Sealing device and method for fire observation hole of coke oven

A sealing device and fire-seeing hole technology, which is applied in the direction of preventing/repairing the leakage of brickwork, and can solve the problems of complicated sealing operation and poor effect of fire-seeing holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

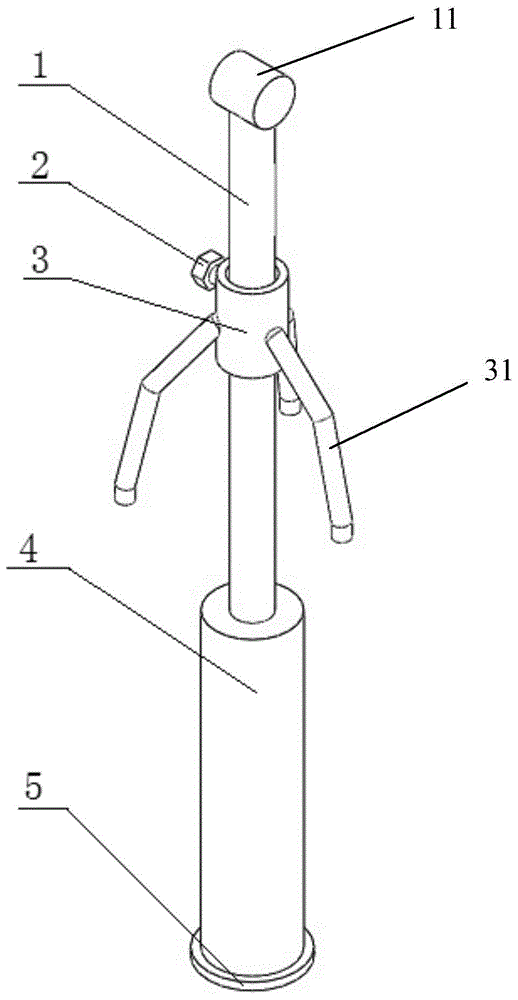

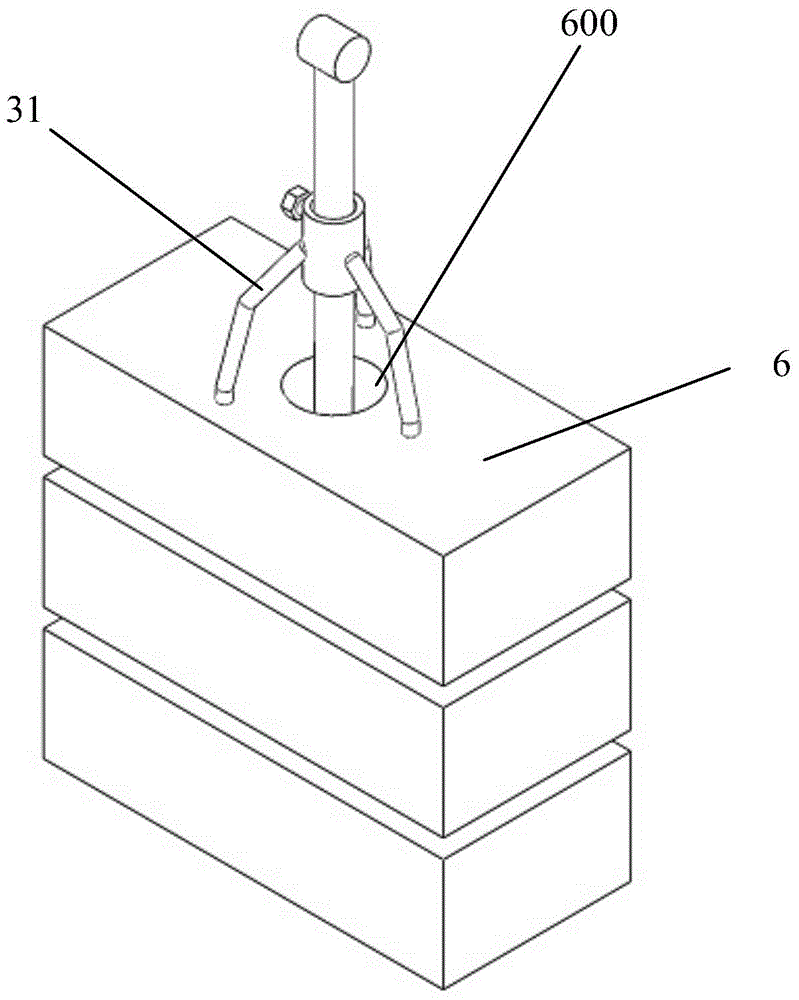

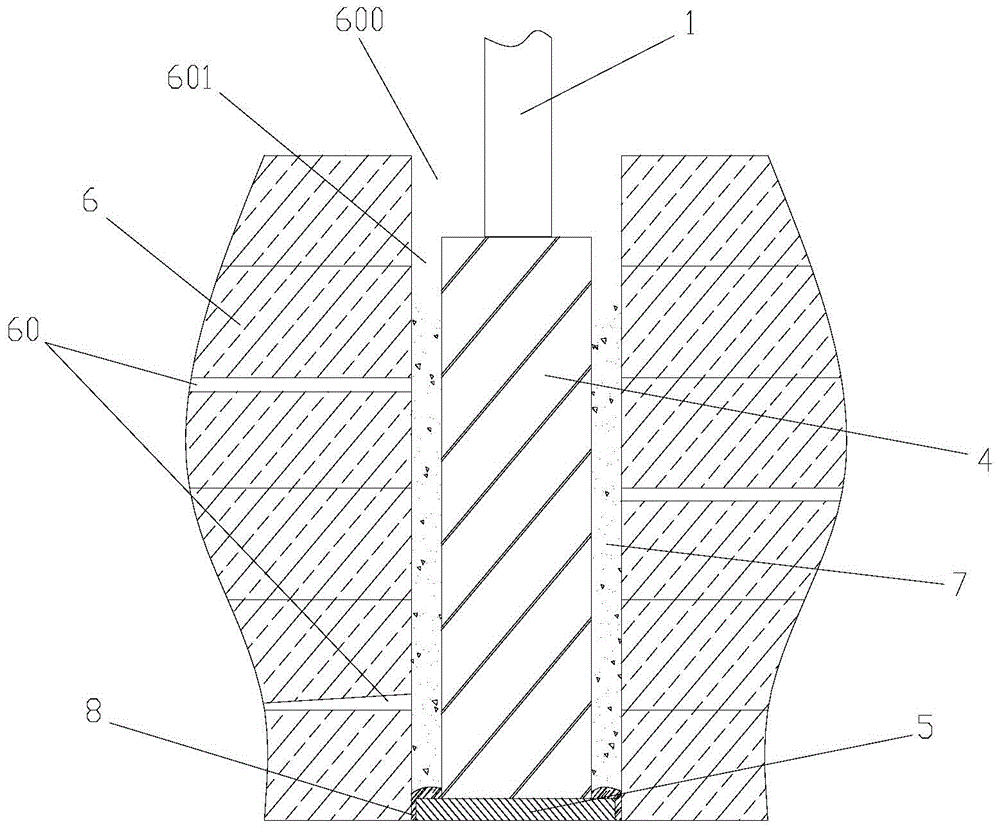

[0024] Such as figure 1 , figure 2 As shown, the embodiment of the sealing device of the present invention includes a wiper 4, a base 5 and a fixing mechanism. Further, the fixing mechanism includes a connecting rod 1 and a positioning structure for determining the position of the wiper 4 in the fire viewing hole (fire stand) 600 through the connecting rod 1 . Furthermore, the positioning structure includes a positioning part 2 , a sleeve 3 and a supporting part 31 .

[0025] Specifically, the wiper 4 is columnar, preferably cylindrical, and its outer diameter can be flexibly changed according to the inner diameter of the fire viewing hole 600 . The center of the wiper 4 can be a cavity or solid, but its side surface is smooth to smooth the grout on the inner wall of the fire hole 600 . Although the outer diameter of the wiper 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com