Vacuum refrigerating tumbling machine

A technology of vacuum refrigeration and tumbling machine, which is applied in the fields of slaughtering, meat processing equipment, food science, etc. It can solve the inconvenient operation position of the mobile vacuum tumbling machine, which affects the production and economic benefits of meat products, and is not conducive to the quality and freshness of meat products. and other problems, to achieve the effect of shortening the refrigeration time, fast refrigeration speed and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

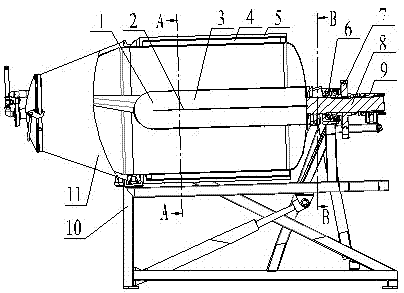

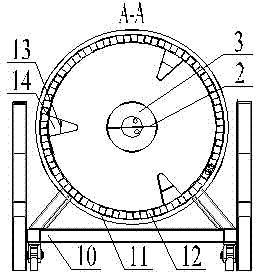

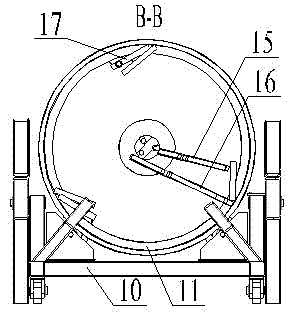

[0017] A vacuum refrigeration tumbler, comprising a tumbler barrel 11 connected to a frame 10, a main shaft 8 fixedly connected to the tumbler barrel 11, and a drive mechanism connected to the main shaft 8, the main shaft 8 being provided with a main water inlet 18 and The main water outlet 19, the outer side of the main shaft 8 is provided with a main shaft sealing sleeve 9 with a water inlet and a water outlet, the inner and outer walls of the tumbler 11 are successively provided with a cooling layer 4 and an insulating layer 5, and the cooling layer 4 is provided with a water inlet And the water outlet, the key is: add an intermediate refrigeration compartment 3 along the axis inside the above-mentioned tumbler 11, and a partition 2 is arranged inside the intermediate refrigeration compartment 3, and the intermediate refrigeration compartment 3 is separated into a water inlet chamber and an outlet chamber by means of the partition board 2 The water inlet bin communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com