Coke-oven wall-surface evaluating apparatus, coke-oven wall-surface repair supporting apparatus, coke-oven wall-surface evaluating method, coke-oven wall-surface repair supporting method, and computer

A technology for evaluating devices and auxiliary devices, used in coke ovens, furnace safety devices, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0057] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings.

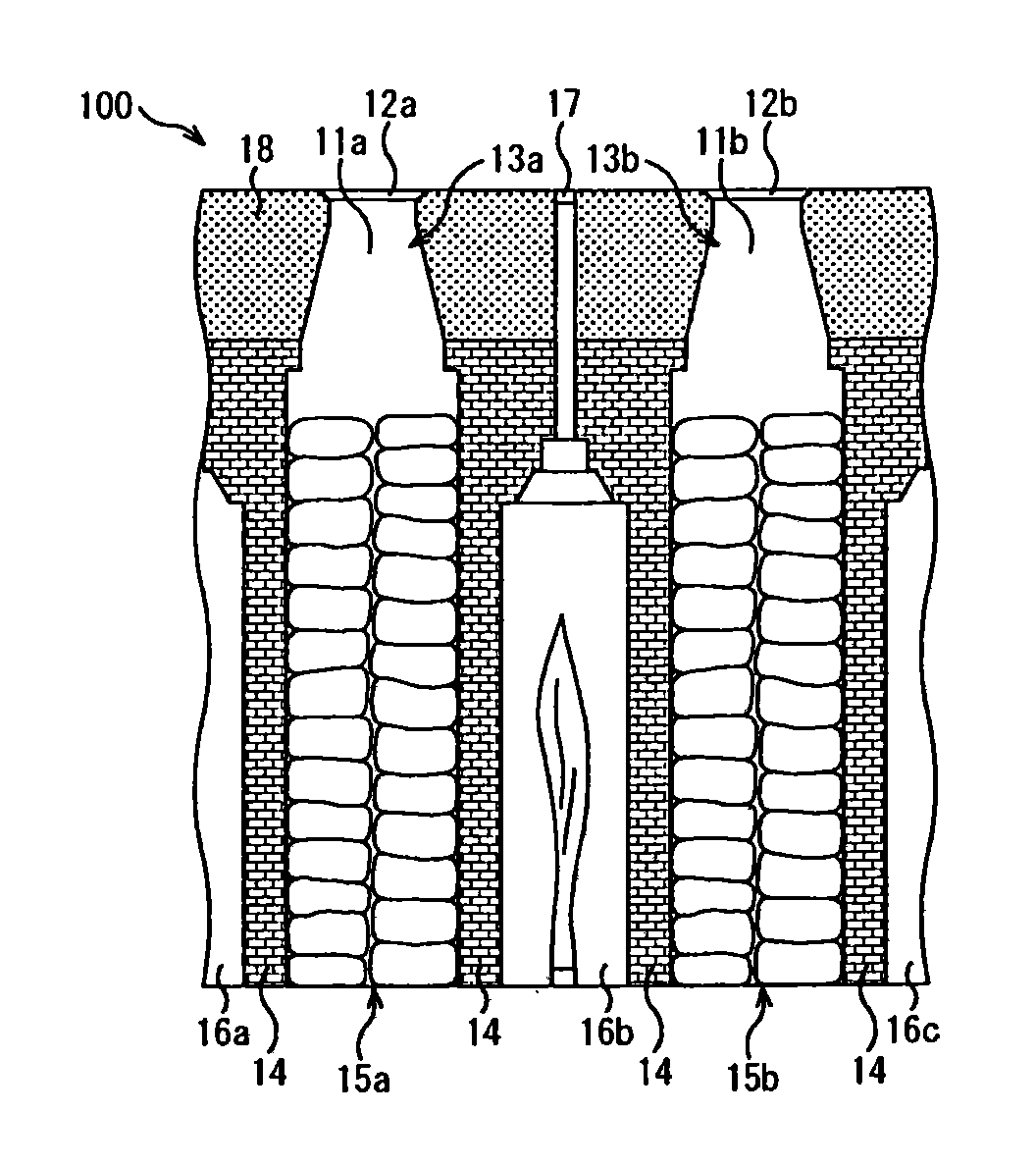

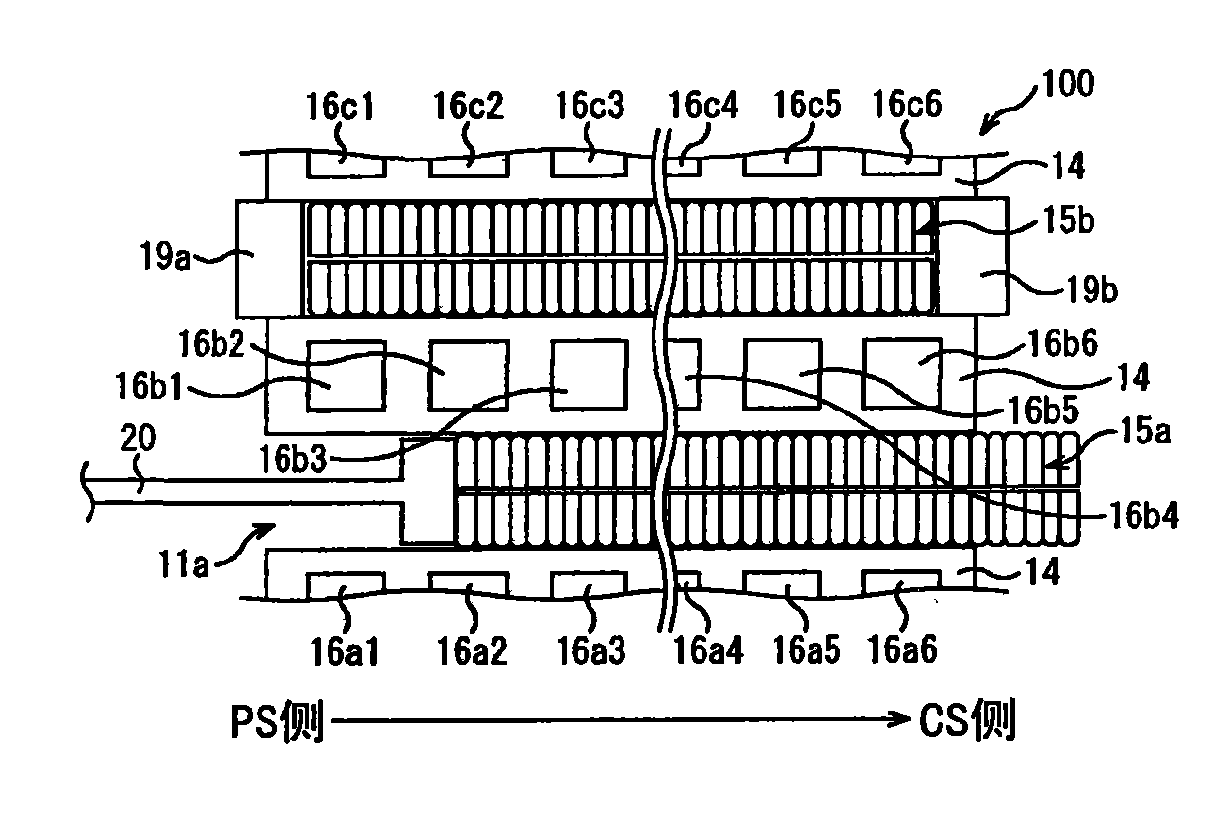

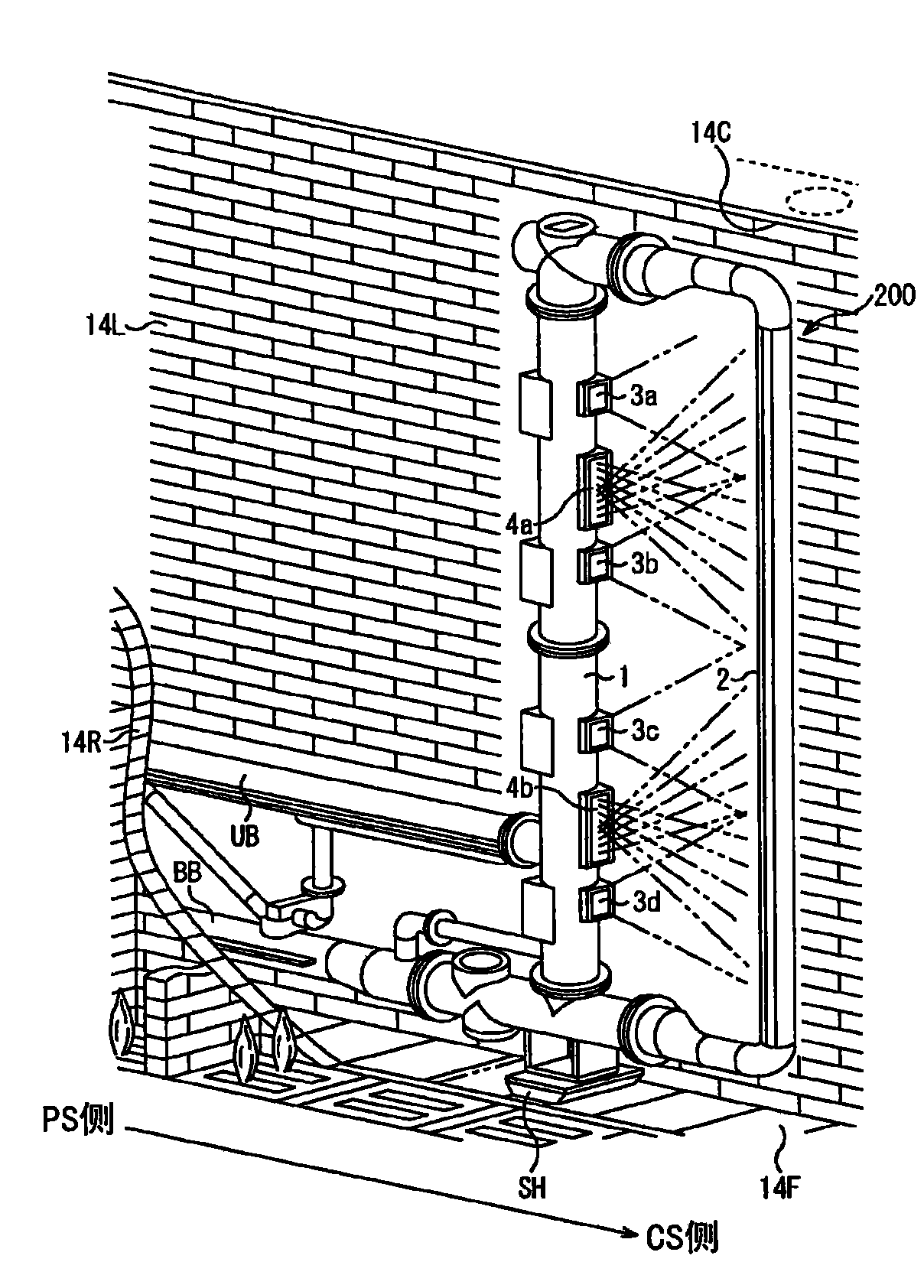

[0058] FIG. 1 is a diagram showing an example of the structure of a coke oven. Specifically, Figure 1A It is a longitudinal cross-sectional view showing an example of the state of the coking chamber vicinity to be measured when viewed in the depth direction of the coking chamber in the entire coke oven 100 . Figure 1B is shown in the entire coke oven 100 when viewed from the upper side of the coke oven 100 Figure 1A A cross-sectional view of the part shown in .

[0059] Such as Figure 1A As shown, in the coking oven 100 , the coking chambers 11a, 11b and the combustion chambers 16a, 16b, 16c are arranged alternately with the furnace wall 14 interposed therebetween. Coal is charged into the carbonization chamber 11a from the coal charging port 13a to manufacture coke 15 . Coke 15 is produced by dry distillation of coal using the heat from the combustion cham...

no. 2 Embodiment approach

[0173] Next, a second embodiment of the present invention will be described. In the present embodiment, as in the first embodiment, the resistance index k is obtained for the plurality of carbonization chambers 11, and the obtained resistance index k is correlated with the extrusion load generated in the plurality of carbonization chambers 11 to simulate the furnace wall. 14 patched. In this way, in this embodiment, the repair of the furnace wall 14 of the carbonization chamber 11 is assisted by using the resistance index k obtained as described in the first embodiment. Therefore, in the description of the present embodiment, detailed description of the same parts as those of the above-mentioned first embodiment will be omitted.

[0174] Figure 18 It is a figure which shows an example of the functional structure of a coke oven wall surface repair assisting device. In addition, the hardware of the coke oven wall repair assisting device 1800 is a device including a CPU, ROM,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com