Coke oven door lining brick repairing process

A furnace door and lining brick technology, which is applied in the field of coking equipment repair, can solve the problems of narrow furnace door and increased labor intensity, and achieve the effect of shortening operation time, reducing labor intensity and not wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A coke oven door lining brick repair process, its process steps are:

[0016] Step 1: Clean the damaged surface first, and remove the tar, coal powder and broken bricks remaining on the damaged surface. This step takes 5 to 9 minutes;

[0017] Step 2: Make the damaged part to be repaired into a pockmarked surface with steel brazing, which is convenient to connect with the repairing material, and blow it clean with compressed air to ensure that the bottom surface is free of ash. This step takes 3 to 6 minutes;

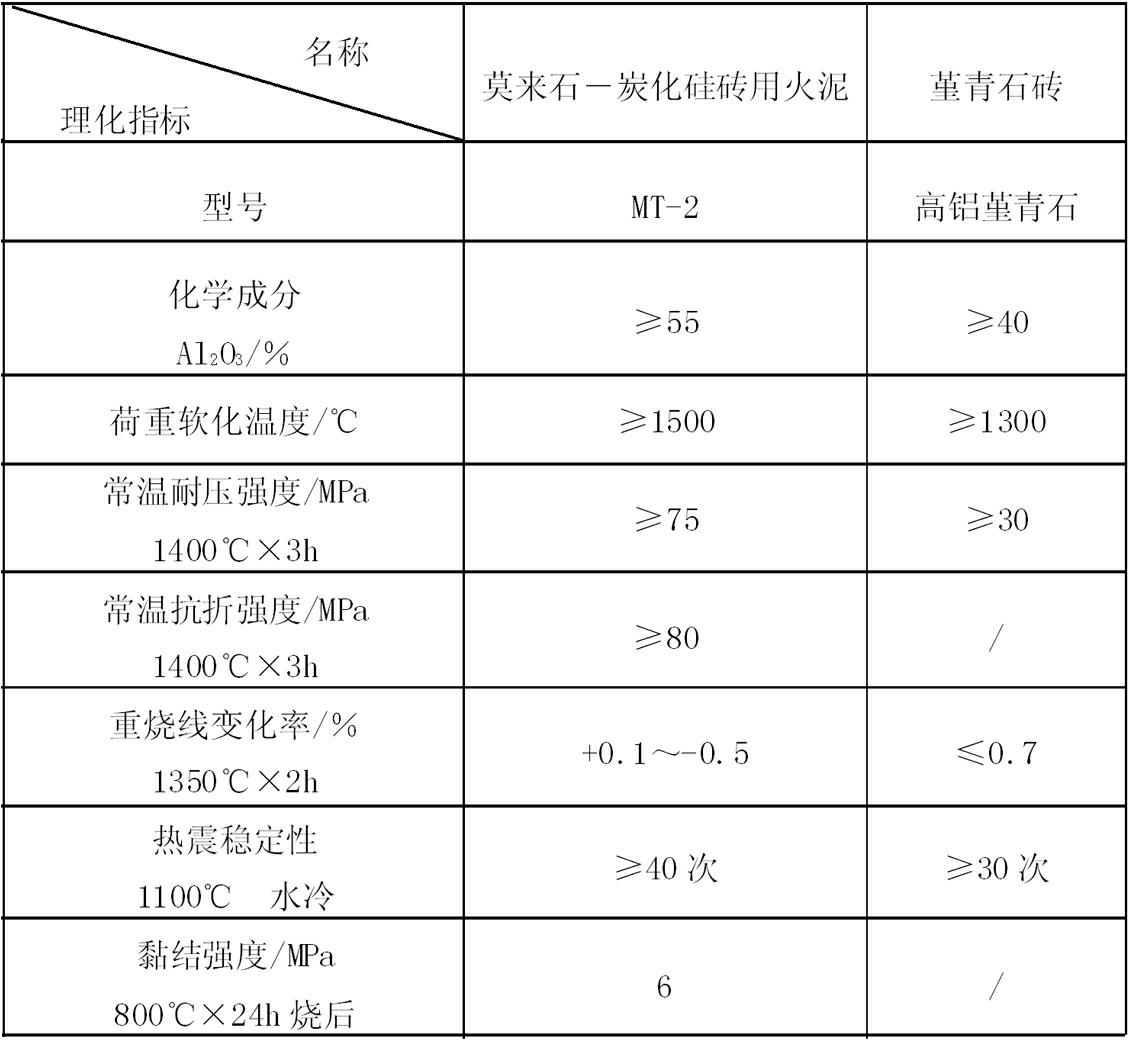

[0018] Step 3: Prepare the furnace door lining brick repair material. The raw materials required for the repair material include: mullite-silicon carbide brick fire clay, aluminate cement and water, and the weight ratio is: mullite-silicon carbide Fireclay 90-95 for bricks, aluminate cement 2-7, water 3, determine the weight of the required materials according to the size of the repaired area and the above weight ratio, and then put it into the mixer and stir for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com