw materials in parts by weight: panax notoginseng, olibanum, myrrh, naze, gastrodia elata, bombyx batryticatus, motherwort fruits, scorpion, lucid ganoderma, Chinese gall, eupolyphaga, rhizoma atractylodis, drynaria rhizome, astragalus membranaceus bark, radix dipsaci, stephania tetrandra, rhizoma cibotii, poria cocos, divaricate saposhnikovia roots, liquorice, periostracum cicada, coptis chinensis and Japanese snailseed roots. The traditional Chinese medicine reducing solution is capable of preventing the green wound from generating the scar, is prepared from pure traditional Chinese medicines and is free of toxic or side effect.

Owner:王青年

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com